Development and application prospect of light and high efficiency heat exchanger in aviation and aerospace

-

摘要:

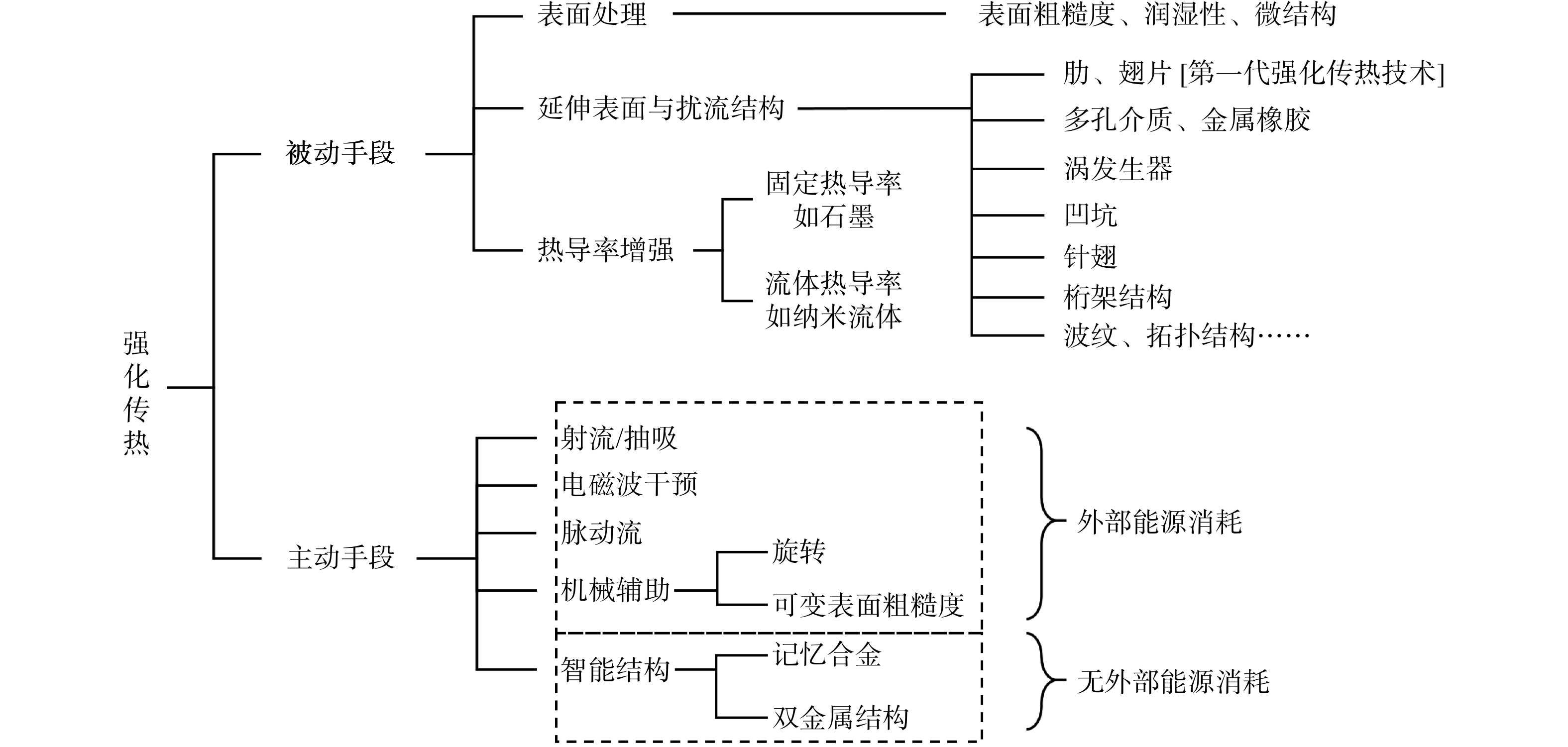

基于航空领域对换热器的特定设计需求,调研分析国内外相关资料,结合工程实践经验,归纳总结了提高换热器性能的主要方法—基于强化传热的性能优化方法和基于交叉学科的换热器种类探索技术。总结当前各种典型强化传热手段的分支分布后,认为基于结构的强化传热仍然是当前研究的主要方向之一,并介绍了一些热点、新型的强化传热结构。在新型换热器种类探索中提出了智能换热器和化学反应换热器的概念,为多工况换热和高热流换热提供解决方案,其中前者的强化传热比率可达2。对航空换热器设计中产生的部分新概念(评价指标/均混流/运行质量)进行了分析探索,补充完善了换热器的设计体系,并在最后对换热器在航空发动机方向的应用前景进行了展望。

Abstract:Based on the specific design requirements of heat exchanger in aviation and aerospace field, existing data were investigated and analyzed. Combined with the engineering practice, the main methods to improve the performance of heat exchanger, including performance optimization method and the interdisciplinary exploration of new types of heat exchangers, were introduced. The branch and distribution of current research on various heat transfer enhancement were summarized. Structure-based enhanced heat transfer was still taken as one of the main research directions, and some novel structures were introduced. In the exploration of new types of heat exchangers, the concepts of smart heat exchanger and chemical reaction heat exchanger were introduced, elaborating the design of heat exchange under multiple working conditions and high heat flow. Among them, the heat transfer enhancement coefficient of the smart heat exchangers can reach up to 2. Some new concepts, including evaluation indicator, uniform-mixed flow and operating weight produced in the design of heat exchanger, were analyzed and explored, which can supplement and improve the design system. Finally, the application prospect of heat exchanger in aviation and aerospace was presented.

-

表 1 强化传热手段对比

Table 1. Comparison of heat transfer enhancement methods

强化传热

手段特性传统主动

强化手段被动强化

手段智能

结构额外动力源 需要 不需要 不需要 系统复杂度 高 低 低 多工况传热调整能力 有 无 有 局部传热调整 有 无 有 工质要求 高 低 低 -

[1] 兰州石油机械研究所. 换热器 [M]. 第2版. 北京: 中国石化出版社, 2013. [2] 于霄,吕多,赵孟,等. 3D打印技术在航空发动机换热器研制中的应用展望[J]. 航空制造技术,2014(22): 43-46. doi: 10.3969/j.issn.1671-833X.2014.22.009YU Xiao,LÜ Duo,ZHAO Meng,et al. Application prospect of 3D printing technology on aeroengine heat exchanger development[J]. Aeronautical Manufacturing Technology,2014(22): 43-46. (in Chinese) doi: 10.3969/j.issn.1671-833X.2014.22.009 [3] 曹玉璋. 航空发动机传热学[M]. 北京: 北京航空航天大学出版社, 2005. [4] 杨世铭, 陶文铨. 传热学[M]. 第4版. 高等教育出版社, 2006. [5] BERGLES A E. ExHFT for fourth generation heat transfer technology[J]. Experimental Thermal and Fluid Science,2002,26(2): 335-344. [6] ALAM T,KIM M H. A comprehensive review on single phase heat transfer enhancement techniques in heat exchanger applications[J]. Renewable and Sustainable Energy Reviews,2018,81: 813-839. doi: 10.1016/j.rser.2017.08.060 [7] KUMAR S,KUMAR A,DARSHAN K A,et al. A review of flow and heat transfer behaviour of nanofluids in micro channel heat sinks[J]. Thermal Science and Engineering Progress,2018,8: 477-493. doi: 10.1016/j.tsep.2018.10.004 [8] SAJID M U,ALI H M. Thermal conductivity of hybrid nanofluids: a critical review[J]. International Journal of Heat and Mass Transfer,2018,126: 211-234. doi: 10.1016/j.ijheatmasstransfer.2018.05.021 [9] LIANG G T,MUDAWAR I. Review of single-phase and two-phase nanofluid heat transfer in macro-channels and micro-channels[J]. International Journal of Heat and Mass Transfer,2019,136: 324-354. doi: 10.1016/j.ijheatmasstransfer.2019.02.086 [10] BISWAS G, CHATTOPADHYAY H. Heat transfer in a channel with built-in wing-type vortex generators[J]. International Journal of Heat and Mass Transfer, 1992, 35(4): 803-814. [11] FIEBIG M,VALENCIA A,MITRA N K. Wing-type vortex generators for fin-and-tube heat exchangers[J]. J Experimental Thermal & Fluid Science,1993,7(4): 287-295. [12] AWAIS M,BHUIYAN A A. Heat transfer enhancement using different types of vortex generators (VGs): A review on experimental and numerical activities[J]. Thermal Science and Engineering Progress,2018,5: 524-545. doi: 10.1016/j.tsep.2018.02.007 [13] DU Wei,LUO Lei,WANG Songtao,et al. Heat transfer and flow structure in a latticework duct with different sidewalls[J]. Journal of Heat Transfer,2019,141(12): 124501-124508. doi: 10.1115/1.4044920 [14] BU Shi,YANG Lianfeng,QIU Hanghai,et al. Effect of sidewall slots and pin fins on the performance of latticework cooling channel for turbine blades[J]. Applied Thermal Engineering,2017,117: 275-288. doi: 10.1016/j.applthermaleng.2017.01.110 [15] RASHIDI S,KASHEFI M H,KIM K C,et al. Potentials of porous materials for energy management in heat exchangers—a comprehensive review[J]. Applied Energy,2019,243: 206-232. doi: 10.1016/j.apenergy.2019.03.200 [16] LI Weihong,YU Guopeng,YU Zhibin. Bioinspired heat exchangers based on triply periodic minimal surfaces for supercritical CO2 cycles[J]. Applied Thermal Engineering,2020,179: 115686.1-115686.11. doi: 10.1016/j.applthermaleng.2020.115686 [17] LI Hua,DENG Hongwu,BAI Lei,et al. Heat transfer in a rotating two-inlet wedge-shaped channel with pin-fins[J]. International Journal of Heat and Mass Transfer,2020,163: 120380.1-120380.9. [18] 闫晓军, 张小勇. 形状记忆合金智能结构[M]. 北京: 科学出版社, 2015: 4-5. [19] DAI Z,FLETCHER D F,HAYNES B S. Impact of tortuous geometry on laminar flow heat transfer in microchannels[J]. International Journal of Heat and Mass Transfer,2015,83: 382-398. doi: 10.1016/j.ijheatmasstransfer.2014.12.019 [20] YANG Dawei,WANG Yan,DING Guifu,et al. Numerical and experimental analysis of cooling performance of single-phase array microchannel heat sinks with different pin-fin configurations[J]. Applied Thermal Engineering,2017,112: 1547-1556. doi: 10.1016/j.applthermaleng.2016.08.211 [21] RAJA K N,SAIDUR R,GHAZALI N N N,et al. Numerical study of thermal enhancement in micro channel heat sink with secondary flow[J]. International Journal of Heat and Mass Transfer,2014,78: 216-223. doi: 10.1016/j.ijheatmasstransfer.2014.06.072 [22] MOHAMMED H A,GUNNASEGARAN P,SHUAIB N H. Numerical simulation of heat transfer enhancement in wavy microchannel heat sink[J]. International Communications in Heat and Mass Transfer,2011,38(1): 63-68. doi: 10.1016/j.icheatmasstransfer.2010.09.012 [23] CHAI Lei,XIA Guodong,WANG Liang,et al. Heat transfer enhancement in microchannel heat sinks with periodic expansion - constriction cross-sections[J]. International Journal of Heat and Mass Transfer,2013,62: 741-751. doi: 10.1016/j.ijheatmasstransfer.2013.03.045 [24] ABDUL H F B,MITHUN K P M,ARAVIND G P,et al. Thermo hydraulic performance analysis of twisted sinusoidal wavy microchannels[J]. International Journal of Thermal Sciences,2018,128: 124-136. doi: 10.1016/j.ijthermalsci.2018.02.018 [25] SON K N,WEIBEL J A,KUMARESAN V,et al. Design of multifunctional lattice-frame materials for compact heat exchangers[J]. International Journal of Heat and Mass Transfer,2017,115: 619-629. doi: 10.1016/j.ijheatmasstransfer.2017.07.073 [26] YAN Hongbin,YANG Xiaohu,LU Tianjian,et al. Convective heat transfer in a lightweight multifunctional sandwich panel with X-type metallic lattice core[J]. Applied Thermal Engineering,2017,127: 1293-1304. doi: 10.1016/j.applthermaleng.2017.08.081 [27] BUEHLER W J,GILFRICH J V,WILEY R C. Effect of Low-temperature phase changes on the mechanical properties of alloys near composition TiNi[J]. Journal of Applied Physics,1963,34(5): 1475-1477. doi: 10.1063/1.1729603 [28] MOHD J J,LEARY M,SUBIC A,et al. A review of shape memory alloy research, applications and opportunities[J]. Materials & Design (1980-2015),2014,56: 1078-1113. [29] MORGAN N B. Medical shape memory alloy applications—the market and its products[J]. Materials Science and Engineering:A,2004,378(1/2): 16-23. [30] 史玉升,伍宏志,闫春泽,等. 4D打印—智能构件的增材制造技术[J]. 机械工程学报,2020,56(15): 15-39.SHI Yusheng,WU Hongzhi,YAN Chunze,et al. Four-dimensional printing—the additive manufacturing technology of intelligent components[J]. Journal of Mechanical Engineering,2020,56(15): 15-39. (in Chinese) [31] 张雨萌, 李洁, 夏进军, 等. 4D打印技术: 工艺、材料及应用[J]. 材料导报. 2021, 35(1): 1212-1223.ZHANG Yumeng, LI Jie, XIA Jinjun, et al. 4D printing: technologies, materials and applications [J]. Material Reports, 2021, 35(1): 1212-1223. (in Chinese) [32] 赵伟,刘立武,孙健,等. 基于形状记忆聚合物复合材料航天航空可变形结构技术研究进展[J]. 宇航材料工艺,2021,51(4): 73-83. doi: 10.12044/j.issn.1007-2330.2021.04.008ZHAO Wei,LIU Liwu,SUN Jian,et al. Progress of aerospace deformable structures based on shape memory polymer composites[J]. Aerospace Materials & Technology,2021,51(4): 73-83. (in Chinese) doi: 10.12044/j.issn.1007-2330.2021.04.008 [33] 何庸. 用于化工装置上的新材料: 使用形状记忆合金的换热器[J]. 石油化工应用,1994(4): 29-31.HE Yong. New materials for chemical plants: heat exchangers using shape memory alloys[J]. Petrochemical Applications,1994(4): 29-31. (in Chinese) [34] 刘航, 冯立强, 刘兴江. 一种形状记忆合金折流板换热器及折流板制备方法: CN105387738A[P]. 2016-03-09. [35] 李耀中, 颜惠庚, 李弘, 等. 换热器的列管: CN102128553A[P]. 2011-07-20. [36] 马跃学,王娟,梁惊涛,等. 记忆合金自调节式高效微型节流制冷器机理研究[J]. 航空兵器,2015(2): 38-41. doi: 10.3969/j.issn.1673-5048.2015.02.008MA Yuexue,WANG Juan,LIANG Jingtao,et al. Study on high-efficiency miniature JT cryocooler regulated by shape memory alloy[J]. Aero Weaponry,2015(2): 38-41. (in Chinese) doi: 10.3969/j.issn.1673-5048.2015.02.008 [37] KITO M, MORI K. Heat exchanger: US4691761[P]. 1987-09-08. [38] BENAFAN O,NOTARDONATO W U,MENEGHELLI B J,et al. Design and development of a shape memory alloy activated heat pipe-based thermal switch[J]. Smart Materials and Structures,2013,22(10): 105017-105034. doi: 10.1088/0964-1726/22/10/105017 [39] SCHNEIDER D,LAUER M,VOIGT I,et al. Development and examination of switchable heat pipes[J]. Applied Thermal Engineering,2016,99: 857-865. doi: 10.1016/j.applthermaleng.2016.01.086 [40] DECASTRO J A, MELCHER K J, NOEBE R D. System-level design of a shape memory alloy actuator for active clearance control in the high-pressure turbine[R]. AIAA 2005-3988, 2005. [41] MONS C M. Wall cooling device: US8561386B2[P]. 2013-10-22. [42] Aris M S, OWEN I, SUTCLIFFE C J. The application of shape memory alloy as vortex generators and flow control devices for enhanced convective heat transfer[R]. FEDSM2007-37080, 2007. [43] ARIS M S,MCGLEN R,OWEN I,et al. An experimental investigation into the deployment of 3-D, finned wing and shape memory alloy vortex generators in a forced air convection heat pipe fin stack[J]. Applied Thermal Engineering,2011,31(14/15): 2230-2240. [44] HAO W,WANG T,JIANG Y Y,et al. Pool boiling heat transfer on deformable structures made of shape-memory-alloys[J]. International Journal of Heat and Mass Transfer,2017,112: 236-247. doi: 10.1016/j.ijheatmasstransfer.2017.04.113 [45] VILARRUBI M,MORELL G,ROSELL J,et al. Experimental characterization of a self-adaptive shape memory alloy cooling approach to regulate temperature under varying heat loads[J]. International Journal of Heat and Mass Transfer,2019,139: 632-640. doi: 10.1016/j.ijheatmasstransfer.2019.05.028 [46] LAHOZ R,GRACIA V L,PUERTOLAS J A. Training of the two-way shape memory effect by bending in NiTi alloys[J]. Journal of Engineering Materials and Technology, Transactions of the ASME,2002,124(4): 397-401. doi: 10.1115/1.1495001 [47] KUMAR P K,LAGOUDAS D C,ZANCA K J,et al. Thermomechanical characterization of high temperature SMA actuators[J]. Proceedings of SPIE - The International Society for Optical Engineering,2006,6170: 617012.1-617012.7. [48] 洪伟. 3D打印可编程形状记忆负泊松比结构的设计与研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.HONG Wei. Design and analysys of programming shape-memory negative-poission-ratio structure based on 3D printing technology[D]. Harbin: Harbin Institute of Technology, 2019. (in Chinese) [49] KHAN M I,PEQUEGNAT A,ZHOU Y N. Multiple memory shape memory alloys[J]. Advanced Engineering Materials,2013,15(5): 386-393. doi: 10.1002/adem.201200246 [50] 邹正平, 王一帆, 额日其太, 等. 高超声速强预冷航空发动机技术研究进展[J]. 航空发动机. 2021, 47(4): 8-21.ZOU Zhengping, WANG Yifan, Eriqitai, et al. Research progress on hypersonic precooled airbreathing engine technology[J]. Aeroengine, 2021, 47(14): 8-21. (in Chinese) [51] EHRFELD W. Microreaction technology: industrial prospects IMRET 3: proceedings of the third international conference on microreaction technology[M]. Berlin Heidelberg: Springer, 2000. [52] WATTON B K, SYMONDS K T, SYMONDS S P. Heat exchanger and/or fluid mixing means: US6736201 B2[P]. 2004-05-18. [53] PRAT L,DEVATINE A,COGNET P,CABASSUD C,et al. Performance evaluation of a novel concept "open plate reactor" applied to highly exothermic reactions[J]. Chemical Engineering & Technology,2005,28(9): 1028-1034. [54] DAVIJANY H B,HAYER F,PHAN K X,et al. Characteristics of an integrated micro packed bed reactor-heat exchanger for methanol synthesis from syngas[J]. Chemical Engineering Journal,2011,167(2-3): 496-503. doi: 10.1016/j.cej.2010.08.074 [55] FERROUILLAT S,TOCHON P,VALLE D D,et al. Open loop thermal control of exothermal chemical reactions in multifunctional heat exchangers[J]. International Journal of Heat & Mass Transfer,2008,49(15/16): 2479-2490. [56] ISMAHILOV Z R,PUSHKAREV V V,PODYACHEVA O Y,et al. A catalytic heat-exchanging tubular reactor for combining of high temperature exothermic and endothermic reactions[J]. Chemical Engineering Journal,2001,82(1/3): 355-360. [57] FERROUILLAT S,TOCHON P,PEERHOSSAINI H. Micromixing enhancement by turbulence: Application to multifunctional heat exchangers[J]. Chemical Engineering and Processing:Process Intensification,2006,45(8): 633-640. doi: 10.1016/j.cep.2006.01.006 [58] GU L D,MIN J C. Airside thermal-hydraulic characteristics for tube bank heat exchangers used to cool compressor bleed air in an aero engine[J]. Applied Thermal Engineering,2018,141: 939-947. doi: 10.1016/j.applthermaleng.2018.06.033 [59] WEN Jie,HUANG Haoran,LI Haiwang,et al. Thermal and hydraulic performance of a compact plate finned tube air-fuel heat exchanger for aero-engine[J]. Applied Thermal Engineering,2017,126: 920-928. doi: 10.1016/j.applthermaleng.2017.07.103 [60] PAPADOPOULOS T, PILIDIS P. Introduction of intercooling in a high bypass jet engine[R]. ASME Paper 2000-GT-150, 2000. [61] YAKINTHOS K,MISSIRLIS D,PALIKARAS A,et al. Optimization of the design of recuperative heat exchangers in the exhaust nozzle of an aero engine[J]. Applied Mathematical Modelling,2007,31(11): 2524-2541. doi: 10.1016/j.apm.2006.10.008 [62] SAIDI A, SUNDÉN B, ERIKSSON D. Intercoolers in gas turbine systems and combi-processes for production of electricity[R]. ASME Paper 2000-GT-0234, 2000. [63] SALTZMAN D,BICHNEVICIUS M,LYNCH S,et al. Design and evaluation of an additively manufactured aircraft heat exchanger[J]. Applied Thermal Engineering,2018,138: 254-263. doi: 10.1016/j.applthermaleng.2018.04.032 [64] CHÁVEZ M M,GONZÁLez L M,VALERO E. Numerical optimization of the fin shape experiments of a heat conjugate problem surface air/oil heat exchanger (SACOC)[J]. International Journal of Heat and Mass Transfer,2022,182: 121971.1-121971.15. [65] 刘荫泽. 适用于航空发动机的一次表面换热器流动传热性能研究[D]. 上海: 上海交通大学, 2017.LIU Mengze. Study on flow and heat transfer of primary surface heat exchanger for aeroengine[D]. Shanghai: Shanghai Jiao Tong University, 2017. (in Chinese) [66] 赵璧,宣益民. 航空发动机间冷器及回热器发展研究综述[J]. 航空学报,2017,38(9): 520934.1-520934.21. doi: 10.7527/S1000-6893.2017.620934ZHAO Bi,XUAN Yimin. A review of research on intercoolers and recuperators in aero-engins[J]. Acta Aeronautica et Astronautica Sinica,2017,38(9): 520934.1-520934.21. (in Chinese) doi: 10.7527/S1000-6893.2017.620934 [67] 张文毓. 印制电路板式换热器的研究与应用[J]. 上海电气技术,2019,12(4): 64-68.ZHANG Wenyu. Research and application of printed circuit board heat exchanger[J]. Journal of Shanghai Electric Technology,2019,12(4): 64-68. (in Chinese) [68] 任勇翔,于霄,张筱喆,等. 类多孔结构超轻高效换热器流动传热特性研究[J]. 南京航空航天大学学报,2019,51(4): 449-455. doi: 10.16356/j.1005-2615.2019.04.004REN Yongxiang,YU Xiao,ZHANG Xiaozhe,et al. Flow and heat transfer characteristics of a ultra-lighted and efficient porous media heat exchanger[J]. Journal of Nanjing University of Aeronautics & Astronautics,2019,51(4): 449-455. (in Chinese) doi: 10.16356/j.1005-2615.2019.04.004 -

下载:

下载: