Analysis of resonant frequency shift phenomenon raised from dynamic strain measurement data of turbine blade in a turbofan engine

-

摘要:

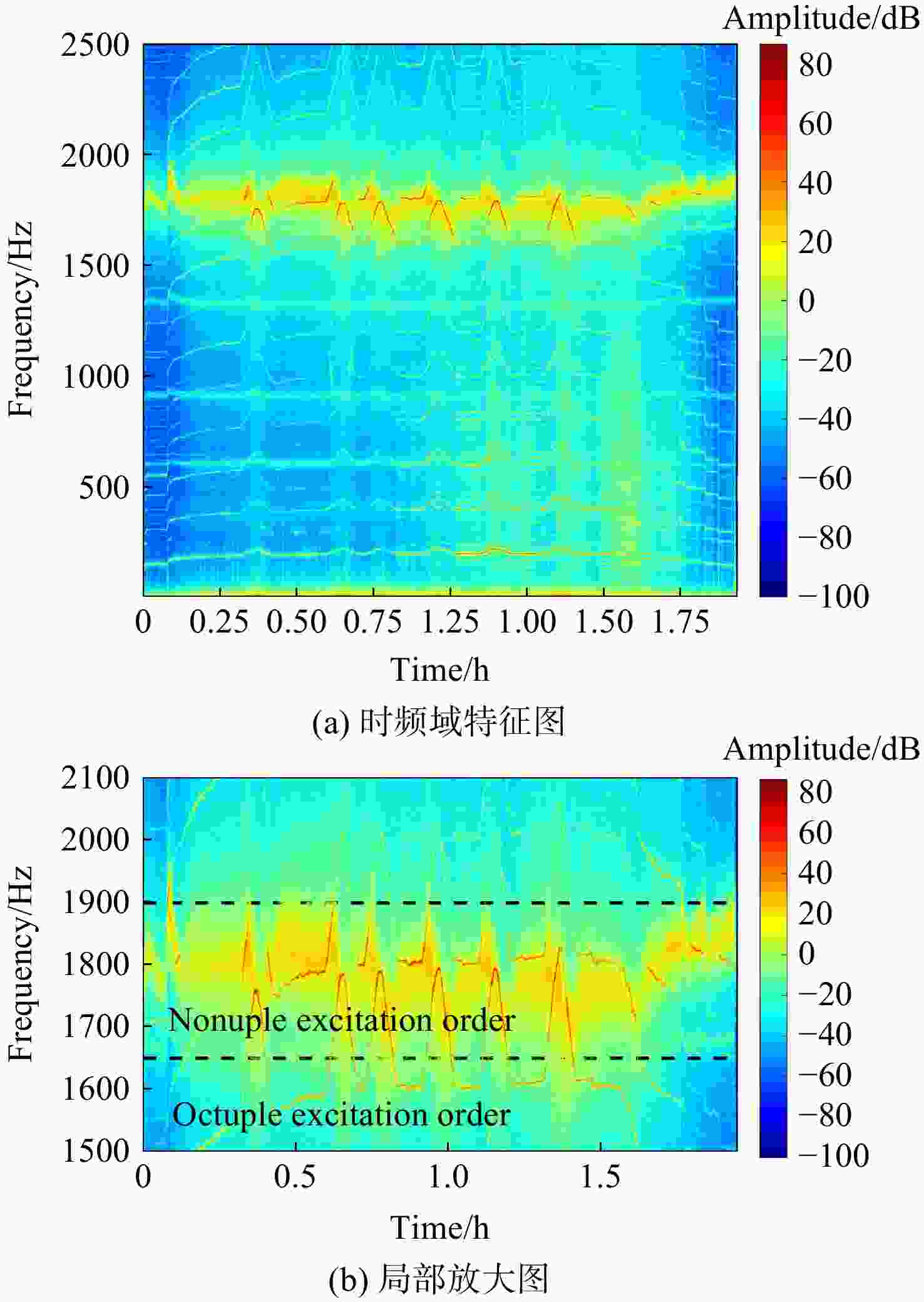

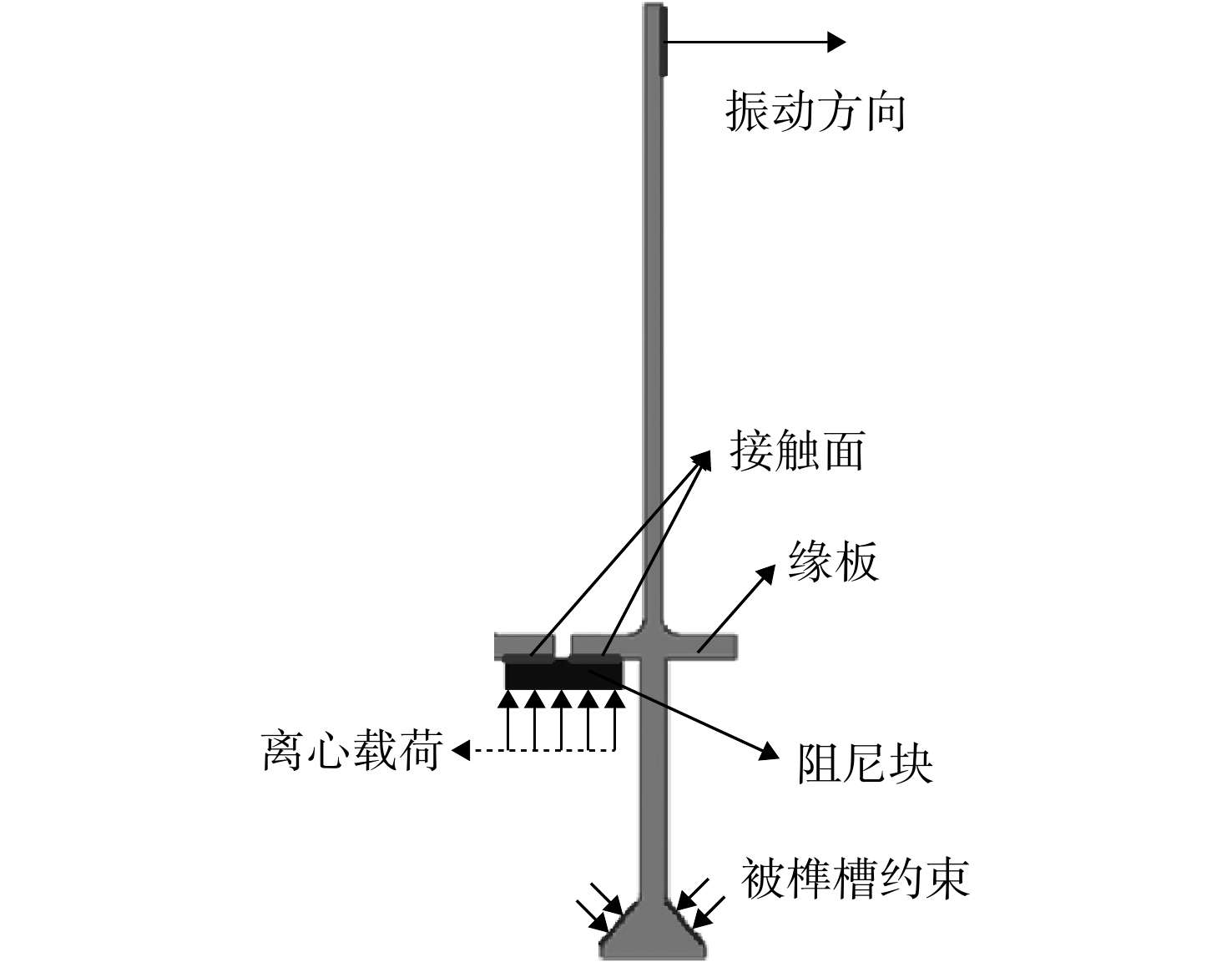

某高推质比涡扇发动机高压涡轮叶片采用缘板干摩擦阻尼设计,以降低叶片振动应力;在核心机地面台架试车中,应变测试数据的频域特征出现漂移现象,振动能量在频域内呈现出窄带随机的特征。围绕该现象,基于试验数据建立了考虑缘板阻尼块影响的单个叶片等效模型,基于时域积分算法和非线性模态理论计算了不同转速下系统的响应特征、摩擦力特征、共振频率特征和摩擦阻尼特征。研究结果表明:转速波动会影响系统的振动响应频域分布特征和共振频率分布范围:在11713 r/min转速状态,9倍频会激起1756~1952 Hz频率带的共振;在13500 r/min转速状态,8倍频会激起1800 Hz频率附近的共振;在13687 r/min转速状态,8倍频会激起1596~1824 Hz频率带的共振;在稳定转速条件下,干摩擦力在最大和最小值之间反复跳变,起到摩擦阻尼效用的同时,带来系统附加刚度的不稳定变化;非线性模态计算结果表明叶片模态频率随振动响应幅值的变化而变化,叶片刚度变化或摩擦力幅值增大均可使叶片模态频率区间变大。

Abstract:A high-pressure turbine blade of a high thrust-to-weight ratio turbofan adopted edge plate damper design to reduce the vibration stress of the blade. During the core machine ground bench test, the frequency-domain characteristics of the strain test data showed drift phenomenon, and the vibration energy presented random feature in a narrow frequency band. The phenomenon was discussed and analyzed at first. Then the equivalent model of a single blade considering the influence of the edge plate damper was established according to test data. Based on the time integration method and the nonlinear modal theory, the response characteristics, friction characteristics, resonant frequency characteristics and friction damping characteristics of the system were calculated under different rotation speeds. The simulation results showed that the rotation speed fluctuation affected the frequency domain distribution characteristics of the vibration response and the resonant frequency range distribution of the system: at 11 713 r/min, the nonuple excitation order induced the resonance frequency band of 1 756—1 952 Hz, at 13 500 r/min, the octuple excitation order induced the resonance frequency around 1 800 Hz, and at 13 687 r/min, the octuple excitation order induced the resonance frequency band of 1 596—1 824 Hz. Under stable rotational speed, the dry friction force jumped alternatively between the maximum and minimum values, which reflected a friction damping effect and brought about unstable changes in the additional stiffness of the system. The nonlinear modal theory results showed that the modal frequency of the damped blade changed with the vibration response amplitude. The decrease of the blade stiffness or the increase of the friction force amplitude can enlarge the modal frequency range.

-

表 1 不同转速对应的系统共振频率和摩擦力

Table 1. Resonance frequency and friction force corresponding to different rotation speeds

转速/

(r/min)激起共振

的倍频最接近共振的

频率/Hz摩擦力

幅值/N11713 9 1756 45.14 13500 8 1800 59.96 13687 8 1 824 61.63 -

[1] GRIFFIN J H,SINHA A. The interaction between mistuning and friction in the forced response of bladed disk assemblies[J]. Journal of Engineering for Gas Turbines and Power,1985,107(1): 205-211. doi: 10.1115/1.3239684 [2] SINHA A,GRIFFIN J H,KIELB R E. Influence of friction dampers on torsional blade flutter[J]. Journal of Engineering for Gas Turbines and Power,1986,108(2): 313-318. doi: 10.1115/1.3239905 [3] 单颖春,郝燕平,朱梓根,等. 干摩擦阻尼块在叶片减振方面的应用与发展[J]. 航空动力学报,2001,16(3): 218-223. doi: 10.3969/j.issn.1000-8055.2001.03.005SHAN Yingchun,HAO Yanping,ZHU Zigen,et al. Application and development of platform friction damper for depressing resonant vibration of blades[J]. Journal of Aerospace Power,2001,16(3): 218-223. (in Chinese) doi: 10.3969/j.issn.1000-8055.2001.03.005 [4] 李琳,刘久周,李超. 航空发动机中的干摩擦阻尼器及其设计技术研究进展[J]. 航空动力学报,2016,31(10): 2305-2317. doi: 10.13224/j.cnki.jasp.2016.10.001LI Lin,LIU Jiuzhou,LI Chao. Review of the dry friction dampers in aero-engine and their design technologies[J]. Journal of Aerospace Power,2016,31(10): 2305-2317. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.10.001 [5] GAGNON L,MORANDINI M,GHIRINGHELLI G L. A review of friction damping modeling and testing[J]. Archive of Applied Mechanics,2022,90(1): 107-126. [6] CAMERON T M,GRIFFIN J H. An alternating frequency/time domain method for calculating the steady-state response of nonlinear dynamic systems[J]. Journal of Applied Mechanics,1989,56(1): 149-154. doi: 10.1115/1.3176036 [7] CHARLEUX D,GIBERT C,THOUVEREZ F,et al. Numerical and experimental study of friction damping blade attachments of rotating bladed disks[J]. International Journal of Rotating Machinery,2006(1): 1-13. [8] PETROV E P,EWINS D J. Analytical formulation of friction interface elements for analysis of nonlinear multi-harmonic vibrations of bladed disks[J]. Journal of Turbomachinery,2003,125(2): 364-371. doi: 10.1115/1.1539868 [9] NACIVET S,PIERRE C,THOUVEREZ F,et al. A dynamic Lagrangian frequency-time method for the vibration of dry-friction-damped systems[J]. Journal of Sound and Vibration,2003,265(1): 201-219. doi: 10.1016/S0022-460X(02)01447-5 [10] LAXALDE D, SALLES L, BLANC L, et al. Non-linear modal analysis for bladed disks with friction contact interfaces[J]. ASME Paper GT2008-50860, 2008. [11] HUANG X R,JÉZÉQUEL L,BESSET S,et al. Nonlinear hybrid modal synthesis based on branch modes for dynamic analysis of assembled structure[J]. Mechanical Systems and Signal Processing,2018,99: 624-646. doi: 10.1016/j.ymssp.2017.07.002 [12] JOANNIN C,THOUVEREZ F,CHOUVION B. Reduced-order modelling using nonlinear modes and triple nonlinear modal synthesis[J]. Computers and Structures,2018,203: 18-33. [13] 黄行蓉, 刘久周, 李琳. 基于非线性模态的复杂系统动力学特性分析方法[J]. 北京航空航天大学学报, 2019, 45(7): 1337-1348.HUANG Xingrong, LIU Jiuzhou, LI Lin. Dynamic characteristics analysis method of complex systems based on nonlinear mode[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(7): 1337-1348. (in Chinese) [14] HONG J,YU P,ZHANG D,et al. Nonlinear dynamic analysis using the complex nonlinear modes for a rotor system with an additional constraint due to rub-impact[J]. Mechanical Systems and Signal Processing,2019,116: 443-461. doi: 10.1016/j.ymssp.2018.06.061 [15] PETROV E P,EWINS D J. Effects of damping and varying contact area at blade-disk joints in forced response analysis of bladed disk assemblies[J]. Journal of Turbomachinery,2006,128(2): 403-410. doi: 10.1115/1.2181998 [16] MENQ C H,BIELAK J,GRIFFIN J H. The influence of microslip on vibratory response: Part Ⅰ a new microslip model[J]. Journal of Sound and Vibration,1986,107(2): 279-293. doi: 10.1016/0022-460X(86)90238-5 [17] MENQ C H,GRIFFIN J H,BIELAK J. The influence of microslip on vibratory response: Part Ⅱ a comparison with experimental results[J]. Journal of Sound and Vibration,1986,107(2): 295-307. doi: 10.1016/0022-460X(86)90239-7 [18] 徐自力,常东锋,刘雅琳. 基于微滑移解析模型的干摩擦阻尼叶片稳态响应分析[J]. 振动工程学报,2008(5): 505-510. doi: 10.3969/j.issn.1004-4523.2008.05.014XU Zili,CHANG Dongfeng,LIU Yalin. Forced response analysis of blade system with dry friction damper using one-bar microslip analytic model[J]. Journal of Vibration Engineering,2008(5): 505-510. (in Chinese) doi: 10.3969/j.issn.1004-4523.2008.05.014 [19] 张大义,杨诚,夏颖,等. 带缘板阻尼结构转子叶片振动特性的影响参数分析[J]. 振动与冲击,2019,38(10): 221-227. doi: 10.13465/j.cnki.jvs.2019.10.033ZHANG Dayi,YANG Cheng,XIA Ying,et al. Influential parameters of rotating blades with under platform dampers[J]. Journal of Vibration and Shock,2019,38(10): 221-227. (in Chinese) doi: 10.13465/j.cnki.jvs.2019.10.033 [20] 张大义,张嵩,付俭伟,等. 转子叶片缘板阻尼结构设计方法[J]. 航空动力学报,2018,33(4): 961-968. doi: 10.13224/j.cnki.jasp.2018.04.023ZHANG Dayi,ZHANG Song,FU Jianwei,et al. Design method for the under platform damper of rotor blade[J]. Journal of Aerospace Power,2018,33(4): 961-968. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.04.023 [21] FEENY B,MOON F C. Chaos in a forced dry friction oscillator: experiments andnumerical modelling[J]. Journal of Sound and Vibration,1994,170(3): 303-323. doi: 10.1006/jsvi.1994.1065 -

下载:

下载: