One-dimensional analysis of unsteady temperature measurement error characteristics of thermocouple

-

摘要:

为揭示热电偶非稳态测温误差的影响机制,建立了热电偶测温一维非稳态计算模型,综合评估了不同安装结构、黏合材料和表面传热系数工况对热电偶非稳态测温误差的影响,深入探究了毕渥数对非稳态测温的影响规律。研究结果表明:考虑环境辐射是必要的,与不考虑辐射传热相比测温时间300 s时的温度相差1.48 K。不同的安装方式对测温误差的影响较大,最大测量温差1.85 K。黏合材料的导热系数越大,正规状况阶段非稳态测温误差越小,测温时间150 s后绝对误差小于0.5 K。表面传热系数对非稳态测温误差起着重要的影响,表面传热系数越大,受初始温度场影响的测温误差越大。黏合材料导热系数为2.4 W/(m·K)时,表面传热系数为50~250 W/(m2·K)的范围内测温误差的变化范围为0.2~1.5 K。研究结果为发动机传热实验中壁温非稳态测量提供了参考。

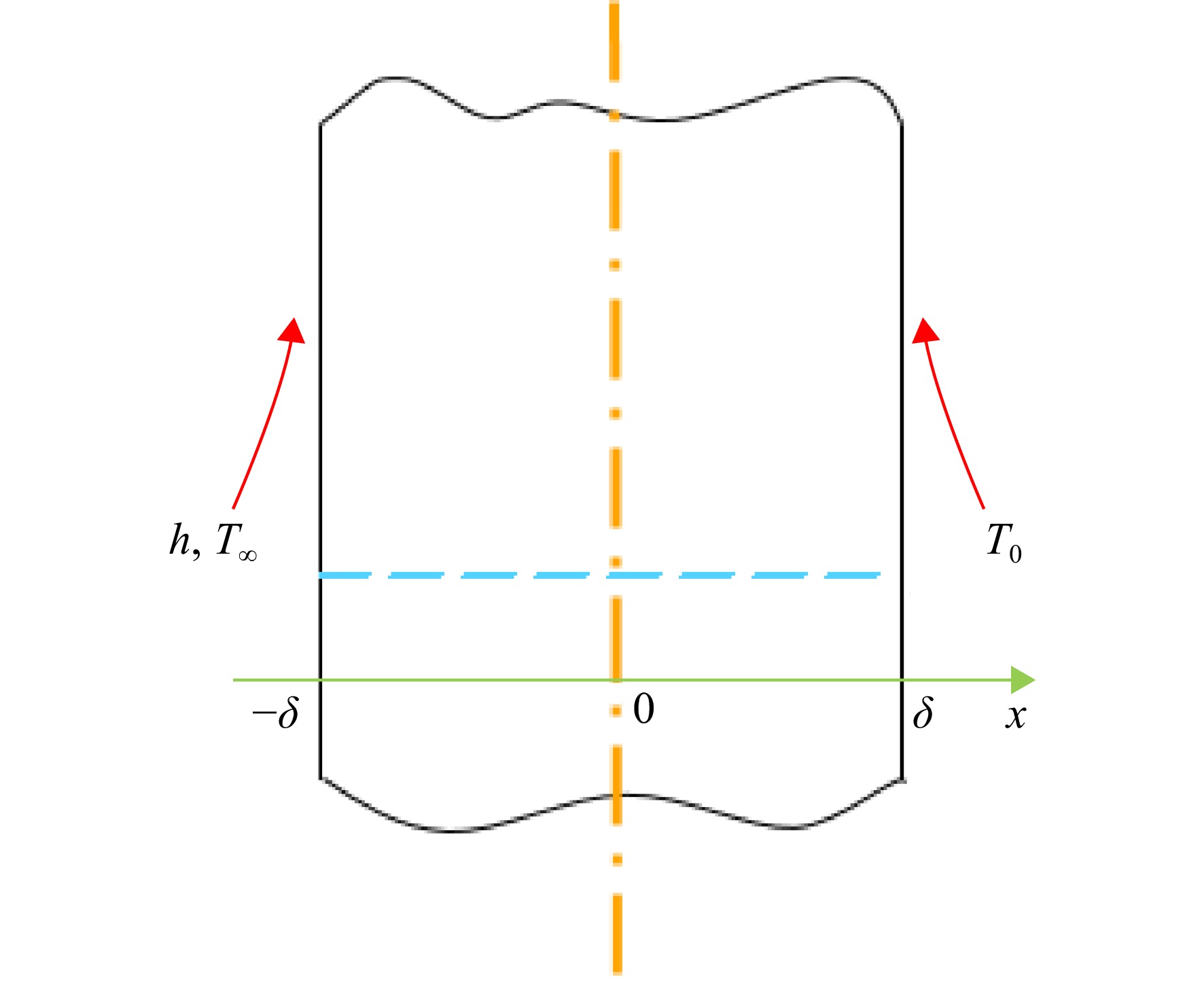

Abstract:To reveal the influence mechanism of temperature measurement error of thermocouple under unsteady operating conditions, one-dimensional unsteady calculation model of temperature measurement of thermocouple was established. A comprehensive evaluation was conducted to reveal the influence of different installation structures, bonding materials and surface heat transfer coefficient conditions on the unsteady temperature measurement error for the thermocouple. The influence of Biot number on unsteady temperature measurement was further explored. Results showed that it is necessary to consider environmental radiation effect. Temperature error was 1.48 K at 300 s temperature measurement time compared with that without consideration of environmental radiation effect. Different installation structures of thermocouple had a greater impact on the temperature measurement error, with a maximum measurement temperature difference of 1.85 K. Moreover, the greater thermal conductivity of the bonding material indicated, the smaller temperature measurement error in the stage of unsteady regular status, and the absolute error was less than 0.5 K after 150 s temperature measurement time. Especially, the surface heat transfer coefficient played an important role in the unsteady temperature measurement error. The larger surface heat transfer coefficient indicated the greater temperature measurement error due to initial temperature field. When the thermal conductivity of bonding material was 2.4 W/(m·K), the variation range of temperature measurement error within the surface heat transfer coefficient range of 50−250 W/(m2·K) was 0.2−0.5 K. Therefore, the research results can provide a reference for the unsteady measurement of wall temperature in the heat transfer experiments of aero-engine.

-

表 1 热电偶测温一维计算模型的初边值条件

Table 1. Initial and boundary conditions of one-dimensional calculation model for thermocouple temperature measurement

参数 数值 热流体温度/K 330 平板初始温度/K 300 表面传热系数/(W/(m2·K)) 50~250 黏合材料的导热系数/(W/(m·K)) 0.05~3.2 总传热时间/s 300 -

[1] BASHA M,SHAAHID S M,AL-HADHRAMI L. Impact of inlet fogging and fuels on power and efficiency of gas turbine plants[J]. Thermal Science,2013,17(4): 1107-1117. doi: 10.2298/TSCI110708042B [2] SOUSA J,VILLAFAÑE L,PANIAGUA G. Thermal analysis and modeling of surface heat exchangers operating in the transonic regime[J]. Energy,2014,64: 961-969. doi: 10.1016/j.energy.2013.11.032 [3] CHANDRASEKARAN N,GUHA A. Development and optimization of a sustainable turbofan aeroengine for improved performance and emissions[J]. Proceedings of the Institution of Mechanical Engineers: Part G Journal of Aerospace Engineering,2013,227(11): 1701-1719. doi: 10.1177/0954410012462183 [4] 杨灿,吴伟力,熊义彬,等. 航空发动机燃烧室出口高温热电偶校准技术[J]. 航空动力学报,2016,31(4): 769-774. doi: 10.13224/j.cnki.jasp.2016.04.001YANG Can,WU Weili,XIONG Yibin,et al. Calibration technology of high-temperature thermocouple for combustor exit of an aero-engine[J]. Journal of Aerospace Power,2016,31(4): 769-774. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.04.001 [5] ZOU Zhengping,YANG Weiping,ZHANG Weihao,et al. Numerical modeling of steady state errors for shielded thermocouples based on conjugate heat transfer analysis[J]. International Journal of Heat and Mass Transfer,2018,119: 624-639. doi: 10.1016/j.ijheatmasstransfer.2017.11.034 [6] JHAJJ K S, CARON E F J R, CHESTER N L, et al. Accuracy of thermocouples in transient surface temperature measurements dominated by radiant heating[R]. ASME Paper IMECE2014-38243, 2014. [7] TSZENG T C,SARAF V. A study of fin effects in the measurement of temperature using surface-mounted thermocouples[J]. Journal of Heat Transfer,2003,125(5): 926-935. doi: 10.1115/1.1597622 [8] WOODBURY K A,GUPTA A. A simple 1D sensor model to account for deterministic thermocouple errors (bias) in the solution of the inverse heat conduction problem[J]. Inverse Problems in Science and Engineering,2008,16(1): 21-37. doi: 10.1080/17415970701198241 [9] PARK J E, CHILDS KW, LUDTKA G M, et al. Correction of errors in intrinsic thermocouple signals recorded during quenching [C]//National Heat Transfer Conference. Minneapolis, US: University of Minnesota System, 1991: 28-31. [10] VAŹQUEZ R, SAŃCHEZ J M. Temperature measurement system for low pressure ratio turbine testing[C]//Proceedings of ASME Turbo Expo 2003 Power for Land, Sea, and Air. Atlanta, Georgia, US: ASME, 2003: 6–19. [11] STRAUBINGER D, ILLÉS B, BERÉNYI R, et al. Simulation of reflow-based heat transfer on different thermocouple constructions[C]//2020 43rd International Spring Seminar on Electronics Technology. Piscataway, US: IEEE, 2020: 1-6. [12] 杨伟平,张伟昊,邹正平,等. 屏蔽式总温热电偶的稳态误差分析及改型设计[J]. 航空动力学报,2018,33(11): 2784-2795. doi: 10.13224/j.cnki.jasp.2018.11.025YANG Weiping,ZHANG Weihao,ZOU Zhengping,et al. Steady state error estimation and modification of a shielded thermocouple[J]. Journal of Aerospace Power,2018,33(11): 2784-2795. (in Chinese) doi: 10.13224/j.cnki.jasp.2018.11.025 [13] 白杰,陈昭,王伟. 热电偶温度测量的误差及影响因素分析[J]. 机床与液压,2017,45(22): 138-141, 183. doi: 10.3969/j.issn.1001-3881.2017.22.036BAI Jie,CHEN Zhao,WANG Wei. Error and influence factor analysis of thermocouple temperature measurement[J]. Machine Tool & Hydraulics,2017,45(22): 138-141, 183. (in Chinese) doi: 10.3969/j.issn.1001-3881.2017.22.036 [14] 李伟. 热电偶测温误差的来源与处理[C]//第十八届中国航空测控技术年会论文集. 青岛: 中国航空工业技术装备工程协会, 2021: 256-259. [15] GRECH A, SANT T, FARRUGIA M. The effects of thermocouple materials and insulating mica in an erodable surface thermocouple[C]// Proceedings of 2008 ASME Summer Heat Transfer Conference. Jacksonville, US: ASME, 2008: 10-14. [16] POPE I,HIDALGO J P,HADDEN R M,et al. A simplified correction method for thermocouple disturbance errors in solids[J]. International Journal of Thermal Sciences,2022,172: 107324. doi: 10.1016/j.ijthermalsci.2021.107324 [17] HAGER N E Jr. Thermocouple probe for surface-temperature measurement[J]. Review of Scientific Instruments,1985,56(3): 421-426. doi: 10.1063/1.1138316 [18] TAN G E, CARTE C, FAN Yuehong. Thermocouple attachment methodology for memory[C]//2021 20th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm). Piscataway, US: IEEE, 2021: 1150-1153. [19] 陈龙,陈跃飞,杨子锷,等. 热电偶测量误差及其注意事项[J]. 计量与测试技术,2017,44(2): 43-46. doi: 10.15988/j.cnki.1004-6941.2017.02.021CHEN Long,CHEN Yuefei,YANG Zie,et al. Thermocouple measurement error and its matters needing attention[J]. Metrology & Measurement Technique,2017,44(2): 43-46. (in Chinese) doi: 10.15988/j.cnki.1004-6941.2017.02.021 [20] 孙昊博,毛晓奇,朱传龙. 航空发动机热电偶传感器稳态测温偏差分析[J]. 航空动力学报,2022,37(9): 2009-2016. doi: 10.13224/j.cnki.jasp.20210417SUN Haobo,MAO Xiaoqi,ZHU Chuanlong. Analysis of steady-state temperature measurement deviation of thermocouple sensors on aeroengine[J]. Journal of Aerospace Power,2022,37(9): 2009-2016. (in Chinese) doi: 10.13224/j.cnki.jasp.20210417 [21] 杨兆欣,曾星,张文清. 气体介质条件下的热电偶动态特性[J]. 航空动力学报,2020,35(12): 2514-2520. doi: 10.13224/j.cnki.jasp.2020.12.005YANG Zhaoxin,ZENG Xing,ZHANG Wenqing. Dynamic characteristics of thermocouple in gas medium[J]. Journal of Aerospace Power,2020,35(12): 2514-2520. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.12.005 [22] 季江华,石坤田,黄波. 热电偶冷热端动态特性对测温精度影响研究[J]. 科学技术创新,2018(20): 58-59. doi: 10.3969/j.issn.1673-1328.2018.20.037JI Jianghua,SHI Kuntian,HUANG Bo. Study on the influence of dynamic characteristics of thermocouple cold and hot ends on temperature measurement accuracy[J]. Scientific and Technological Innovation,2018(20): 58-59. (in Chinese) doi: 10.3969/j.issn.1673-1328.2018.20.037 [23] 季念,马朝臣. 一种屏蔽式总温探头设计及其测量误差估计[J]. 航空动力学报,2023,38(7): 1749-1761. doi: 10.13224/j.cnki.jasp.20210620JI Nian,MA Chaochen. Design and measurement error estimation of a shielded total temperature probe[J]. Journal of Aerospace Power,2023,38(7): 1749-1761. (in Chinese) doi: 10.13224/j.cnki.jasp.20210620 [24] 韩省思, 毛军逵. 热电偶埋设方式对测温精度的影响研究[C]//中国航天第三专业信息网第四十届技术交流会暨第四届空天动力联合会议论文集: S07发动机热管理相关技术. 昆明: 中国航天第三专业信息网, 2019: 141-152. [25] 杜冠廷. 热电偶测量表面温升的误差和优化研究[D]. 广州: 华南理工大学, 2023.DU Guanting. Research on error and optimization of thermocouple measuring surface temperature rise[D]. Guangzhou: South China University of Technology, 2023. (in Chinese) [26] 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006. [27] 曹玉璋, 邱绪光. 实验传热学[M]. 北京: 国防工业出版社, 1998. -

下载:

下载: