-

摘要:

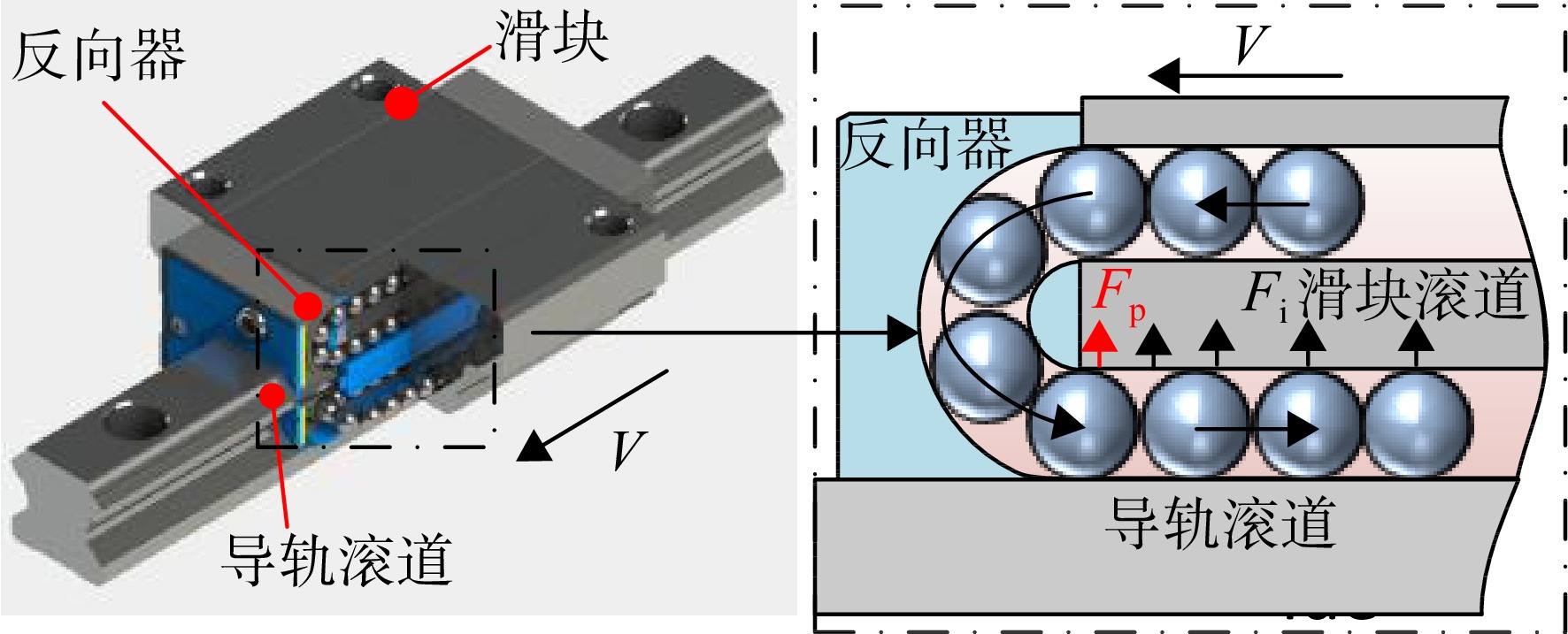

为提升滚动直线导轨副耐磨性,结合导轨副摩擦磨损试验及理论分析,将最大碰撞力,最大接触应力,摩擦阻力作为导轨副耐磨性能的表征和优化目标。根据设计要求,确定滑块反力约束函数和结构参数约束范围。通过分析模型的参数灵敏度,选取初始接触角,滑块滚道曲率比,滚珠直径和导轨高度增量作为设计变量;优化使用CCRD联合Kriging响应面构建代理模型;通过NSGA-Ⅱ算法,使结构在最大接触应力仅增加4.33%的情况下,摩擦阻力降低2.09%,最大碰撞力降低15.00%。设计变量中滚珠直径由5.56 mm降低至5.1744 mm,初始接触角由45°降低至38.878°,两者变动最大。基于Spearman相关性分析,可知滚珠直径与滑块反力相关系数值为0.23,初始接触角与滑块反力系数值达到−0.82,两者在优化中相互平衡达到最优解。

Abstract:In order to improve the wear resistance of rolling linear guide, combined with the wear test and theoretical analysis, the maximum impact force, maximum contact stress and friction resistance are taken as optimization goals. The constraint function of slider reaction force and the range of structural parameters were determined by desgin requirement. By analyzing the parameter sensitivity, initial contact angle, curve ratio of the slider raceway, ball diameter and the increment of the rail height were selected as variables; The optimization used CCRD and Kriging response surface to construct the agent model. Though the NSGA-Ⅱ algorithm, the friction resistance and maximum impact force of the structure were reduced by 2.09% and 15.00% respectively, while the maximum contact stress increased by only 4.33%. The ball diameter decreased from 5.56 to 5.1744 mm, and the initial contact angle decreased from 45 to 38.878°. Though Spearman correlation analysis, it is known that the coefficient value between the ball diameter and the slider reaction force is 0.23, and the coefficient value between the initial contact angle and slider reaction force are −0.82. These two variables balance each other to achieve the optimal solution in optimization.

-

Key words:

- rolling linear guide /

- wear resistance /

- optimization design /

- Kriging /

- NSGA-Ⅱ algorithm

-

表 1 有限元模型结果

Table 1. FEM Model results

参数 试验数据 求解结果 修正结果 误差 Fry2/N 8400 15344.8 8439.61 0.5% 表 2 参数灵敏度表

Table 2. Parameter sensitivity table

参数 Fm Ff σmax Fry2 Da 0.93 0.14 −0.19 0.23 α −0.01 −0.27 −0.18 −0.81 G1 0 −0.05 −0.04 −0.05 f −0.26 −0.91 0.92 −0.43 Xa 0.28 −0.03 −0.03 −0.02 表 3 相关系数矩阵表

Table 3. Correlation coefficient matrix

项目 Fry2 Fm Ff σmax Fry2 1 0.32 0.70 −0.23 Fm 1 0.33 −0.40 Ff 1 −0.75 σmax 1 表 4 优化结果

Table 4. Optimization results

项目/单位 原结果 优化结果 σmax/MPa 2215.2 2283.6 Ff /N 7.9009 7.3739 Fm/N 244.36 207.33 Da/mm 5.56 5.1744 α/(°) 45 38.878 f 0.52 0.52076 Xa/mm 0 0.24664 Fry2/N 8439.64 8478.2 表 5 最终结果

Table 5. Final result

项目 σmax /MPa Ff /N Fm/N Fry2 /N 计算结果 2311.1 7.7351 207.71 8787.9 变动率/% 4.33 −2.09 −15.00 4.13 准确率/% 98.81 95.33 99.82 96.48 表 6 结构参数相关系数表

Table 6. Correlation coefficient of structural parameters

结构参数 目标函数与约束函数 Fry2 Fm Ff σmax Da 0.23 0.93 0.14 −0.19 α −0.82 −0.01 −0.27 −0.19 -

[1] 徐起贺,陈静. 滚动直线导轨副的研究现状及发展动向[J]. 河南机电高等专科学校学报,2009,17(2): 1-3. XU Qihe,CHEN Jing. Research situation and developing trends of liner motion ball guide[J]. Journal of Henan Mechanical and Electrical Engineering College,2009,17(2): 1-3. (in Chinese XU Qihe, CHEN Jing . Research situation and developing trends of liner motion ball guide[J]. Journal of Henan Mechanical and Electrical Engineering College,2009 ,17 (2 ):1 -3 . (in Chinese)[2] 夏兆才. 6202型深沟球轴承沟曲率的磨损研究与结构优化[D]. 南京: 东南大学,2020. XIA Zhaocai. Research on groove abrasion and structure optimization of 6202 deep groove ball bearing[D]. Nanjing: Southeast University,2020. (in ChineseXIA Zhaocai. Research on groove abrasion and structure optimization of 6202 deep groove ball bearing[D]. Nanjing: Southeast University, 2020. (in Chinese) [3] ROSSOPOULOS G N,PAPADOPOULOS C I,LEONTOPOULOS C. Tribological comparison of an optimum single and double slope design of the stern tube bearing,case study for a marine vessel[J]. Tribology International,2020,150: 106343. doi: 10.1016/j.triboint.2020.106343 [4] SARUHAN H. Optimum design of rotor-bearing system stability performance comparing an evolutionary algorithm versus a conventional method[J]. International Journal of Mechanical Sciences,2006,48(12): 1341-1351. doi: 10.1016/j.ijmecsci.2006.07.009 [5] ZHANG Shuai,CUI Yongcun,HU Zhonghui,et al. Thermal-stress-wear coupled characteristics of oil seal in airframe rod end-bearing[J]. Tribology International,2021,163: 107132. doi: 10.1016/j.triboint.2021.107132 [6] 欧屹,梁医,冯虎田. 数控机床功能部件-滚动直线导轨副分册[M]. 北京: 机械工业出版社,2018. [7] HAN Huaizhi,YU Ruitian,LI Bingxi,et al. Multi-objective optimization of corrugated tube with loose-fit twisted tape using RSM and NSGA-II[J]. International Journal of Heat and Mass Transfer,2019,131: 781-794. doi: 10.1016/j.ijheatmasstransfer.2018.10.128 [8] LIAN Yongsheng,LIOU M S. Multiobjective optimization using coupled response surface model and evolutionary algorithm[J]. AIAA Journal,2005,43(6): 1316-1325. doi: 10.2514/1.12994 [9] 冯吉路,孙志礼,李皓川,等. 基于Kriging模型的轴承结构参数优化设计方法[J]. 航空动力学报,2017,32(3): 723-729. FENG Jilu,SUN Zhili,LI Haochuan,et al. Optimization design method of bearing structure parameters based on Kriging model[J]. Journal of Aerospace Power,2017,32(3): 723-729. (in Chinese FENG Jilu, SUN Zhili, LI Haochuan, et al . Optimization design method of bearing structure parameters based on Kriging model[J]. Journal of Aerospace Power,2017 ,32 (3 ):723 -729 . (in Chinese)[10] 惠文华,刘家浚,朱宝亮,等. 摩擦学与耐磨性设计[M]. 南京: 东南大学出版社,1993. [11] HUNG J P,SHIH-SHYN WU J,CHIU J Y. Impact failure analysis of re-circulating mechanism in ball screw[J]. Engineering Failure Analysis,2004,11(4): 561-573. doi: 10.1016/j.engfailanal.2004.01.002 [12] SHIMIZU S. Load distribution and accuracyrigidity of linear motion ball guides system[J]. Journal of the Japan Society for Precision Engineering,1990,56(8): 1445-1451. doi: 10.2493/jjspe.56.1445 [13] TAO Weijun,ZHONG Yang,FENG Hutian,et al. Model for wear prediction of roller linear guides[J]. Wear,2013,305(1/2): 260-266. [14] 王民,乐兵兵,裴二阳. 基于Hertz接触的滚珠直线导轨副接触刚度建模与分析[J]. 北京工业大学学报,2015,41(8): 1128-1132,1150. WANG Min,LE Bingbing,PEI Eryang. Contact stiffness modeling and analysis of linear ball guides based on hertz contact theory[J]. Journal of Beijing University of Technology,2015,41(8): 1128-1132,1150. (in Chinese doi: 10.11936/bjutxb2014120030 WANG Min, LE Bingbing, PEI Eryang . Contact stiffness modeling and analysis of linear ball guides based on hertz contact theory[J]. Journal of Beijing University of Technology,2015 ,41 (8 ):1128 -1132, 1150 . (in Chinese) doi: 10.11936/bjutxb2014120030[15] International Organization for Standardization. Ball screws: Part 4 Static axial rigidity: ISO 3408-4 [S]. Switzerland: BSI,2006: 12-13. [16] TONG V C,KHIM G,PARK C H,et al. Linear ball guide design optimization considering stiffness,friction force,and basic dynamic load rating using particle swarm optimization[J]. Journal of Mechanical Science and Technology,2020,34(3): 1313-1323. doi: 10.1007/s12206-020-0230-4 [17] WONG S M,HOBBS R E,ONOF C. An adaptive response surface method for reliability analysis of structures with multiple loading sequences[J]. Structural Safety,2005,27(4): 287-308. doi: 10.1016/j.strusafe.2005.02.001 [18] STEPHANOU M,VARUGHESE M. Sequential estimation of Spearman rank correlation using Hermite series estimators[J]. Journal of Multivariate Analysis,2021,186: 104783. doi: 10.1016/j.jmva.2021.104783 -

下载:

下载: