Response surface characteristic analysis of jet precooling on aero-engine inlet temperature

-

摘要:

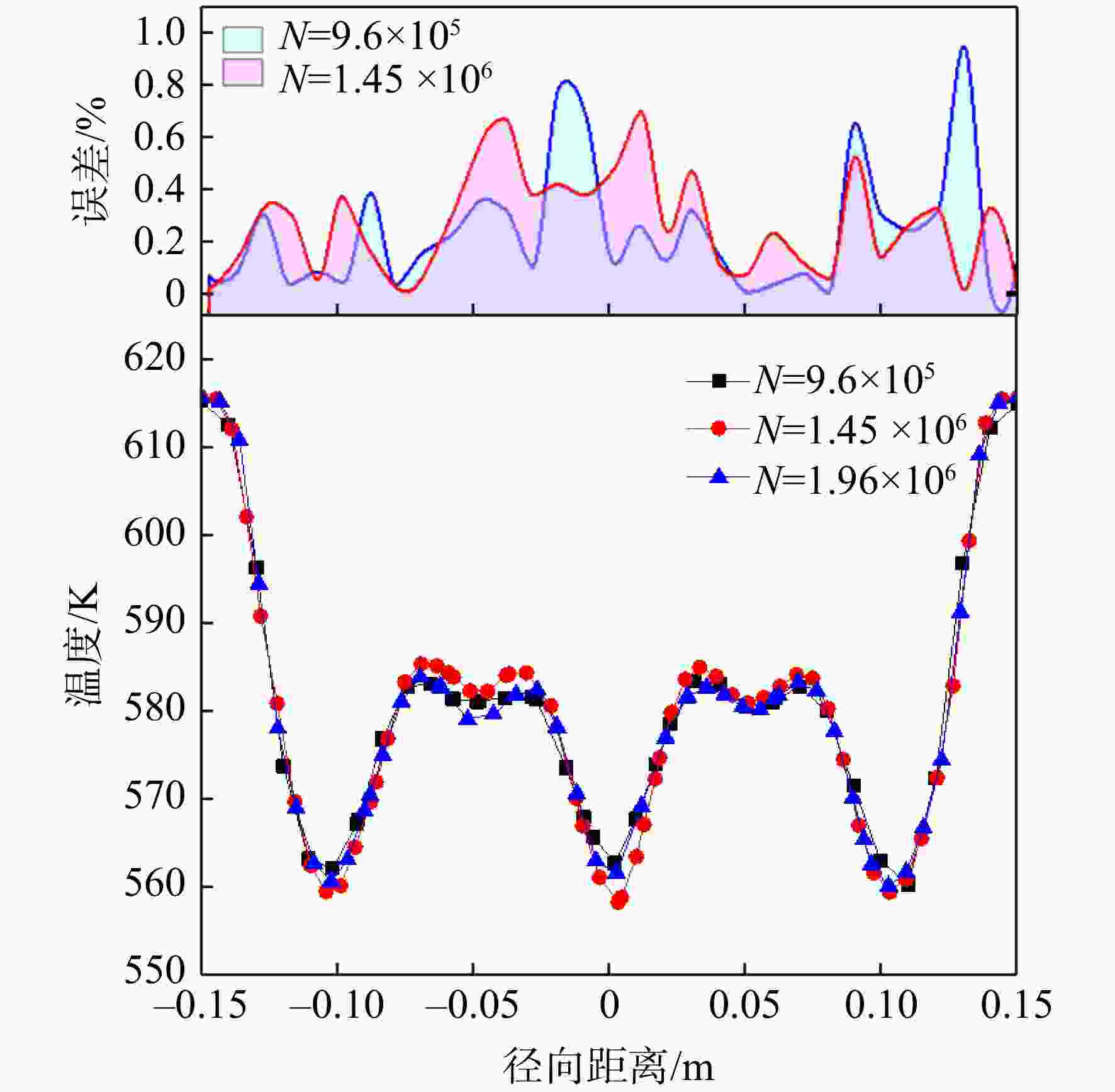

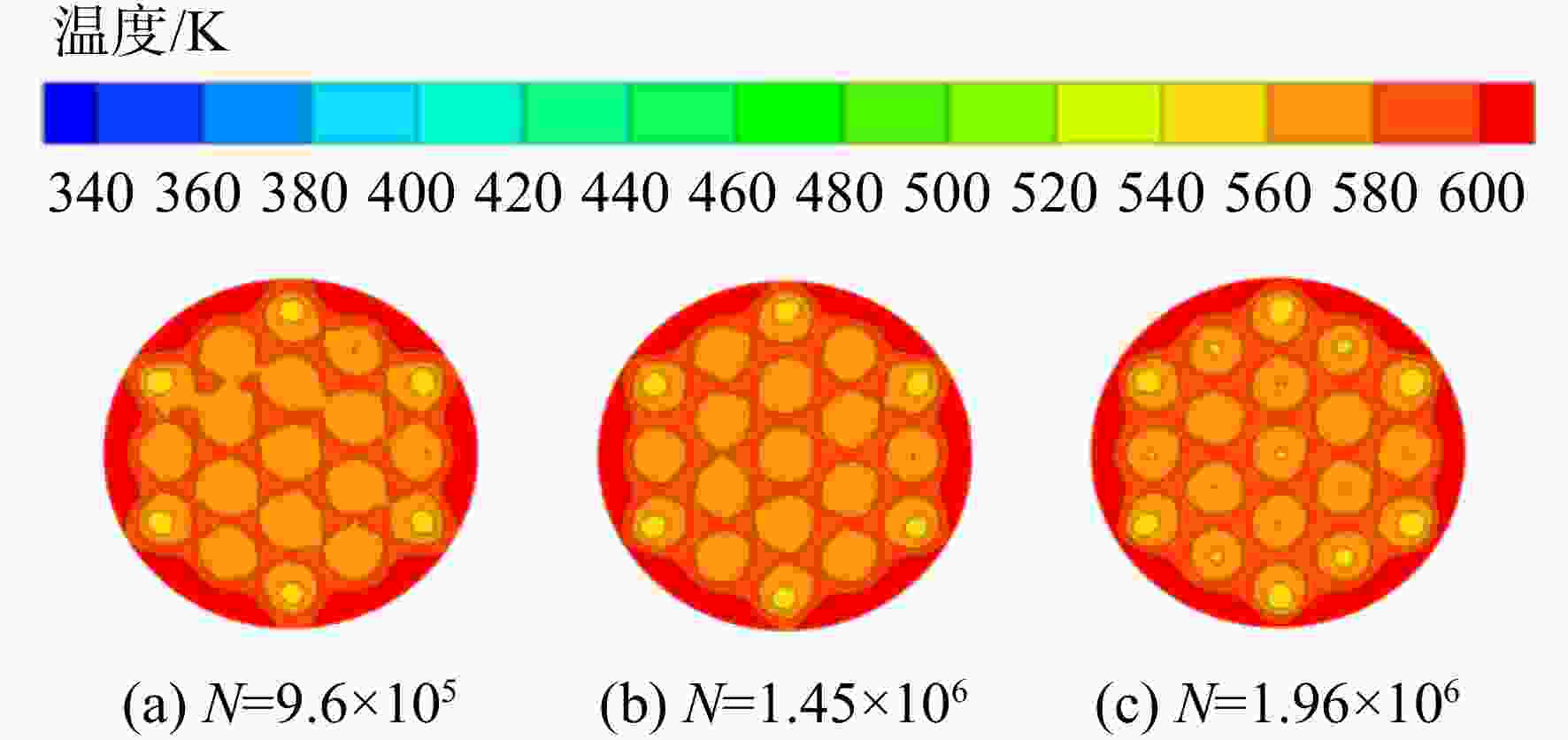

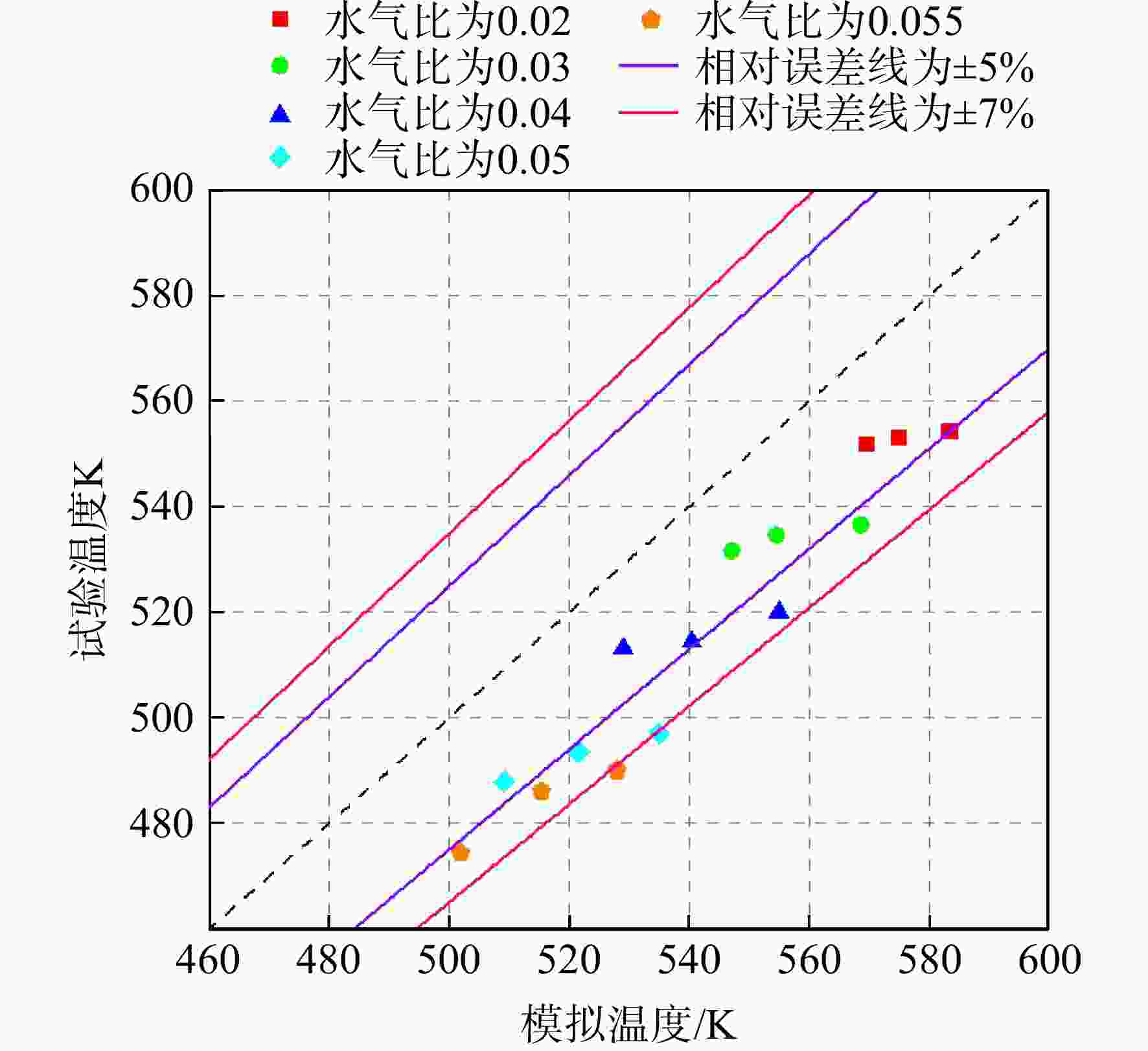

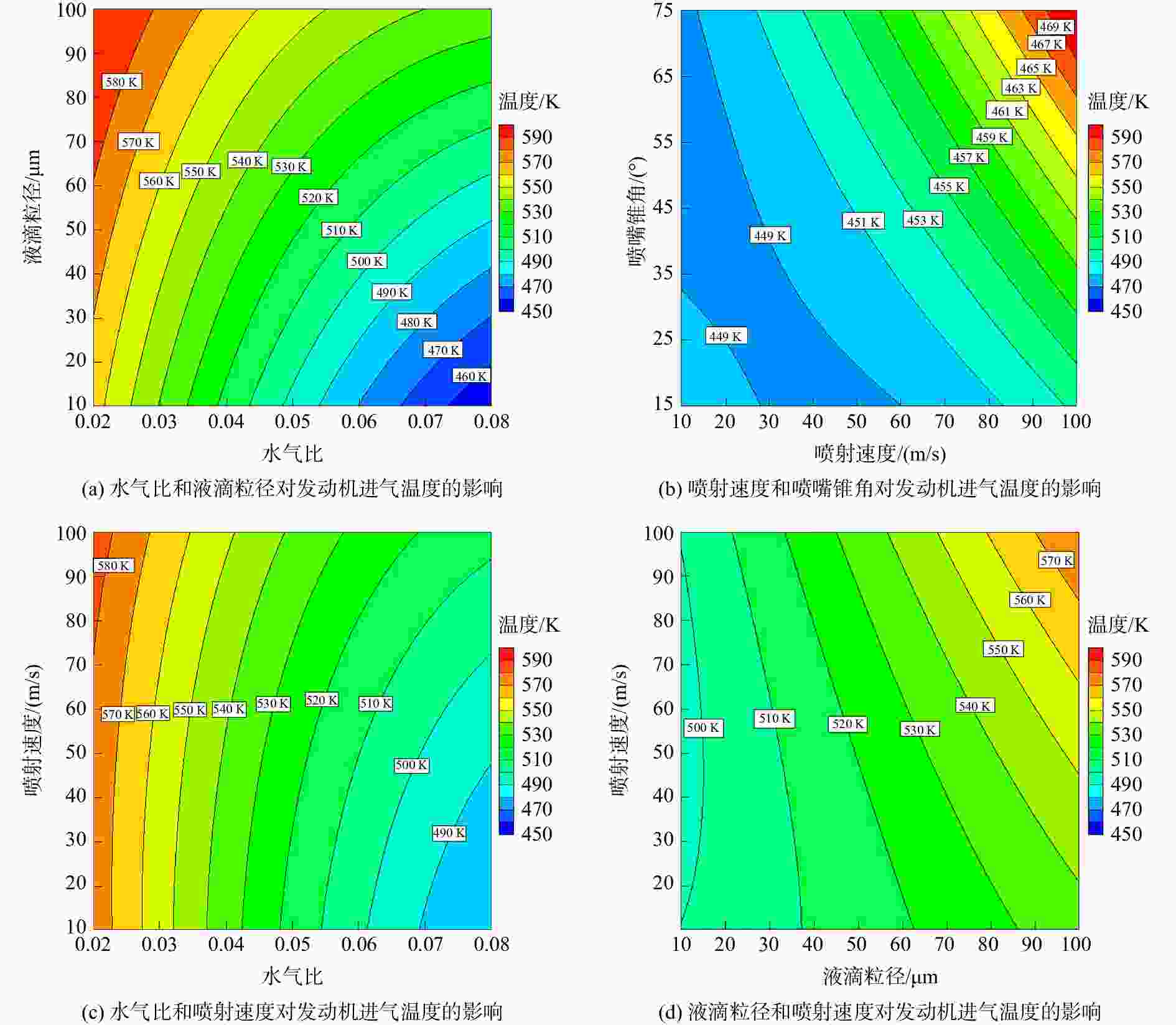

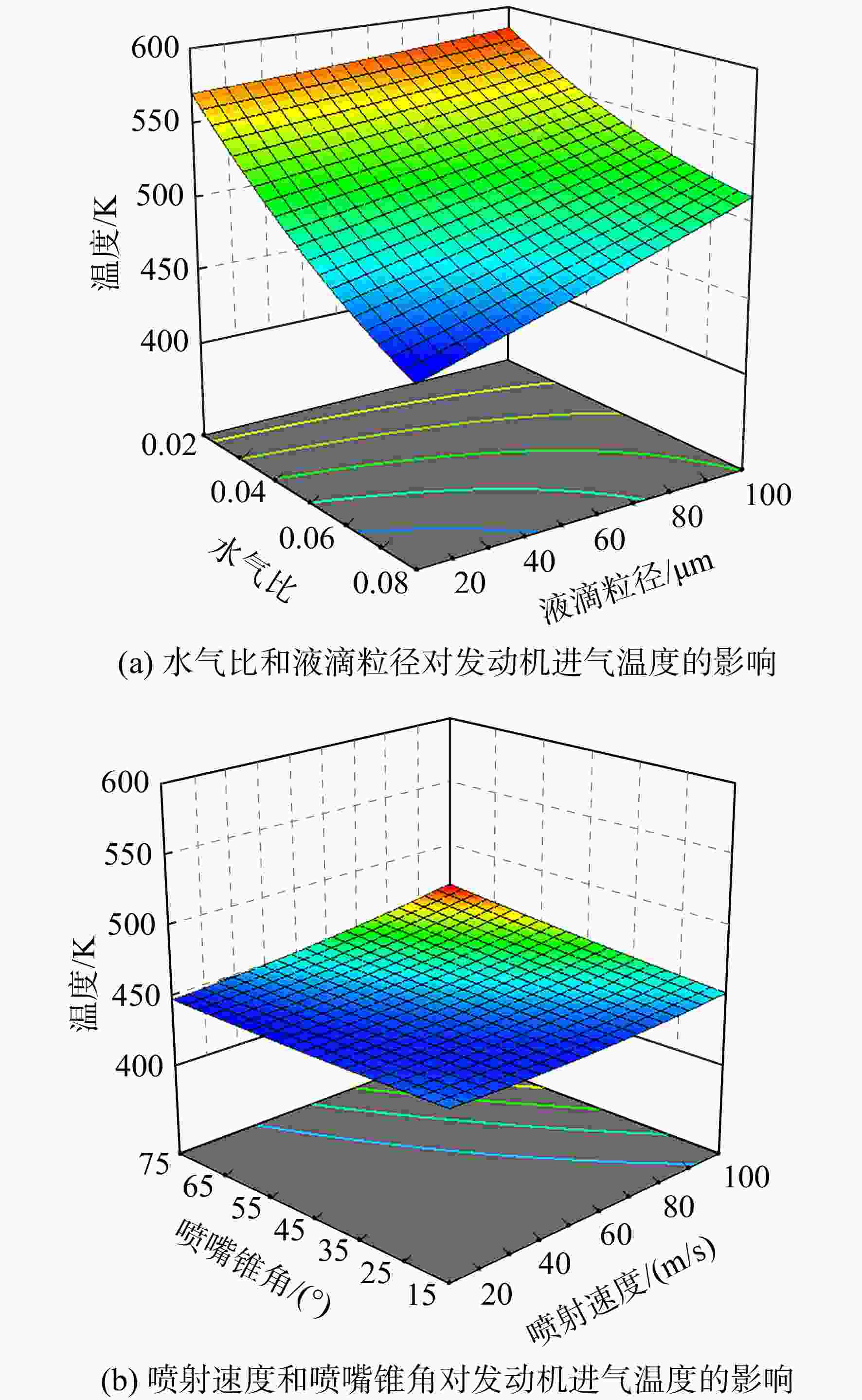

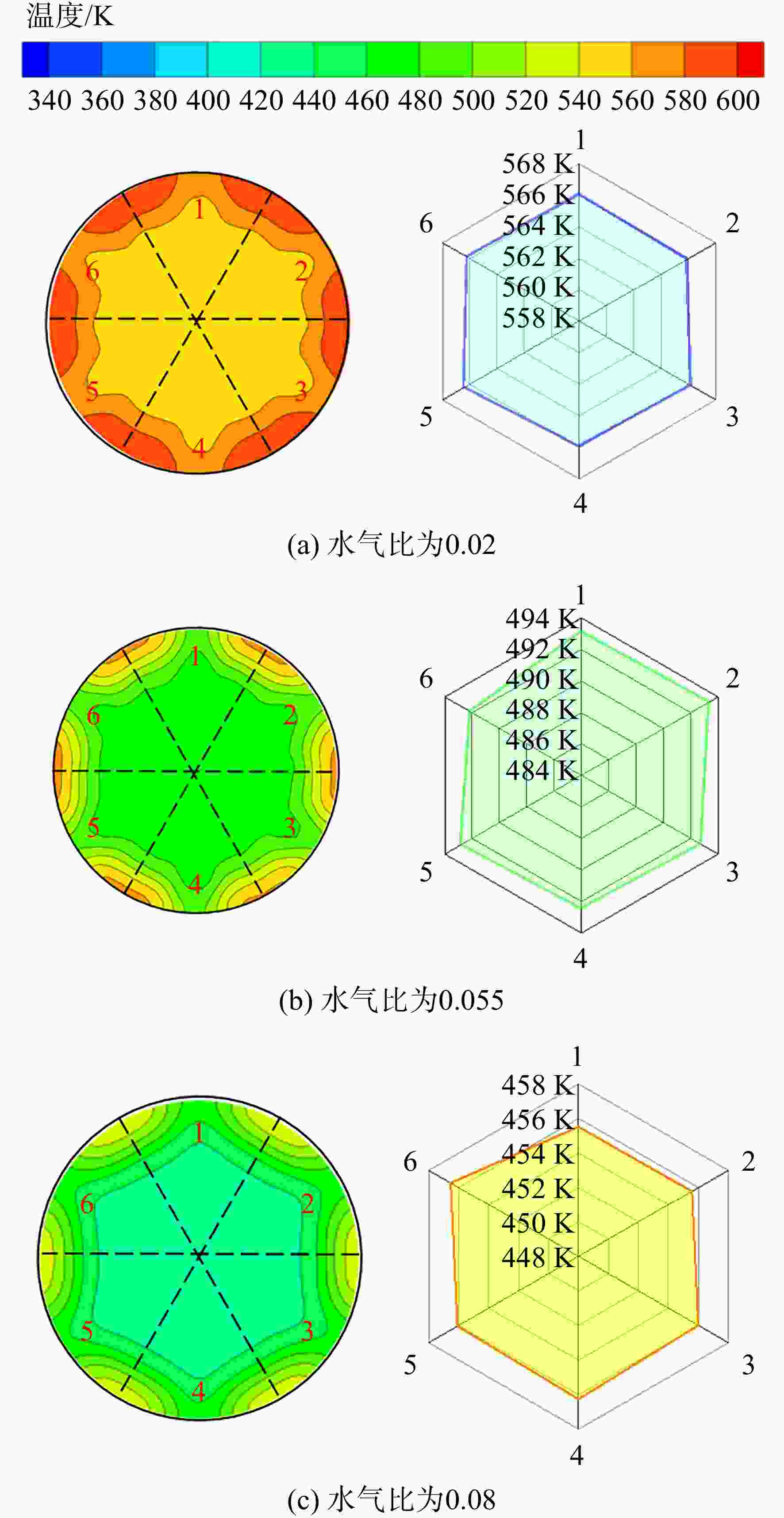

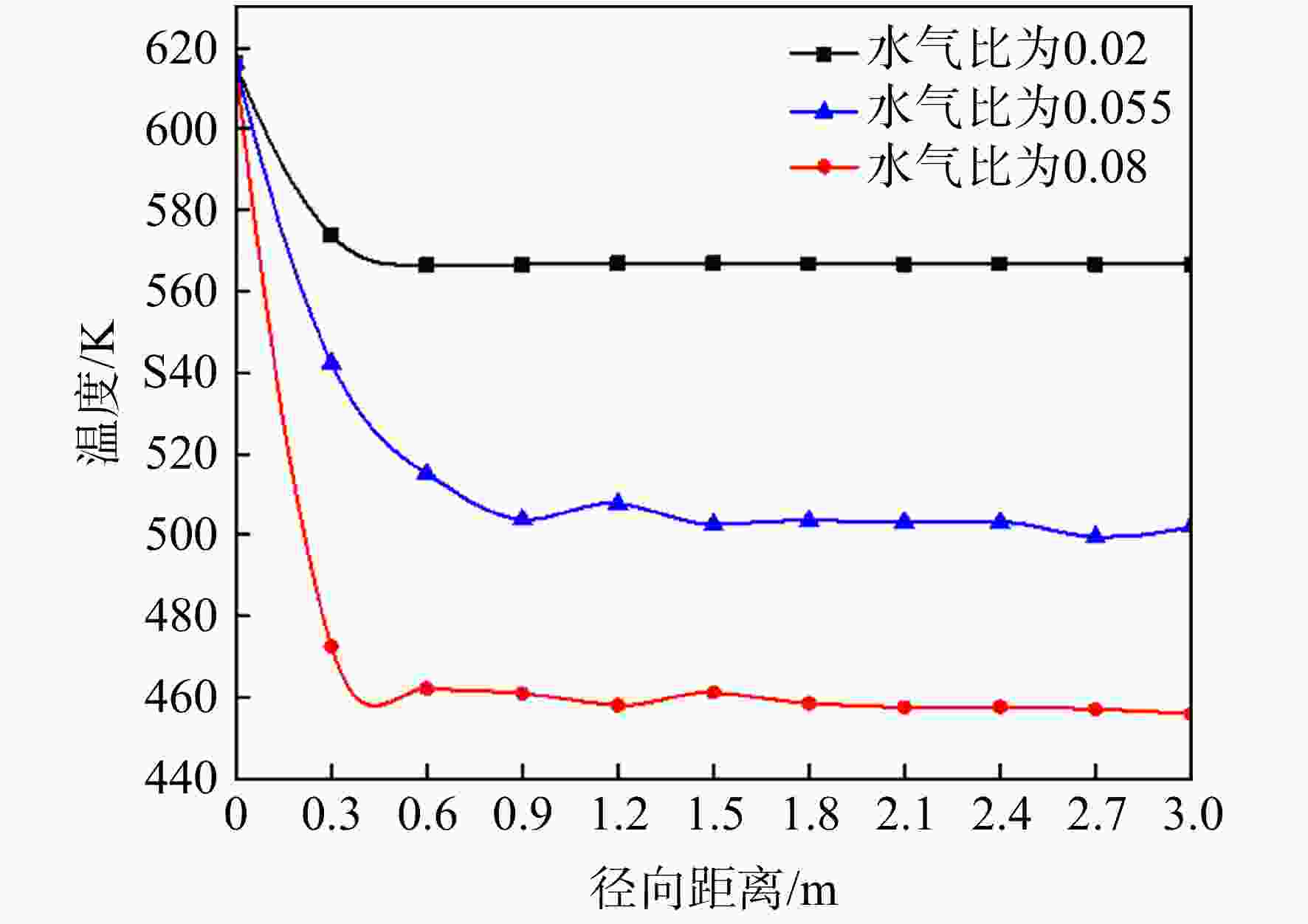

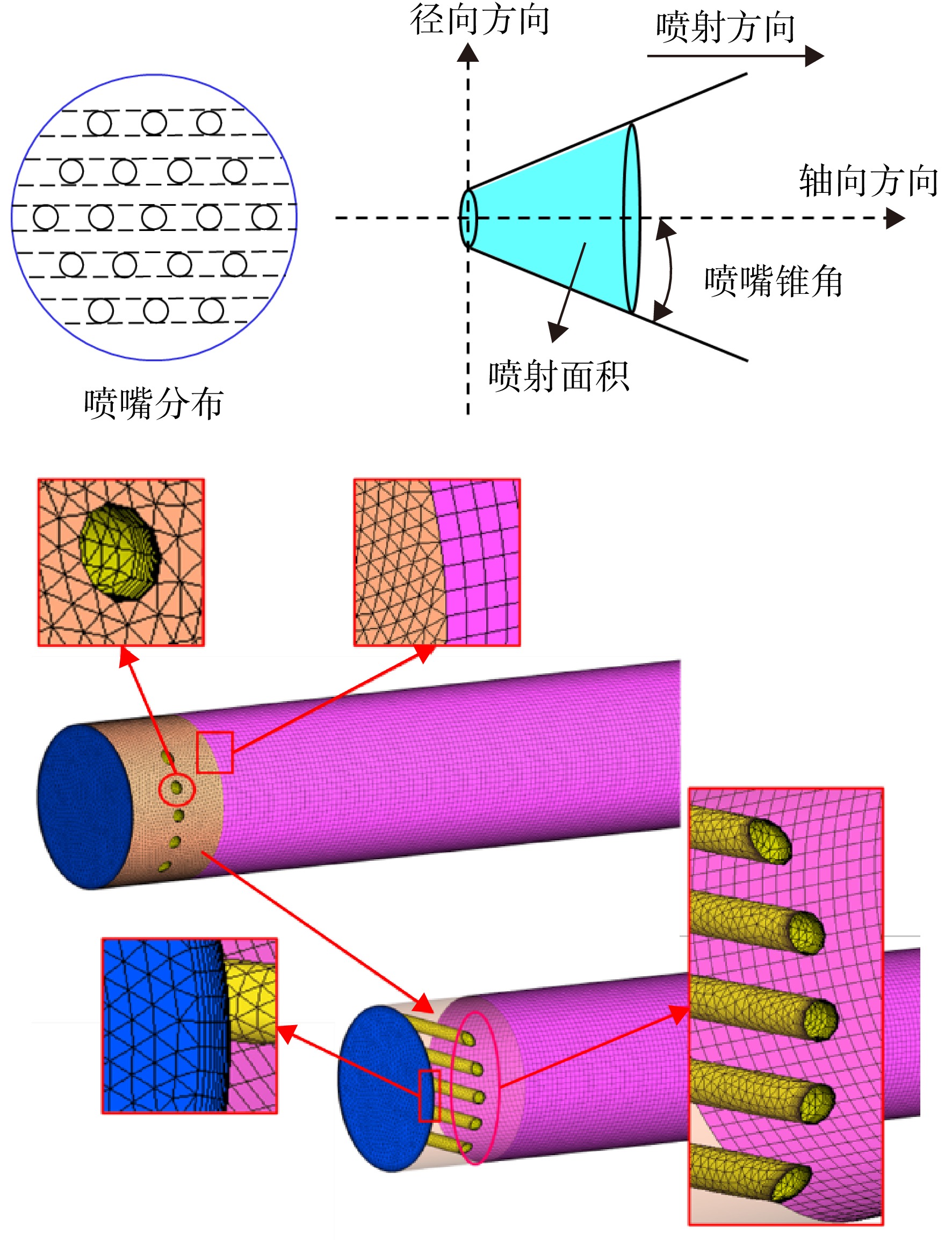

为了研究射流预冷技术对预压段温度场的影响,采用欧拉-拉格朗日方法建立了液滴雾化蒸发过程的三维数学模型。气液两相之间的传质和动量交换是通过双向耦合的方法实现的。通过与已有试验结果的比较,验证了该数学模型的准确性。采用响应面法分析了水气比、喷射速度、液滴尺寸和喷嘴锥角对航空发动机进气温度的影响,建立了四因素三水平响应面法。结果表明:发动机进气空气温度的降温比为3.67%~26.02%。建立了基于多元回归方法的可视化非线性多变量设计优化方程,得到了水气比、喷射速度、液滴尺寸和喷嘴锥角对进气冷却效果的影响。当水气比为0.08、液滴尺寸为10.47 μm、喷射速度为39.52 m/s、喷嘴锥角为24.79°时,发动机最低预压缩冷却段温度为449.60 K。

Abstract:To investigate the influence of jet precooling technology on the temperature field in the pre-compressor section, a three-dimensional mathematical model was proposed to study the droplet atomization and evaporation process using the Eulerian-Lagrangian method. The mass transfer and momentum exchange between gas-liquid phase were realized by two-way coupling method. Compared with existing experimental results, the accuracy of the temperature in the mathematical model was verified. The effects of water-air ratio, velocity, particle size, and cone angle on the temperature of inlet air were analyzed by response surface methodology in the aero-engine, and a four-factor and three-level response surface methodology was established. The results showed that the temperature drop ratio of engine intake air temperature was 3.67%−26.02%. The visualized nonlinear multivariable design optimization equation based on multiple regression method and the effects of water-air ratio, velocity, particle size and cone angle on inlet cooling effect were obtained. When the water-air ratio was 0.08, the particle size was 10.47 μm, the velocity was 39.52 m/s and the cone angle was 24.79°, the minimum inlet temperature of aero-engine was 449.60 K.

-

Key words:

- jet precooling /

- response surface analysis /

- inlet temperature /

- atomization /

- evaporation

-

表 1 设计因素编码与水平

Table 1. Code and level of design factors

因素 变量代号 水平值 −1 0 +1 水气比 X1 0.02 0.05 0.08 液滴粒径 X2 10 55 100 喷射速度 X3 10 55 100 喷嘴锥角 X4 15 45 75 表 2 响应面试验设计和结果

Table 2. Response surface test design and results

试验号 水气比 液滴粒径/μm 喷射速度/(m/s) 喷嘴锥角/(°) 1 0.02 10 55 45 2 0.08 10 55 45 3 0.02 100 55 45 4 0.08 100 55 45 5 0.05 55 10 15 6 0.05 55 100 15 7 0.05 55 10 75 8 0.05 55 100 75 9 0.02 55 55 15 10 0.08 55 55 15 11 0.02 55 55 75 12 0.08 55 55 75 13 0.05 10 10 45 14 0.05 100 10 45 15 0.05 10 100 45 16 0.05 100 100 45 17 0.02 55 10 45 18 0.08 55 10 45 19 0.02 55 100 45 20 0.08 55 100 45 21 0.05 10 55 15 22 0.05 100 55 15 23 0.05 10 55 75 24 0.05 100 55 75 25 0.05 55 55 45 26 0.05 55 55 45 27 0.05 55 55 45 28 0.05 55 55 45 29 0.05 55 55 45 表 3 回归方程的方差分析表

Table 3. Variance analysis of regression equation

来源 平方和 均方误差 F值 P值 备注 模型 35601.00 2542.93 270.52 < 0.0001 模型显著 X1 21727.66 21727.66 2311.40 < 0.0001 X2 9855.06 9855.06 1048.38 < 0.0001 X3 1412.57 1412.57 150.27 < 0.0001 X4 308.26 308.26 32.79 < 0.0001 X1X2 732.44 732.44 77.92 < 0.0001 X1X3 163.34 163.34 17.38 0.0009 X2X3 457.71 457.71 48.69 < 0.0001 X2X4 52.02 52.02 5.53 0.0338 X3X4 100.59 100.59 10.70 0.0056 $X_1^2 $ 741.86 741.86 78.92 < 0.0001 $X_3^2 $ 64.04 64.04 6.81 0.0206 残差 131.60 9.40 失拟项 131.60 13.16 纯误差 0 0 表 4 回归方程误差统计分析

Table 4. Statistical analysis of regression equation error

统计项目 数值 标准偏差 3.07 变异系数 0.5771 精密度 64.5877 多元相关系数 0.9963 调整后的多元相关系数 0.9926 预测的多元相关系数 0.9788 -

[1] 尚守堂,田方超,扈鹏飞. 涡轮发动机射流预冷关键技术分析[J]. 航空科学技术,2018,29(1): 1-3.SHANG Shoutang,TIAN Fangchao,HU Pengfei. Key technology analysis of mass injecting pre-compressor cooling turbine engine[J]. Aeronautical Science & Technology,2018,29(1): 1-3. (in Chinese) [2] HALL E W, WILCOX E C. Theoretical comparison of several methods of thrust augmentation for turbojet engines[R]. NACA Report-992, 1950. [3] YOUNG D A, OLDS J. Responsive access small cargo affordable launch (RASCAL) independent performance evaluation[R]. AIAA-2005-3241, 2005. [4] KLOESEL K, CLARK C. Preliminary MIPCC enhanced F-4 and F-15 performance characteristics for a first stage reusable launch vehicle[R]. AIAA-2013-5528, 2013. [5] CARTER P, BALEPIN V. Mass injection and precompressor cooling engines analyses[R]. AIAA-2002-4127, 2002. [6] CHAKER M A,MEHER-HOMJI C B,MEE T III. Inlet fogging of gas turbine engines: experimental and analytical investigations on impaction pin fog nozzle behavior[J]. Journal of Engineering for Gas Turbines and Power,2006,128(4): 826-839. doi: 10.1115/1.1808429 [7] CHAKER M,MEHER-HOMJI C B,MEE T III. Inlet fogging of gas turbine engines: Part Ⅰ fog droplet thermodynamics, heat transfer, and practical considerations[J]. Journal of Engineering for Gas Turbines and Power,2004,126(3): 545-558. doi: 10.1115/1.1712981 [8] CHAKER M, MEHER-HOMJI C B, MEE T. Inlet fogging of gas turbine engines: Part B fog droplet sizing analysis, nozzle types, measurement and testing[R]. The Netherlands, Amsterdam: ASME Turbo Expo: Power for Land, Sea, and Air, 2009: 429-441. [9] 商旭升,蔡元虎,陈玉春,等. 高速飞行器用射流预冷却涡轮基发动机性能模拟[J]. 中国空间科学技术,2005,25(4): 54-58.SHANG Xusheng,CAI Yuanhu,CHEN Yuchun,et al. Performance simulation of the mass injection pre-cooled TBCC engine for hypersonic vehicles[J]. Chinese Space Science and Technology,2005,25(4): 54-58. (in Chinese) [10] 涂洪妍,邓远灏,康松,等. 水气比对射流预冷喷射特性影响的数值研究[J]. 推进技术,2017,38(6): 1302-1309.TU Hongyan,DENG Yuanhao,KANG Song,et al. Numerical simulation for effects for water/air ratio on injection characteristics with water injection pre-compressor cooling[J]. Journal of Propulsion Technology,2017,38(6): 1302-1309. (in Chinese) [11] 耿欣,薛秀生,王晓良. 射流预冷试验用温度探针的设计与测试[J]. 航空发动机,2020,46(3): 84-89.GENG Xin,XUE Xiusheng,WANG Xiaoliang. Design and test of temperature probe for jet pre-cooling test[J]. Aeroengine,2020,46(3): 84-89. (in Chinese) [12] 耿欣,王晓良,薛秀生. 射流预冷试验防水温度传感器设计[J]. 航空发动机,2019,45(2): 69-73.GENG Xin,WANG Xiaoliang,XUE Xiusheng. Design of water-proof temperature sensor for jet pre-cooling test[J]. Aeroengine,2019,45(2): 69-73. (in Chinese) [13] 林阿强,郑群,吴锋,等. 航空涡轮发动机射流预冷技术研究[J]. 推进技术,2020,41(4): 721-728.LIN Aqiang,ZHENG Qun,WU Feng,et al. Investigation on mass injection pre-cooling technology of aero-turbine engine[J]. Journal of Propulsion Technology,2020,41(4): 721-728. (in Chinese) [14] 叶巍,乔渭阳,侯敏杰. 发动机在进气温度畸变条件下的特性研究[J]. 推进技术,2008,29(6): 677-680.YE Wei,QIAO Weiyang,HOU Minjie. Study for the effects of inlet temperature distortion on engine performance[J]. Journal of Propulsion Technology,2008,29(6): 677-680. (in Chinese) [15] 谢业平,刘永泉,潘宝军. 真实进气条件下发动机气动稳定性计算方法[J]. 航空动力学报,2019,34(4): 804-812.XIE Yeping,LIU Yongquan,PAN Baojun. Aerodynamic calculation method of engine stability under actual inlet condition[J]. Journal of Aerospace Power,2019,34(4): 804-812. (in Chinese) [16] 刘旭峰,常鸿雯,薛洪科,等. 射流预冷装置温降与流阻特性试验研究[J]. 航空发动机,2018,44(2): 81-86.LIU Xufeng,CHANG Hongwen,XUE Hongke,et al. Investigation on temperature drop and flow resistance characteristics of mass injection pre-compressor cooling device[J]. Aeroengine,2018,44(2): 81-86. (in Chinese) [17] 林阿强,刘高文,吴锋,等. 高马赫数涡轮发动机射流预冷特性研究[J]. 推进技术,2021,42(10): 2218-2228.LIN Aqiang,LIU Gaowen,WU Feng,et al. Mass injection pre-compressor cooling characteristics in high Mach number turbine engine[J]. Journal of Propulsion Technology,2021,42(10): 2218-2228. (in Chinese) [18] 陆禹铭,徐倩楠,吴锋,等. 喷水射流预冷对发动机进气温度及流场变化影响的数值研究[J]. 推进技术,2020,41(9): 1999-2010.LU Yuming,XU Qiannan,WU Feng,et al. Numerical study on effects of water injection pre-compressor cooling on engine inlet temperature and flow field change[J]. Journal of Propulsion Technology,2020,41(9): 1999-2010. (in Chinese) [19] HOSSEINZADEH A,NAJAFPOOR A A,JAFARI A J,et al. Application of response surface methodology and artificial neural network modeling to assess non-thermal plasma efficiency in simultaneous removal of BTEX from waste gases: effect of operating parameters and prediction performance[J]. Process Safety and Environmental Protection,2018,119: 261-270. doi: 10.1016/j.psep.2018.08.010 [20] YOLMEH M,JAFARI S M. Applications of response surface methodology in the food industry processes[J]. Food and Bioprocess Technology,2017,10(3): 413-433. doi: 10.1007/s11947-016-1855-2 [21] AZARI A,GHOLAMI M,TORKSHAVAND Z,et al. Evaluation of basic violet 16 adsorption from aqueous solution by magnetic zero valent iron-activated carbon nanocomposite using response surface method: isotherm and kinetic studies[J]. Journal of Mazandaran University of Medical Sciences,2015,24: 333-347. [22] LIN Aqiang,ZHOU Jie,FAWZY H,et al. Evaluation of mass injection cooling on flow and heat transfer characteristics for high-temperature inlet air in a MIPCC engine[J]. International Journal of Heat and Mass Transfer,2019,135: 620-630. doi: 10.1016/j.ijheatmasstransfer.2019.02.025 [23] 李艳军,常鸿雯,薛洪科,等. 射流装置降温性能评估及敏感性分析[J]. 航空发动机,2017,43(1): 85-90.LI Yanjun,CHANG Hongwen,XUE Hongke,et al. Sensibility analysis and evaluation of cooling performance on injection device[J]. Aeroengine,2017,43(1): 85-90. (in Chinese) [24] LAWSON J M,GANAPATHISUBRAMANI B. Mass transfer from small spheroids suspended in a turbulent fluid[J]. Journal of Fluid Mechanics,2021,929: 1-19. [25] 李莉,张赛,何强,等. 响应面法在试验设计与优化中的应用[J]. 实验室研究与探索,2015,34(8): 41-45.LI Li,ZHANG Sai,HE Qiang,et al. Application of response surface methodology in experiment design and optimization[J]. Research and Exploration in Laboratory,2015,34(8): 41-45. (in Chinese) [26] 郭勤涛,张令弥,费庆国. 用于确定性计算仿真的响应面法及其试验设计研究[J]. 航空学报,2006,27(1): 55-61.GUO Qintao,ZHANG Lingmi,FEI Qingguo. Response surface method and its experimental design for deterministic computer simulation[J]. Acta Aeronautica et Astronautica Sinica,2006,27(1): 55-61. (in Chinese) -

下载:

下载: