Experiment on shape and thickness of liquid film formed by impinging jets on solid walls

-

摘要:

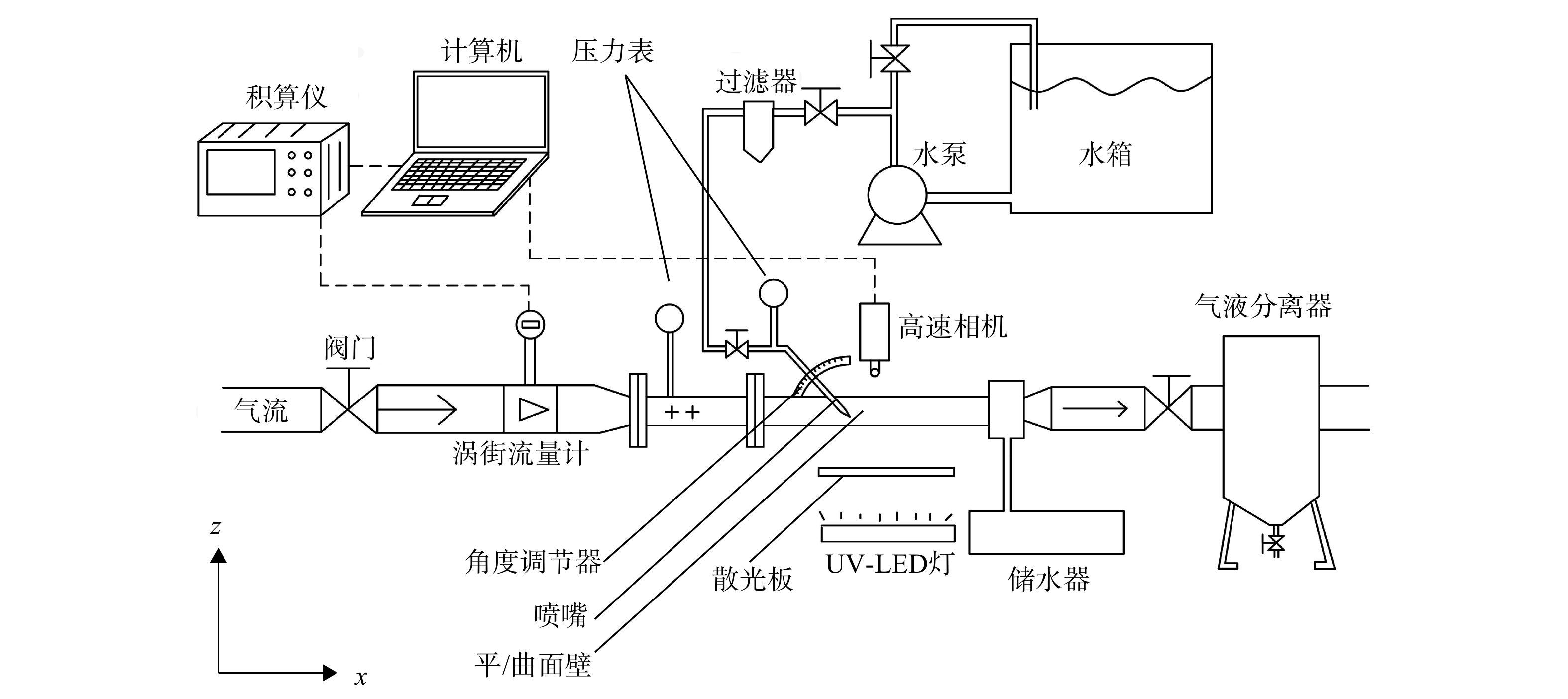

为了研究射流撞壁形成液膜的主要特征,采用基于紫外线发光二极管灯-诱导荧光法(UVLED-induced fluorescence,LEDIF)和高速相机的测试方法对液膜形状和厚度进行了实验研究。结果表明,曲面和平面液膜长度和宽度均随射流速度增加而增加。随着气流速度增加,平面和曲面液膜均长度增加,宽度都减小。随着壁面曲率半径的增加,液膜宽度稍有增加,而液膜长度增加较为明显。随着射流速度的增加,平面和曲面液膜厚度整体上都逐渐减小。而当射流速度进一步增加时,转捩现象开始出现,此时液膜厚度均会迅速增加。曲面液膜的转捩临界速度为19.10~25.08 m/s,而平面液膜转捩速度约为25.08~35.92 m/s。随着气流速度的增加,平面液膜厚度逐渐减小,而曲面液膜厚度在

x= 0~55 mm时随气流速度增加而增加,在x> 55 mm时随气流速度增加而减小。对不同的曲率半径,液膜厚度沿Ψ 1圆周方向呈“W”形,而随着曲率半径的增加,“W”逐渐变得扁平,但是位于中间(Ψ 1= 0°)的厚度基本不变。Abstract:In order to investigate the main characteristics of the liquid film formed by impinging jets on solid walls, the shape and thickness of the liquid film were investigated experimentally based on ultraviolet light emitting diode induced fluorescence (LEDIF)and a high-speed camera. The experiment results showed that the length and width of the liquid films on the curved wall and flat wall increased as the jet velocity increased. As the airflow velocity increased, the lengths of the liquid films on both the flat and curved walls increased, while the widths decreased. The width of the liquid film increased slightly, but the length of the liquid film increased obviously as the radius of curvature increased. The thickness of the liquid film on the flat and curved walls decreased gradually as the jet velocity increased. The transition occurred when the jet velocity reached the critical value, and the thickness of the liquid film increased rapidly. The critical velocity of the liquid film on the curved wall was 19.10—25.08 m/s, while that of the liquid film on the flat wall was 25.08—35.92 m/s, approximately. As the airflow velocity increased, the thickness of the liquid film on the flat wall decreased gradually, while the thickness of the liquid film on the curved wall increased when

x =0—55 mm, and decreased whenx >55 mm. For the different radius of curvature, the liquid film thickness had a shape of “W” along the circumferential directionΨ 1. And the “W” was flattened gradually as the radius of curvature increased, but the thickness in the middle (Ψ 1 =0°) was kept unchanged.-

Key words:

- jets impingement /

- liquid film /

- liquid film shape /

- liquid film thickness /

- curved wall

-

表 1 试验参数及工况表

Table 1. Experimental parameters and test conditions

序号 Uair/(m/s) U0/(m/s) R/mm 1 0 9.6 30, ∞ 2 0 13.2 30, ∞ 3 0 19.1 30, ∞ 4 0 25.08 30, ∞ 5 0 35.92 30, ∞ 6 10 13.2 30, ∞ 7 20 13.2 30, ∞ 8 30 13.2 30, ∞ 9 40 13.2 30, ∞ 10 50 13.2 30, ∞ 11 0 13.2 20 12 0 13.2 40 -

[1] MITRA S K,LI X,RENKSIZBULUT M. On the breakup of viscous liquid sheets by dual-mode linear analysis[J]. Journal of Propulsion and Power,2001,17(3): 728-735. [2] WANG Ruixiang,HUANG Yong,FENG Xiang,et al. Semi-empirical model for the engine liquid fuel sheet formed by the oblique jet impinging onto a plate[J]. Fuel,2018,233: 84-93. doi: 10.1016/j.fuel.2018.06.028 [3] SI Z,SHIMASAKI N,NISHIDA K,et al. Experimental study on impingement spray and near-field spray characteristics under high-pressure cross-flow conditions[J]. Fuel,2018,218: 12-22. doi: 10.1016/j.fuel.2018.01.011 [4] PETRUCHIK A I,SOLODUKHIN A D,FISENKO S P. Simulation of cooling of water droplet and film flows in large natural wet cooling towers[J]. Journal of Engineering Physics and Thermophysics,2001,74(1): 62-68. doi: 10.1023/A:1016673803772 [5] 王慧洁,许坤梅. 液体火箭发动机燃烧室壁液膜冷却的数值模拟[J]. 航空动力学报,2018,33(11): 2660-2668. doi: 10.13224/j.cnki.jasp.2018.11.012WANG Huijie,XU Kunmei. Numerical simulation of liquid film cooling for combustion chamber wall of liquid rocket engine[J]. Journal of Aerospace Power,2018,33(11): 2660-2668. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.11.012 [6] KUCERA J T,RUBIN L M,UWAI K,et al. Fabrication of nanometer smooth Bi2Sr2CaCu2O8+δ films by reac-tive cosputtering from elemental targets with pure ozone[J]. Physica C Superconductivity,1992,192(1/2): 23-30. [7] INOUE C, WATANABE T, HIMENO T. Study on atomization process of liquid sheet formed by impinging jets[R]. AIAA-2008-4847, 2008. [8] GRADECK M,KOUACHI A,LEBOUCHE M,et al. Boiling curves in relation to quenching of a high temperature moving surface with liquid jet impingement[J]. International Journal of Heat and Mass Transfer,2009,52(5/6): 1094-1104. [9] GUHA A,BARRON R M,BALACHANDAR R. An experimental and numerical study of water jet cleaning process[J]. Journal of Materials Processing Technology,2011,211(4): 610-618. doi: 10.1016/j.jmatprotec.2010.11.017 [10] FRASER N. A photographic investigation into the disintegration of liquid sheets[J]. Philosophical Transactions of the Royal Society of London,1954,247(924): 101-130. doi: 10.1098/rsta.1954.0014 [11] 林庆国,杨成虎,刘犇. 射流角度和壁面曲率对撞壁液膜的影响[J]. 国防科技大学学报,2013,35(2): 17-21.LIN Qingguo,YANG Chenghu,LIU Ben. Effect of impingement angle and wall curvature on liquid film[J]. Journal of National University of Defense Technology,2013,35(2): 17-21. (in Chinese) [12] 唐亮,胡锦华,刘计武,等. 倾斜射流撞壁实验研究及液膜几何参数建模[J]. 航空学报,2020,41(12): 1-10.TANG Liang,HU Jinhua,LIU Jiwu,et al. Experimental study on oblique jet wall impingement and geometrical parameter modeling of liquid film[J]. Acta Aeronautica et Astronautica Sinica,2020,41(12): 1-10. (in Chinese) [13] 唐亮,李平,周立新,等. 倾斜射流撞壁形成的液膜外形的理论建模[J]. 推进技术,2021,42(2): 327-334. doi: 10.13675/j.cnki.tjjs.190766TANG Liang,LI Ping,ZHOU Lixin,et al. Theoretical modeling of liquid sheet shape formed by oblique jet impinging onto wall[J]. Journal of Propulsion Technology,2021,42(2): 327-334. (in Chinese) doi: 10.13675/j.cnki.tjjs.190766 [14] GOOD R, NOLLET B. Fluid film distribution investigation for liquid film cooling application[C]// 53rd AIAA/SAE/ASEE Joint Propulsion Conference.Atlanta,US: AIAA, 2017: 1-6. [15] WILSON D I,LE B L,DAO H,et al. Surface flow and drainage films created by horizontal impinging liquid jets[J]. Chemical Engineering Science,2012,68(1): 449-460. doi: 10.1016/j.ces.2011.10.003 [16] WANG T,FARIA D,STEVENS L J,et al. Flow patterns and draining films created by horizontal and inclined co-herent water jets impinging on vertical walls[J]. Chemical Engineering Science,2013,102(1): 585-601. [17] KATE R P,DAS P K,CHAKRABORTY S. Hydraulic jumps due to oblique impingement of circular liquid jets on a flat horizontal surface[J]. Journal of Fluid Mechanics,2007,573: 247-263. doi: 10.1017/S0022112006003818 [18] TAYLOR G. Formation of thin flat sheets of water[J]. Proceedings of the Royal Society A,1960,259(1296): 1-17. [19] RANZ W E. Some experiments on the dynamics of liquid films[J]. Journal of Applied Physics,1959,30(12): 1950-1955. doi: 10.1063/1.1735095 [20] WATSON E J. The radial spread of a liquid jet over a horizontal plane[J]. Journal of Fluid Mechanics,2006,20(3): 481-499. [21] CHOO Y J,KANG B S. Parametric study on impinging-jet liquid sheet thickness distribution using an interfero-metric method[J]. Experiments in Fluids,2001,31(1): 56-62. doi: 10.1007/s003480000258 [22] INAMURA T,YANAOKA H,TOMODA T. Prediction of mean droplet size of sprays issued from wall impingement injector[J]. AIAA Journal,2004,38(3): 614-621. [23] INAMURA T,AMAGASAKI S,YANAOKA H. Thickness of liquid film formed by impinging jets on a concave wall[J]. Journal of Propulsion and Power,2007,23(3): 612-617. doi: 10.2514/1.27691 [24] GOREN S L. The instability of an annular thread of fluid[J]. Journal of Fluid Mechanics,1962,12(2): 309-319. doi: 10.1017/S002211206200021X [25] 何昌升,刘云鹏,韩宗英,等. 平板式预膜喷嘴初次雾化特性试验[J]. 航空动力学报,2020,35(3): 482-492.HE Changsheng,LIU Yunpeng,HAN Zongying,et al. Experiment on primary atomization characteristics of planar prefilming nozzle[J]. Journal of Aerospace Power,2020,35(3): 482-492. (in Chinese) [26] AZUMA T,HOSHINO T. The radial flow of a thin liquid film: 2nd report, liquid film thickness[J]. Bulletin of JSME,1984,27(234): 2763-2770. doi: 10.1299/jsme1958.27.2763 -

下载:

下载: