Different reaction mechanism on simulations of jet flames using flamelet model

-

摘要:

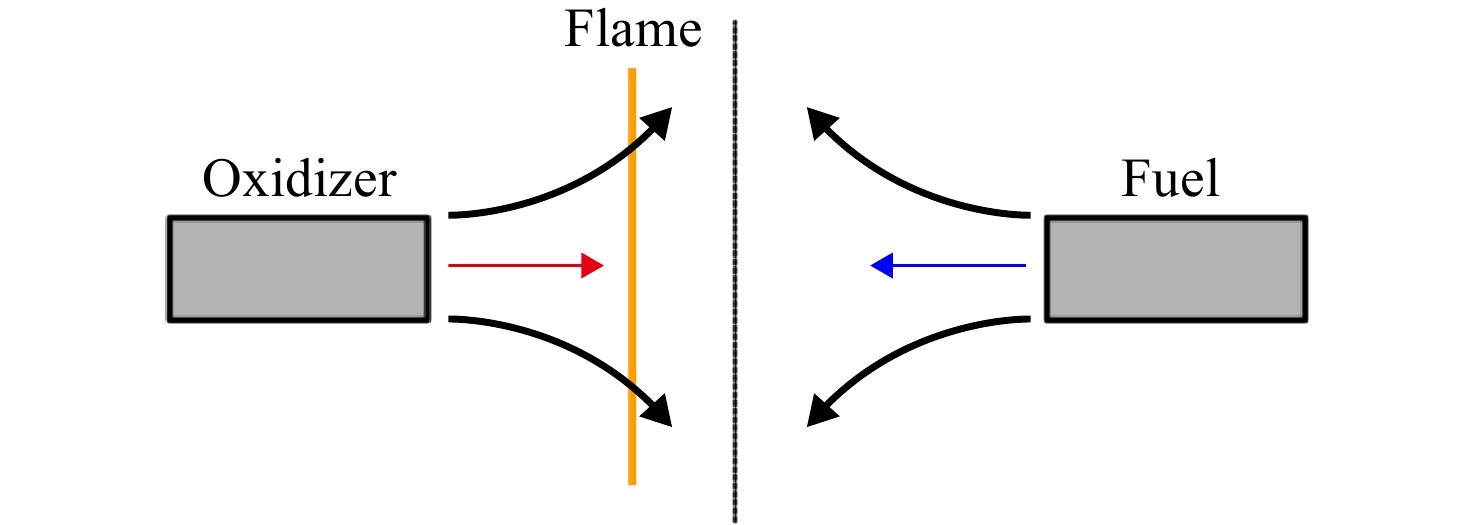

用一维火焰分析并构建火焰面数据库,基于稳态层流火焰面(SLFM)模型分析不同化学反应机理对火焰面数据库及模拟结果的影响。基于大涡模拟(LES)程序AECSC(aero engine combustor simulation code)软件,SLFM模型结合DRG(direct relation graph)方法简化机理、Smooke机理、GRI 3.0详细机理模拟高雷诺数甲烷射流Flame D、E、F火焰,其中GRI 3.0机理的温度平均值和脉动值与实验数据最接近。相比LES-概率密度函数输运方程湍流燃烧(TPDF)模型,LES-SLFM方法计算速度快,整体精度接近TPDF计算结果。对化学机理影响火焰面数据库,从而影响模拟时间和精度的原因进行了系统分析。LES-SLFM模型结合详细机理速度快、精度合适,未来可以进一步用燃烧室算例检验,具有应用的潜力和发展价值。

Abstract:The effects of different chemical reaction mechanisms on the flame surface database and simulation results based on the steady laminar flamelet model (SLFM) were analyzed by using one-dimensional flame analysis and constructing a flamelet database. Based on the large eddy simulation (LES) program AECSC (aero engine combustor simulation code) software, the SLFM model was combined with DRG (direct relation graph) method simplified mechanism, Smooke mechanism, and GRI 3.0 detailed mechanism to simulate Flame D, E, and F jet flames, among which the average temperature and pulsation values of GRI 3.0 mechanism were the closest to the experimental data. The LES-SLFM model was faster and had comparable overall accuracy compared with the LES and probability density functional transport equation turbulent combustion (TPDF) models. The chemical mechanism affected the flamelet database and thus the time and accuracy of the simulation. The LES-SLFM model combined with the detailed mechanism was fast and had suitable accuracy, which should be further tested in the combusor simulation, presenting potential and value for future applications.

-

表 1 甲烷-空气扩散火焰边界条件

Table 1. Boundary condition of methane-air diffusion flame

入口类型 单位面积流量/

(kg·m−2·s−1)组分构成

(体积分数)温度/K 燃料 0.5501 100% CH4 300 氧化剂 0.9467 79% N2,21% O2 300 表 2 火焰面数据库边界条件

Table 2. Boundary condition of the flamelet library

入口类型 初始流量/

(kg·m−2·s−1)组分构成

(体积分数)温度/K 燃料 0.1 25% CH4,

59.25%N2 15.75% O2291 氧化剂 0.1 79% N2,21% O2 291 表 3 Sandia Flames边界条件

Table 3. Boundary condition of Sandia Flames

入口类型 速度/(m/s) 混合物分数 温度/K 中心射流 49.9 (Flame D)

74.4 (Flame E)

99.2 (Flame F)1 291 值班入口 11.4 0.271 1 888 空气伴流 0.9 0 291 表 4 各模型计算Flame D的平均温度误差

Table 4. Mean error of mean temperature of different models simulating Flame D

% 模型 z/D=1 z/D=3 z/D=7.5 z/D=30 z/D=60 总平均误差 SLFM

(GRI 3.0)9.98 8.82 9.65 19.1 27.1 17.2 SLFM

(Smooke)10.7 5.57 38.5 38.9 14.5 25.3 SLFM

(DRG)9.00 16.0 51.0 39.0 22.0 26.2 TPDF 10.0 6.00 10.0 8.00 15.0 9.80 -

[1] POPE S B. The probability approach to the modelling of turbulent reacting flows[J]. Combustion and Flame,1976,27: 299-312. doi: 10.1016/0010-2180(76)90035-3 [2] PETERS N. Laminar diffusion flamelet models in non-premixed turbulent combustion[J]. Progress in Energy and Combustion Science,1984,10(3): 319-339. doi: 10.1016/0360-1285(84)90114-X [3] PETERS N. Laminar flamelet concepts in turbulent combustion[J]. Symposium (International) on Combustion,1988,21(1): 1231-1250. doi: 10.1016/S0082-0784(88)80355-2 [4] MÖBUS H,GERLINGER P,BRÜGGEMANN D. Scalar and joint scalar-velocity-frequency Monte Carlo PDF simulation of supersonic combustion[J]. Combustion and Flame,2003,132(1/2): 3-24. [5] PIERCE C D,MOIN P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion[J]. Journal of Fluid Mechanics,2004,504: 73-97. doi: 10.1017/S0022112004008213 [6] 陆阳. 燃烧计算中火焰面模型的研究[D]. 合肥: 中国科学技术大学, 2009.LU Yang. A study on flamelet model in combustion simulation[D]. Hefei: University of Science and Technology of China, 2009. (in Chinese) [7] 韩宗英,何昌升,李井华,等. 钝体稳定射流火焰的火焰面模型数值研究[J]. 航空动力学报,2020,35(2): 337-347. doi: 10.13224/j.cnki.jasp.2020.02.013HAN Zongying,HE Changsheng,LI Jinghua,et al. Investigation of flamelet modeling for bluff-body stabilized jet flame[J]. Journal of Aerospace Power,2020,35(2): 337-347. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.02.013 [8] NIKOLAOU Z M,CHRYSOSTOMOU C,VERVISCH L,et al. Progress variable variance and filtered rate modelling using convolutional neural networks and flamelet methods[J]. Flow, Turbulence and Combustion,2019,103(2): 485-501. doi: 10.1007/s10494-019-00028-w [9] PRIELER R,DEMUTH M,SPOLJARIC D,et al. Numerical investigation of the steady flamelet approach under different combustion environments[J]. Fuel,2015,140: 731-743. doi: 10.1016/j.fuel.2014.10.006 [10] 王方,窦力,魏观溢,等. 基于PDF-LES模型的凹腔支板火焰稳定器模拟[J]. 工程热物理学报,2021,42(3): 758-767.WANG Fang,DOU Li,WEI Guanyi,et al. The simulation of cavity flameholder by PDF-LES method[J]. Journal of Engineering Thermophysics,2021,42(3): 758-767. (in Chinese) [11] 邢竞文,金捷,王方. 基于释热率分析的钝体贫油熄火过程分析[J]. 北京航空航天大学学报,2022,48(3): 473-484. doi: 10.13700/j.bh.1001-5965.2020.0588XING Jingwen,JIN Jie,WANG Fang. Lean blowoff process of bluff body based on heat release rate analysis[J]. Journal of Beijing University of Aeronautics and Astronautics,2022,48(3): 473-484. (in Chinese) doi: 10.13700/j.bh.1001-5965.2020.0588 [12] JONES W P,LYRA S,NAVARRO-MARTINEZ S. Large eddy simulation of a swirl stabilized spray flame[J]. Proceedings of the Combustion Institute,2011,33(2): 2153-2160. doi: 10.1016/j.proci.2010.07.032 [13] GOODWIN D G, MOFFAT H K, SPETH R L. Cantera: an object-oriented software toolkit for chemical kinetics, thermodynamics, and transport processes[EB/OL]. [2022-12-22]. https: //www.cantera.org/ [14] DI MARE F,JONES W P,MENZIES K R. Large eddy simulation of a model gas turbine combustor[J]. Combustion and Flame,2004,137(3): 278-294. doi: 10.1016/j.combustflame.2004.01.008 [15] BILGER R W,STÅRNER S H,KEE R J. On reduced mechanisms for methane-air combustion in nonpremixed flames[J]. Combustion and Flame,1990,80(2): 135-149. doi: 10.1016/0010-2180(90)90122-8 [16] BRANLEY N,JONES W P. Large eddy simulation of a turbulent non-premixed flame[J]. Combustion and flame,2001,127(1/2): 1914-1934. [17] SMOOKE M D,PURI I K,SESHADRI K. A comparison between numerical calculations and experimental measurements of the structure of a counterflow diffusion flame burning diluted methane in diluted air[J]. Symposium (International) on Combustion,1988,21(1): 1783-1792. doi: 10.1016/S0082-0784(88)80412-0 [18] SMITH G P, GOLDEN D M, FRENKLACH M, et al. GRI-MECH 3.0[EB/OL]. [2021-12-22]http: //www.me.berkeley.edu/gri_mech/ [19] SMOOKE S D. Reduced kinetic mechanisms and asymptotic approximations for methane-air flames: a topical volume[M]. Berlin: Springer-Verlag, 1991. [20] ZHOU C W,LI Y,BURKE U,et al. An experimental and chemical kinetic modeling study of 1, 3-butadiene combustion: ignition delay time and laminar flame speed measurements[J]. Combustion and Flame,2018,197: 423-438. doi: 10.1016/j.combustflame.2018.08.006 [21] XUE J,XI S,WANG F. An extensive study on skeletal mechanism reduction for the oxidation of C0–C4 fuels[J]. Combustion and Flame,2020,214: 184-198. doi: 10.1016/j.combustflame.2019.12.035 [22] BARLOW R S,FRANK J H. Effects of turbulence on species mass fractions in methane/air jet flames[J]. Symposium (International) on Combustion,1998,27(1): 1087-1095. doi: 10.1016/S0082-0784(98)80510-9 [23] SUNG C J,LAW C K,CHEN J Y. Augmented reduced mechanisms for NO emission in methane oxidation[J]. Combustion and Flame,2001,125(1/2): 906-919. [24] JONES W P,PRASAD V N. Large eddy simulation of the sandia flame series (D–F) using the Eulerian stochastic field method[J]. Combustion and Flame,2010,157(9): 1621-1636. doi: 10.1016/j.combustflame.2010.05.010 -

下载:

下载: