Superiority analysis of mass injection pre-compressor cooling technology based on aircraft-engine integration model

-

摘要:

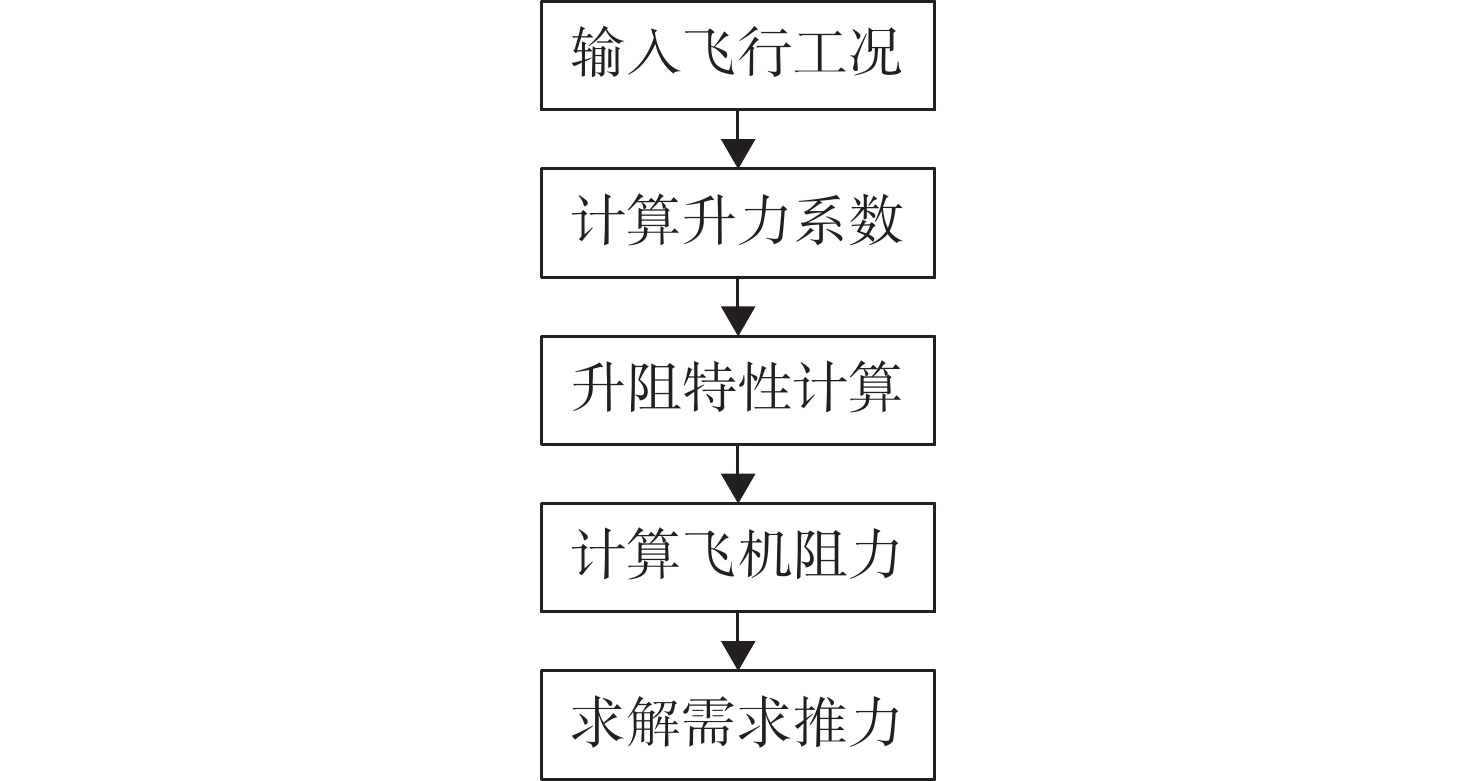

为探索射流预冷技术在未来先进航空动力上的应用前景,基于涡喷发动机建立飞发一体化性能仿真计算模型,并选取水作为预冷剂,分析不同飞行状态与预冷方案对飞机作战性能、发动机热力性能及热端部件温度的影响规律。结果表明:启用射流预冷技术可有效增加发动机推力,提升飞机的爬升性能与加速性能,帮助飞机在规定任务内减少机动时间与载荷消耗,同时预冷技术可提升压气机末级引气冷却品质,从而降低涡轮叶片表面温度,增强发动机可靠性。在飞发推力匹配条件与涡轮叶片表面温度约束下,射流预冷可有效提升飞机的极限飞行能力,当预冷剂流量为1 kg/s时,飞机理论升限与最大马赫数分别提升11.67%和10.51%。

Abstract:In order to explore the application prospect of mass injection pre-compressor cooling technology in advanced aero-engines in the future, a simulation model of aircraft-engine integration was built based on turbojet engine, water was selected as the coolant, and the effects of different flight conditions and precooling schemes on aircraft combat capability, engine performance and temperature of hot end component were analyzed. The results showed that the thrust of aero-engine can be increased by mass injection pre-compressor cooling technology, which can improve the climbing and acceleration performance of aircraft and reduce the mission time and load consumption within the assigned task. The surface temperature of turbine blade can be also decreased with the reduction of the temperature of bleed air due to mass injection pre-compressor cooling technology. Given the matching principle of aircraft-engine thrust and the constraint of the surface temperature of turbine blade, the ultimate flight performance of aircraft can be improved effectively by mass injection pre-compressor cooling technology. If the flow rate of coolant was 1 kg/s, the theoretical ceiling and maximum Mach number of aircraft can be increased by 11.67% and 10.51%, respectively.

-

表 1 设计点循环参数取值

Table 1. Cycle parameters of design point

循环参数 H=0 km, Ma=0 H=11 km, Ma=0.9 进口流量/(kg/s) 125 35 压气机压比 12 6.85 涡轮前温度/K 1 850 1 200 最高涡轮前温度/K 2 000 2 000 燃烧效率 0.999 0.975 压气机绝热效率 0.8 0.79 涡轮绝热效率 0.9 0.88 涡轮导叶引气比例/% 9 9 涡轮动叶引气比例/% 6 6 飞机引气比例/% 1 1 表 2 设计点模型验证

Table 2. Validation of design points

设计点 性能参数 模型 GasTurb 误差/% 1 推力/kN 126.69 126.96 −0.21 耗油率/(kg/(N·h)) 0.1117 0.1096 1.92 2 推力/kN 18.05 18.11 −0.33 耗油率/(kg/(N·h)) 0.1196 0.1162 2.93 表 3 发动机非设计点

Table 3. Off-design points of the aero-engine

非设计点 飞机状态 H/km Ma 发动机工作状态 1 起飞滑跑 0 0.1 加力最大状态 2 低空爬升 5 0.5 最大状态 3 亚声速巡航 11 0.9 巡航状态 4 超声速巡航 11 1.5 巡航状态 5 近实用升限 20 2.5 加力最大状态 -

[1] DAI Jian,ZUO Qiuru. Key technologies for thermodynamic cycle of precooled engines: a review[J]. Acta Astronautica,2020,177: 299-312. doi: 10.1016/j.actaastro.2020.07.039 [2] MURTHY S N B. Developments in high-speed vehicle propulsion systems[M]. Reston, VA, US: AIAA, 1996: 698-712. [3] WANG Zhenguo,WANG Yuan,ZHANG Jianqiang,et al. Overview of the key technologies of combined cycle engine precooling systems and the advanced applications of micro-channel heat transfer[J]. Aerospace Science and Technology,2014,39: 31-39. doi: 10.1016/j.ast.2014.08.008 [4] BARON B, DOWMAN H W, DACKIS W C. Experimental investigation of thrust augmentation of axial-flow-type 4000-pound-thrust turbojet engine by water and alcohol injection at compressor inlet[R]. NACA-RM-E7K14, 1948. [5] WILCOX E C, TROUT E W. Analysis of thrust augmentation of turbojet engines by water injection at compressor inlet including charts for calculating compression processes with water injection[R]. NACA TR-1006, 1951. [6] BEKE A. Analytical investigation of the effect of water injection on supersonic turbojet-engine-inlet matching and thrust augmentation[R]. NACA TN-3922, 1957. [7] EDWARDS Z B, NEELY J, WARD T R. Investigation of the effect of pre-compressor evaporative cooling on the performance of a J57-P11 turbojet engine[R]. AEDC-TN-58-7, 1958. [8] KING L D. Design and testing of a pre-compressor cooling system for a high speed aircraft[R]. Texas: Chase Vought Corporation, 1961. [9] KIRKLAND F P. Water spray system development test final report[R]. Fort Worth, US: General Dynamics Fort Worth Division, FZT-628-005, 1975. [10] CARTER P, BALEPIN V, SPATH T, et al. MIPCC technology development [R]. AIAA 2003-6929, 2003. [11] 刘旭峰,常鸿雯,薛洪科,等. 射流预冷装置温降与流阻特性试验研究[J]. 航空发动机,2018,44(2): 81-86. doi: 10.13477/j.cnki.aeroengine.2018.02.014LIU Xufeng,CHANG Hongwen,XUE Hongke,et al. Investigation on temperature drop and flow resistance characteristics of mass injection pre-compressor cooling device[J]. Aeroengine,2018,44(2): 81-86. (in Chinese) doi: 10.13477/j.cnki.aeroengine.2018.02.014 [12] 涂洪妍,邓远灏,康松,等. 水气比对射流预冷喷射特性影响的数值研究[J]. 推进技术,2017,38(6): 1302-1309. doi: 10.13675/j.cnki.tjjs.2017.06.013TU Hongyan,DENG Yuanhao,KANG Song,et al. Numerical simulation for effects for water/air ratio on injection characteristics with water injection pre-compressor cooling[J]. Journal of Propusion Technology,2017,38(6): 1302-1309. (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.06.013 [13] LIN Aqiang,ZHOU Jie,HAMZA F,et al. Evaluation of mass injection cooling on flow and heat transfer characteristics for high-temperature inlet air in a MIPCC engine[J]. International Journal of Heat and Mass Transfer,2019,135: 620-630. doi: 10.1016/j.ijheatmasstransfer.2019.02.025 [14] 陆禹铭,徐倩楠,吴锋,等. 喷水射流预冷对发动机进气温度及流场变化影响的数值研究[J]. 推进技术,2020,41(9): 1999-2010. doi: 10.13675/j.cnki.tjjs.190819LU Yuming,XU Qiannan,WU Feng,et al. Numerical study on effects of water injection pre-compressor cooling on engine inlet temperature and flow field change[J]. Journal of Propusion Technology,2020,41(9): 1999-2010. (in Chinese) doi: 10.13675/j.cnki.tjjs.190819 [15] 商旭升,蔡元虎,陈玉春,等. 高速飞行器用射流预冷却涡轮基发动机性能模拟[J]. 中国空间科学技术,2005,25(4): 54-58. doi: 10.3321/j.issn:1000-758X.2005.04.009SHANG Xusheng,CAI Yuanhu,CHEN Yuchun,et al. Performance simulation of the mass injection pre-cooled TBCC engine for hypersonic vehicles[J]. Chinese Space Science and Technology,2005,25(4): 54-58. (in Chinese) doi: 10.3321/j.issn:1000-758X.2005.04.009 [16] MEHTA U,BOWLES J,MELTON J,et al. Water injection pre-compressor cooling assist space access[J]. The Aeronautical Journal,2015,119(1212): 145-171. doi: 10.1017/S0001924000010319 [17] DAVID A B N,UYIOGHOSA I. Aero engine compressor cooling by water injection: Part 1 evaporative compressor model[J]. Energy,2018,160: 1224-1235. doi: 10.1016/j.energy.2018.05.170 [18] DAVID A B N,UYIOGHOSA I. Aero engine compressor cooling by water injection: Part 2 performance and emission reductions[J]. Energy,2018,160: 1236-1243. doi: 10.1016/j.energy.2018.05.171 [19] XIONG Yuefei,QIN Jiang,CHENG Kunlin,et al. Influence of water injection on performance of scramjet engine[J]. Energy,2020,201: 117477.1-117477.10. doi: 10.1016/j.energy.2020.117477 [20] MATTINGLY J D. Aircraft engine design, Second edition[M]. Reston, US: AIAA, 2002. [21] 沙正平. 飞机设计手册: 第4册 军用飞机总体设计[M]. 北京: 航空工业出版社, 2005. [22] WILCOCK R C,YOUNG J B,HORLOCK J H. The effect of turbine blade cooling on the cycle efficiency of gas turbine power cycles[J]. Journal of Engineering for Gas Turbines and Power,2005,127(1): 109-120. doi: 10.1115/1.1805549 -

下载:

下载: