Atomization characteristics of planar prefilming nozzle

-

摘要:

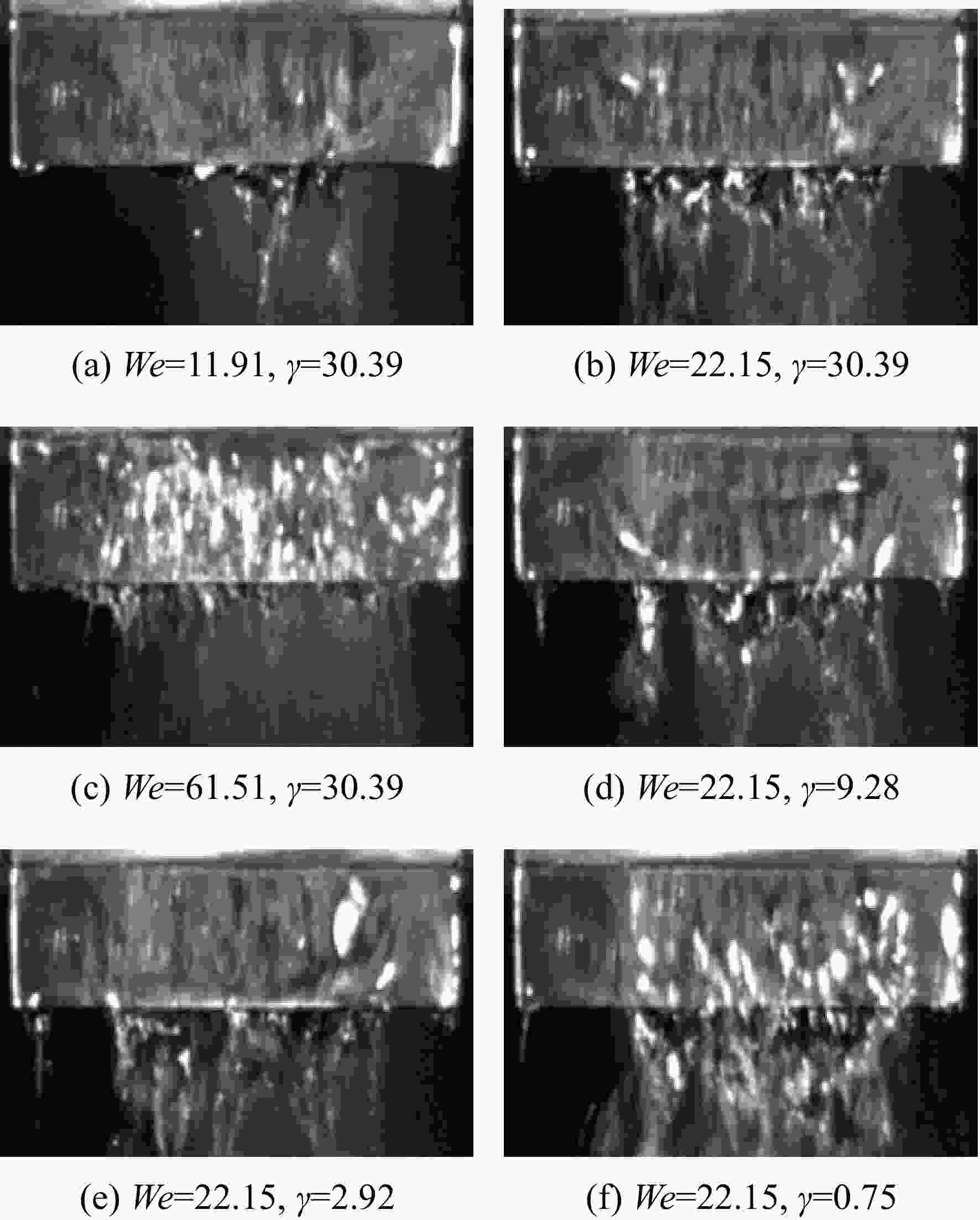

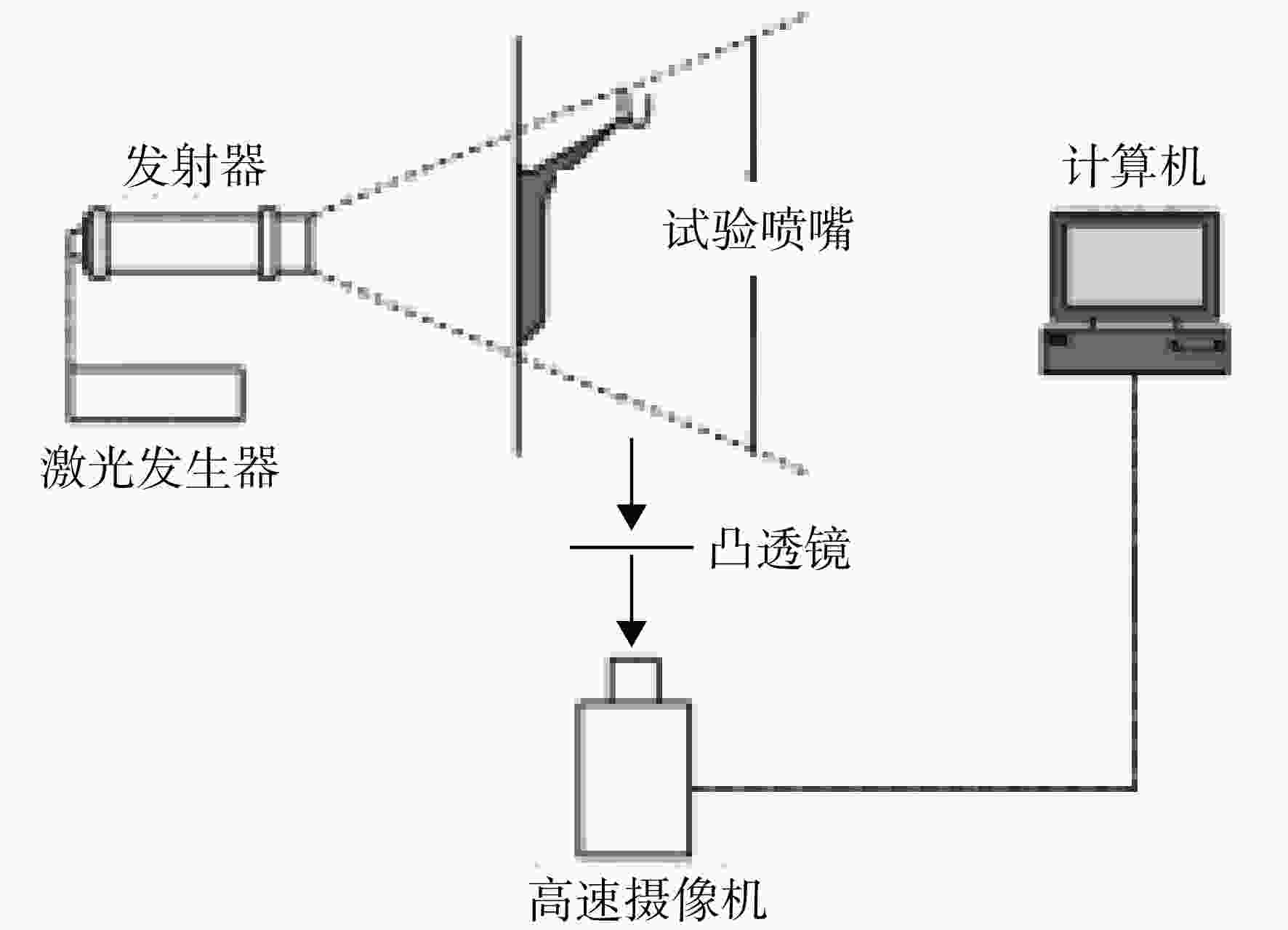

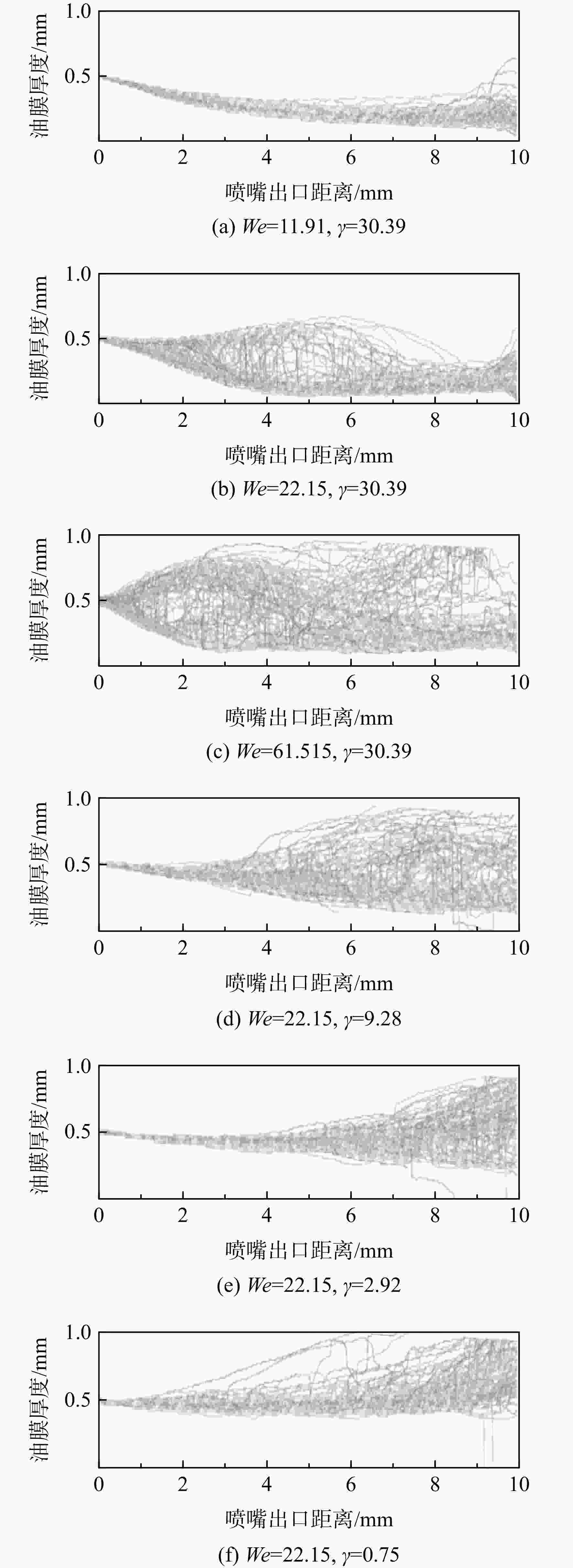

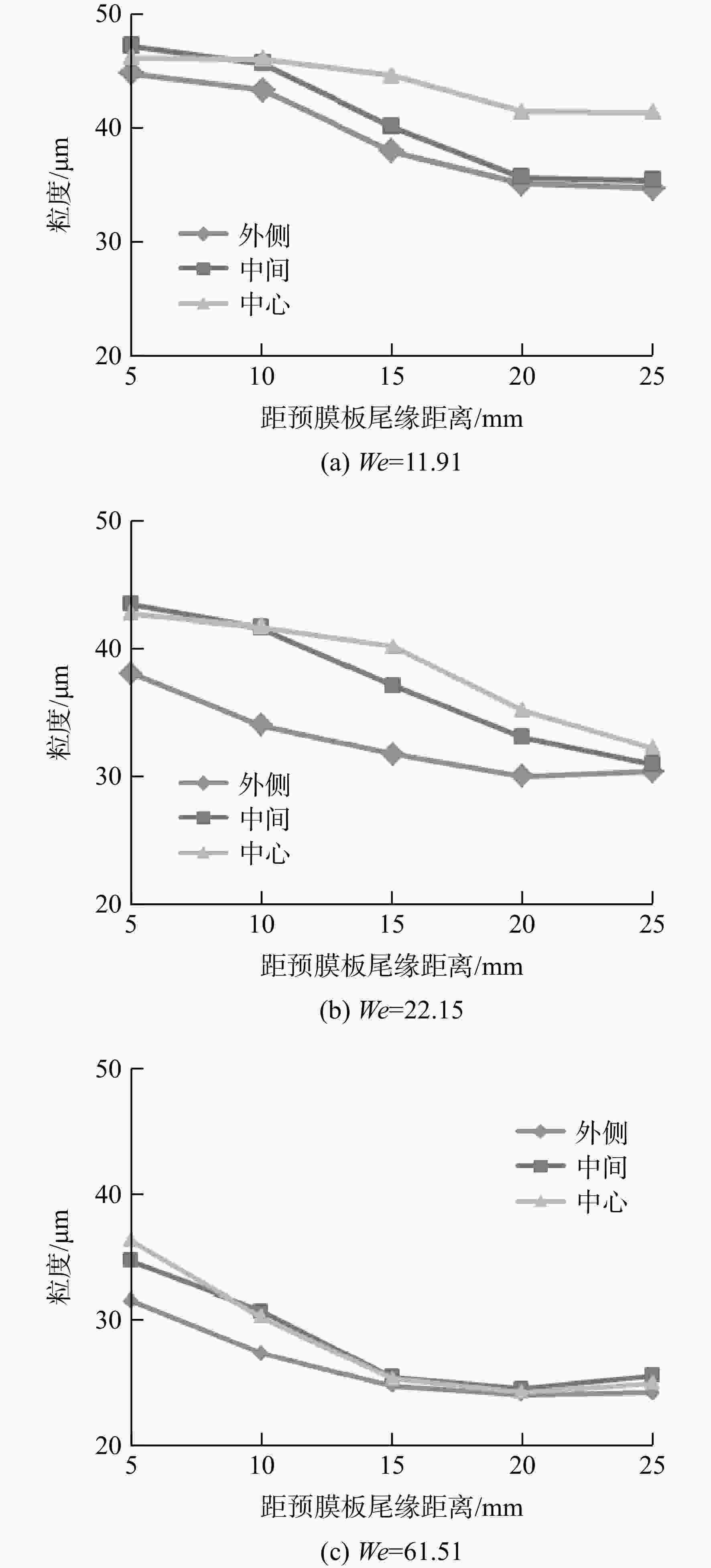

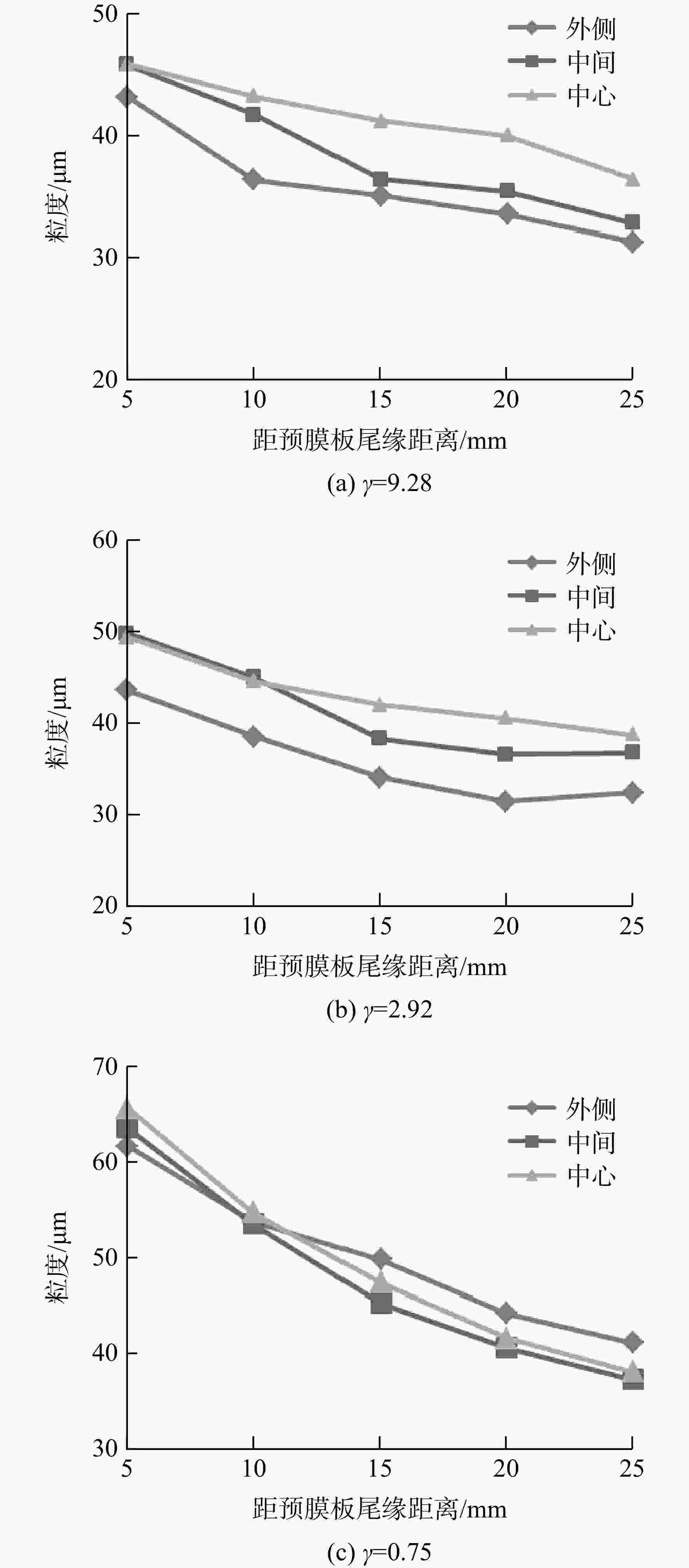

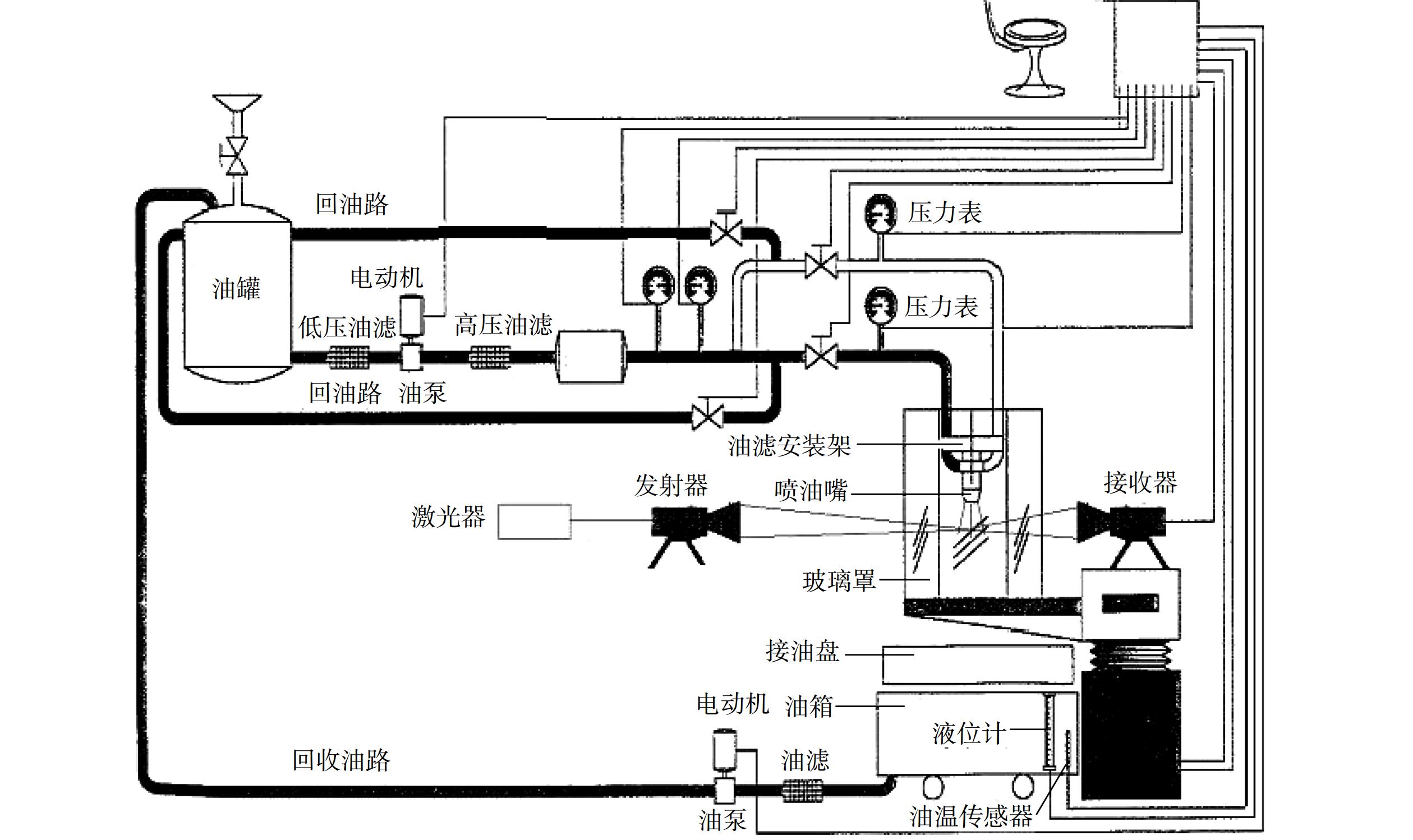

试验研究了韦伯数、气液动量比对预膜喷嘴雾化特性的影响。应用高速相机正面拍摄获得油膜表面波动形态,并用本征正交分解法分析了油膜波动频率,利用液相不连续思想获取油膜厚度;应用相位多普勒粒子分析仪获得了油滴索太尔直径。结果表明:气液动量比对油膜厚度影响较大,韦伯数对油膜波动频率影响较大。气液动量比由0.75增大到30.39,最小油膜厚度由0.38 mm减小到0.15 mm,而雾化粒度仅由38.8 μm减小到33.5 μm;韦伯数由11.91增大到61.51,油膜波动频率由2.9 Hz增大到207.0 Hz,初始雾化距离明显减小,雾化粒度由37.1 μm减小到24.9 μm。

Abstract:The effects of Weber number and air-liquid momentum ratio on the atomization characteristics of prefilm nozzle were experimentally studied. The fluctuation shape of oil film is obtained by front photographing with high-speed camera, and the fluctuation frequency of oil film is analyzed by proper orthogonal decomposition method. The oil film thickness is obtained by using the idea of liquid discontinuity, the atomized droplets SMD is measured with PDPA. The results show: The air-liquid momentum ratio has a great effects on the oil film thickness, and the Weber number has a great effects on the oil film fluctuation frequency. The air-liquid momentum ratio increased from 0.75 to 30.39, the minimum oil film thickness decreased from 0.38 mm to 0.15 mm, and the SMD increased from 38.8 μm reduced to 33.5 μm; The Weber number increased from 11.91 to 61.51, the oil film fluctuation frequency increased from 2.9 Hz to 207.0 Hz, the initial atomization distance decreased significantly, and the SMD reduced from 37.1 μm to 24.9 μm.

-

Key words:

- prefilming nozzle /

- Weber number /

- momentum ratio /

- oil film thickness /

- fluctuation frequency /

- atomized particle size

-

表 1 试验工况

Table 1. Test conditions

工况 燃油速度/

(m/s)空气速度/

(m/s)韦伯数 气液动量比 1 0.14 22 11.91 30.39 2 0.21 30 22.15 3 0.28 50 61.51 4 0.38 30 22.15 9.28 5 0.678 2.92 6 1.34 0.75 表 2 不同韦伯数油膜波动频率

Table 2. Oil film fluctuation frequency with different We

韦伯数 波动频率/Hz 11.91 2.9 22.15 90.5 61.51 207.0 表 3 不同气液动量比油膜波动频率

Table 3. Oil film fluctuation frequency with differentγ

气液动量比 波动频率/Hz 30.39 90.5 9.28 18.1 2.92 30.1 0.75 41.3 表 4 不同韦伯数雾化粒度

Table 4. SMD with different We

韦伯数 雾化粒度/μm 距预膜板尾缘距离/mm 5 10 15 20 25 11.91 46.0 45.0 40.1 37.4 37.1 22.15 41.4 39.2 37.1 34.5 31.2 61.51 34.1 29.4 25.2 24.2 24.9 表 5 不同气液动量比雾化粒度

Table 5. SMD with different

$ \boldsymbol{\gamma } $ 气液

动量比雾化粒度/μm 距预膜板尾缘距离/mm 5 10 15 20 25 9.28 45.0 40.5 37.6 36.3 33.5 2.92 47.6 42.7 38.2 36.2 36.0 0.75 63.5 53.9 47.4 42.1 38.8 -

[1] 甘晓华. 航空燃气轮机燃油喷嘴技术[M]. 北京: 国防工业出版社,2006. GAN Xiaohua. Aero gas turbine engine fuel nozzle technology[M]. Beijing: National Defense Industry Press,2006. (in ChineseGAN Xiaohua. Aero gas turbine engine fuel nozzle technology[M]. Beijing: National Defense Industry Press, 2006. (in Chinese) [2] DÉJEAN B,BERTHOUMIEU P,GAJAN P. Experimental study on the influence of liquid and air boundary conditions on a planar air-blasted liquid sheet: Part Ⅱ prefilming zone length[J]. International Journal of Multiphase Flow,2016,79: 214-224. doi: 10.1016/j.ijmultiphaseflow.2015.09.001 [3] 王宏明,全中,甘晓华. 燃油喷嘴对燃烧性能的控制研究[J]. 推进技术,1991,12(6): 36-41. WANG Hongming,QUAN Zhong,GAN Xiaohua. An investigation on fuel nozzles on combustion performance[J]. Journal of Propulsion Technology,1991,12(6): 36-41. (in Chinese WANG Hongming, QUAN Zhong, GAN Xiaohua . An investigation on fuel nozzles on combustion performance[J]. Journal of Propulsion Technology,1991 ,12 (6 ):36 -41 . (in Chinese)[4] 何昌升. 平板式预膜喷嘴初次雾化特性研究[D]. 南京: 南京航空航天大学,2020. HE Changsheng. Research on primary atomization characteristics of planar prefilming nozzle[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2020. (in ChineseHE Changsheng. Research on primary atomization characteristics of planar prefilming nozzle[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020. (in Chinese) [5] CHEN S K,LEFEBVRE A H,ROLLBUHLER J. Influence of ambient air pressure on effervescent atomization[J]. Journal of Propulsion and Power,1993,9(1): 10-15. doi: 10.2514/3.11479 [6] WANG X F,LEFEBVRE A H. Influence of fuel temperature on atomization performance of pressure-swirl atomizers[J]. Journal of Propulsion and Power,1988,4(3): 222-227. doi: 10.2514/3.23052 [7] LEFEBVRE A,MILLER D. The development of an air blast atomizer for gas turbine application[J]. Journal of Propulsion and Power,1966,193: 356-368. [8] 金如山. 航空燃气轮机燃烧室[M]. 北京: 宇航出版社,1988. JIN Rushan. Aviation gas turbine combustion chamber[M]. 北京: 宇航出版社,1988. (in Chinese [9] 赵其寿,甘晓华. 空气雾化喷嘴内液膜对雾化性能的作用[J]. 推进技术,1991,12(4): 42-48. ZHAO Qishou,GAN Xiaohua. Effect of liquid film on atomizing performance in airblast atomizers[J]. Journal of Propulsion Technology,1991,12(4): 42-48. (in Chinese ZHAO Qishou, GAN Xiaohua . Effect of liquid film on atomizing performance in airblast atomizers[J]. Journal of Propulsion Technology,1991 ,12 (4 ):42 -48 . (in Chinese)[10] DÉJEAN B,BERTHOUMIEU P,GAJAN P. Experimental study on the influence of liquid and air boundary conditions on a planar air-blasted liquid sheet: Part Ⅰ liquid and air thicknesses[J]. International Journal of Multiphase Flow,2016,79: 202-213. doi: 10.1016/j.ijmultiphaseflow.2015.09.002 [11] CARVALHO I S,HEITOR M V,SANTOS D. Liquid film disintegration regimes and proposed correlations[J]. International Journal of Multiphase Flow,2002,28(5): 773-789. doi: 10.1016/S0301-9322(01)00088-X [12] PARK J,HUH K Y,LI Xianguo,et al. Experimental investigation on cellular breakup of a planar liquid sheet from an air-blast nozzle[J]. Physics of Fluids,2004,16(3): 625-632. doi: 10.1063/1.1644575 [13] BERTHOUMIEU P,LAVERGNE G. Video techniques applied to the characterization of liquid sheet breakup[J]. Journal of Visualization,2001,4(3): 267-275. doi: 10.1007/BF03182587 [14] 顾大鹏,胡文成,窦义涛. 燃油喷嘴雾化特性试验研究[J]. 航空发动机,2021,47(1): 86-90. GU Dapeng,HU Wencheng,DOU Yitao. Experimental study on spray characteristics of a fuel atomizer[J]. Aeroengine,2021,47(1): 86-90. (in Chinese GU Dapeng, HU Wencheng, DOU Yitao . Experimental study on spray characteristics of a fuel atomizer[J]. Aeroengine,2021 ,47 (1 ):86 -90 . (in Chinese)[15] 张举星,邸东,张萍,等. 高温高压下平板预膜喷嘴初次雾化试验[J]. 航空动力学报,2022,37(1): 55-66. ZHANG Juxing,DI Dong,ZHANG Ping,et al. Experiment on primary atomization of flat prefilm nozzle under high temperature and high pressure[J]. Journal of Aerospace Power,2022,37(1): 55-66. (in Chinese ZHANG Juxing, DI Dong, ZHANG Ping, et al . Experiment on primary atomization of flat prefilm nozzle under high temperature and high pressure[J]. Journal of Aerospace Power,2022 ,37 (1 ):55 -66 . (in Chinese)[16] 周兵,吉洪湖,张宝诚. 旋流空气对双油路离心喷嘴雾化特性影响的实验[J]. 航空动力学报,2013,28(9): 1933-1941. ZHOU Bing,JI Honghu,ZHANG Baocheng. Experiment of swirled air effect on spray characteristic of double-line pressure-swirl atomizer[J]. Journal of Aerospace Power,2013,28(9): 1933-1941. (in Chinese ZHOU Bing, JI Honghu, ZHANG Baocheng . Experiment of swirled air effect on spray characteristic of double-line pressure-swirl atomizer[J]. Journal of Aerospace Power,2013 ,28 (9 ):1933 -1941 . (in Chinese)[17] 秦文瑾,徐礼辉,卢登标,等. 本征正交分解法对正十二烷喷雾射流的解析[J]. 航空动力学报,2021,36(9): 1917-1923. QIN Wenjin,XU Lihui,LU Dengbiao,et al. Analysis of n-dodecane spray jet by proper orthogonal decomposition[J]. Journal of Aerospace Power,2021,36(9): 1917-1923. (in Chinese QIN Wenjin, XU Lihui, LU Dengbiao, et al . Analysis of n-dodecane spray jet by proper orthogonal decomposition[J]. Journal of Aerospace Power,2021 ,36 (9 ):1917 -1923 . (in Chinese)[18] 陈豪. 直喷汽油机缸内过程稳定性机理的可视化研究[D]. 上海: 上海交通大学,2014. CHEN Hao. Analyzing cycle-to-cycle variations of In-cylinder processes in an optical spark-ignition direct-injection engine[D]. Shanghai: Shanghai Jiao Tong University,2014. (in ChineseCHEN Hao. Analyzing cycle-to-cycle variations of In-cylinder processes in an optical spark-ignition direct-injection engine[D]. Shanghai: Shanghai Jiao Tong University, 2014. (in Chinese) -

下载:

下载: