Stator stall and partial clearance control of compressor

-

摘要:

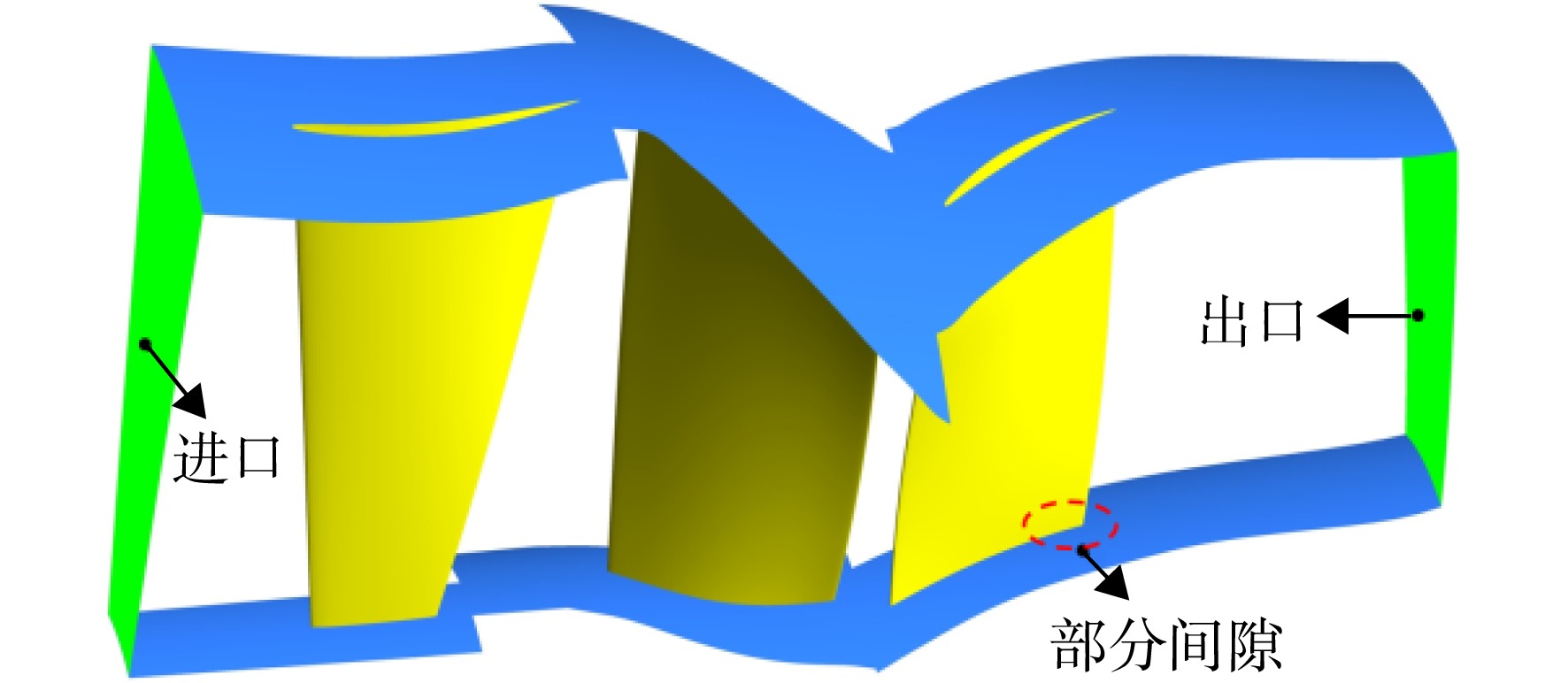

通过对某8级压气机进行数值计算得到了在设计转速下船舶压气机的流场特点与失稳机理。同时以此8级压气机中的前1.5级被作为研究对象探究压气机静叶轮毂静叶局部缝隙对角区失速的影响。结果表明,在设计转速下近失速点流动的不稳定性主要发生在静叶角区,主要原因是静叶角区失速。角区出现闭式分离泡并堵塞流场。1.5级压气机的计算结果表明,设计转速下压气机的失稳原因与8级压气机相同。通过在不同位置设置静叶局部缝隙可以发现,静叶局部缝隙能够有效的拓宽压气机裕度。其中在中间位置的缝隙扩稳效果最好,可以将裕度从22.1%提升为27.2%,最大效率从93.9%下降到93.21%。其他位置间隙所产生泄漏流动量不足,无法完全消除角区失速涡。最佳静叶局部缝隙的位置是在近失速点角区失速涡的涡核处,此时能保证间隙泄漏流动量最大。

Abstract:By numerical calculation of an 8-stage compressor, the characteristics and instability mechanism of marine compressor at design speed were obtained. At the same time, the first 1.5-stage of an 8-stage compressor was chosen to study the influence mechanism of the partial clearance on hub corner stall. The results showed that the flow instability mainly occurred in the hub-corner of stator at the design speed. The main reason is hub corner stall. The closed separation appeared in the corner and block the flow field. The 1.5-stage compressor result showed that the reason for compressor instability at design speed is the same as that of the 8-stage compressor. the partial clearance at different positions can widen effectively the margin. The effect of clearance was best when the clearance was in the middle. The clearance can not only increase the margin from 22.1% to 27.2%, but also cause the minimum loss at the maximum efficiency operation (from 93.9% to 93.21%). The leakage momentum caused by the clearance in other positions was not enough to eliminate the stall vortex in the hub. The optimal clearance was near the vortex core of stall vortex in the hub corner, where the leakage momentum was the maximum.

-

Key words:

- stator stall /

- partial clearance /

- stall point /

- margin /

- leakage

-

表 1 100%转速压气机裕度

Table 1. Compressor margin at 100% rotation speed

项目 原型 尾缘 后部 中间 前部 裕度/% 22.1 23.01 24.84 27.8 25.16 效率/% 93.90 93.51 93.31 93.21 92.4 -

[1] HORLOCK J H,LOUIS J F,PERCIVAL P M E,et al. Wall stall in compressor cascades[J]. Journal of Basic Engineering,1966,88(3): 637-648. doi: 10.1115/1.3645925 [2] JOSLYN H, DRING R. Multi-stage compressor airfoil aerodynamics: Ⅰ airfoil potential flow analysis, Ⅱ airfoil boundary layer analysis[R]. AIAA1986-1744, 1986. [3] SCHULZ H D,GALLUS H D. Experimental investigation of the three-dimensional flow in an annular compressor cascade[J]. Journal of Turbomachinery,1988,110(4): 467-478. doi: 10.1115/1.3262220 [4] GANNON A J,HOBSON G V. Pre-stall instability distribution over a transonic compressor rotor[J]. Journal of Fluids Engineering,2009,131(5): 51106. doi: 10.1115/1.3112388 [5] THIAM A, WHITTLESEY R, WARK C, et al. Corner separation and the on-set of stall in an axial compressor[R]. AIAA2008-4299, 2008. [6] YAMADA K,FURUKAWA M,TAMURA Y,et al. Large-scale detached-eddy simulation analysis of stall inception process in a multistage axial flow compressor[J]. Journal of Turbomachinery,2017,139(7): 071002. doi: 10.1115/1.4035519 [7] 陆华伟,郑雨晨,郭爽,等. 周向槽抽吸影响扩压叶栅流动损失与旋涡结构研究[J]. 工程热物理学报,2019,40(1): 60-67.LU Huawei,ZHENG Yuchen,GUO Shuang,et al. Study on flow loss and vortex structure of compressor cascade with circumferential suction groove[J]. Journal of Engineering Thermophysics,2019,40(1): 60-67. (in Chinese) [8] 韩兴伟,陆华伟,钟兢军,等. 组合抽吸槽对跨声速压气机转子性能影响的数值研究[J]. 大连海事大学学报,2017,43(1): 40-44,52.HAN Xingwei,LU Huawei,ZHONG Jingjun,et al. Numerical simulation of effect of boundary layer suction with multi-slots on transonic compressor rotor performance[J]. Journal of Dalian Maritime University,2017,43(1): 40-44,52. (in Chinese) [9] FENG Yanyan,SONG Yanping,CHEN Fu,et al. Effect of endwall vortex generator jets on flow separation control in a linear compressor cascade[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering,2015,229(12): 2221-2230. doi: 10.1177/0954410015573340 [10] 李艺雯,张千丰,李继超,等. 高负荷叶栅中康达喷气控制方法的设计及分析[J]. 工程热物理学报,2018,39(4): 738-746.LI Yiwen,ZHANG Qianfeng,LI Jichao,et al. Design and analysis of coanda jet in a highly-loaded compressor cascade[J]. Journal of Engineering Thermophysics,2018,39(4): 738-746. (in Chinese) [11] 张海灯,吴云,李应红,等. 高负荷压气机失速及其等离子体流动控制[J]. 工程热物理学报,2019,40(2): 289-299.ZHANG Haideng,WU Yun,LI Yinghong,et al. Rotating stall of a highly loaded compressor and its plasma flow control[J]. Journal of Engineering Thermophysics,2019,40(2): 289-299. (in Chinese) [12] 柳阳威, 梁斐杰, 孙槿静, 等. 抑制压气机静子角区分离的等离子体组合激励布局方法: CN103807218B[P]. 2017-01-11. [13] 王如根,胡加国,李仁康,等. 高负荷压气机叶栅开缝射流分离控制效果研究[J]. 推进技术,2018,39(6): 1250-1259.WANG Rugen,HU Jiaguo,LI Renkang,et al. Effects of separation control using slot jet approach in critically loaded compressor cascade[J]. Journal of Propulsion Technology,2018,39(6): 1250-1259. (in Chinese) [14] 周志涛,樊澍,胡峰,等. 射流预冷对高空高马赫数下压气机性能影响的数值研究[J]. 热能动力工程,2021,36(9): 95-100.ZHOU Zhitao,FAN Shu,HU Feng,et al. Numerical study on the influence of jet pre-cooling on compressor performance under high altitude and high Mach[J]. Journal of Engineering for Thermal Energy and Power,2021,36(9): 95-100. (in Chinese) [15] SMITH L H Jr,YEH H. Sweep and dihedral effects in axial-flow turbomachinery[J]. Journal of Basic Engineering,1963,85(3): 401-414. doi: 10.1115/1.3656623 [16] FILIPPOV G A,WANG Zhongqi. The calculation of axial symmetric flow in a turbine stage with small ratio of diameter to blade length[J]. Journal of Moscow Power Institute,1963,47: 63-78. [17] 刘艳明,汪亮,尚东然,等. 基于端壁涡流发生器的压气机叶栅角区分离控制研究[J]. 推进技术,2019,40(6): 1285-1292.LIU Yanming,WANG Liang,SHANG Dongran,et al. Investigation of corner separation control for compressor cascade based on endwall vortex generator[J]. Journal of Propulsion Technology,2019,40(6): 1285-1292. (in Chinese) [18] 马姗,楚武利,张皓光,等. 涡流发生器和附面层抽吸相结合对于低速压气机叶栅性能的影响[J]. 推进技术,2019,40(3): 515-524.MA Shan,CHU Wuli,ZHANG Haoguang,et al. Combined effects of vortex generator and boundary layer suction on performance of low-speed compressor cascade[J]. Journal of Propulsion Technology,2019,40(3): 515-524. (in Chinese) [19] 徐志晖,洪林. 组合型周向槽机匣处理优化方案的数值研究[J]. 流体机械,2017,45(9): 40-44,39.XU Zhihui,HONG Lin. Numerical investigation of optimized schemes of the combined circumferential groove casing treatment[J]. Fluid Machinery,2017,45(9): 40-44,39. (in Chinese) [20] 崔建光,叶学民,李春曦. 斜沟槽机匣处理对轴流风机性能影响的数值研究[J]. 流体机械,2017,45(1): 30-37.CUI Jianguang,YE Xuemin,LI Chunxi. Simulation of the effect of sloped trench casing treatment on the performance of an axial flow fan[J]. Fluid Machinery,2017,45(1): 30-37. (in Chinese) [21] ZHAO Wenfeng,ZHENG Qun,MALIK A,et al. The effect of trailing edge clearance in suppressing hub-corner stall[J]. Energies,2019,12(2): 1-17. -

下载:

下载: