Study of film cooling characteristics on plug of two-dimensional (2-D) plug nozzle

-

摘要:

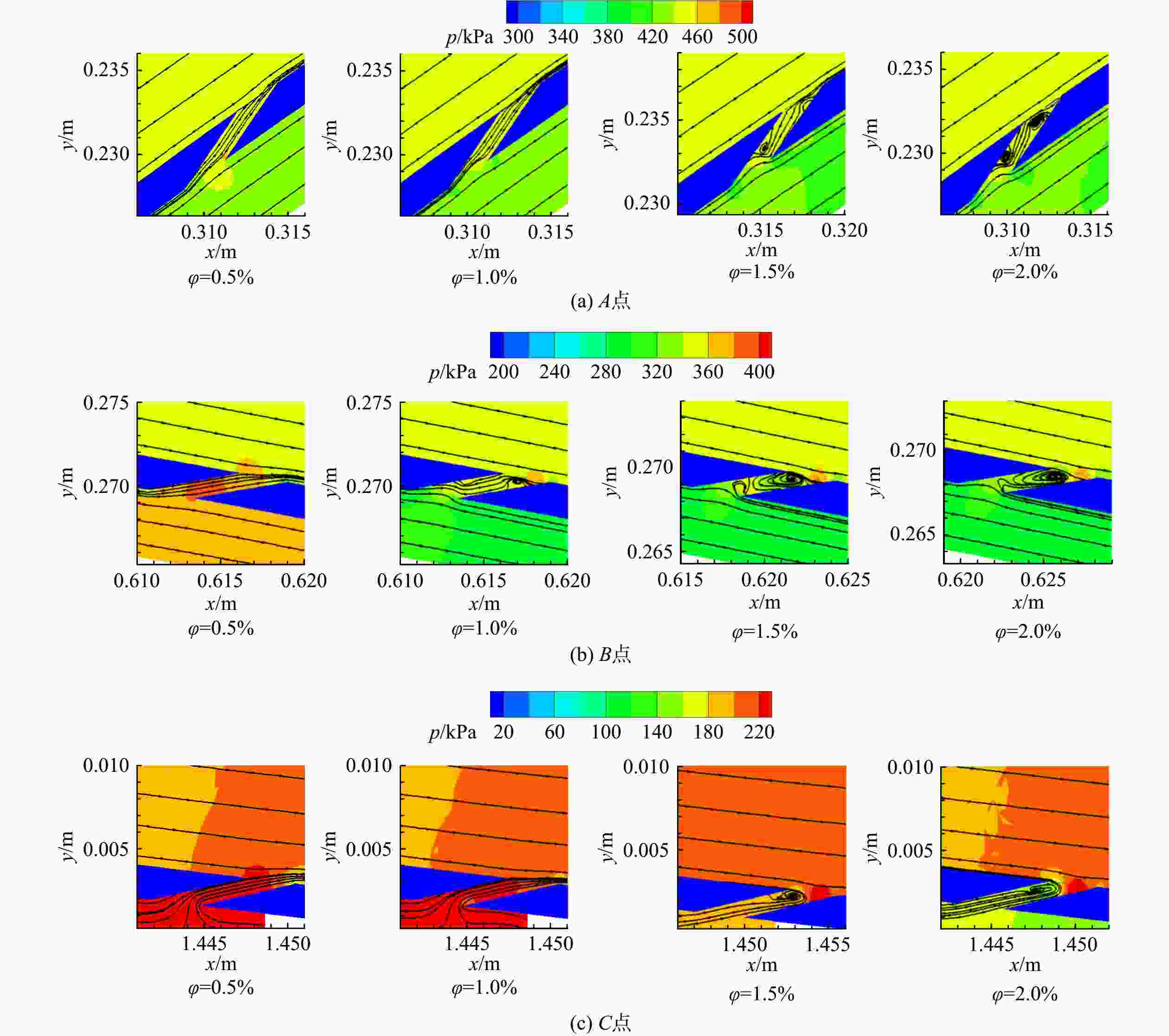

加力状态使得二元塞式喷管热负荷急剧升高,势必需要引入冷气对塞锥进行冷却。在缩比模型试验验证的基础上,采用全尺寸模型数值仿真,对比分析了入口总压比、开孔率和气膜孔径对二元塞式喷管流动和冷却特性的影响。结果表明:在研究参数范围内,气膜冷却能够显著降低塞锥表面温度,对喷管推力系数影响甚微;以无冷却为基准,入口总压比从1.02增至1.20,塞锥表面温度降低了20%~45%,总压恢复系数降低了0.22%~1.26%;增大开孔率会导致冷却通道压力降低、气膜出流阻力增大,在塞锥尾部甚至出现热气倒灌,综合考虑整个塞锥表面的冷气出流状况,小开孔率结构更具优势;减小气膜孔径意味着气膜孔数目增加、气膜覆盖范围增大,使得塞锥冷却效果有微弱的改善。

Abstract:The heat load of 2-D plug nozzle sharply increases under the afterburning condition, therefore, it is necessary to introduce cold air to cool the plug. Based on subscale model experiment verification, a numerical simulation of full-scale model was performed to investigate the effect of plug film cooling on the aerodynamic and cooling performance of 2-D plug nozzle. The effects of total pressure ratio of inlets, diameter of film holes and perforated percentage of film holes were analyzed by contrast. The calculation results indicated that: within the range of the study parameters, film cooling made the plug surface temperature significantly drop and had a little effect on the thrust coefficient of the nozzle. Compared with the case without cooling, the total pressure ratio of inlets increased from 1.02 to 1.20, the surface temperature of the plug decreased by 20% to 45% and the total pressure recovery coefficient decreased by 0.22% to 1.26%. A lower channel pressure and a bigger film outflow resistance were caused by a higher perforated percentage of film holes, which even caused the hot gas backflow in the tail of plug. Considering the cooling air discharge condition of the whole plug surface, a small perforated percentage of film holes showed more advantages. Reducing the diameter of film holes meant increasing the amount of film holes and the film coverage, thus making the cooling effect slightly enhanced.

-

表 1 气膜孔结构和冷气参数

Table 1. Parameters of film structure and cooling air

参数 模型 Ⅰ Ⅱ Ⅲ Ⅳ s/mm 15.71 15.71 10.47 7.85 p/mm 10 5 5 5 φ/% 0.5 1.0 1.5 2.0 d/mm 0.6,0.8,1.0 ζ 1.02,1.05,1.10,1.15,1.20 表 2 不同入口总压比下塞锥冷却流量比

Table 2. Plug cooling flow ratio under different total pressure ratio of inlets

ζ χ/% 1.02 3.63 1.05 4.54 1.10 5.40 1.15 6.07 1.20 6.67 表 3 不同开孔率下塞锥冷却流量比

Table 3. Plug cooling flow ratio under different perforated percentage

% φ χ 0.5 4.54 1.0 4.91 1.5 4.95 2.0 5.15 表 4 不同气膜孔径下塞锥冷却流量占比

Table 4. Plug cooling flow ratio vs diameter of film holes

d/mm χ/% 0.6 4.23 0.8 4.44 1.0 4.54 -

[1] 徐顶国,艾俊强,雷武涛,等. 未来新一代轰炸机隐身特性需求分析[J]. 航空工程进展,2018,9(4): 451-457. XU Dingguo,AI Junqiang,LEI Wutao,et al. Analysis on stealth requirement of next-generation bomber in the future[J]. Advances in Aeronautical Science and Engineering,2018,9(4): 451-457. (in ChineseXU Dingguo, AI Junqiang, LEI Wutao, et al. Analysis on stealth requirement of next-generation bomber in the future[J]. Advances in Aeronautical Science and Engineering, 2018, 9(4): 451-457. (in Chinese) [2] 张加圣,王海涛,万小朋,等. 第四代战斗机性能指标概述[J]. 航空制造技术,2008,51(16): 66-69. ZHANG Jiasheng,WANG Haitao,WAN Xiaopeng,et al. Summarization of the fourth generation fighter performance[J]. Aeronautical Manufacturing Technology,2008,51(16): 66-69. (in Chinese doi: 10.3969/j.issn.1671-833X.2008.16.012ZHANG Jiasheng, WANG Haitao, WAN Xiaopeng, et al. Summarization of the fourth generation fighter performance[J]. Aeronautical Manufacturing Technology, 2008, 51(16): 66-69. (in Chinese) doi: 10.3969/j.issn.1671-833X.2008.16.012 [3] 林鹏,左林玄,王霄,等. 未来作战飞机飞发一体化技术的思考[J]. 航空动力,2018(2): 52-57. LIN Peng,ZUO Linxuan,WANG Xiao,et al. Discussion on aircraft/engine integration technology of future combat aircraft[J]. Aerospace Power,2018(2): 52-57. (in ChineseLIN Peng, ZUO Linxuan, WANG Xiao, et al. Discussion on aircraft/engine integration technology of future combat aircraft[J]. Aerospace Power, 2018(2): 52-57. (in Chinese) [4] HEARTH D P,GORTON G C. Investigation of thrust and drag characteristics of a plug-type exhaust nozzle: NACA-RM-E53L16 [R]. National Advisory Committee for Aeronautics in America,1954. [5] CIEPLUCH C,KRULL H,STEFFEN F W. Preliminary investigation of performance of variable-throat extended-plug-type nozzles over wide range of nozzle pressure ratios: NACA-RM-E53J28[R]. National Advisory Committee for Aeronautics in America,1954. [6] PETIT J,CAPONE F. Performance characteristics of a wedge nozzle installed on an F-18 propulsion wind tunnel model: AIAA 1979-1164[R]. Reston,Virigina: Proceedings of the 15th Joint Propulsion Conference,1979. [7] 王长辉,刘宇,戴梧叶. 塞锥型面简化与截短对塞式喷管性能的影响[J]. 推进技术,2002,23(5): 438-440. WANG Changhui,LIU Yu,DAI Wuye. Effects of plug contour simplification and truncation on linear plug nozzle[J]. Journal of Propulsion Technology,2002,23(5): 438-440. (in Chinese doi: 10.3321/j.issn:1001-4055.2002.05.021WANG Changhui, LIU Yu, DAI Wuye. Effects of plug contour simplification and truncation on linear plug nozzle[J]. Journal of Propulsion Technology, 2002, 23(5): 438-440. (in Chinese) doi: 10.3321/j.issn:1001-4055.2002.05.021 [8] CHENOWETH F,JERACKI R J. Coolant flow effects on the performance of a conical plug nozzle at Mach numbers from 0 to 2.0[R]. NASA TM-X-2076,1970. [9] ROMMEL T,HAGEMANN G,SCHLEY C A,et al. Plug nozzle flowfield analysis[J]. Journal of Propulsion and Power,1997,13(5): 629-634. doi: 10.2514/2.5227 [10] FUJII K,IMAI K,SATO T. Computational analysis of the flow field near the boat-tail region of annular plug nozzles[J]. JSME International Journal Series B,2002,45(4): 745-751. doi: 10.1299/jsmeb.45.745 [11] 盛超,滕状,李庆林,等. 塞式矢量喷管热态内流特性试验[J]. 航空发动机,2020,46(6): 29-33. SHENG Chao,TENG Zhuang,LI Qinglin,et al. Experiment on hot internal flow characteristics of plug vectoring nozzle[J]. Aeroengine,2020,46(6): 29-33. (in ChineseSHENG Chao, TENG Zhuang, LI Qinglin, et al. Experiment on hot internal flow characteristics of plug vectoring nozzle[J]. Aeroengine, 2020, 46(6): 29-33. (in Chinese) [12] VEEN R V,GENTRY R,HOFFMAN J D. Design of shrouded-plug nozzles for maximum thrust[J]. AIAA Journal,1974,12(9): 1193-1197. doi: 10.2514/3.49452 [13] SULE W,MUELLER T. Annular truncated plug nozzle flowfield and base pressure characteristics: AIAA 1973-137 [R] Reston,Virigina: Proceedings of the 11th Aerospace Sciences Meeting,1973. [14] CLER D,MASON M,GUTHRIE A. Experimental investigation of spherical-convergent-flap thrust-vectoring two-dimensional plug nozzles: AIAA 1993-2431[R]. Reston,Virigina: Proceedings of the 29th Joint Propulsion Conference and Exhibit,1993. [15] 张靖周,王旭,单勇. 塞锥后体气膜冷却对轴对称塞式喷管红外辐射和气动性能的影响[J]. 航空学报,2015,36(8): 2601-2608. ZHANG Jingzhou,WANG Xu,SHAN Yong. Effects of plug rear-body film cooling on infrared radiation and aerodynamic performance of axisymmetric plug nozzle[J]. Acta Aeronautica et Astronautica Sinica,2015,36(8): 2601-2608. (in ChineseZHANG Jingzhou, WANG Xu, SHAN Yong. Effects of plug rear-body film cooling on infrared radiation and aerodynamic performance of axisymmetric plug nozzle[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(8): 2601-2608. (in Chinese) [16] 周兵,吉洪湖. 塞锥气膜冷却对二元塞式喷管红外特征的影响[J]. 航空动力学报,2016,31(12): 2895-2903. ZHOU Bing,JI Honghu. Effect of wedge film cooling on the infrared signature of two-dimensional wedge nozzle[J]. Journal of Aerospace Power,2016,31(12): 2895-2903. (in ChineseZHOU Bing, JI Honghu. Effect of wedge film cooling on the infrared signature of two-dimensional wedge nozzle[J]. Journal of Aerospace Power, 2016, 31(12): 2895-2903. (in Chinese) [17] 陈俊,吉洪湖. 二元塞式喷管红外特征及壁面降温的红外抑制效果计算[J]. 航空动力学报,2012,27(11): 2429-2435. CHEN Jun,JI Honghu. Numerical simulation of the infrared radiation characteristics and infrared restraining effect of lower wall temperature for two-dimensional plug nozzle[J]. Journal of Aerospace Power,2012,27(11): 2429-2435. (in ChineseCHEN Jun, JI Honghu. Numerical simulation of the infrared radiation characteristics and infrared restraining effect of lower wall temperature for two-dimensional plug nozzle[J]. Journal of Aerospace Power, 2012, 27(11): 2429-2435. (in Chinese) [18] NOSEK S M,STRAIGHT D M. Heat transfer characteristics of partially film cooled plug nozzle on a J-85 afterburning turbojet engine[R]. NASA TM X-3362,1976. [19] CLARK J,LIEBERMAN A. Thermal design study of an air-cooled plug-nozzle system for a supersonic cruise aircraft[R]. NASA TM X-2475,1972. [20] 征建生,单勇,张靖周. 二元塞式矢量喷管塞锥尾缘冷却及红外辐射抑制效果[J]. 航空学报,2017,38(12): 121384. ZHENG Jiansheng,SHAN Yong,ZHANG Jingzhou. Cooling and infrared radiation suppression effect of plug trailing-body of two-dimensional vector plug nozzle[J]. Acta Aeronautica et Astronautica Sinica,2017,38(12): 121384. (in ChineseZHENG Jiansheng, SHAN Yong, ZHANG Jingzhou. Cooling and infrared radiation suppression effect of plug trailing-body of two-dimensional vector plug nozzle[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(12): 121384. (in Chinese) [21] HARRINGTON D,NOSEK S,STRAIGHT D. Cold-flow performance of several variations of a ram-air-cooled plug nozzle for supersonic-cruise aircraft[R]. NASA TM X-3110,1974. -

下载:

下载: