Effect of end-clearance sealed structure of guide vane on variable nozzle turbine performance

-

摘要:

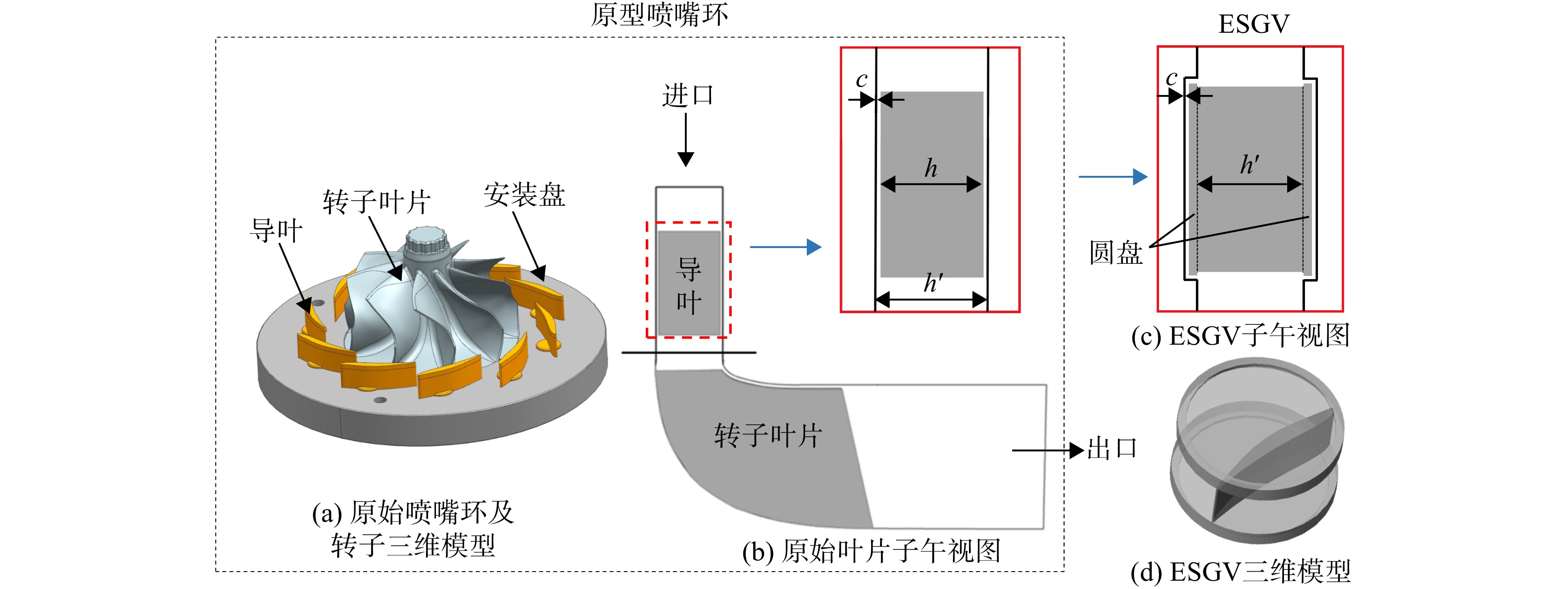

基于传统可调涡轮导叶,设计了一种带有端隙密封结构的喷嘴环导叶(end-clearance sealed guide vane, ESGV)。在导叶不同开度下,对ESGV可调涡轮进行数值模拟,分析了ESGV对可调涡轮性能的影响,结果表明:ESGV可以有效的抑制导叶端隙泄漏流,能够明显改善喷嘴环和转子通道的流动状态,进而提高涡轮效率。对ESGV可调涡轮和原始涡轮进行涡轮特性试验,结果显示:两型涡轮流量特性大致相同时,在导叶中开度下,ESGV涡轮效率较原始涡轮提高了5%,验证了ESGV方案的有效性。

-

关键词:

- 带有端隙密封结构的喷嘴环导叶(ESGV) /

- 可调径向涡轮 /

- 间隙泄漏流 /

- 涡轮性能 /

- 泄漏损失

Abstract:Based on the traditional variable nozzle turbine guide vane, an end-clearance sealed guide vane (ESGV) was designed. The effect of ESGV on the performance of the turbine was analyzed by numerical simulation under different guide openings. The results showed that ESGV can effectively suppress the end-wall clearance leakage flow of the guide vane and improve the flow state of nozzle ring and rotor channel, and then enhance the turbine efficiency. Finally, the turbine performance tests of the ESGV turbine and the prototype turbine were carried out. The results showed that, when the flow characteristic curves of the two turbines were roughly the same, the efficiency of the ESGV turbine was 5% higher than that of the prototype turbine at the medium opening.

-

表 1 原始导叶与ESGV主要参数

Table 1. Main parameters for the original guide vane and ESGV

参数 数值 参数 数值 原始导叶 叶片数量 10 ESGV 叶高/mm 6.77 轮缘面端面间隙/mm 0.15 圆盘直径/mm 19.8 轮毂面端面间隙/mm 0.15 圆盘厚度/mm 2 弦长/mm 19 圆盘凹槽直径/mm 17.8 导叶高度/mm 6.47 圆盘凹槽深度/mm 0.5 表 2 网格信息

Table 2. Mesh quality information

模型 节点数 延展比 正交比 长宽比 转子 688848 2.81 18.5 462 导叶 406386 2.08 31.8 242 圆盘 436810 10.7 38.1 825 -

[1] DASGUPTA S,SARMAH P,BORTHAKUR P P. Application of variable geometry turbine turbochargers to gasoline engines-A review[J]. IOP Conference Series: Materials Science and Engineering,2020,943(1): 012010.1-012010.15. [2] FENELEY A J,PESIRIDIS A,ANDWARI A M. Variable geometry turbocharger technology for exhaust energy recovery and boosting-a review[J]. Renewable and Sustainable Energy Reviews,2017,71: 959-975. doi: 10.1016/j.rser.2016.12.125 [3] MA Chaochen,HUANG Zhi,QI Mingxu. Investigation on the forced response of a radial turbine under aerodynamic excitations[J]. Journal of Thermal Science,2016,25(2): 130-137. doi: 10.1007/s11630-016-0843-1 [4] CHITRAKAR S,NEOPANE H P,DAHLHAUG O G. The numerical and experimental investigation of erosion induced leakage flow through guide vanes of Francis turbine[J]. IOP Conference Series:Earth and Environmental Science,2019,240: 072002.1-072002.10. [5] 赵奔,马朝臣,胡良军,等. 导叶间隙不确定性对可调向心涡轮影响数值研究[J]. 推进技术,2014,35(4): 492-498. doi: 10.13675/j.cnki.tjjs.2014.03.003ZHAO Ben,MA Chaochen,HU Liangjun,et al. Numerical investigation on effects of uncertain nozzle vane clearance on variable geometry radial turbine performance[J]. Journal of Propulsion Technology,2014,35(4): 492-498. (in Chinese) doi: 10.13675/j.cnki.tjjs.2014.03.003 [6] ZHAO Ben,WANG Leilei,HOU Hongjun. Numerical analysis for impacts of nozzle end-clearances on aerodynamic performance and forced response in a VNT turbine[J]. Chinese Journal of Aeronautics,2018,31(5): 1030-1040. doi: 10.1016/j.cja.2018.02.015 [7] ZHONG Fangpan,ZHOU Chao. Effects of tip gap size on the aerodynamic performance of a cavity-winglet tip in a turbine cascade[J]. Journal of Turbomachinery,2017,139(10): 101009.1-101009.9. [8] FU Yunfeng,CHEN Fu,LIU Huaping,et al. Experimental and numerical study of honeycomb tip on suppressing tip leakage flow in turbine cascade[J]. Journal of Turbomachinery,2018,140(6): 061006.1-061006.10. [9] LI Jun,DU Kun,SONG Liming. Effects of tip cavity geometries on the aerothermal performance of the transonic turbine blade with cavity tip[J]. Proceedings of the Institution of Mechanical Engineers:Part A Journal of Power and Energy,2016,230(3): 319-331. doi: 10.1177/0957650915626833 [10] MARAL H,ALPMAN E,KAVURMACıOĞLU L,et al. A genetic algorithm based aerothermal optimization of tip carving for an axial turbine blade[J]. International Journal of Heat and Mass Transfer,2019,143: 118419.1-118419.13. [11] GAO Jie,WEI Ming,LIU Pengfei,et al. Improved clearance designs to minimize aerodynamic losses in a variable geometry turbine vane cascade[J]. Proceedings of the Institution of Mechanical Engineers: Part C Journal of Mechanical Engineering Science,2018,232(17): 3085-3101. doi: 10.1177/0954406217729716 [12] LIM B, PARK T, KANG Y S. Stall warning using the rotor tip pressure in a transonic axial compressor with circumferential grooves[R]. ASME Paper GT2018-76301, 2018. [13] ALONE D B, KUMAR S S, THIMMAIAH S, et al. Experimental investigation on the effect of porosity of bend skewed casing treatment on a single stage transonic axial flow compressor[R]. ASME Paper GT2014-26102, 2014 [14] ZHANG Qianfeng,DU Juan,LI Jichao,et al. Dual stability enhancement mechanisms of axial-slot casing treatment in a high-speed mixed-flow compressor with various tip clearances[J]. Chinese Journal of Aeronautics,2021,34(4): 19-31. doi: 10.1016/j.cja.2020.08.019 [15] YANG D, LAO D, YANG C, et al. Investigations on the generation and weakening of shock wave in a radial turbine with variable guide vanes[R]. ASME Paper GT2016-57047, 2016. [16] 侯红娟,王磊磊,李延昭. 可调向心涡轮导叶叶顶间隙及其调节方法的研究[J]. 海峡科技与产业,2017(4): 99-100. doi: 10.3969/j.issn.1006-3013.2017.04.036HOU Hongjuan,WANG Leilei,LI Yanzhao. Study on tip clearance of adjustable centripetal turbine guide vane and its adjustment method[J]. Technology and Industry Across the Straits,2017(4): 99-100. (in Chinese) doi: 10.3969/j.issn.1006-3013.2017.04.036 [17] WANG Zhihui,MA Chaochen,HUANG Zhi,et al. A novel variable geometry turbine achieved by elastically restrained nozzle guide vanes[J]. Proceedings of the Institution of Mechanical Engineers: Part D Journal of Automobile Engineering,2020,234(9): 2312-2329. doi: 10.1177/0954407020909662 [18] 黄文梅. 气动位置控制系统的状态反馈调节[J]. 湖南大学学报(自然科学版),1990,17(1): 11-18.HUANG Wenmei. State varable feedback control for pneumatical positioning systems[J]. Journal of Hunan University (Natural Science),1990,17(1): 11-18. (in Chinese) -

下载:

下载: