Progress on mechanism of flow and heat transfer and modeling of turbine blade squealer tip

-

摘要:

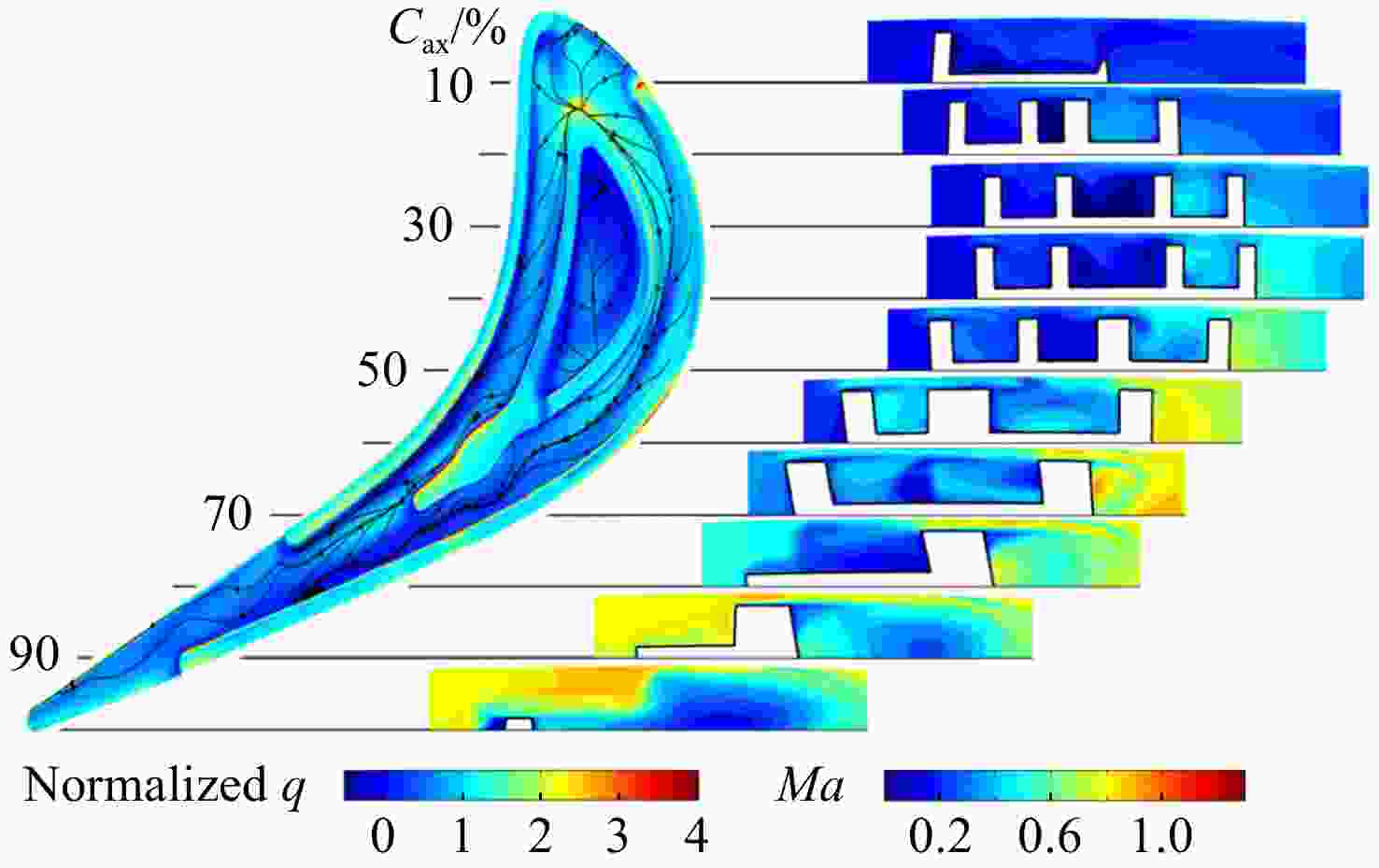

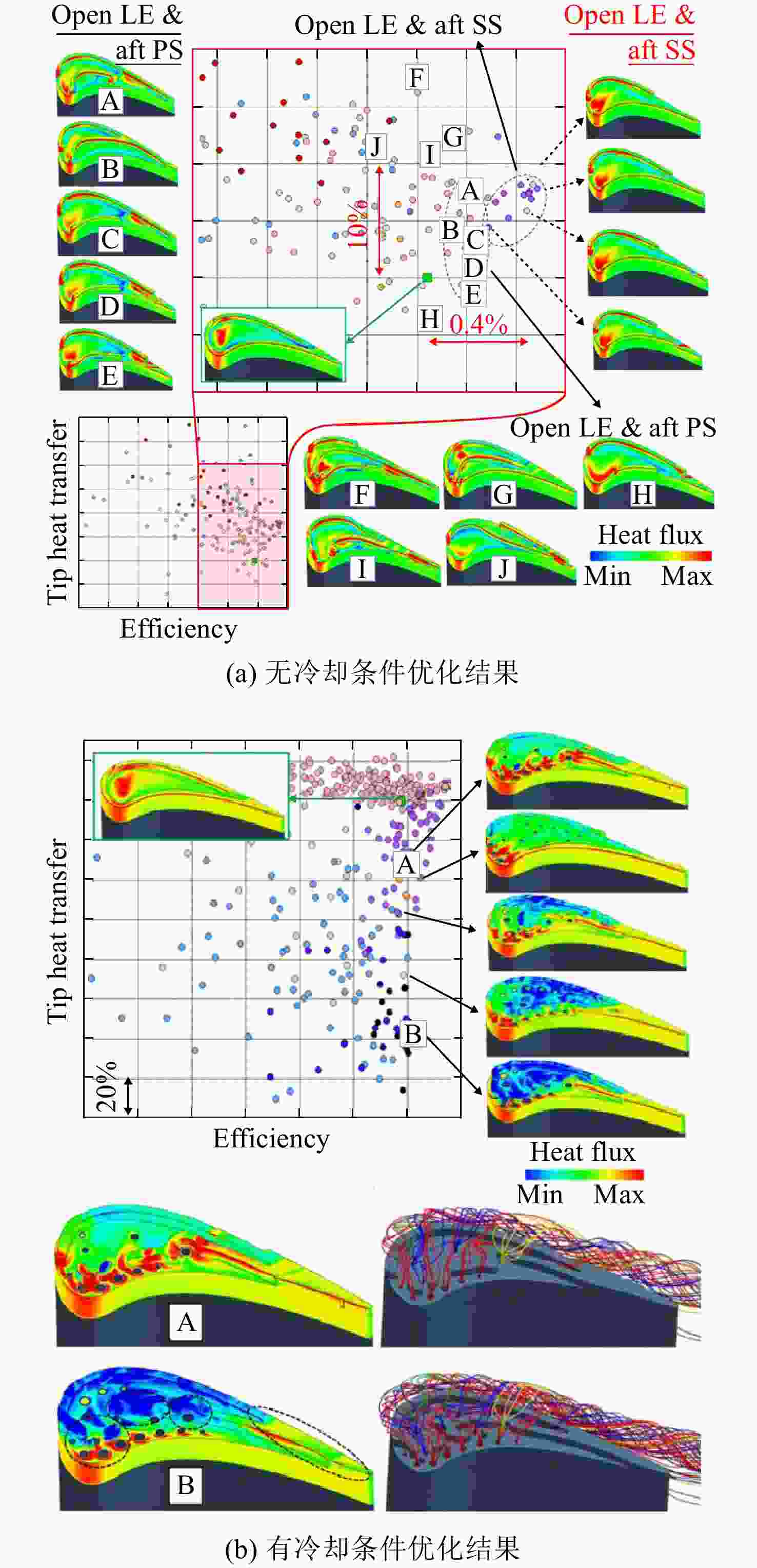

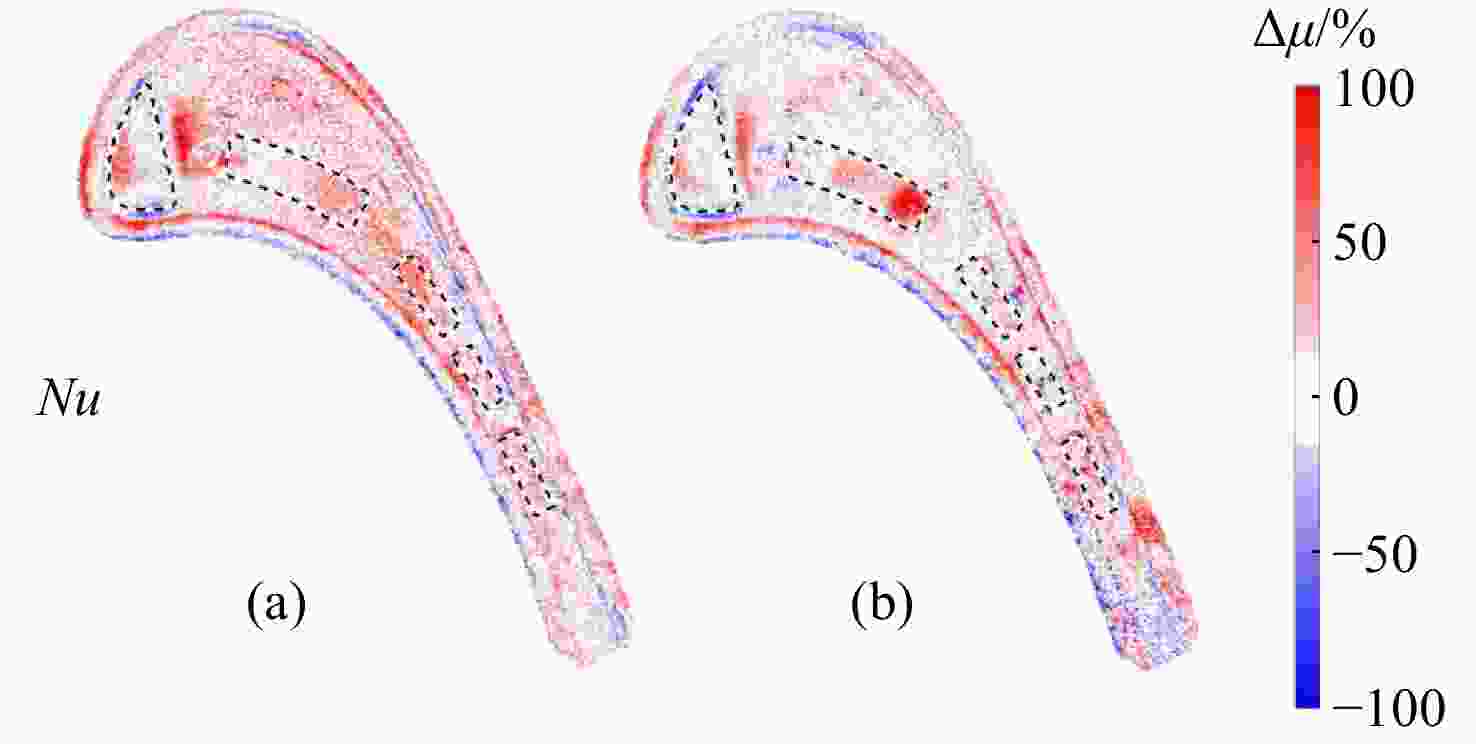

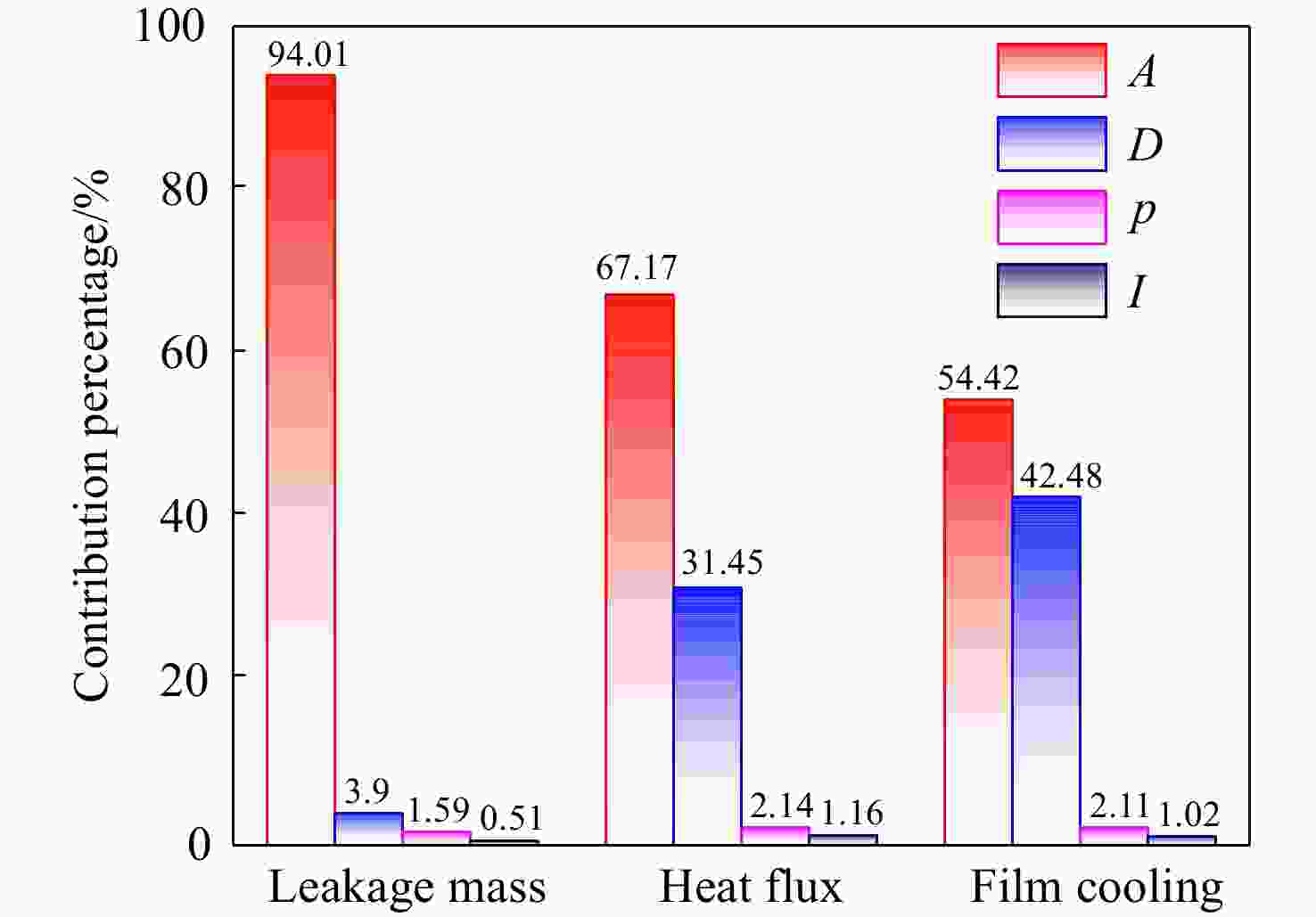

针对凹槽叶尖流动机理及组织方法,考虑冷却的凹槽叶尖气动与传热特征分析和凹槽叶尖泄漏流动的模化等相关工作的研究进展进行了简要总结。已有的研究表明:凹槽内部的流动对传热有明显的影响;凹槽内的冷却气与泄漏流动存在较强的相互作用,合理的凹槽形状和喷气孔位置可以有效提升叶尖的气动效率并降低热负荷;叶尖的加工和气动参数的不确定性会显著影响凹槽叶尖性能;通过对凹槽内流动结构进行模化,得到的考虑喷气的可压缩条件下的凹槽叶尖性能预测模型经过了实验和数值模拟的结果验证,可以有效评估凹槽叶尖性能,并为工程设计提供参考。

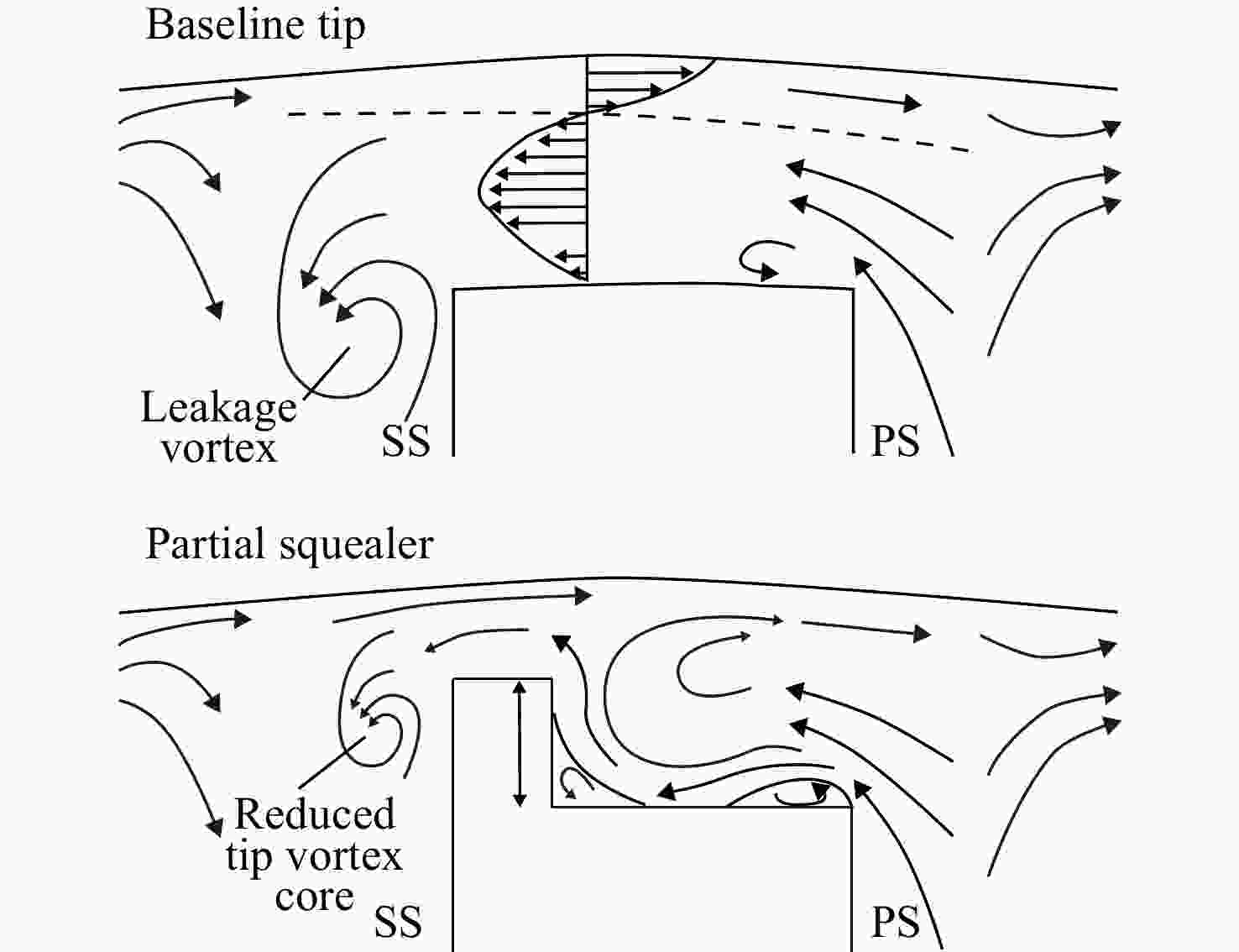

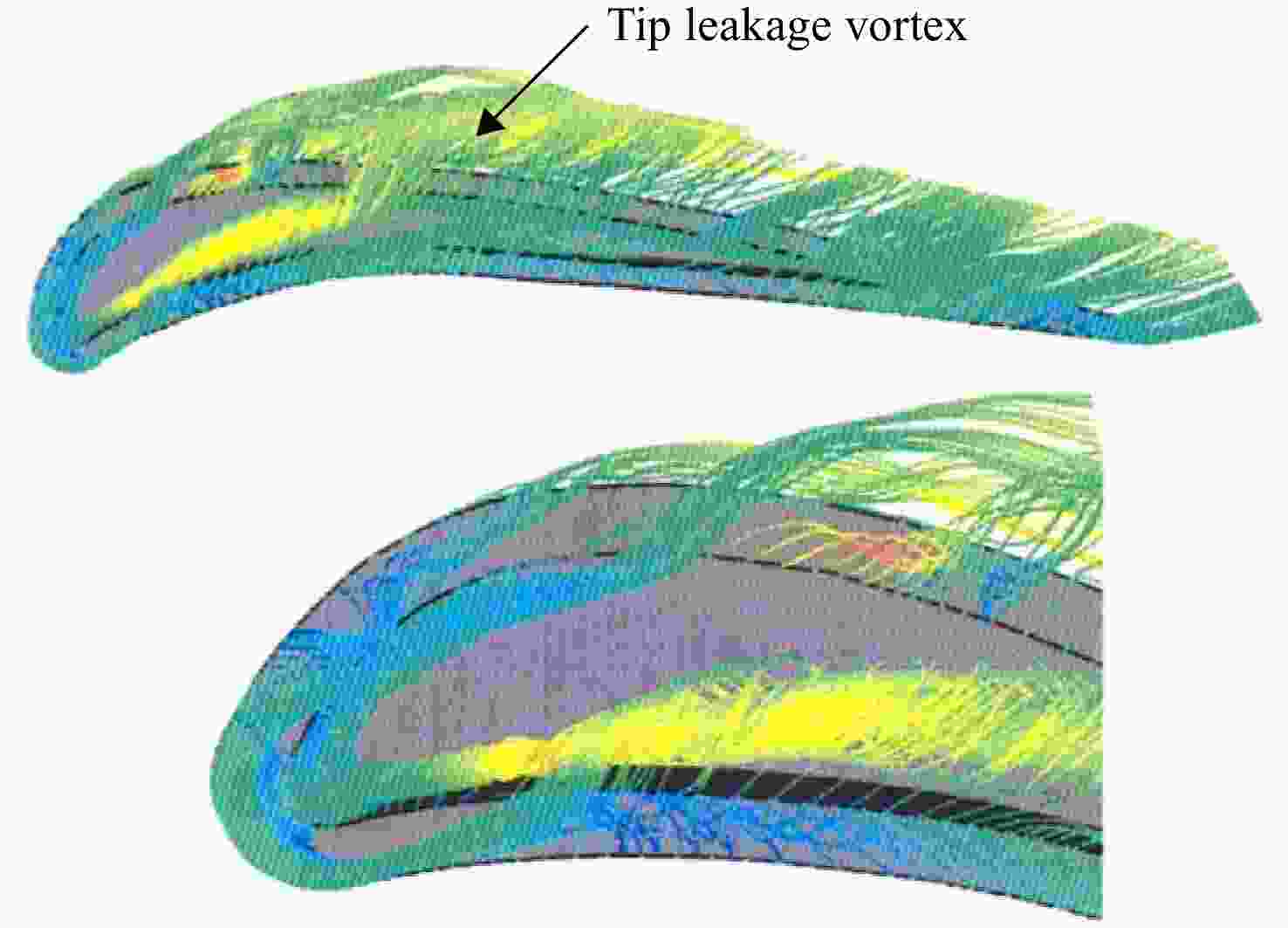

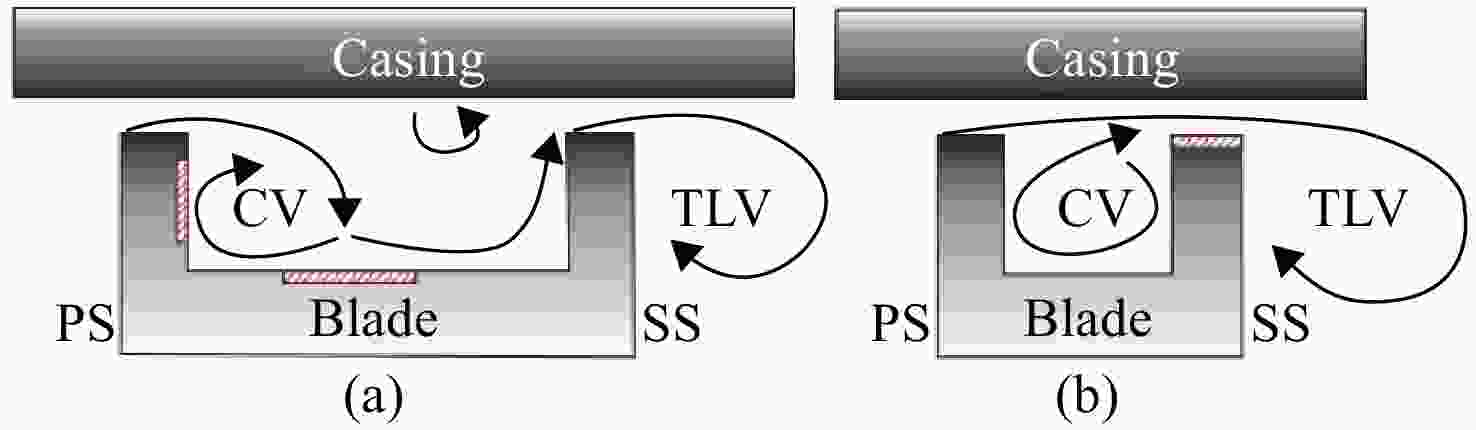

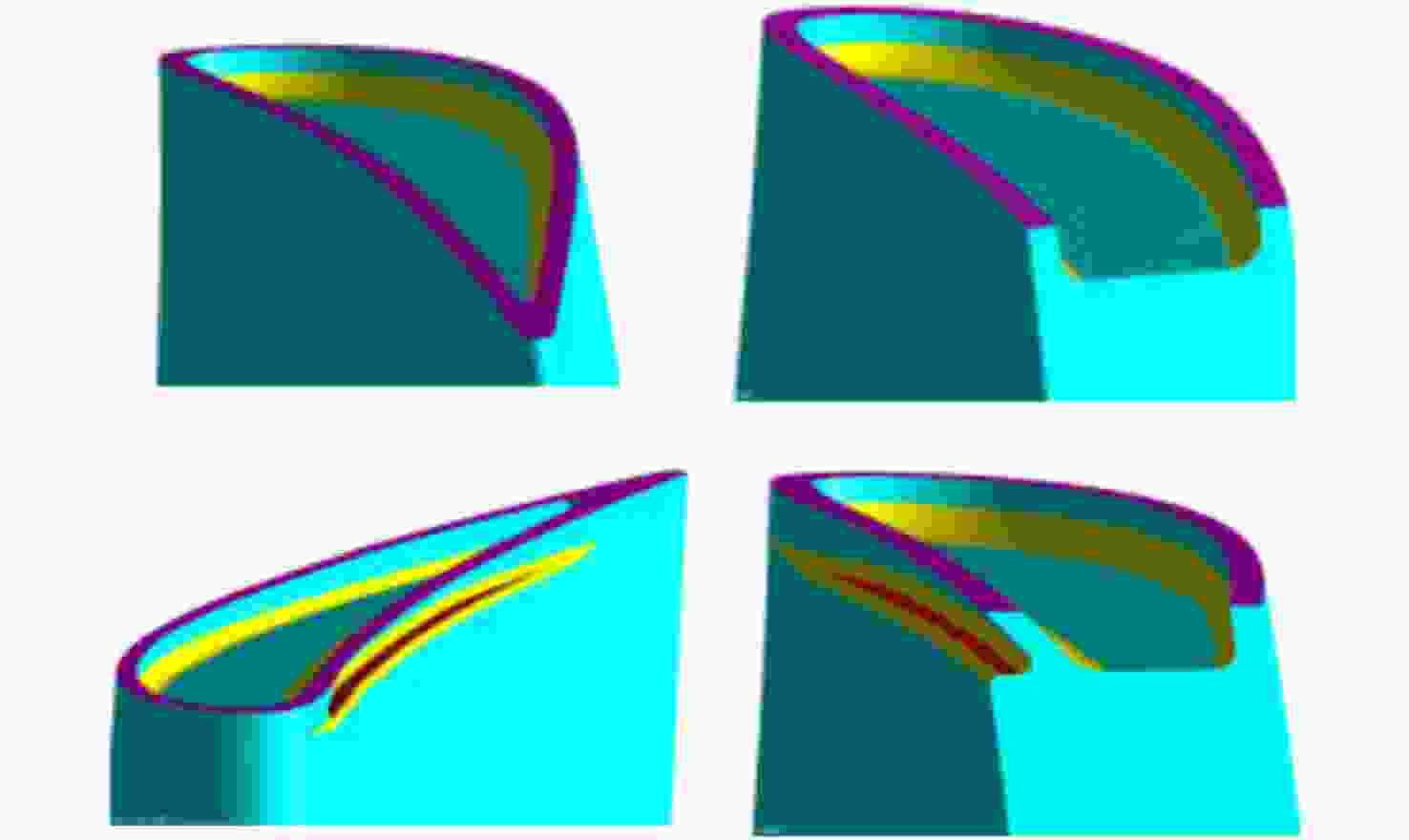

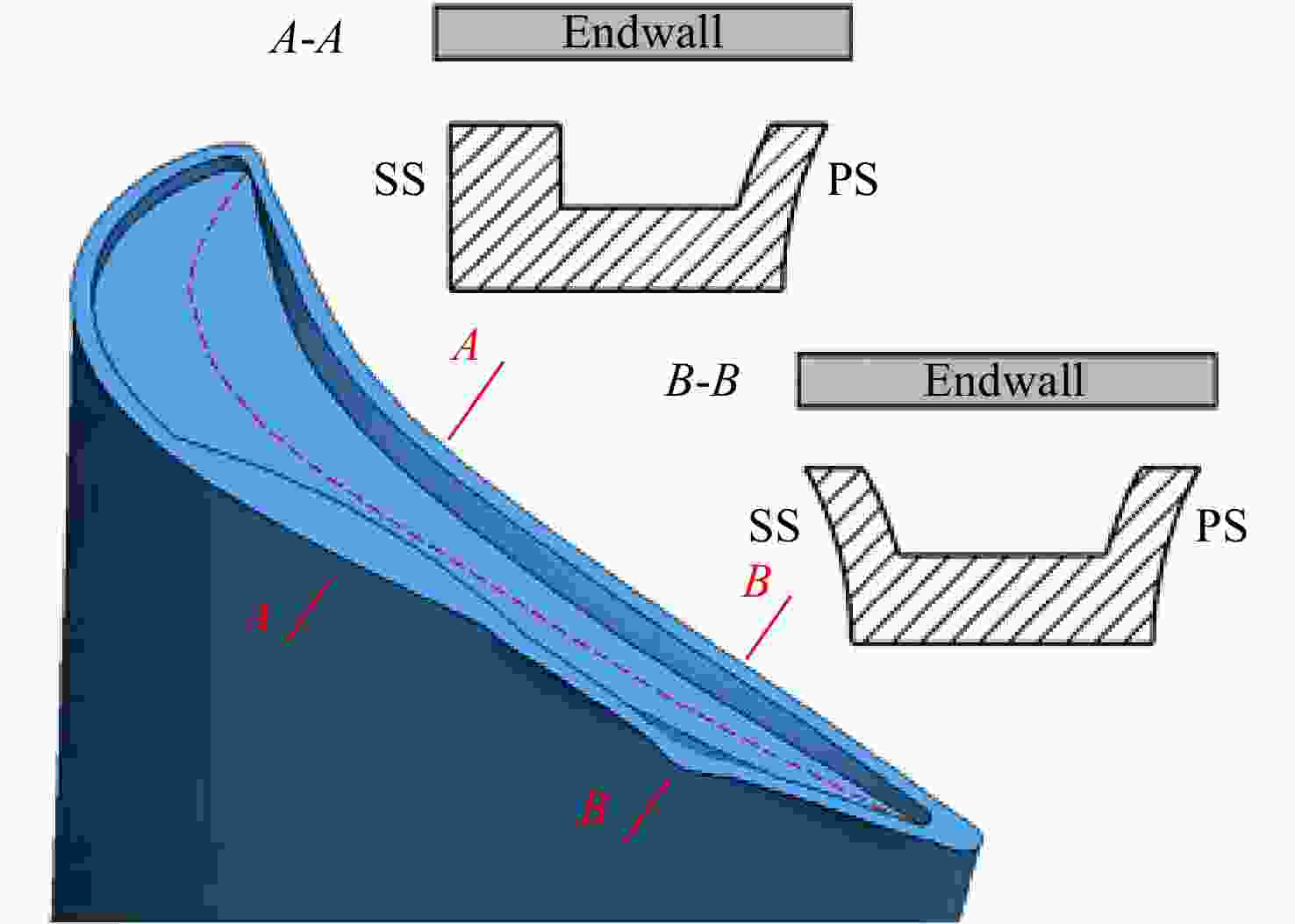

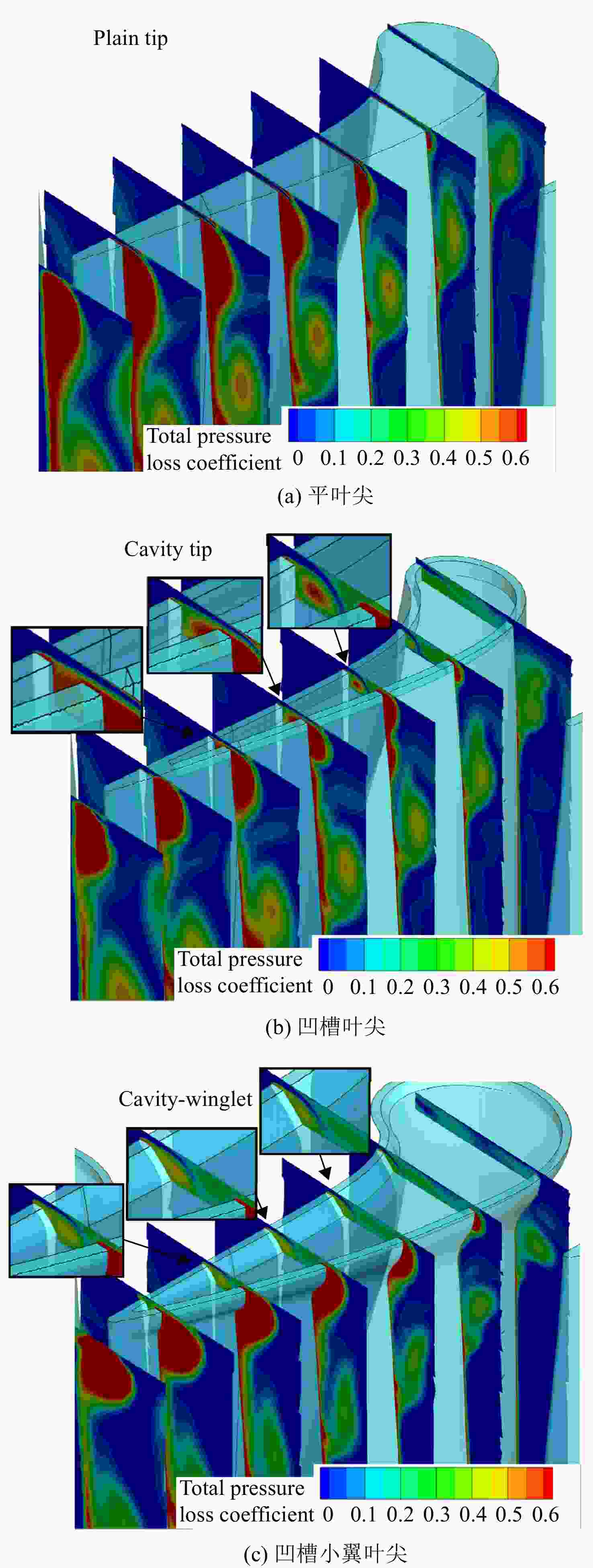

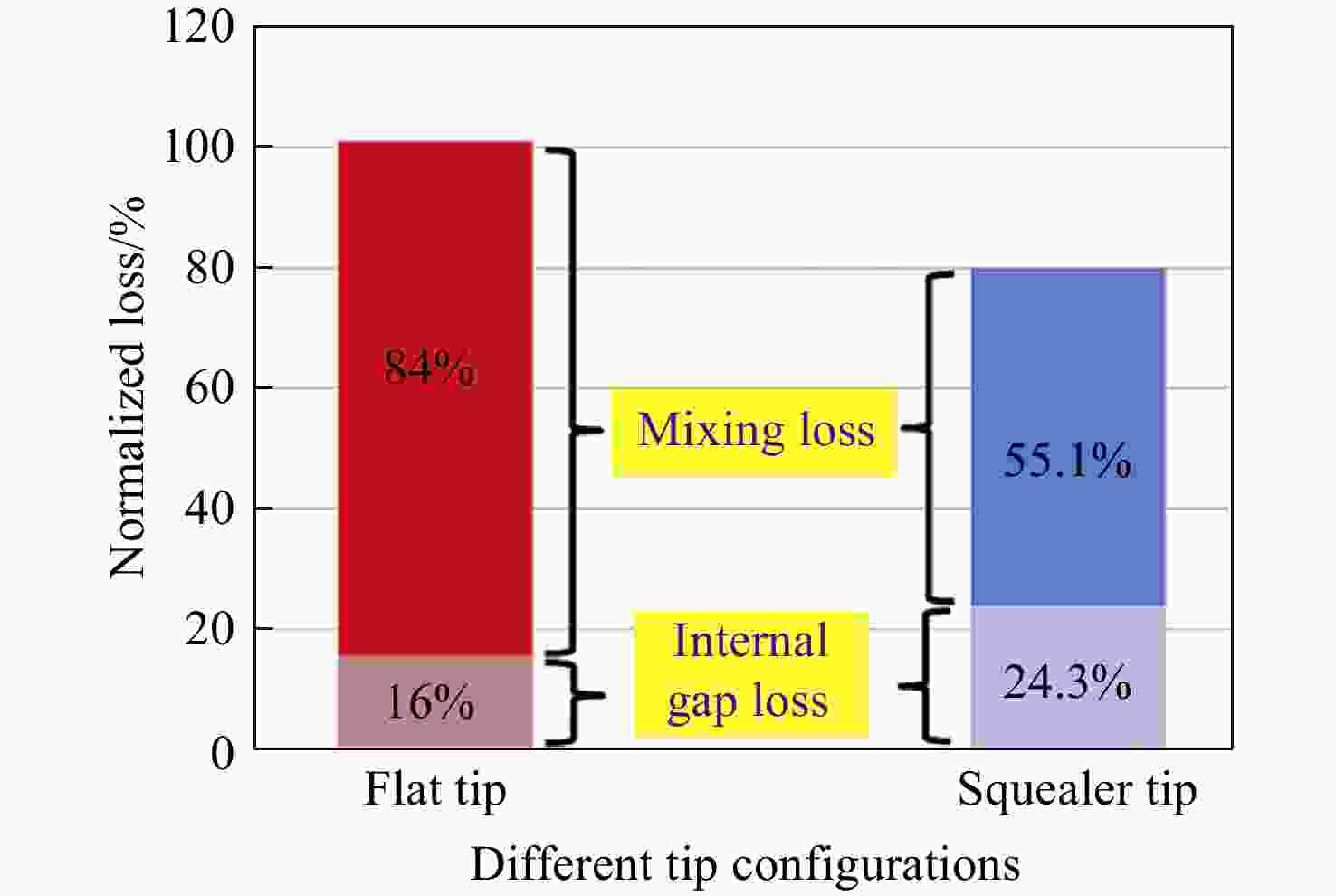

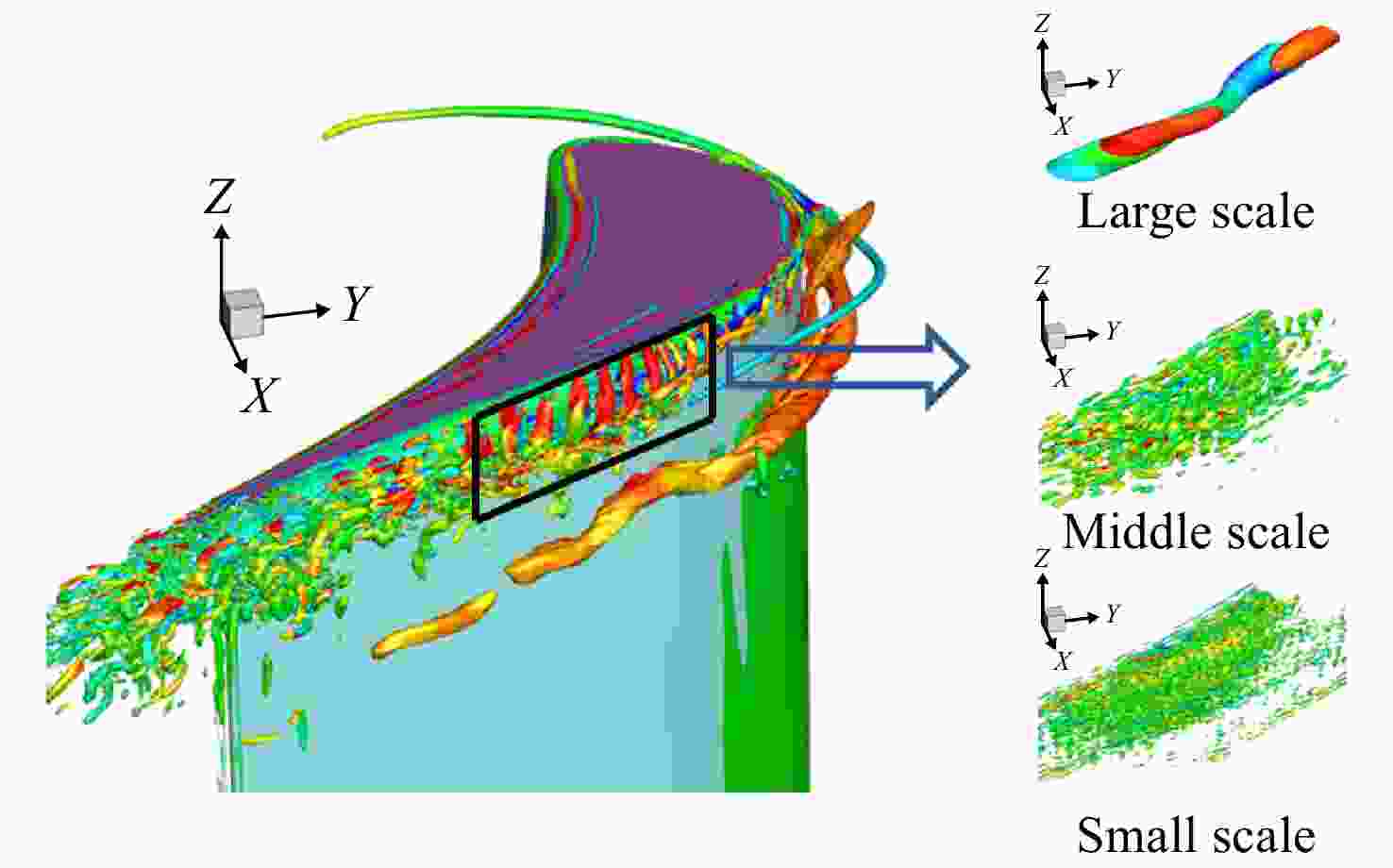

Abstract:According to the flow mechanism and organization method of squealer tip, the analysis of aerodynamic and heat transfer characteristics of squealer tip considering cooling, and the modeling of leakage flow of squealer tip were summarized. The results showed that the flow inside the cavity had an obvious effect on the heat transfer. There was a strong interaction between the cooling gas in the cavity and the leakage flow. Reasonable cavity shape and jet hole position can effectively improve the aerodynamic performance and reduce the heat load of the blade tip; The uncertainty of blade tip machining and aerodynamic parameters could significantly affect the performance of squealer tip. By modeling the vortex structure in the cavity, the performance prediction model of the squealer tip considering the compressibility of air jet was verified by experiment and numerical simulation results. The model can effectively evaluate the performance of the squealer tip and provide a reference for engineering design.

-

-

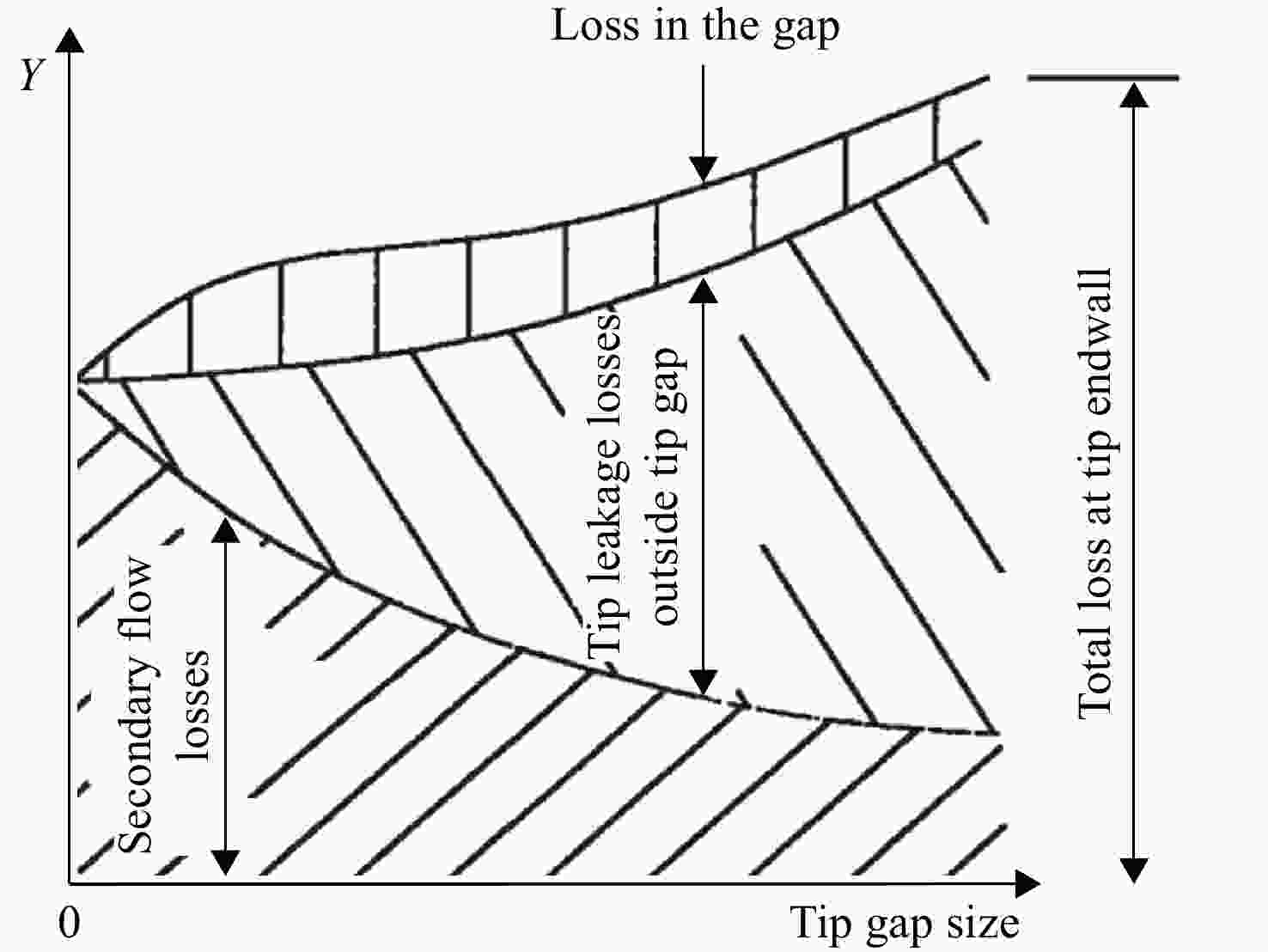

[1] DENTON J D. The 1993 IGTI scholar lecture: loss mechanisms in turbomachines[J]. Journal of Turbomachinery,1993,115(4): 621-656. doi: 10.1115/1.2929299 [2] ZOU Z, WANG S, LIU H, et al. Axial turbine aerodynamics for aero-engines[M]. Singapore City & Shanghai: Springer & Shanghai Jiao Tong University Press, 2018. [3] MOORE J, TILTON J S. Tip leakage flow in a linear turbine cascade[J]. Journal of Turbomachinery, 1988, 110(1): 18-26. [4] 杨益,马宏伟. 轴流涡轮叶尖泄漏流动实验测量技术研究进展[J]. 实验流体力学,2021,35(6): 28-43. doi: 10.11729/syltlx20200107YANG Yi,MA Hongwei. Progress of experimental research on axial turbine tip leakage flow[J]. Journal of Experiments in Fluid Mechanics,2021,35(6): 28-43. (in Chinese) doi: 10.11729/syltlx20200107 [5] BUNKER R S. Axial turbine blade tips: function, design, and durability[J] Journal of Propulsion and Power, 2006, 22(2): 271-285. [6] HAN J C. Fundamental gas turbine heat transfer[J]. Journal of Thermal Science & Engineering Applications,2013,5(2): 021007.1-021007.15. [7] 邵飞. 涡轮叶尖泄漏精细流动机理及组织方法[D]. 北京: 北京航空航天大学, 2017.SHAO Fei. Flow mechanism and organizing method for the turbine tip leakage flow[D]. Beijing: Beihang University, 2017. (in Chinese) [8] AMERI A A,STEINTHORSSON E,RIGBY D L. Effect of squealer tip on rotor heat transfer and efficiency[J]. Journal of Turbomachinery,1998,120(4): 753-759. [9] 皮骏,杜旭博,孔庆国,等. 冲击式凹槽叶尖流动换热特性[J]. 航空动力学报,2019,34(2): 331-340. doi: 10.13224/j.cnki.jasp.2019.02.009PI Jun,DU Xubo,KONG Qingguo,et al. Investigation on flow and heat transfer characteristics of impulse squealer tip[J]. Journal of Aerospace Power,2019,34(2): 331-340. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.02.009 [10] 杨蓓洁,谭晓茗,单勇,等. 肋条结构对气膜冷却凹槽叶尖流动换热的影响[J]. 航空动力学报,2021,36(7): 1462-1471. doi: 10.13224/j.cnki.jasp.20200434YANG Beijie,TAN Xiaoming,SHAN Yong,et al. Effects of rib structure on flow and heat transfer characteristics of film cooling rotor blade with squealer tip[J]. Journal of Aerospace Power,2021,36(7): 1462-1471. (in Chinese) doi: 10.13224/j.cnki.jasp.20200434 [11] 李杰. LEAP-X发动机的创新性技术[J]. 航空科学技术,2011,22(4): 12-14. doi: 10.3969/j.issn.1007-5453.2011.04.004LI Jie. Technology innovations of LEAP-X[J]. Aeronautical Science & Technology,2011,22(4): 12-14. (in Chinese) doi: 10.3969/j.issn.1007-5453.2011.04.004 [12] NEWTON P J, LOCK G D, KRISHNABABU S K, et al. Aero-thermal investigation of tip leakage flow in axial flow turbines: Part 3 tip cooling[R]. ASME Paper GT 2007-27368, 2007. [13] WANG Z,ZHANG Q,LIU Y,et al. Impact of cooling injection on the transonic over-tip leakage flow and squealer aerothermal design optimization[J]. Journal of Turbomachinery,2015,137(6): 062603.1-062603.7. [14] WANG Y,SONG Y,YU J,et al. Effect of cooling injection on the leakage flow of a turbine cascade with honeycomb tip[J]. Applied Thermal Engineering,2018,133: 690-703. doi: 10.1016/j.applthermaleng.2018.01.090 [15] LU S,MA Q,ZHANG Q,et al. Cutback squealer tip trailing edge cooling performance[J]. International Journal of Heat and Mass Transfer,2020,154: 119632.1-119632.15. [16] RAINS D A. Tip clearance flows in axial flow compressors and pumps[D]. Pasadena, US: California Institute of Technology, 1954. [17] BINDON J P. The measurement and formation of tip clearance loss[J]. Journal of Turbomachinery, 1989, 111(3): 257-263. [18] DISHART P T,MOORE J. Tip leakage losses in a linear turbine cascade[J]. Journal of Turbomachinery,1990,112(4): 599-608. doi: 10.1115/1.2927700 [19] YARAS M I,SJOLANDER S A. Prediction of tip-leakage losses in axial turbines[J]. Journal of Turbomachinery,1992,114(1): 204-210. doi: 10.1115/1.2927987 [20] YARAS M I,SJOLANDER S A. Effects of simulated rotation on tip leakage in a planar cascade of turbine blade: Part 1 tip gap flow[J]. Journal of Turbomachinery,1992,114(1): 652-659. [21] YOUNG J B,WILCOCK R C. Modeling the air-cooled gas turbine: Part 2 coolant flows and losses[J]. Journal of Turbomachinery,2002,124(2): 207-213. doi: 10.1115/1.1415037 [22] BOOTH T C,DODGE P R,HEPWORTH H K. Rotor-tip leakage: Part Ⅰ basic methodology[J]. Journal of Engineering for Gas Turbines & Power,1982,104(1): 154-161. [23] WADIA A R,BOOTH T C. Rotor-tip leakage: Part Ⅱ design optimization through viscous analysis and experiment[J]. Journal of Engineering for Power,1982,104(1): 162-169. doi: 10.1115/1.3227245 [24] KRISHNABABU S K,NEWTON P J,DAWES W N,et al. Aerothermal investigation of tip leakage flow in axial flow turbines: Part 1 effect of tip geometry and tip clearance gap[J]. Journal of Turbomachinery,2009,131(1): 011006.1-011006.14. [25] KEGALJ M, SCHMID G, SCHIFFER H P, et al. Experimental and numerical investigation of tip leakage flow in a 1/2 stage turbine rig comparing flat and cavity-squealer tip geometries[R]. ASME Paper GT2012-69568, 2012. [26] AZAD G S,HAN J C,BUNKER R S,et al. Effect of squealer geometry arrangement on a gas turbine blade tip heat transfer[J]. Journal of Turbomachinery,2002,124(6): 452-459. [27] CAMCI C,DEY D,KAVURMACIOGLU L. Aerodynamics of tip leakage flows near partial squealer rims in an axial flow turbine stage[J]. Journal of Turbomachinery,2005,127(1): 14-24. doi: 10.1115/1.1791279 [28] MARAL H, SENEL C B, KAVURMACIOGLU L, et al. Aerothermal performance of partial and cavity squealer tip in a linear turbine cascade[R]. Istanbul, Turkey: ICAME2016, 2016. [29] SCHABOWSKI Z,HODSON H P,GIACCHE D,et al. Aeromechanical optimization of a winglet-squealer tip for an axial turbine[J]. Journal of Turbomachinery,2014,136(7): 071004.1-071004.12. [30] ZHOU C,HODSON H P,TIBBOTT I,et al. Effects of winglet geometry on the aerodynamic performance of tip leakage flow in a turbine cascade[J]. Journal of Turbomachinery,2013,135(7): 051009.1-051009.10. [31] ZOU Z,SHAO F,LI Y,et al. Dominant flow structure in the squealer tip gap and its impact on turbine aerodynamic performance[J]. Energy,2017,138: 167-184. doi: 10.1016/j.energy.2017.07.047 [32] COULL J D, AKTINS N R, HODSON H P. High efficiency cavity winglets for high pressure turbines[R]. ASME Paper GT2014-25261, 2014. [33] 邹正平,姚李超,轩笠铭,等. 涡轮转子凹槽叶尖泄漏流动气动热力特征[J]. 推进技术,2020,41(9): 1975-1987. doi: 10.13675/j.cnki.tjjs.200246ZOU Zhengping,YAO Lichao,XUAN Liming,et al. Aero-thermodynamic characteristics of tip leakage flow in turbine rotor with squealer tip[J]. Journal of Propulsion Technology,2020,41(9): 1975-1987. (in Chinese) doi: 10.13675/j.cnki.tjjs.200246 [34] ZENG F,DU J,HUANG L,et al. An experimental method for squealer tip flow field considering relative casing motion[J]. Chinese Journal of Aeronautics,2020,33(7): 1942-1952. doi: 10.1016/j.cja.2020.03.002 [35] 杜金霖,邹正平,黄霖,等. 计及机匣相对运动的涡轮叶片叶顶凹槽流动研究[J]. 实验流体力学,2021,35(2): 22-35. doi: 10.11729/syltlx20200073DU Jinlin,ZOU Zhengping,HUANG Lin,et al. Experimental and numerical study of squealer tip flow field considering relative casing motion[J]. Journal of Experiments in Filud Mechanics,2021,35(2): 22-35. (in Chinese) doi: 10.11729/syltlx20200073 [36] 王元鹏. 涡轮凹槽叶尖复杂流动若干问题的研究[D]. 北京: 北京航空航天大学, 2021.WANG Yuanpeng. A study on several problems of the flow of turbine cavity tip [D]. Beijing: Beihang University, 2021. (in Chinese) [37] PRAKASH C,LEE C P,CHERRY D G,et al. Analysis of some improved blade tip concepts[J]. Journal of Turbomachinery,2006,128(4): 639-642. doi: 10.1115/1.2220050 [38] YANG D, FENG Z. Tip leakage flow and heat transfer predictions for turbine blades[R]. ASME Paper GT2007-27728, 2007. [39] TALLMAN J,LAKSHMINARAYANA B. Numerical simulation of tip leakage flow in axial flow turbines with emphasis on flow physics: Part 1 effect of tip clearance height[J]. Journal of Turbomachinery,2013,123(4): 314-323. [40] MAESSCHALCK C D,LAVAGNOLI S,PANIAGUA G,et al. Aerothermodynamics of tight rotor tip clearance flows in high-speed unshrouded turbines[J]. Applied Thermal Engineering,2014,65(1/2): 343-351. [41] JEONG J S,LEE S W. Full aerodynamic loss data for efficient squealer tip design in an axial flow turbine[J]. Energy,2020,206: 118170.1-118170.11. [42] GAO J,ZHENG Q,XU T,et al. Inlet conditions effect on tip leakage vortex breakdown in unshrouded axial turbines[J]. Energy,2015,91: 255-263. doi: 10.1016/j.energy.2015.08.065 [43] HUANG L, ZOU Z. Mixing mechanism of multi-scale flow in tip region of turbine rotor[R]. ASME Paper GT2022-82137, 2022. [44] YANG D,YU X,FENG Z. Investigation of leakage flow and heat transfer in a gas turbine blade tip with emphasis on the effect of rotation[J]. Journal of Turbomachinery,2010,132(4): 041010.1-041010.9. [45] 杜昆,李军. 涡轮叶片凹槽状叶顶非定常流动传热特性的数值研究[J]. 推进技术,2017,38(3): 551-558. doi: 10.13675/j.cnki.tjjs.2017.03.010DU Kun,LI Jun. Numerical investigations on unsteady leakage flow and heat transfer characteristics of turbine blade with squealer tip[J]. Journal of Propulsion Technology,2017,38(3): 551-558. (in Chinese) doi: 10.13675/j.cnki.tjjs.2017.03.010 [46] 王维杰,卢少鹏,马海腾,等. 高压涡轮尾切凹槽叶尖冷却换热特性[J]. 航空动力学报,2019,34(10): 2131-2139. doi: 10.13224/j.cnki.jasp.2019.10.006WANG Weijie,LU Shaopeng,MA Haiteng,et al. Cooling and heat transfer characteristics of high-pressure turbine blade with cut-back squealer tip[J]. Journal of Aerospace Power,2019,34(10): 2131-2139. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.10.006 [47] DUNN M G,HALDEMAN C W. Time-averaged heat flux for a recessed tip, lip, and platform of a transonic turbine blade[J]. Journal of Turbomachinery,2000,122(4): 692-698. doi: 10.1115/1.1311285 [48] SAKAOGLU S,KAHVECI H S. Effect of cavity depth on thermal performance of a cooled blade tip under rotation[J]. International Journal of Heat and Mass Transfer,2019,143: 118561.1-118561.11. [49] 于飞龙,上官博,李园园,等. 重型燃气轮机透平第一级动叶复合冷却数值研究[J]. 中国电机工程学报,2016,35(1): 179-186. doi: 10.13334/j.0258-8013.pcsee.2016.01.019YU Feilong,SHANGGUAN Bo,LI Yuanyuan,et al. Numerical investigation on compound cooling effect of the heavy-duty gas turbine first stage blade[J]. Proceedings of the CSEE,2016,35(1): 179-186. (in Chinese) doi: 10.13334/j.0258-8013.pcsee.2016.01.019 [50] KRISHNABABU S K,DAWES W N,HODSON H P,et al. Aerothermal investigations of tip leakage flow in axial flow turbines: Part Ⅱ effect of relative casing motion[J]. Journal of Turbomachinery,2009,131(1): 011007.1-011007.10. [51] MISCHO B,BURDET A,ABHARI R. Influence of stator-rotor interaction on the aerothermal performance of recess blade tips[J]. Journal of Turbomachinery,2010,133(1): 011023.1-011023.11. [52] KANG D B,LEE S W. Effects of squealer rim height on heat/mass transfer on the floor of cavity squealer tip in a high turning turbine blade cascade[J]. International Journal of Heat and Mass Transfer,2016,99: 283-292. doi: 10.1016/j.ijheatmasstransfer.2016.03.121 [53] SEO Y C,LEE S W. Heat/mass transfer over the plane tip equipped with a full coverage winglet in a turbine cascade: Part 2 tip surface data[J]. International Journal of Heat & Mass Transfer,2015,88: 974-981. [54] ZOU Z,XUAN L,CHEN Y,et al. Effects of flow structure on heat transfer of squealer tip in a turbine rotor blade[J]. International Communications in Heat and Mass Transfer,2020,114(5): 104588.1-104588.14. [55] KIM Y W,METZGER D E. Heat transfer and effectiveness on film cooled turbine blade tip models[J]. Journal of Turbomachinery,1995,117(1): 12-21. doi: 10.1115/1.2835630 [56] MHETRAS S,NARZARY D,GAO Z,et al. Effect of a cutback squealer and cavity depth on film-cooling effectiveness on a gas turbine blade tip[J]. Journal of Turbomachinery,2008,130(2): 021002.1-021002.13. [57] AHN J,MHETRAS S. Film-cooling effectiveness on a gas turbine blade tip using pressure-sensitive paint[J]. Journal of Turbomachinery,2005,127(5): 521-530. [58] MA H,ZHANG Q,HE L,et al. Cooling injection effect on a transonic squealer tip: Part 1 experimental heat transfer results and CFD validation[J]. Journal of Turbomachinery,2017,139(5): 052506.1-052506.9. [59] YAO C, XIA J, ZHANG B, et al. Investigation of the film-cooling and flow characteristics of trapezoidal slot scheme on the blade tip with partial pressure side squealer in transonic flow[J]. International Journal of Thermal Sciences, 2022, 179: 107583.1-107583.13. [60] NIU M,ZANG S. Numerical investigation of active tip-clearance control through tip cooling injection in an axial turbine cascade[J]. Journal of Thermal Science,2009,18(4): 306-312. doi: 10.1007/s11630-009-0306-z [61] NIU M,ZANG S. Experimental and numerical investigations of tip injection on tip clearance flow in an axial turbine cascade[J]. Experimental Thermal and Fluid Science,2011,35(6): 1214-1222. doi: 10.1016/j.expthermflusci.2011.04.009 [62] GAO J,ZHENG Q,ZHANG Z,et al. Aero-thermal performance improvements of unshrouded turbines through management of tip leakage and injection flows[J]. Energy,2014,69: 648-660. doi: 10.1016/j.energy.2014.03.060 [63] VOLINO R J. Control of tip leakage in a high pressure turbine cascade using tip blowing[J]. Journal of Turbomachinery, 2017, 139(6): 061008.1-061008.12. [64] 轩笠铭,邹正平,赵强,等. 叶顶喷气对凹槽叶尖气动性能的影响[J]. 航空动力学报,2022,37(5): 1030-1041. doi: 10.13224/j.cnki.jasp.20210104XUAN Liming,ZOU Zhengping,ZHAO Qiang,et al. Effect of tip injection on aerodynamic performance of squealer tip[J]. Journal of Aerospace Power,2022,37(5): 1030-1041. (in Chinese) doi: 10.13224/j.cnki.jasp.20210104 [65] MA H,ZHANG Q,HE L,et al. Cooling injection effect on a transonic squealer tip: Part II analysis of aerothermal interaction physics[J]. Journal of Turbomachinery,2017,139(5): 052507.1-052507.9. [66] ZOU Z,LIU J,ZHANG W,et al. Shroud leakage flow models and a multi-dimensional coupling CFD (computational fluid dynamics) method for shrouded turbines[J]. Energy,2016,103: 410-429. doi: 10.1016/j.energy.2016.02.070 [67] DUAN P H,HE L. Application of multiscale methodology for transonic turbine blade tip cooling design[J]. Journal of Turbomachinery,2020,142(8): 081011.1-081011.9. [68] DUAN P H,HE L. Optimization of turbine cascade squealer tip cooling design by combining shaping and flow injection.[J]. Journal of turbomachinery,2021,143(11): 111007.1-111007.9. [69] DU K,LI Z,LI J,et al. Influences of a multi-cavity tip on the blade tip and the over tip casing aerothermal performance in a high pressure turbine cascade[J]. Applied Thermal Engineering,2019,147: 347-360. doi: 10.1016/j.applthermaleng.2018.10.093 [70] CERNAT B C,PATY M,MAESSCHALCK C D,et al. Experimental and numerical investigation of optimized blade tip shapes: part I turbine rainbow rotor testing and numerical methods[J]. Journal of turbomachinery,2019,141(1): 011006.1-011006.13. [71] PATY M,CERNAT B C,MAESSCHALCK C D,et al. Experimental and numerical investigation of optimized blade tip shapes-part II: tip flow analysis and loss mechanisms[J]. Journal of turbomachinery,2019,141(1): 011007.1-011007.13. [72] SAKAOGLU S,KAHVECI H S. Effect of turbine blade tip cooling configuration on tip leakage flow and heat transfer[J]. Journal of turbomachinery,2020,142(2): 021008.1-021008.11. [73] MAESSCHALCK C D,ANDREOLI V,PANIAGUA G,et al. Aerothermal optimization of turbine squealer tip geometries with arbitrary cooling injection[J]. Journal of Turbomachinery,2021,143(11): 111010.1-111010.12. [74] VIERIA J,COULL J,IRELAND P,et al. Aerothermal effect of cavity welding beads on a transonic squealer tip[J]. Journal of turbomachinery,2021,143(11): 111009.1-111009.11. [75] YAN X,YE M,HE K. Investigations into heat transfer and aerodynamic performance of a worn squealer tipped turbine stage[J]. Journal of Turbomachinery,2020,142(9): 091012.1-091012.21. [76] MONTOMOLI F,MASSINI M,SALVADORI S. Geometrical uncertainty in turbomachinery: tip gap and fillet radius[J]. Computers and Fluids,2011,46(1): 362-368. doi: 10.1016/j.compfluid.2010.11.031 [77] SHI W,CHEN P,LI X,et al. Uncertainty quantification of the effects of squealer tip geometry deviation on aerothermal performance[J]. Proceedings of the Institution of Mechanical Engineers Part A Journal of Power and Energy,2020,234(7): 1026-1038. doi: 10.1177/0957650919898617 [78] HUANG M,LI Z,LI J,et al. Uncertainty quantification and sensitivity analysis of aerothermal performance for the turbine blade squealer tip[J]. International Journal of Thermal Sciences,2022,175(5): 107460.1-107460.16. [79] 黄明,李志刚,李军,等. 涡轮动叶凹槽状叶顶传热特性和气动性能的不确定性量化研究[J]. 推进技术,2022,43(3): 200722.1-200722.13. doi: 10.13675/j.cnki.tjjs.200722HUANG Ming,LI Zhigang,LI Jun,et al. Uncertainty quantification analysis on heat transfer characteristics and aerodynamic performance of turbine blade squealer tip[J]. Journal of Propulsion Technology,2022,43(3): 200722.1-200722.13. (in Chinese) doi: 10.13675/j.cnki.tjjs.200722 [80] YANG H,ZHANG W,ZOU Z,et al. The development and applications of a loading distribution based tip leakage loss model for unshrouded gas turbines[J]. Journal of Turbomachinery,2020,142(7): 071005.1-071005.12. [81] 轩笠铭, 邹正平, 曾飞. 跨音涡轮转子叶尖间隙内流动分析与建模[EB/OL] [2022-08-07]. https://doi.org/10.13700/j.bh.1001-5965.2021.0635.XUAN Liming, ZOU Zhengping, ZENG Fei. Flow analysis and modeling in tip clearance of transonic turbine rotor[EB/OL]. [2022-08-07].https://doi.org/10.13700/j.bh.1001-5965.2021.0635. (in Chinese) -

下载:

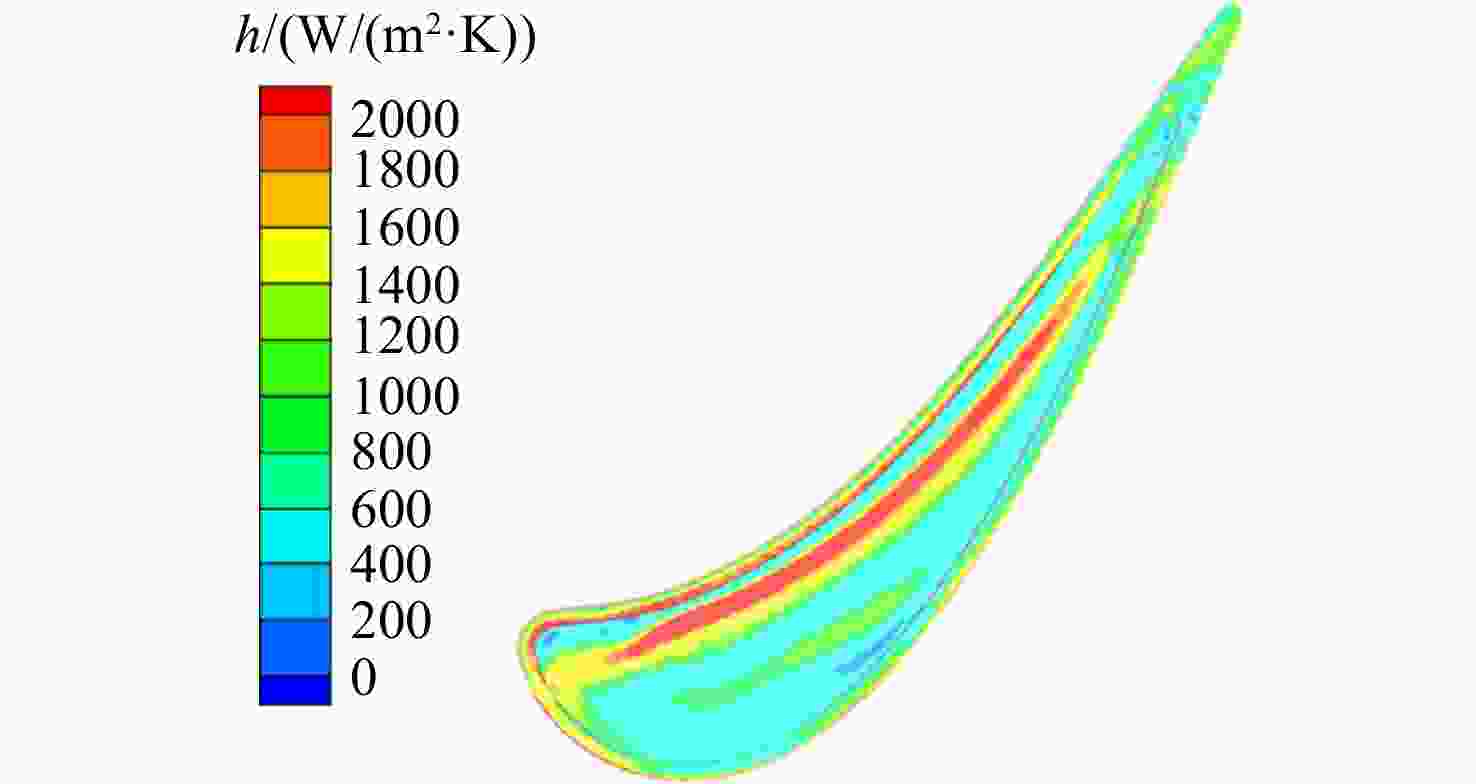

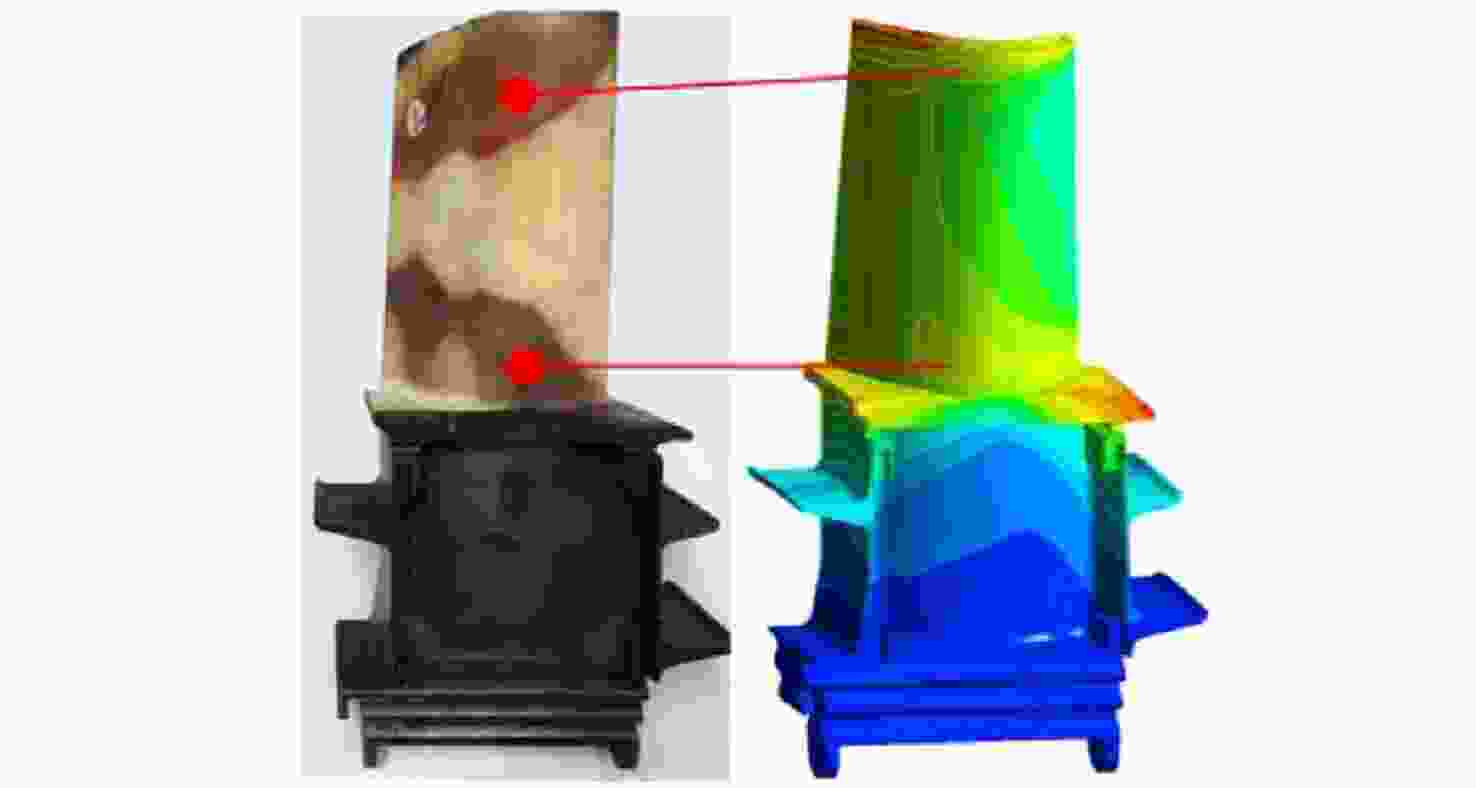

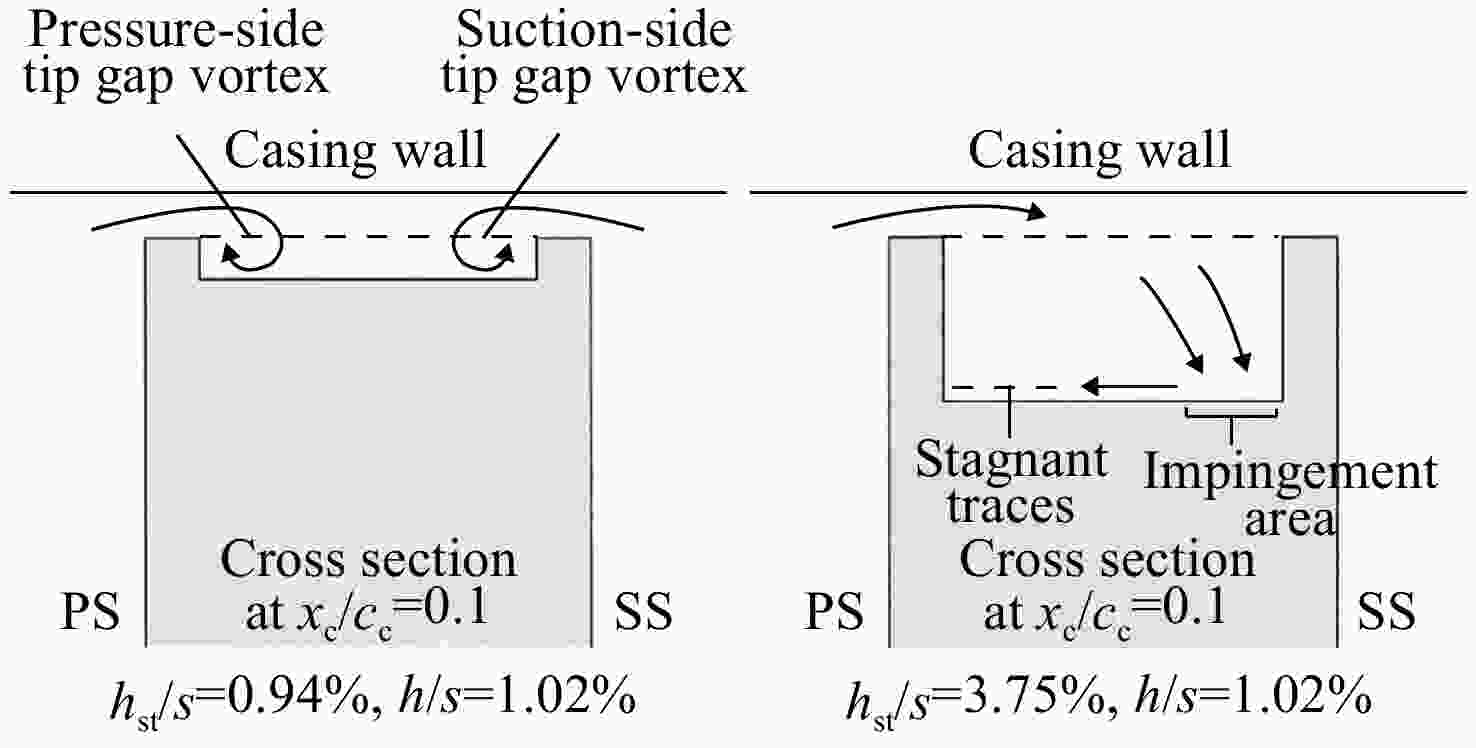

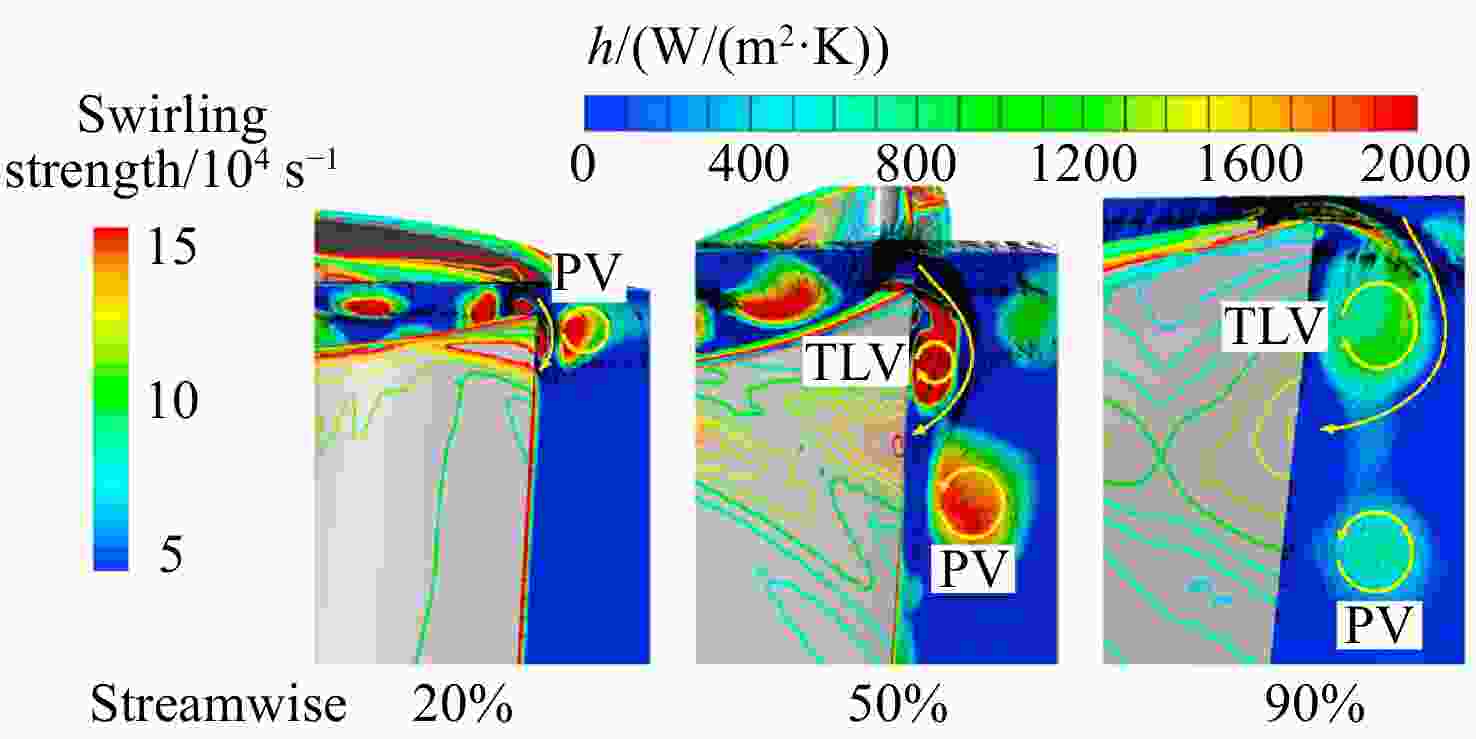

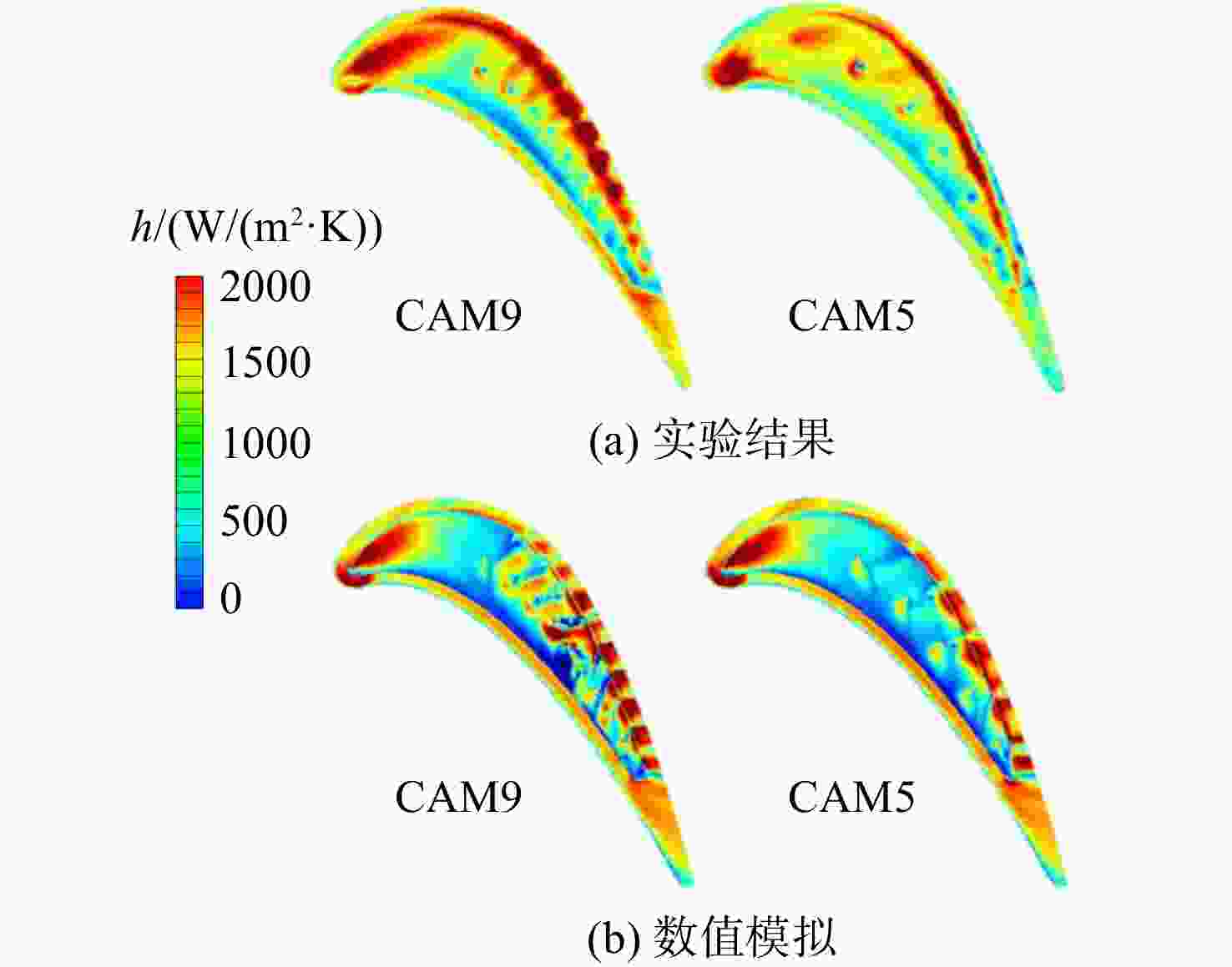

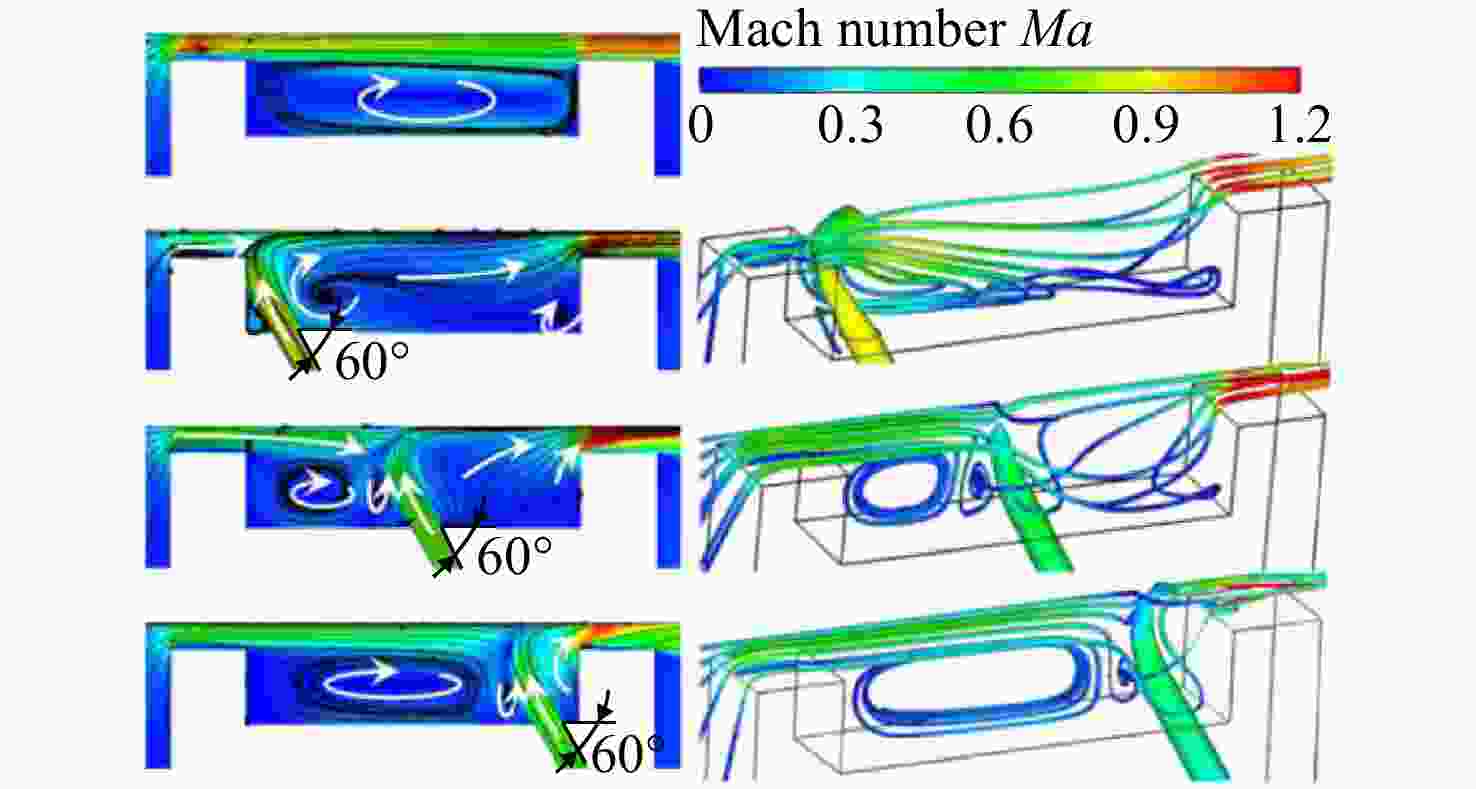

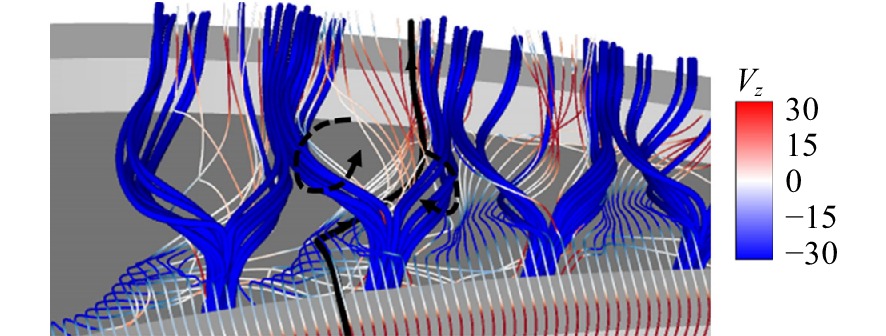

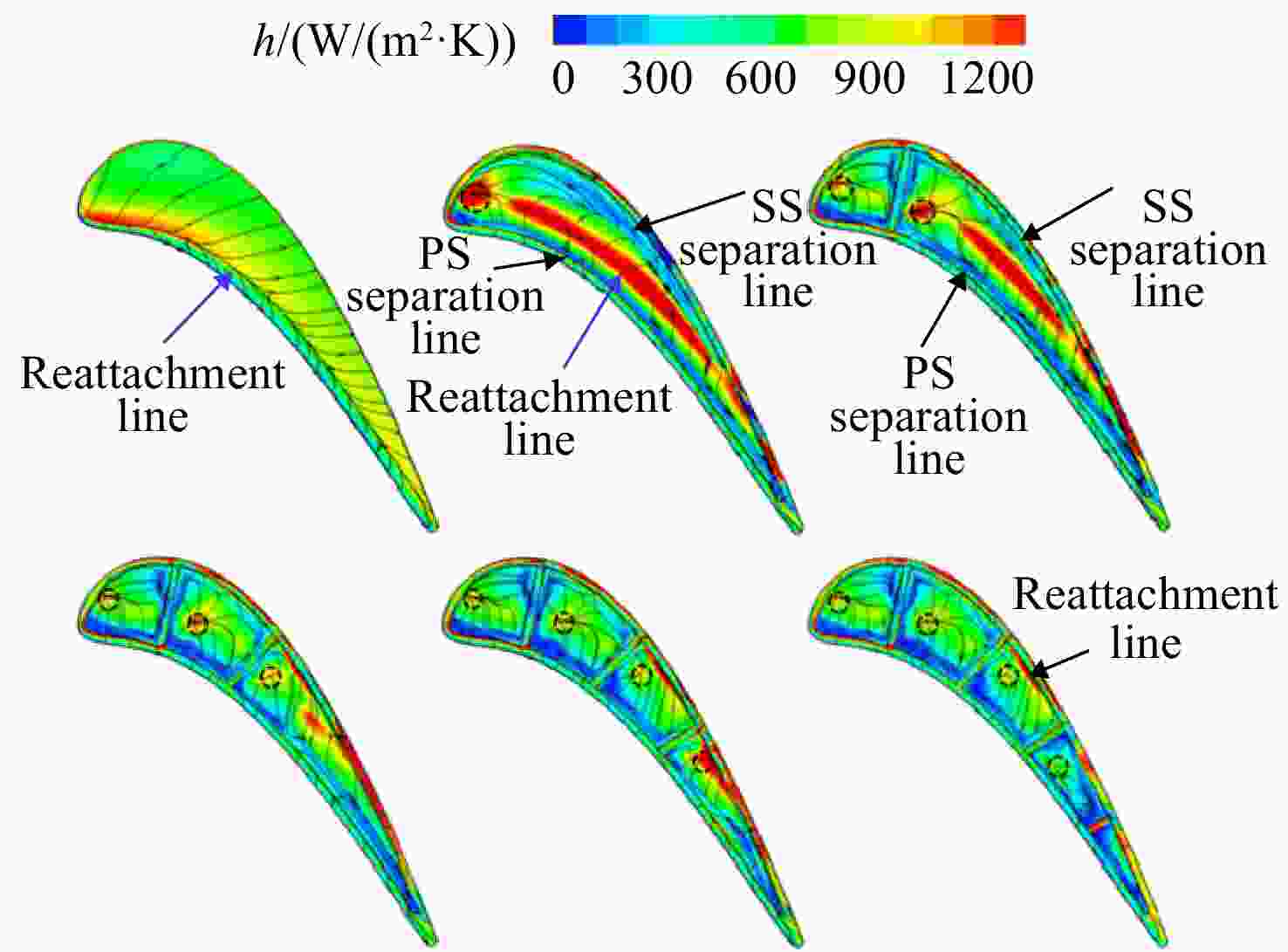

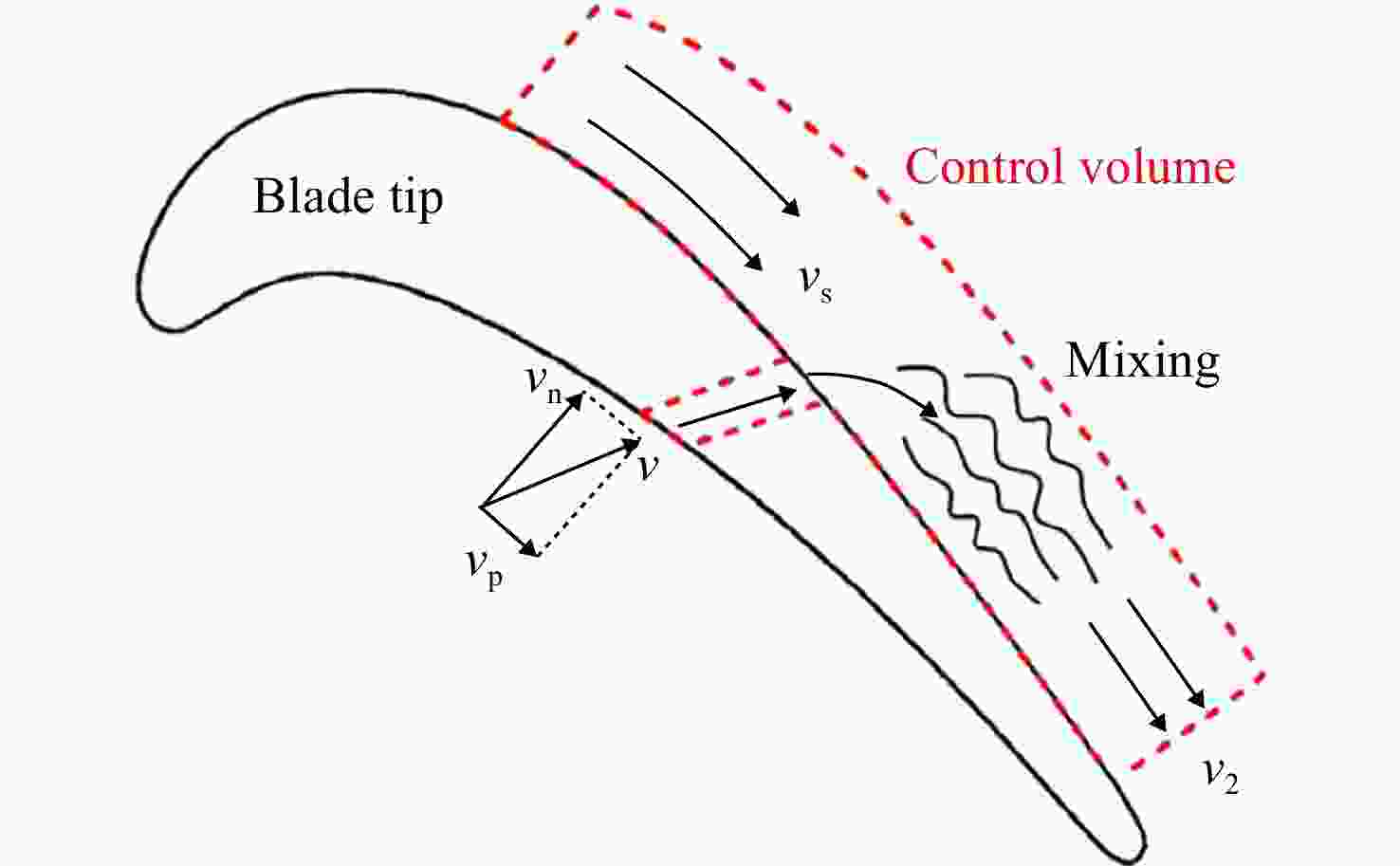

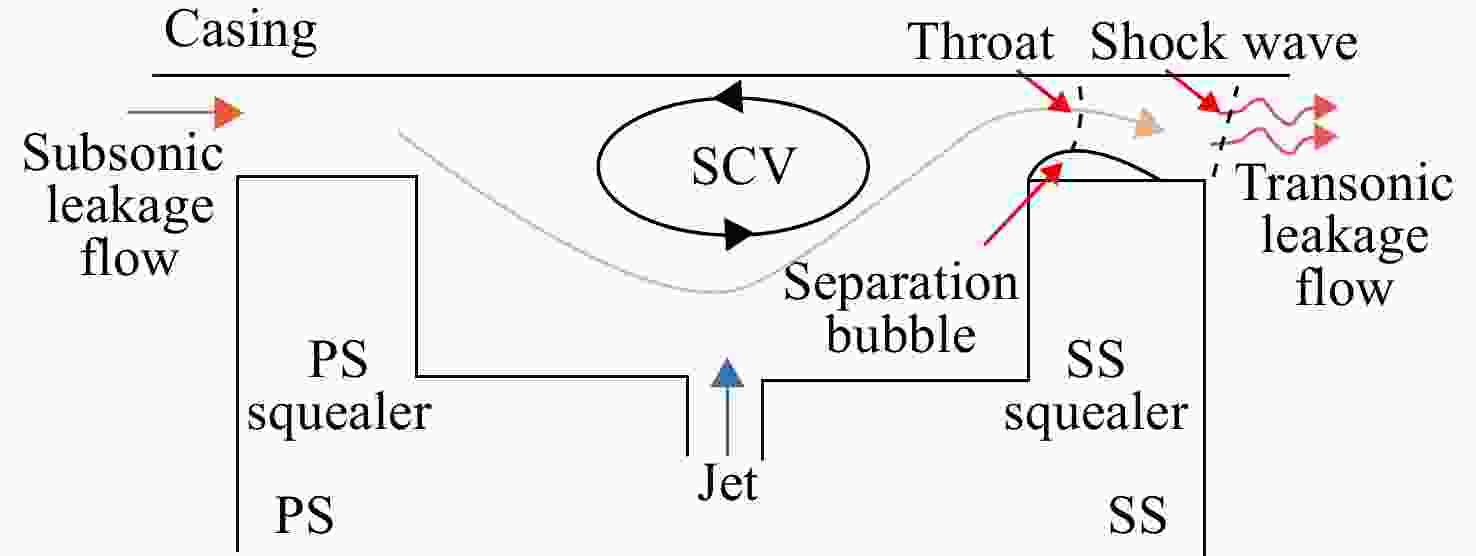

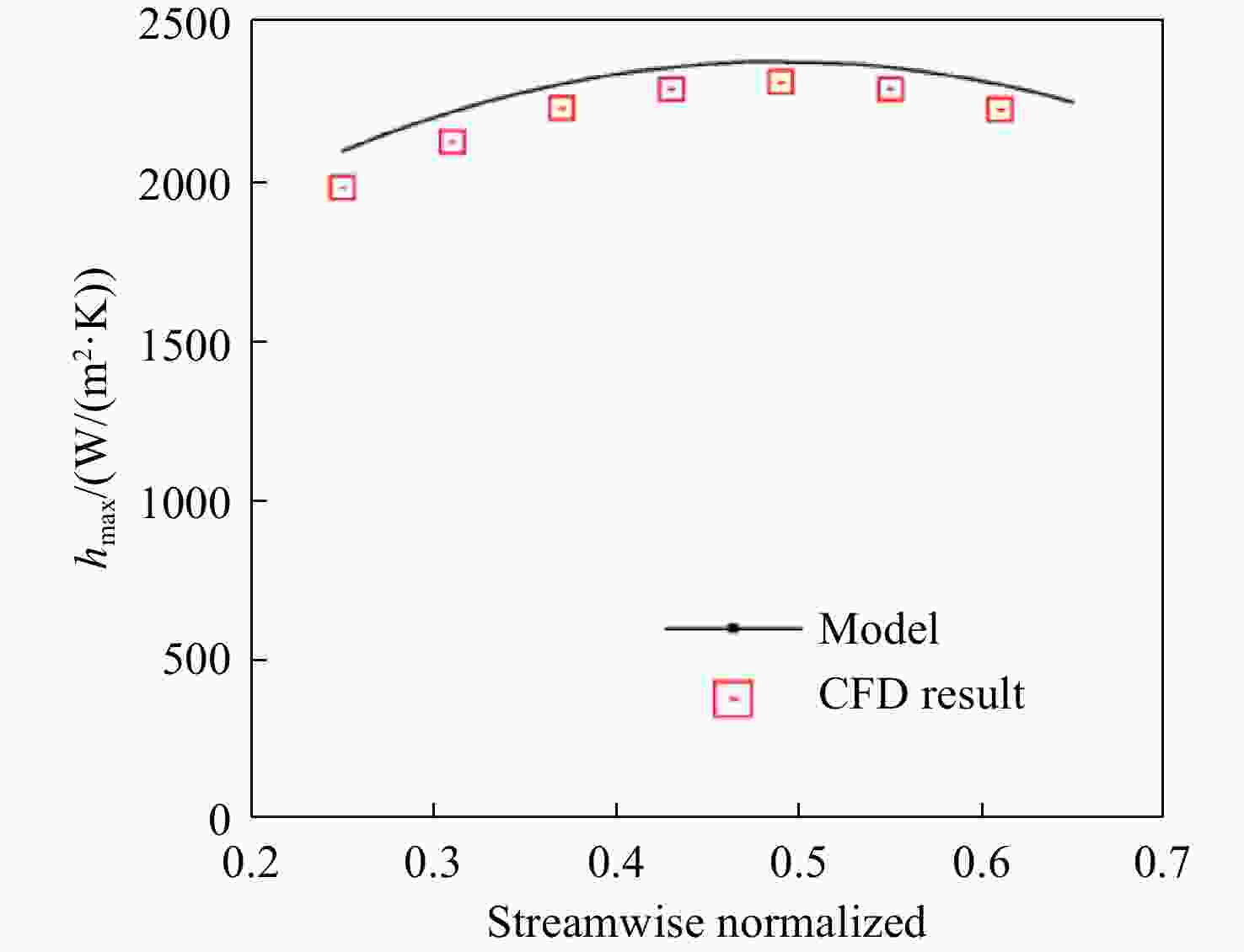

下载: