Effect investigation of combined variable speed of rotor/turboshaft engine power turbine on the performance

-

摘要:

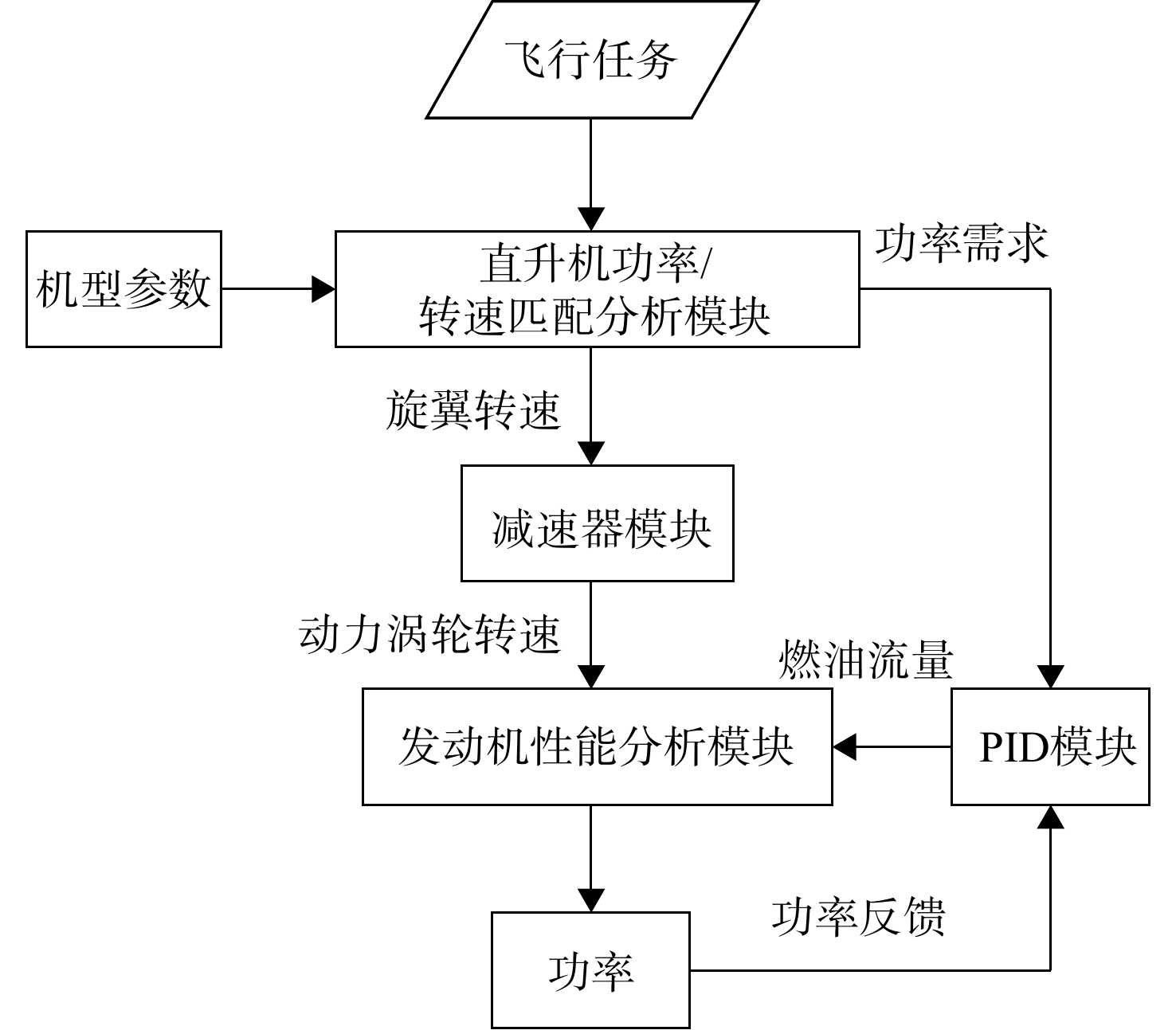

分别建立了考虑飞行工况条件的旋翼最优转速及功率需求计算模型、动力涡轮可变速的涡轴发动机性能分析模型,以此发展了旋翼/涡轴发动机转速联合优化分析方法及程序,并以UH60A直升机及T700涡轴发动机为对象进行了典型飞行包线下的性能分析。结果表明:动力涡轮转速可变后压气机、高压涡轮稳态匹配工作线变化不大,但动力涡轮自身等熵效率随转速降低有明显下降,其性能需进一步提升。与定转速运行模式相比,完成典型飞行任务后,旋翼/涡轴发动机协同变速运行可使得总耗油量明显降低约5%。

Abstract:The calculation model of optimal rotor speed and power demand considering flight conditions and the performance analysis model of turboshaft engine with variable speed power turbine were built respectively. Based on these models, the performance analysis method and program of rotor /turboshaft engine power turbine were developed, and the performance analysis under typical flight envelope was carried out for UH60A helicopter and T700 turboshaft engine. The results showed that when the speed of power turbine becames variable, the steady-state matching working line of compressor and high-pressure turbine changed slightly. However, the isentropic efficiency of the power turbine decreased significantly as the speed decreased, indicating that further improvements in its performance were necessary. Compared with the constant speed operation mode, after a completion of a typical flight mission, the coordinated variable speed operation of rotor /turboshaft engine could reduce fuel consumption by nearly 5%.

-

Key words:

- rotor /

- power turbine /

- turboshaft engine /

- variable speed /

- fuel consumption

-

参数类型及单位 数值 主旋翼半径R/m 8.178 尾翼半径Rtr /m 1.676 主旋翼翼弦/m 0.5273 尾翼翼弦/m 0.2469 主旋翼叶片数 4 尾翼叶片数 4 等效平板面积比(f/A) 0.016 平均叶片截面阻力系数Cd0 0.012 主旋翼与尾翼距离L/m 9.93 主旋翼常规转速ω/(rad/s) 27 尾翼与主旋翼速比α 4.6 直升机质量W/N 71168 飞行速度范围V/(m/s) 0/90 旋翼实度σ(叶片实际面积/盘面积) 0.082 模型设计参数 数值 空气流量/(kg/s) 4.612 进气总压恢复系数 0.988 压气机压比 17.5 压气机效率 0.821 压气机/高压涡轮转速/(r/min) 44700 燃烧室总压损失 0.04 燃烧室效率 0.985 燃油流量/(kg/s) 0.101 高压涡轮效率 0.85 高压涡轮落压比 4.283 动力涡轮设计转速/(r/min) 20900 动力涡轮效率 0.85 动力涡轮落压比 3.3897 表 3 设计点计算参数

Table 3. Design point calculation parameters

设计点 S2 S3 S4 S5 S6 S7 焓值/(kJ/kg) 288.18 735.31 1624.71 1187.10 903.80 903.80 总温/K 288.17 721.11 1454.44 1098.33 857.22 857.22 总压/Pa 100010 1764400 1694000 395300 116000 114400 动力涡轮输出功率/kW 1343 耗油率SFC/(kg/kWh) 0.2708 总热效率 0.3084 表 4 UH-60A飞行任务参数

Table 4. UH-60A mission parameters

任务区间 飞行距离/时间/(km/s) 海拔高度/m 起飞爬升 0/10 0~100 加速(0~90 m/s) 0.6/13.5 100 前飞和爬升 9.5/107 100~1500 巡航(84 m/s) 100/1190 1500 前飞和爬升 5/62 1500~3000 巡航(70 m/s) 314/4490 3000 前飞和下降 20/578 3000~10 悬停 0/300 10 降落 0/10 10~0 总计 449.1 km/6760.5 s -

[1] PROUTY R W. Should we consider variable rotor speeds[J]. Vertiflite,2004,50(4): 24-27. [2] 韩东. 变转速旋翼直升机性能及配平研究[J]. 航空学报,2013,34(6): 1241-1248. HAN Dong. Study on the performance and trim of helicopters with variable speed rotors[J]. Acta Aeronautica et Astronautica Sinica,2013,34(6): 1241-1248. (in ChineseHAN Dong. Study on the performance and trim of helicopters with variable speed rotors[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(6): 1241-1248. (in Chinese) [3] JOHNSON W,YAMAUCHI G K,WATTS M E. NASA heavy lift rotorcraft systems investigation[R]. NASA/TP-2005-213467,2005. [4] SNYDER C A,ACREE C W. Preliminary assessment of variable speed power turbine technology on civil tiltrotor size and performance[R]. ARC-E-DAA-TN5287,2012. [5] ACREE C,YEO H,SINSAY J. Performance optimization of the NASA large civil tiltrotor[R]. London,UK: International Powered Lift Conference,2008. [6] SNYDER C A,THURMAN D R. Effects of gas turbine component performance on engine and rotary wing vehicle size and performance[R]. NASA/TM-2010-216907,2010. [7] SNYDER C A,THURMAN D R. Gas turbine characteristics for a large civil tilt-rotor (LCTR)[R]. NASA/TM-2010-216089,2010. [8] MISTÉ G A, BENINI E. Performance of a turboshaft engine for helicopter applications operating at variable shaft speed[C]//Proceedings of ASME 2012 Gas Turbine India Conference, Mumbai, Maharashtra, India:ASME, 2013: 701-715. [9] MISTÉ G A,BENINI E,GARAVELLO A,et al. A methodology for determining the optimal rotational speed of a variable RPM main rotor/turboshaft engine system[J]. Journal of the American Helicopter Society,2015,60(3): 1-11. [10] MISTÉ G A, PELLEGRINI A, BENINI E. Variable speed power turbine preliminary design optimization for rotorcraft applications[R].Barcelona, Spain: 11th World Congress on Computational Mechanics (WCCM XI),5th European Conference on Computational Mechanics (ECCM V),6th European Conference on Computational Fluid Dynamics (ECFD VI), 2014. [11] DANGELO M. Wide speed range turboshaft study[R]. NASA-CR-198380, 1995. [12] 张绍文,潘尚能,罗建桥. 高速旋翼机变转速动力涡轮的发展[J]. 国际航空,2015(11): 65-67. ZHANG Shaowen,PAN Shangneng,LUO Jianqiao. Development of variable speed power turbines for high speed rotorcraft[J]. International Aviation,2015(11): 65-67. (in ChineseZHANG Shaowen, PAN Shangneng, LUO Jianqiao. Development of variable speed power turbines for high speed rotorcraft[J]. International Aviation, 2015(11): 65-67. (in Chinese) [13] HENDRICKS E S,JONES S M,GRAY J S. Design optimization of a vari-able-speed power-turbine:AIAA 2014-3445[R]. Cleveland, US:AIAA, 2014. [14] MCVETTA A B,GIEL P W,WELCH G E. Aerodynamic measurements of a variable-speed power-turbine blade section in a transonic turbine cascade at low inlet turbulence: GT2013-94695[R]. San Antonio,Texas,US: ASME,2013. [15] MCVETTA A B, GIEL P W, WELCH G E. Aerodynamic investigation of incidence angle effects in a large scale transonic turbine cascade: AIAA 2012-3879[R]. Reston,Virigina: AIAA,2012. [16] AMERI A A,GIEL P W,FLEGEL A B. Simulation of VSPT experimental cascade under high and low free-stream turbulence conditions: AIAA 2014-3935 [R]. Reston,Virginia: AIAA,2014. [17] ROBUCK M,WILKERSON J,MACIOLEK R,et al. The effect of rotor cruise tip speed,engine technology and engine/drive system RPM on the NASA large civil tiltrotor (LCTR2) size and performance[R]. NASA/CR–2013-216593,2012. [18] ROBUCK M,WILKERSON J,ZHANG Y,et al. Design study of propulsion and drive systems for the large civil tiltrotor (LCTR2) rotorcraft[R]. NASA/TM-2013-218102,2014. [19] ROBUCK M,ZHANG Y. Engine power turbine and propulsion pod arrangement study[R]. NASA/CR-2014-216661,2014. [20] DIOTTAVIO J,FRIEDMANN D. Operational benefits of an optimal,widely variable speed rotor[C]// Phoenix,US: American Helicopter Society International,American Helicopter Society 66th Annual Forum Proceedings. 2010: 11-13. [21] 张雅铭. 直升机需用功率计算方法研究[J]. 直升机技术,2003(1): 1-5. ZHANG Yaming. Research of computing method for helicopter required power[J]. Helicopter Technique,2003(1): 1-5. (in ChineseZHANG Yaming. Research of computing method for helicopter required power[J]. Helicopter Technique, 2003(1): 1-5. (in Chinese) [22] JEFFRYES W C,THOMAS M L. Toolbox for the modeling and analysis of thermodynamic systems (T-MATS) user’s guide[R]. NASA TM-2014-216638,2014. [23] BALLIN M G. A high fidelity real-time simulation of a small turboshaft engine[M]. Moffett Field,Calif. : National Aeronautics and Space Administration,Ames Research Center,1988. -

下载:

下载: