Numerical investigation on bristles buoyancy effect of brush seals with fluid-structure interaction

-

摘要:

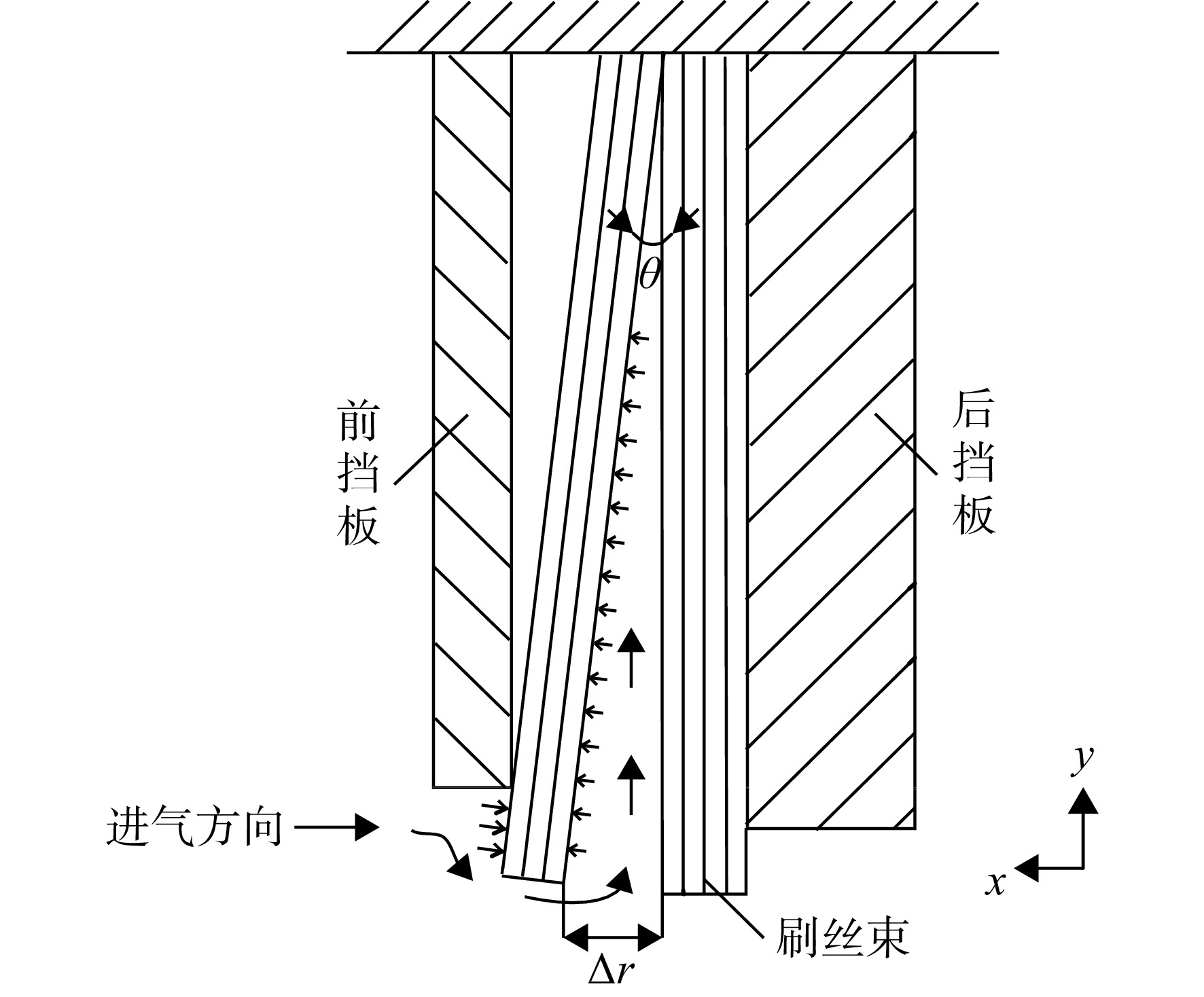

基于简化悬臂梁模型分析了刷式密封刷丝浮升效应理论,采用ALE(arbitrary Lagrange-Euler)流固耦合方法建立了刷式密封刷丝浮升效应三维瞬态数值求解模型,在验证了数值模型准确性基础上,研究了刷丝总体变形特性,量化分析了刷丝自由端轴向、径向和总体变形量,研究了结构参数与工况参数对刷式密封刷丝浮升效应的影响规律,揭示了刷式密封刷丝浮升效应诱发机理。研究结果表明:刷式密封刷丝浮升效应是前排刷丝受非定常径向气流作用产生的刷丝扰动现象,刷丝浮升效应会使前排刷丝向来流方向发生较大变形,并使前排刷丝与转子面产生径向间隙,泄漏量增加。当进出口压比从2提高至4,刷丝自由端平均变形量增加了47%,将前挡板保护高度从1.5 mm提高至2.5 mm,刷丝自由端平均变形量增加了36%,均使刷丝浮升效应增强。刷式密封前挡板与刷丝束间隙提供的径向气流通道,进出口压差在前挡板与刷丝束间隙内产生的径向压力梯度是刷丝浮升效应的诱发条件,提高刷丝直径和降低前挡板与刷丝束间隙均可降低刷丝浮升效应。

-

关键词:

- 刷式密封 /

- 刷丝浮升效应 /

- ALE(arbitrary Lagrange-Euler)方法 /

- 流固耦合 /

- 变形特性

Abstract:The bristles buoyancy effect of brush seal directly affect its sealing performance and service life. The theory of brush seal bristles buoyancy effect was analyzed, and the three-dimensional transient numerical model of brush seal bristles buoyancy effect was established using arbitrary Lagrange Euler (ALE) fluid-structure coupling method. Based on the accuracy of numerical model, the overall deformation characteristics of bristles were studied, and the axial, radial and total deformations of bristle tips were quantitatively analyzed. The effects of structural parameters and working parameters on bristles buoyancy effect of brush seal were studied, and the inducing mechanism of bristles buoyancy effect of brush seal was revealed. The research results showed that the bristles buoyancy effect of brush seal contributed to the disturbance of the front bristles caused by the unsteady radial airflow. The bristles buoyancy effect of brush seal can cause large deformation of the front bristles in the direction of the flow, generate radial clearance between the front plate and the rotor surface, and increase the leakage. When the inlet and outlet pressure ratio increased from 2 to 4, the average deformation of bristle tips increased by 47%, and the protection height of the front plate increased from 1.5mm to 2.5mm, and the average deformation of bristle tips increased by 36%, both of which enhanced the bristles buoyancy effect. The radial airflow channel was provided by the clearance between the front plate and the bristle pack, and the radial pressure gradient was generated by the inlet and outlet pressure difference in the clearance between the front plate and the bristle pack as the inducing condition of the bristles buoyancy effect. The bristles buoyancy effect can be reduced by increasing the diameter of the bristles and reducing the clearance between the front plate and the bristle pack.

-

表 1 刷式密封结构参数

Table 1. Strctural parameters of brush seals

结构参数 数值 前挡板宽度wf/mm 1.0 后挡板宽度wb/mm 2.0 刷丝束轴向厚度ws/mm 1.5 前挡板保护高度hf/mm 1.5、2.0、2.5 后挡板保护高度hb/mm 1.0 刷丝束与转子面间隙hg/mm 0 刷丝束与前挡板间隙wg/mm 0.6、0.7、0.8 刷丝直径D/mm 0.06、0.07、0.08 刷丝间距d/mm 0.006、0.007、0.008 刷丝径向长度L/mm 10.4 表 2 网格无关性验证

Table 2. Grid independence verification

网格数量/104 泄漏量相对误差(%) 75 14.25 126 8.63 188 2.14 226 0.88 264 0.6 表 3 模型工况参数

Table 3. Operating parameters of model

工况参数 数值 进口压力/MPa 0.2、0.3、0.4 出口压力/MPa 0.1 刷丝与刷丝间摩擦因数 0.3 刷丝与挡板间摩擦因数 0.3 -

[1] 李军,李志刚,张元桥,等. 刷式密封技术的研究进展[J]. 航空发动机,2019,45(2): 74-84. LI Jun,LI Zhigang,ZHANG Yuanqiao,et al. Research progress of brush seal technology[J]. Aeroengine,2019,45(2): 74-84. (in ChineseLI Jun, LI Zhigang, ZHANG Yuanqiao, et al. Research progress of brush seal technology[J]. Aeroengine, 2019, 45(2): 74-84. (in Chinese) [2] BAYLEY F J,LONG C A. A combined experimental and theoretical study of flow and pressure distributions in a brush seal[J]. Journal of Engineering for Gas Turbines and Power,1993,115(2): 404-410. doi: 10.1115/1.2906723 [3] SAIM D,MEHMET D,NORMAN T,et al. Fundamental design issues of brush seals for industrial applications[J]. Journal of Turbomachinery,2002,124(2): 293-300. doi: 10.1115/1.1451847 [4] MILLENER P J,EDMUNDS T M,1996,Brush seal with porous upstream side-plate: US5496045[P]. 1996-05-05. [5] DOGU Y,AKSIT M F. Effects of geometry on brush seal pressure and flow fields-part i: front plate configurations[J]. Journal of Turbomachinery,2006,128(2): 367-368. doi: 10.1115/1.2101857 [6] 邱波,李军. 刷式密封流动与换热及力学特性的研究进展[J]. 热力透平,2013,42(3): 141-149. QIU Bo,LI Jun. A review of flow and heat transfer,mechanical characteristics of brush seals[J]. Thermal Turbine,2013,42(3): 141-149. (in ChineseQIU Bo, LI Jun. A review of flow and heat transfer, mechanical characteristics of brush seals[J]. Thermal Turbine, 2013, 42(3): 141-149. (in Chinese) [7] MODI V. Modeling bristle lift-off in idealized brush seal configurations [R]. AMSE Paper 1994-GT-71,1994. [8] BASU P,DATTA A,LOEWENTHAL R,et al. Hysteresis and bristle stiffening effects in brush seals[J]. Journal of Propulsion and Power,1994,10(4): 569-575. doi: 10.2514/3.23810 [9] CRUDGINGTON P,BOWSHER A,WALIA J,et al. Bristle angle effects on brush seal contact pressures: AIAA 2009-5168[C]//Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston,Virigina: AIAA,2009: 61-65. [10] AKSOY S,AKSIT M. Evaluation of pressure-stiffness coupling in brush seals[C]//Joint Propulsion Conference and Exhibit. Nashville: AIAA 2013: 45-48. [11] ZHAO Haifang,STANGO R J. Analytical approach for investigating bristle/backplate hysteresis phenomenon in brush seals[J]. Journal of Propulsion and Power,2007,23(2): 273-282. doi: 10.2514/1.20682 [12] 陈春新,李军,丰镇平. 刷式密封刷丝束与转子接触力的数值研究[J]. 西安交通大学学报,2010,44(7): 23-27. CHEN Chunxin,LI Jun,FENG Zhenping. Numerical investigation into bristle-rotor contact force of brush seals[J]. Journal of Xi’an Jiaotong University,2010,44(7): 23-27. (in ChineseCHEN Chunxin, LI Jun, FENG Zhenping. Numerical investigation into bristle-rotor contact force of brush seals[J]. Journal of Xi’an Jiaotong University, 2010, 44(7): 23-27. (in Chinese) [13] 邱波,李军,丰镇平. 考虑刷丝变形的刷式密封摩擦热效应研究[J]. 工程热物理学报,2013,34(11): 2030-2034. QIU Bo,LI Jun,FENG Zhenping. Investigations on frictional heat generation of brush seals with consideration of bristle deflections[J]. Journal of Engineering Thermophysics,2013,34(11): 2030-2034. (in ChineseQIU Bo, LI Jun, FENG Zhenping. Investigations on frictional heat generation of brush seals with consideration of bristle deflections[J]. Journal of Engineering Thermophysics, 2013, 34(11): 2030-2034. (in Chinese) [14] 李朋飞,胡娅萍,吉洪湖. 低滞后刷式密封泄漏特性与滞后效应研究[J]. 润滑与密封,2020,45(10): 52-58. LI Pengfei,HU Yaping,JI Honghu. Investigation on leakage characteristics and hysteresis effect of low hysteresis brush seals[J]. Lubrication Engineering,2020,45(10): 52-58. (in Chinese doi: 10.3969/j.issn.0254-0150.2020.10.009LI Pengfei, HU Yaping, JI Honghu. Investigation on leakage characteristics and hysteresis effect of low hysteresis brush seals[J]. Lubrication Engineering, 2020, 45(10): 52-58. (in Chinese) doi: 10.3969/j.issn.0254-0150.2020.10.009 [15] 杜宸宇,孙丹,刘永泉,等. 刷式密封吹下效应诱发机理流固耦合数值研究[J]. 航空动力学报,2021,36(2): 310-319. DU Chenyu,SUN Dan,LIU Yongquan,et al. Numerical investigation on induced mechanism of blow-down effect of brush seals with fluid-structure interaction[J]. Journal of Aerospace Power,2021,36(2): 310-319. (in ChineseDU Chenyu, SUN Dan, LIU Yongquan, et al. Numerical investigation on induced mechanism of blow-down effect of brush seals with fluid-structure interaction[J]. Journal of Aerospace Power, 2021, 36(2): 310-319. (in Chinese) [16] PHILIP R,JENS F. Investigation of brush seal instabilities[C]//Propulsion and Energy Forum. Braunschweig: AIAA,2020: 38-44. [17] CHEW J W,LAPWORTH B L,MILLENER P J. Mathematical modeling of brush seals[J]. International Journal of Heat and Fluid Flow,1995,16(6): 493-500. doi: 10.1016/0142-727X(95)00061-T [18] YAHYA D. Investigation of brush seal flow characteristics using bulk porous medium approach[J]. Journal of Engineering for Gas Turbines and Power,2005,127(1): 136-144. doi: 10.1115/1.1808425 [19] DOGU Y,AKSIT M F,DEMIROGLU M,et al. Evaluation of flow behavior for clearance brush seals[J]. Journal of Engineering for Gas Turbines and Power,2008,130(1): 1-9. [20] 邱波,李军. 刷式密封传热特性研究[J]. 西安交通大学学报,2011,45(9): 94-100. QIU Bo,LI Jun. Investigation on the heat transfer characteristics of brush seals[J]. Journal of Xi’an Jiaotong University,2011,45(9): 94-100. (in ChineseQIU Bo, LI Jun. Investigation on the heat transfer characteristics of brush seals[J]. Journal of Xi’an Jiaotong University, 2011, 45(9): 94-100. (in Chinese) [21] 孙丹,李国勤,艾延廷,等. 基于三维实体建模的刷式密封传热机理数值研究[J]. 航空动力学报,2019,34(8): 1633-1643. SUN Dan,LI Guoqin,AI Yanting,et al. Numerical study on heat transfer mechanism of brush seal based on three-dimensional solid modeling[J]. Journal of Aerospace Power,2019,34(8): 1633-1643. (in ChineseSUN Dan, LI Guoqin, AI Yanting, et al. Numerical study on heat transfer mechanism of brush seal based on three-dimensional solid modeling[J]. Journal of Aerospace Power, 2019, 34(8): 1633-1643. (in Chinese) [22] 李浩,孙丹,赵欢,等. 刷式密封流动传热特性数值方法[J]. 航空动力学报,2021,36(9): 1826-1838. LI Hao,SUN Dan,ZHAO Huan,et al. Numerical method of flow and heat transfer characteristics of brush seals[J]. Journal of Aerospace Power,2021,36(9): 1826-1838. (in ChineseLI Hao, SUN Dan, ZHAO Huan, et al. Numerical method of flow and heat transfer characteristics of brush seals[J]. Journal of Aerospace Power, 2021, 36(9): 1826-1838. (in Chinese) -

下载:

下载: