Influence study of flow angularity on measuring device in wind tunnel flow field calibration

-

摘要:

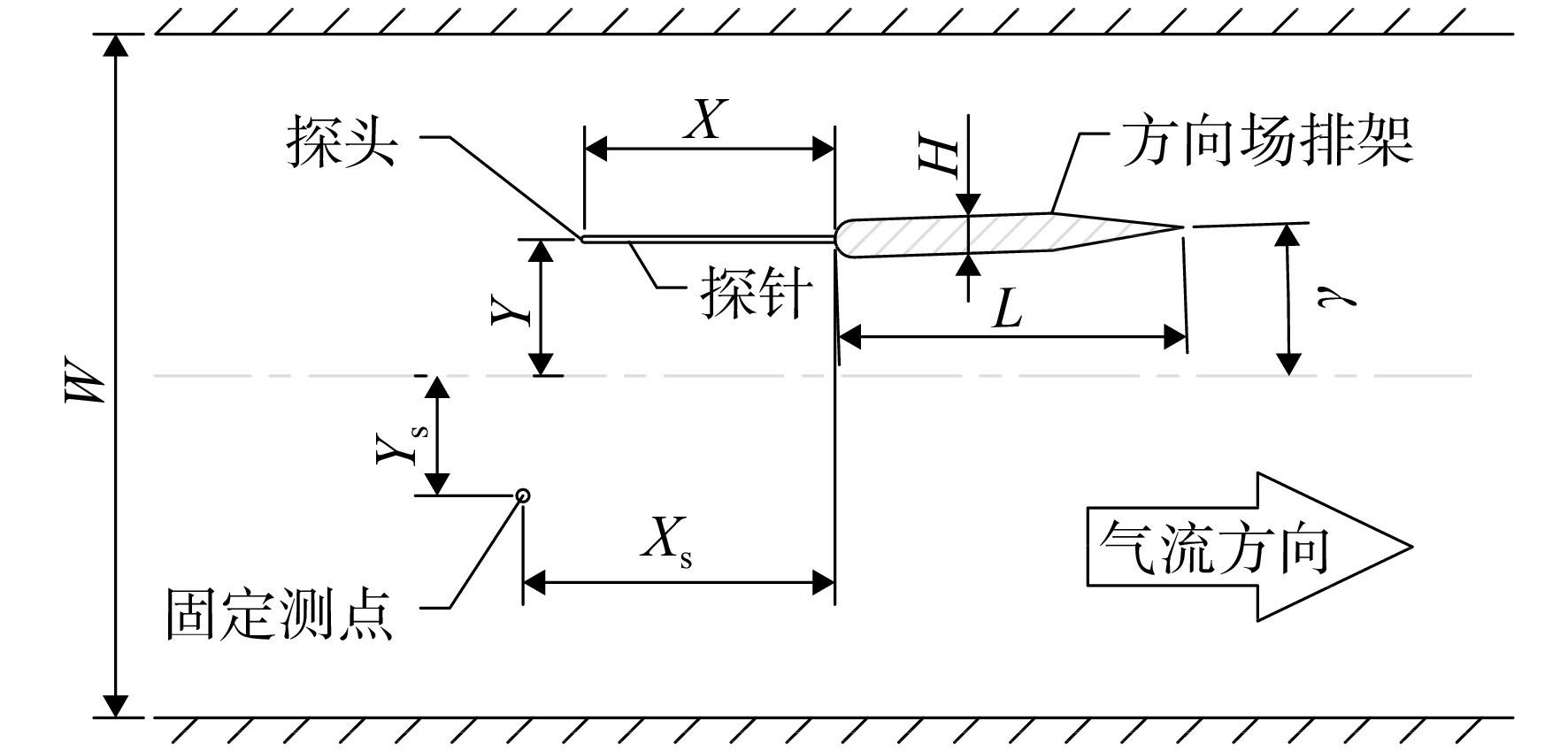

为确定排架设计参数对低速风洞流场校测中方向场局部气流偏角的影响,采用数值模拟与试验对比验证的方式进行了研究,证明当前所采用的方法能够对排架设计参数进行有效评估。采用该数值模拟方法,针对排架的阻塞度、偏离试验段轴线距离、安装角度以及方向场探针的长度等参数,对局部气流偏角测量的影响进行了分析,得到了影响规律,并建立了影响模型。结果表明:排架的阻塞度、排架偏离试验段轴线距离以及方向场探针的长度对局部气流偏角的测试影响明显;如排架气动尺寸或测试方法设计不当,将导致测试结果与真实结果差异较大,得到错误的风洞方向场品质的评估结果。

Abstract:In order to determine the influence of flow angularity on design parameters of measuring device in low speed wind tunnel flow field calibration, wind tunnel experiment and numerical simulation were conducted to prove the feasibility of the adopted method of assessment. Numerical simulation method was carried out to study the influence of local flow angularity on measuring device blockage, offset, angle of attack and probe length. The law of influence was obtained and the mathematical model of influence was established. The results showed that: 1) the angle of attack, the offset of measuring device and the length of probe have obvious influence on the local flow angularity experiment results, 2) if the measuring device or test method was not properly designed, the error of flow angularity test results could be too large, even leading to wrong experimental conclusion about flow angularity.

-

Key words:

- low speed wind tunnel /

- flow angularity /

- measuring device /

- influence /

- flow field calibration

-

-

[1] ARRINGTON E A,GONSALEZ J C,CURRY Ⅲ M R. Subsonic calibration of the NASA Gelenn Research Center 10- by 10-foot supersonic wind tunnel(1998 test): AIAA-2000-2448[R]. Denver,US: 21st Aerodynamic Measurement Technology and Ground Testing Conference,2000. [2] KMAK F. Modernization and activation of the NASA Ames 11- by 11-Foot Transonic Wind Tunnel: AIAA 2000-2680[R]. Reston,Virigina: Proceedings of the 21st Aerodynamic Measurement Technology and Ground Testing Conference,2000. [3] COLIN P B. Aerodynamic calibration of an automotive climatic wind tunnel: AIAA-2005-4279 [R]. Tucson,Arizona: 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit,2005. [4] RINEHART D A,JOHNSON A M. Full aerothermal characterization of the NASA Glenn Research Center 9- by 15-foot low-speed wind tunnel[R]. NASA/CR-20205005811,2021. [5] MOONEN P,BLOCKEN B,CARMELIET J. Indicators for the evaluation of wind tunnel test section flow quality and application to a numerical closed-circuit wind tunnel[J]. Journal of Wind Engineering and Industrial Aerodynamics,2007,95(9/10/11): 1289-1314. [6] 李峰,高超,张正科,等. NF-6增压连续式跨声速风洞流场特性与标模试验[J]. 实验流体力学,2013,27(1): 61-64,92. LI Feng,GAO Chao,ZHANG Zhengke,et al. The test of characteristics of flow area and calibration model in NF-6 pressurized continuous transonic wind tunnel[J]. Journal of Experiments in Fluid Mechanics,2013,27(1): 61-64,92. (in ChineseLI Feng, GAO Chao, ZHANG Zhengke, et al. The test of characteristics of flow area and calibration model in NF-6 pressurized continuous transonic wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2013, 27(1): 61-64, 92. (in Chinese) [7] 贾忠湖,赵元立,吕卫民,等. HY-750开口回流低速风洞[J]. 流体力学实验与测量,2001,15(4): 64-69. JIA Zhonghu,ZHAO Yuanli,LU Weimin,et al. HY-750 open return circuit low speed wind tunnel[J]. Experiments and Measurements in Fluid Mechanics,2001,15(4): 64-69. (in ChineseJIA Zhonghu, ZHAO Yuanli, LU Weimin, et al. HY-750 open return circuit low speed wind tunnel[J]. Experiments and Measurements in Fluid Mechanics, 2001, 15(4): 64-69. (in Chinese) [8] 余世策,蒋建群,楼文娟,等. 大型回流边界层风洞的气动与结构设计[J]. 实验流体力学,2014,28(2): 59-64,68. YU Shice,JIANG Jianqun,LOU Wenjuan,et al. Aerodynamic and structural design of large recirculating boundary-layer wind tunnel[J]. Journal of Experiments in Fluid Mechanics,2014,28(2): 59-64,68. (in ChineseYU Shice, JIANG Jianqun, LOU Wenjuan, et al. Aerodynamic and structural design of large recirculating boundary-layer wind tunnel[J]. Journal of Experiments in Fluid Mechanics, 2014, 28(2): 59-64, 68. (in Chinese) [9] 胡丹梅,孙凯,张志超. 回流式低速风洞流场品质的测试及分析[J]. 上海电力学院学报,2016,32(3): 211-215,220. HU Danmei,SUN Kai,ZHANG Zhichao. Testing and analysis of the flow quality of the low speed closed circuit wind tunnel[J]. Journal of Shanghai University of Electric Power,2016,32(3): 211-215,220. (in ChineseHU Danmei, SUN Kai, ZHANG Zhichao. Testing and analysis of the flow quality of the low speed closed circuit wind tunnel[J]. Journal of Shanghai University of Electric Power, 2016, 32(3): 211-215, 220. (in Chinese) [10] 齐娟,周云龙,李峰. 直流式低速风洞流动特性研究[J]. 东北电力大学学报(自然科学版),2009,29(1): 19-22. QI Juan,ZHOU Yunlong,LI Feng. Study on the flow characteristics in a newly constructed low speed blow down wind tunnel[J]. Journal of Northeast Dianli University (Natural Science Edition),2009,29(1): 19-22. (in ChineseQI Juan, ZHOU Yunlong, LI Feng. Study on the flow characteristics in a newly constructed low speed blow down wind tunnel[J]. Journal of Northeast Dianli University (Natural Science Edition), 2009, 29(1): 19-22. (in Chinese) [11] 符澄,彭强,李先锋,等. 亚声速气流中五孔探针的校准及应用[J]. 实验流体力学,2011,25(3): 87-90. FU Cheng,PENG Qiang,LI Xianfeng,et al. Five-hole flow angle probe calibration and measurement in subsonic flow[J]. Journal of Experiments in Fluid Mechanics,2011,25(3): 87-90. (in Chinese doi: 10.3969/j.issn.1672-9897.2011.03.019FU Cheng, PENG Qiang, LI Xianfeng, et al. Five-hole flow angle probe calibration and measurement in subsonic flow[J]. Journal of Experiments in Fluid Mechanics, 2011, 25(3): 87-90. (in Chinese) doi: 10.3969/j.issn.1672-9897.2011.03.019 [12] 姜健,屈霁云,赵海刚. 五孔探针的设计制造及标定方法研究[J]. 工程与试验,2014,54(1): 59-63. JIANG Jian,QU Jiyun,ZHAO Haigang. Study on development and calibration method for five-hole probe[J]. Engineering & Test,2014,54(1): 59-63. (in ChineseJIANG Jian, QU Jiyun, ZHAO Haigang. Study on development and calibration method for five-hole probe[J]. Engineering & Test, 2014, 54(1): 59-63. (in Chinese) [13] 王涛,李飞行. 五孔探针结构和校准[J]. 现代机械,2012(4): 19-22. WANG Tao,LI Feixing. Construction and calibration of five-hole probe[J]. Modern Machinery,2012(4): 19-22. (in ChineseWANG Tao, LI Feixing. Construction and calibration of five-hole probe[J]. Modern Machinery, 2012(4): 19-22. (in Chinese) [14] GONSALEZ J C,ARRINGTON E. Five-hole flow angle probe calibration for the NASA Glenn icing research tunnel[R]. AIAA 96-2201,1996. [15] 符澄,彭强,李毅,等. 开孔壁蜂窝器整流特性实验研究[J]. 实验流体力学,2016,30(5): 17-22. FU Cheng,PENG Qiang,LI Yi,et al. Experimental study of flow straightening and turbulence reduction characteristics for porosity honeycomb[J]. Journal of Experiments in Fluid Mechanics,2016,30(5): 17-22. (in ChineseFU Cheng, PENG Qiang, LI Yi, et al. Experimental study of flow straightening and turbulence reduction characteristics for porosity honeycomb[J]. Journal of Experiments in Fluid Mechanics, 2016, 30(5): 17-22. (in Chinese) [16] 熊建军,王辉,马军,等. 基于龙门结构的风洞流场校测架测控系统设计与应用[J]. 测控技术,2014,33(12): 85-87,91. XIONG Jianjun,WANG Hui,MA Jun,et al. Design and application for control system of wind tunnel flow quality testing device based on the Longmen framework[J]. Measurement & Control Technology,2014,33(12): 85-87,91. (in Chinese doi: 10.3969/j.issn.1000-8829.2014.12.023XIONG Jianjun, WANG Hui, MA Jun, et al. Design and application for control system of wind tunnel flow quality testing device based on the Longmen framework[J]. Measurement & Control Technology, 2014, 33(12): 85-87, 91. (in Chinese) doi: 10.3969/j.issn.1000-8829.2014.12.023 [17] 郭隆德. 风洞非接触测量技术[M]. 北京: 国防工业出版社,2013. GUO Longde. Non-contact measurement technology in wind tunnel[M]. Beijing: National Defense Industry Press,2013. (in ChineseGUO Longde. Non-contact measurement technology in wind tunnel[M]. Beijing: National Defense Industry Press, 2013. (in Chinese) [18] 唐青,陈立平,张瑞瑞,等. IEA-Ⅰ型航空植保高速风洞的设计与校测[J]. 农业工程学报,2016,32(6): 73-81. TANG Qing,CHEN Liping,ZHANG Ruirui,et al. Design and test of IEA-Ⅰ high speed wind tunnel for aerial plant protection[J]. Transactions of the Chinese Society of Agricultural Engineering,2016,32(6): 73-81. (in ChineseTANG Qing, CHEN Liping, ZHANG Ruirui, et al. Design and test of IEA-Ⅰ high speed wind tunnel for aerial plant protection[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(6): 73-81. (in Chinese) -

下载:

下载: