Surge identification of a turboshaft engine based on sound pressure signal

-

摘要:

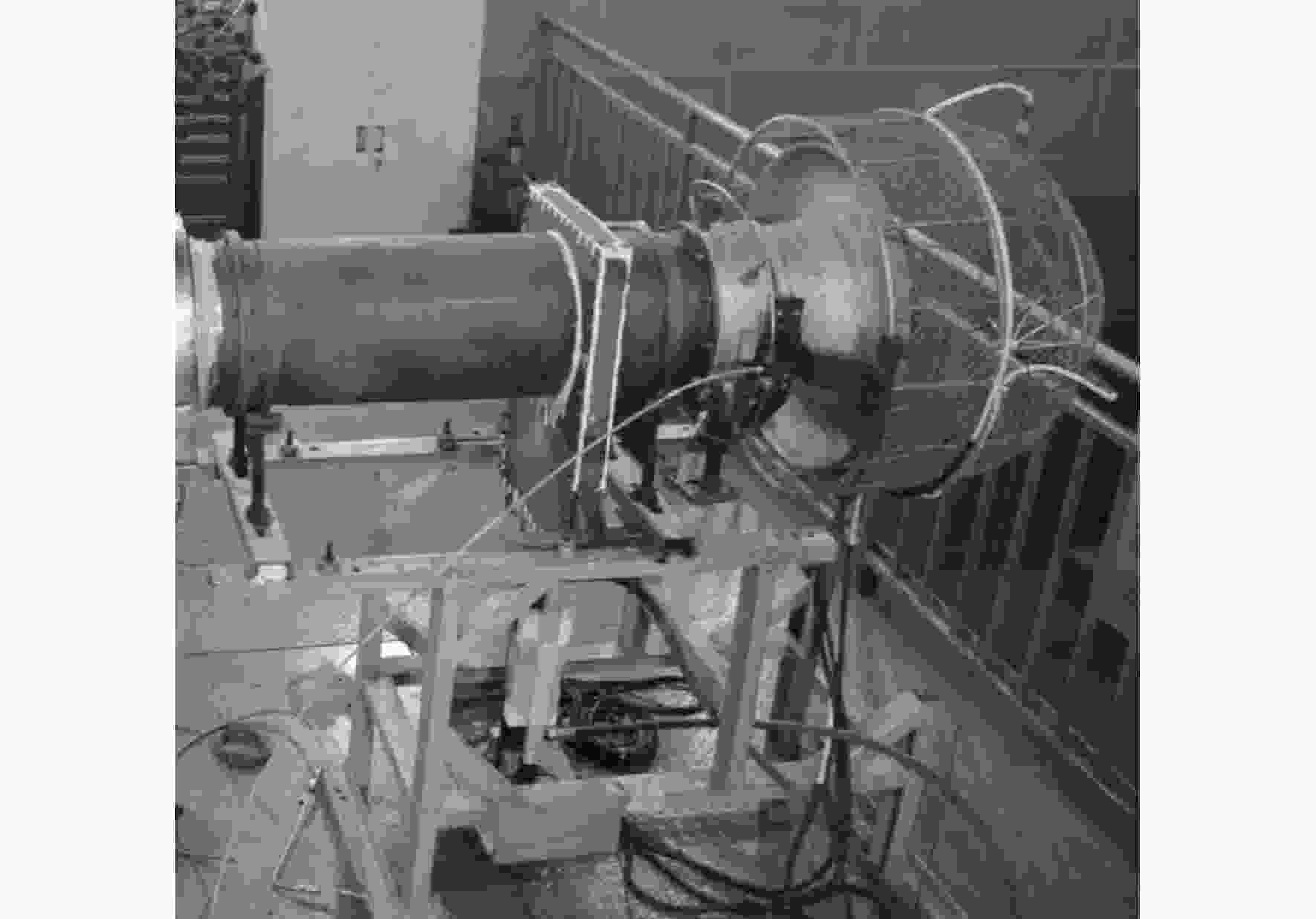

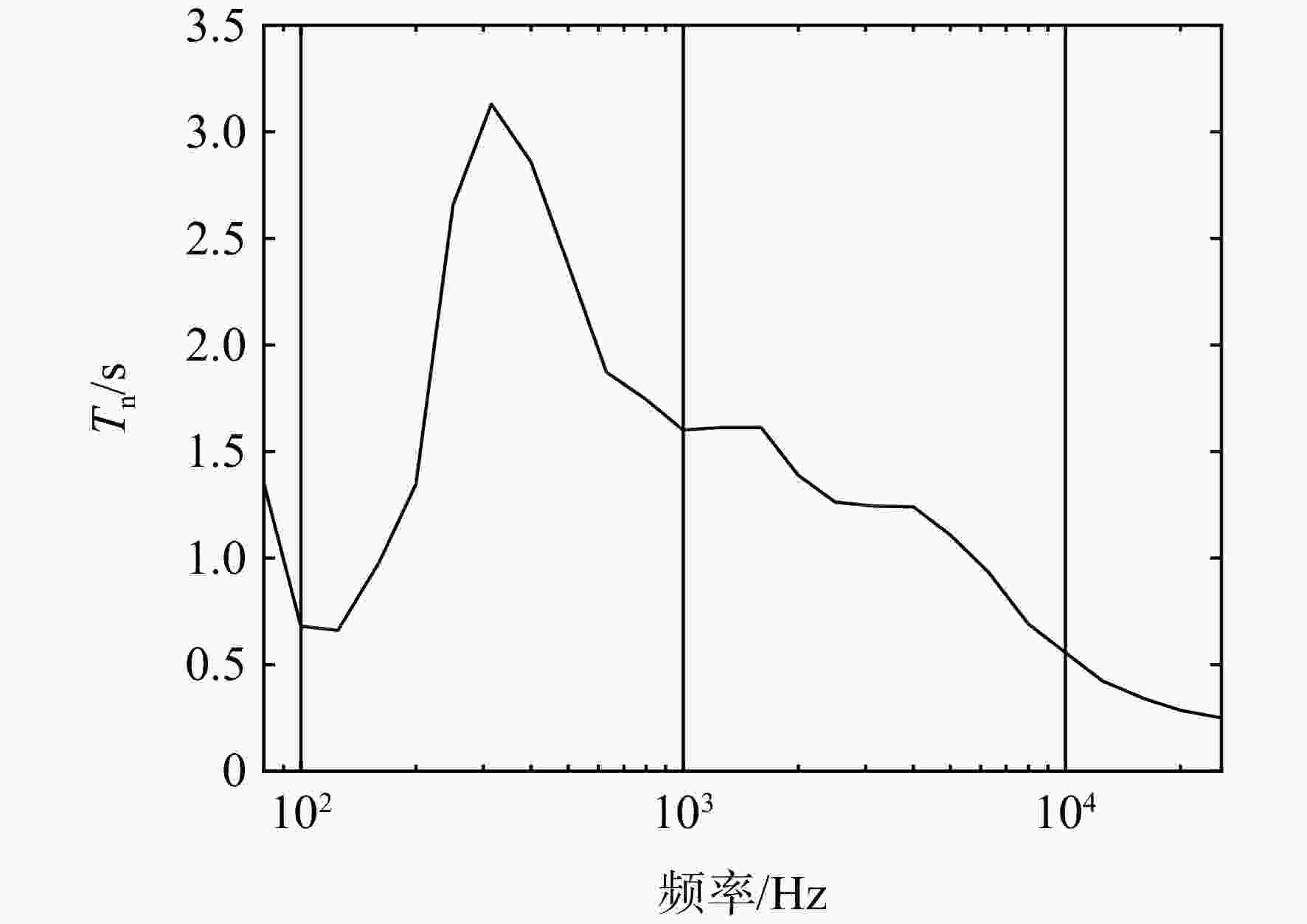

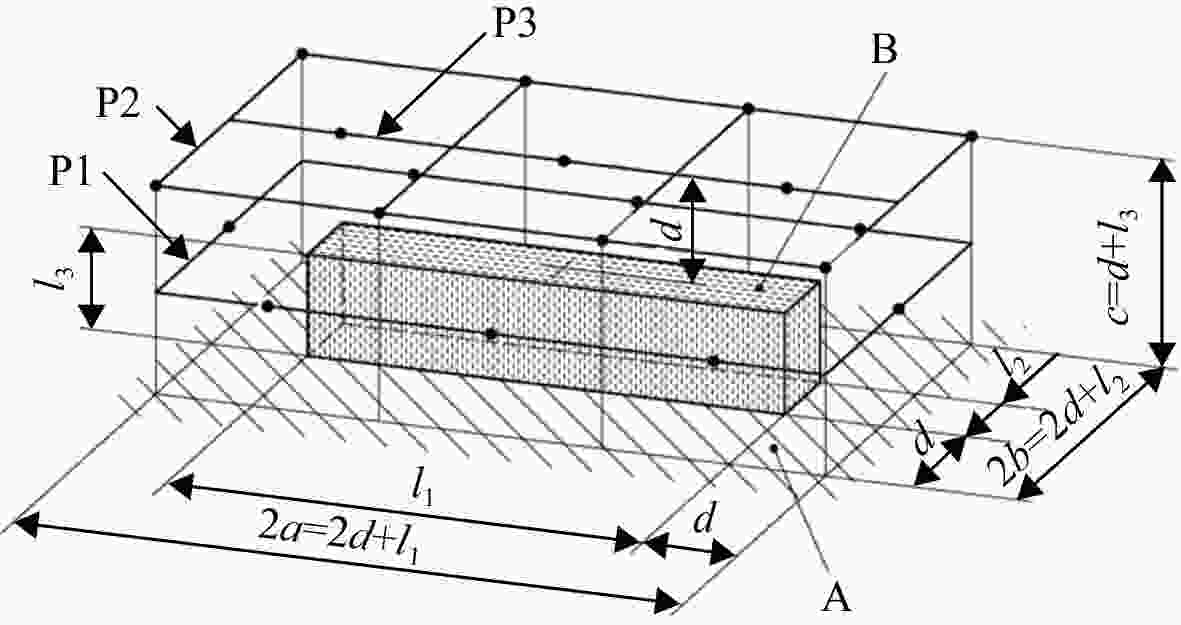

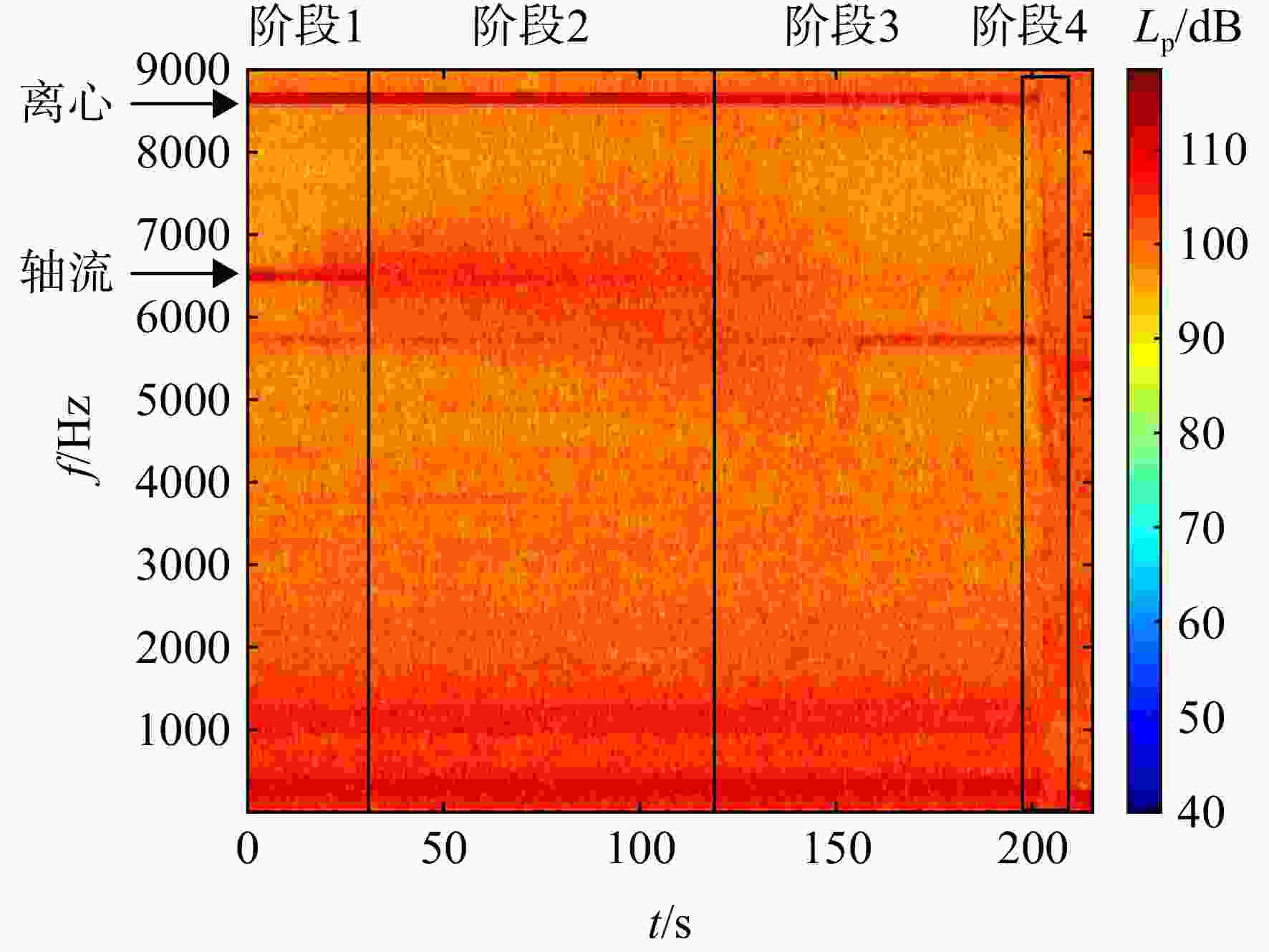

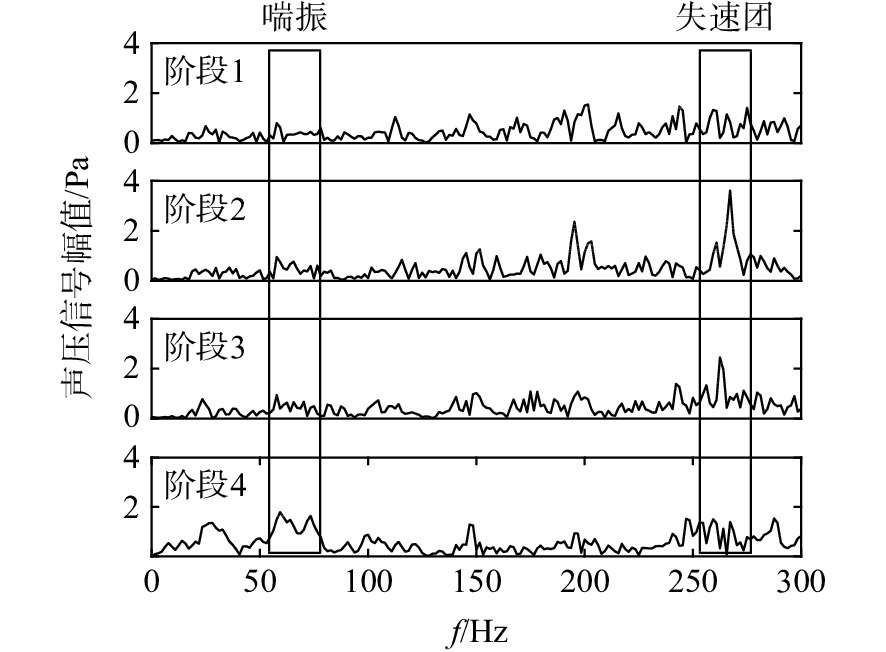

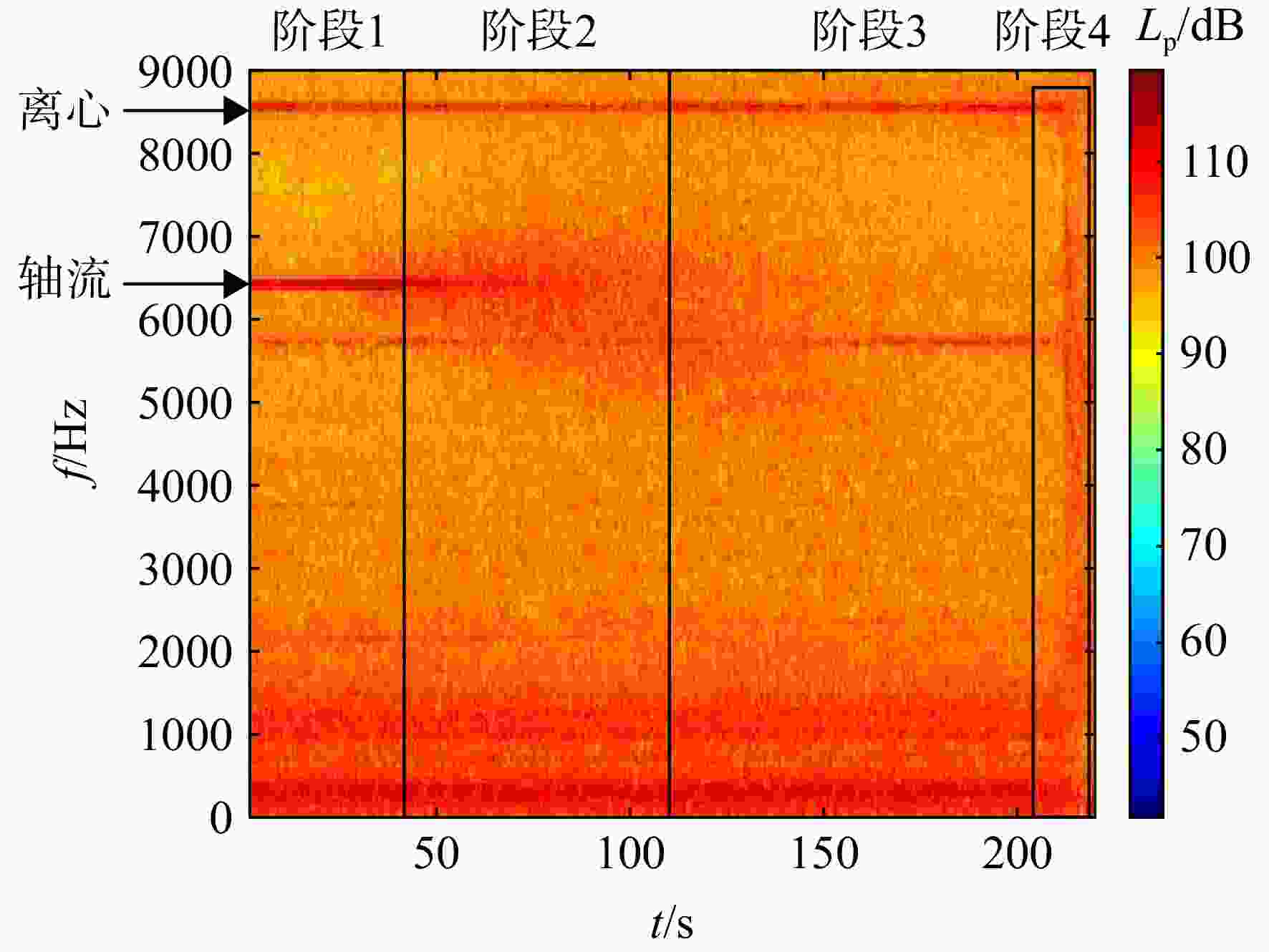

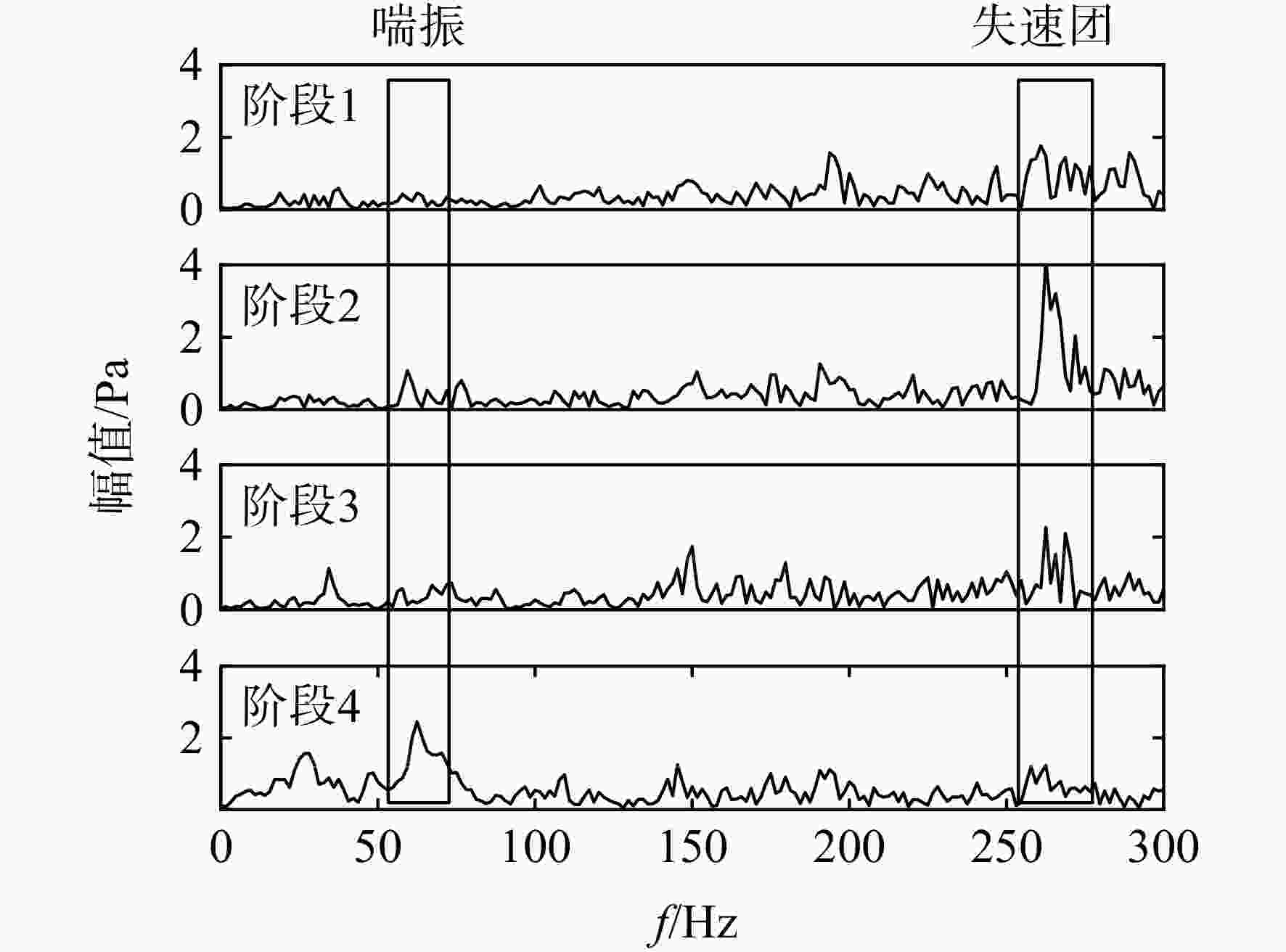

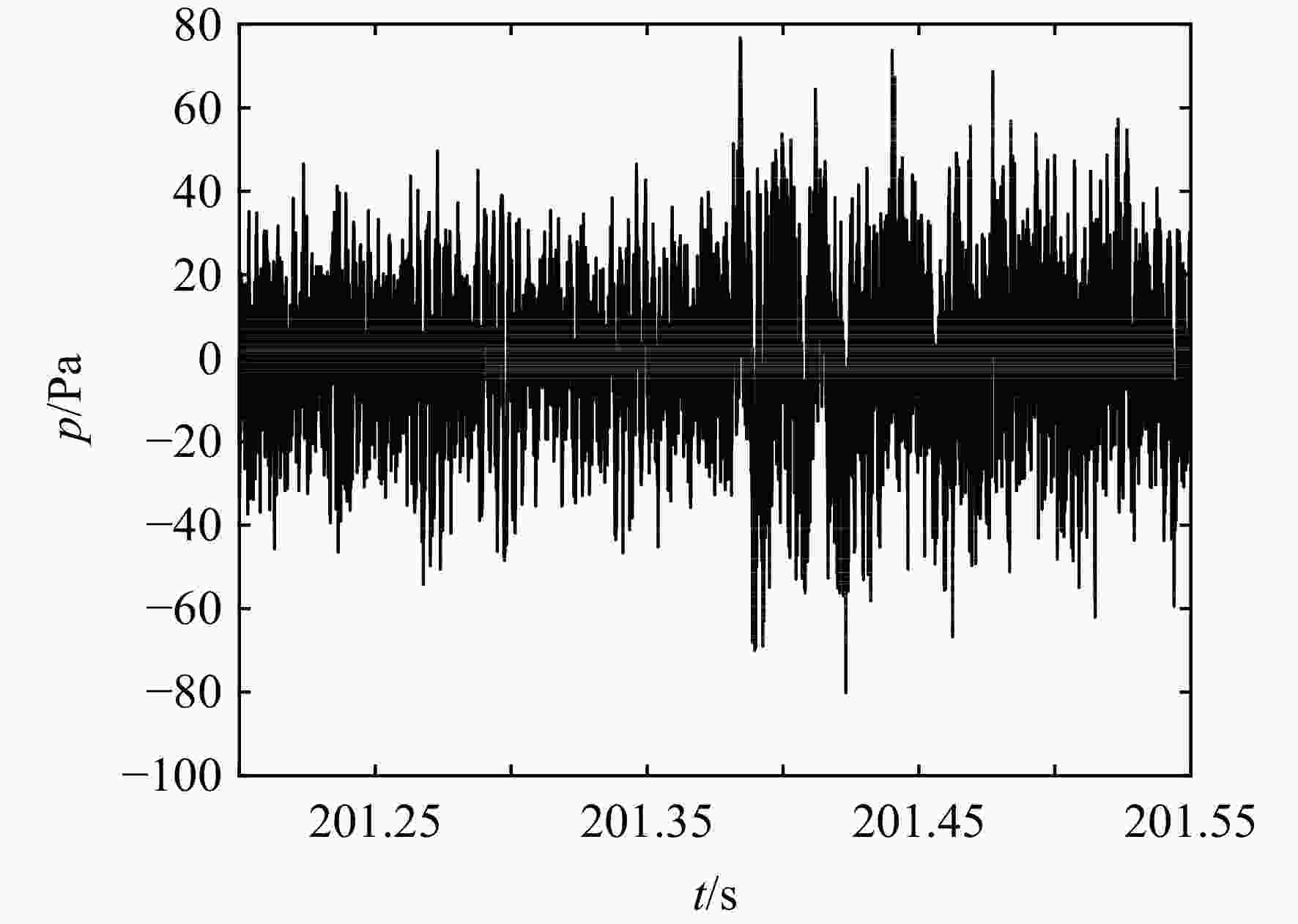

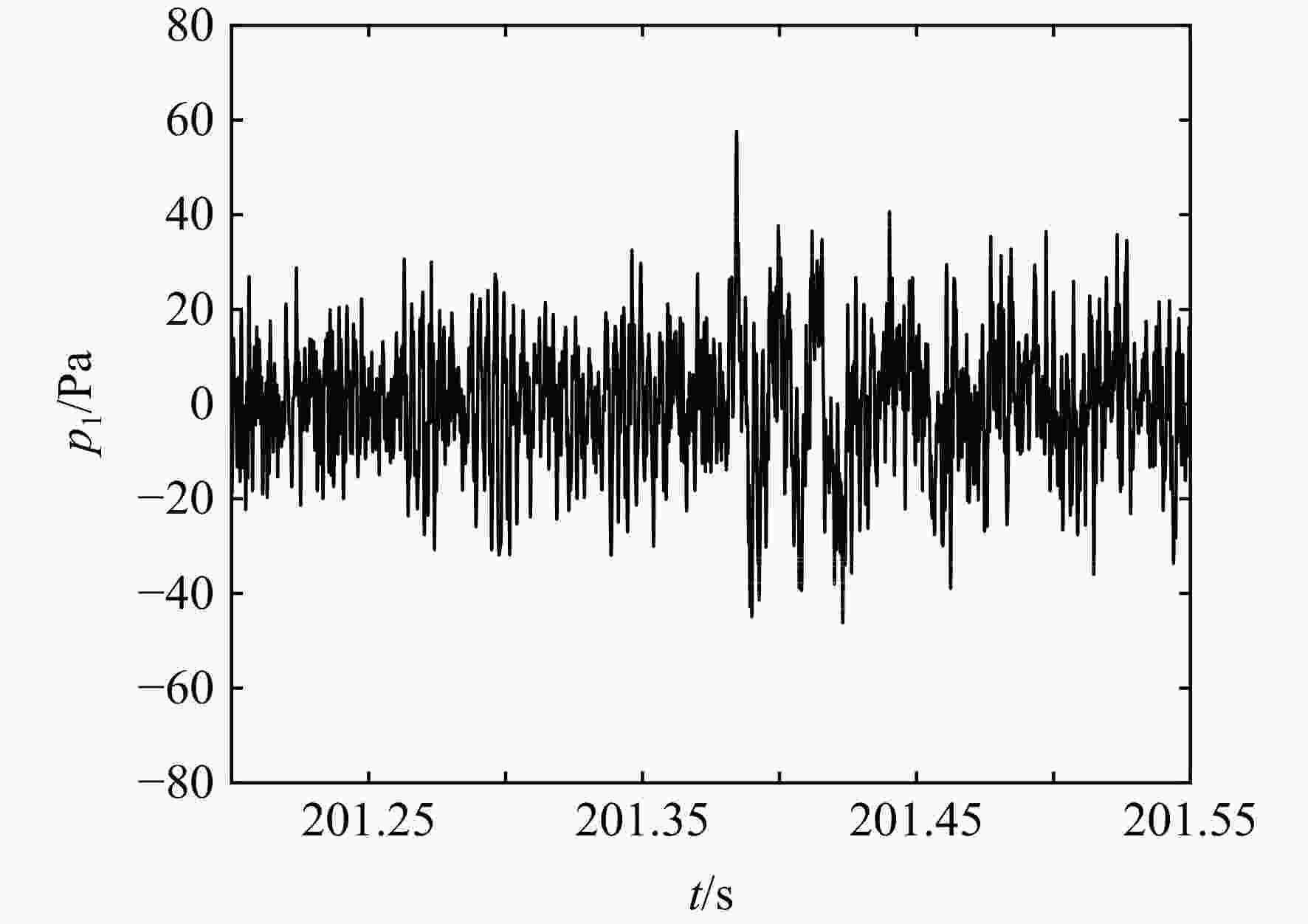

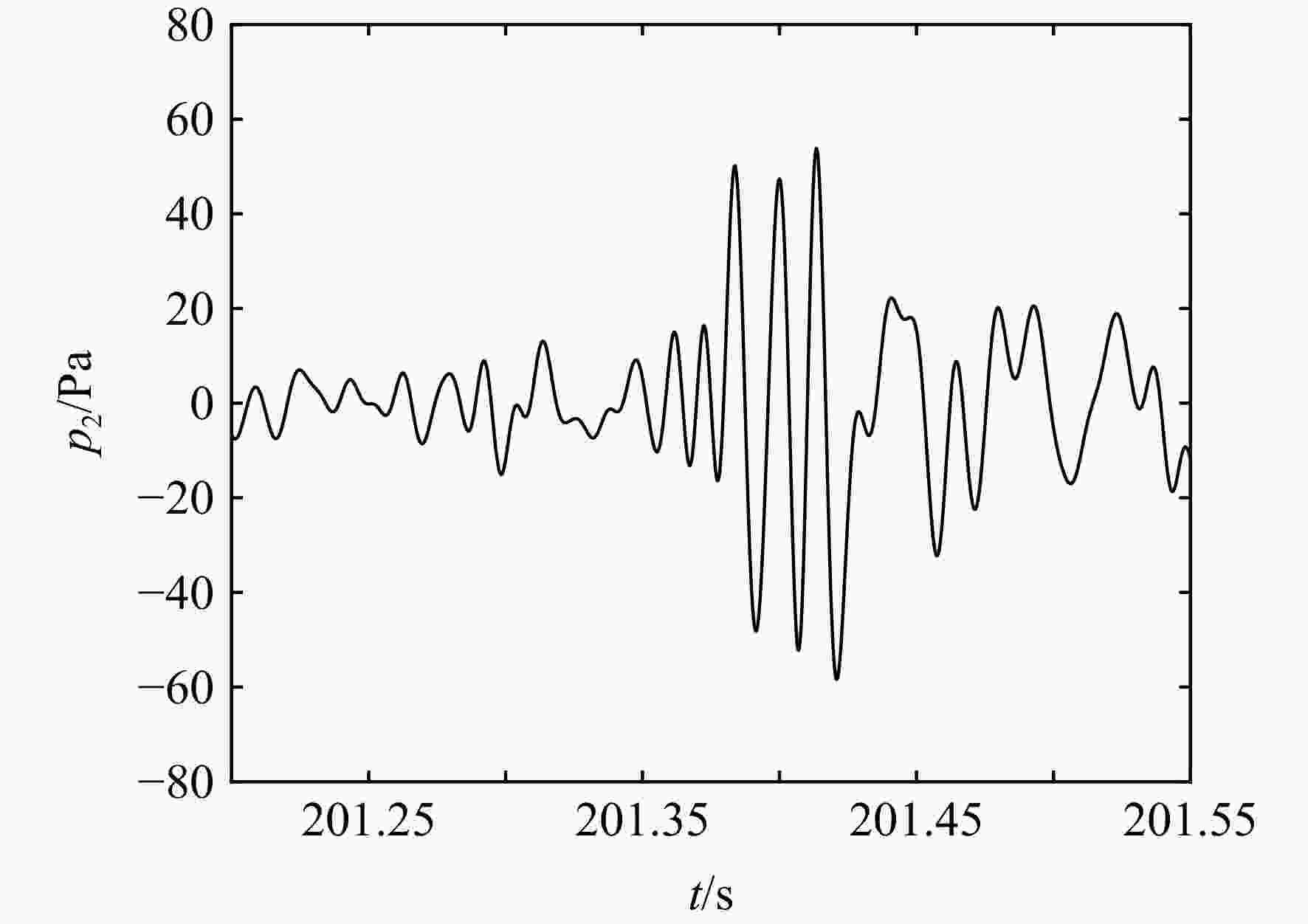

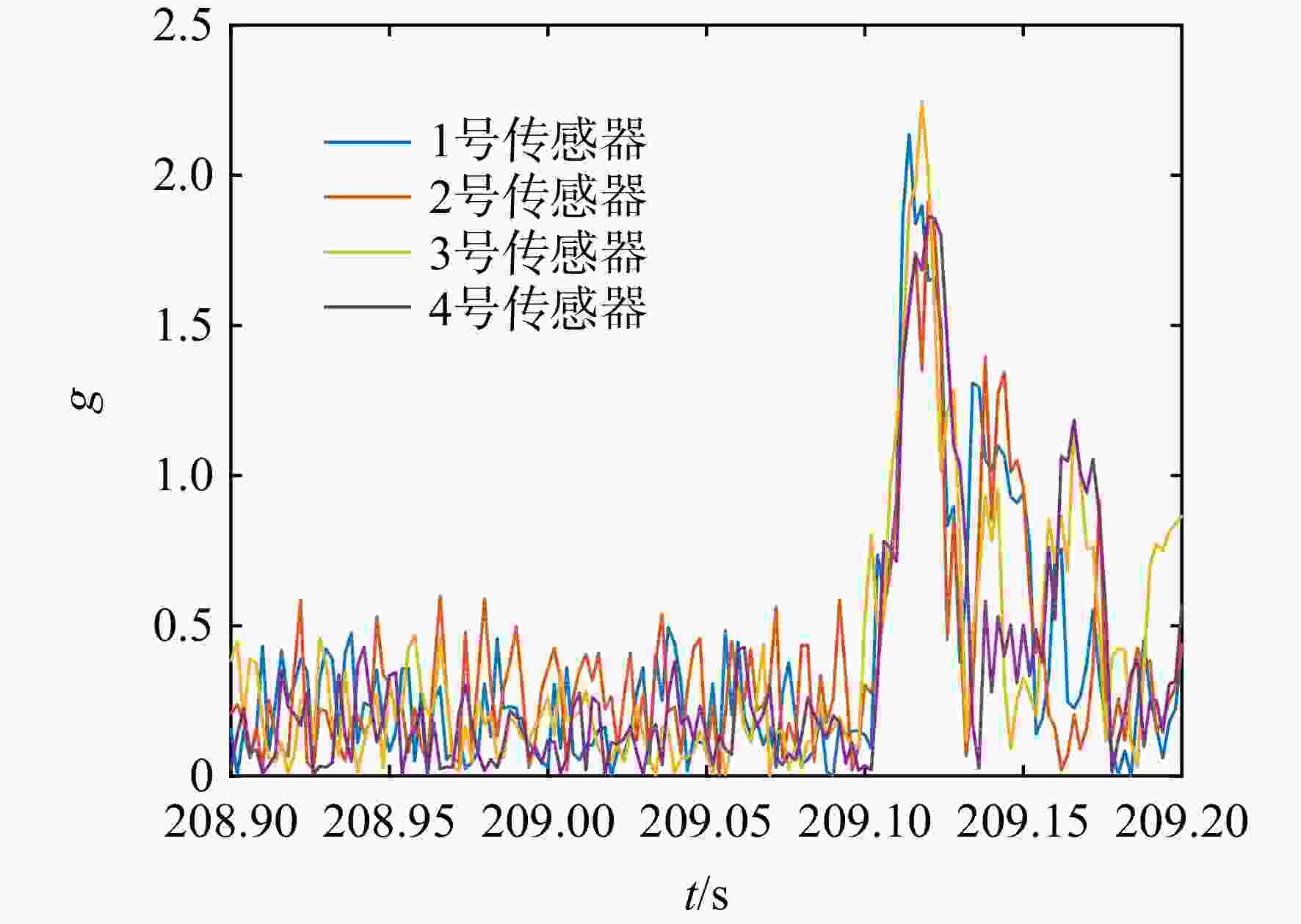

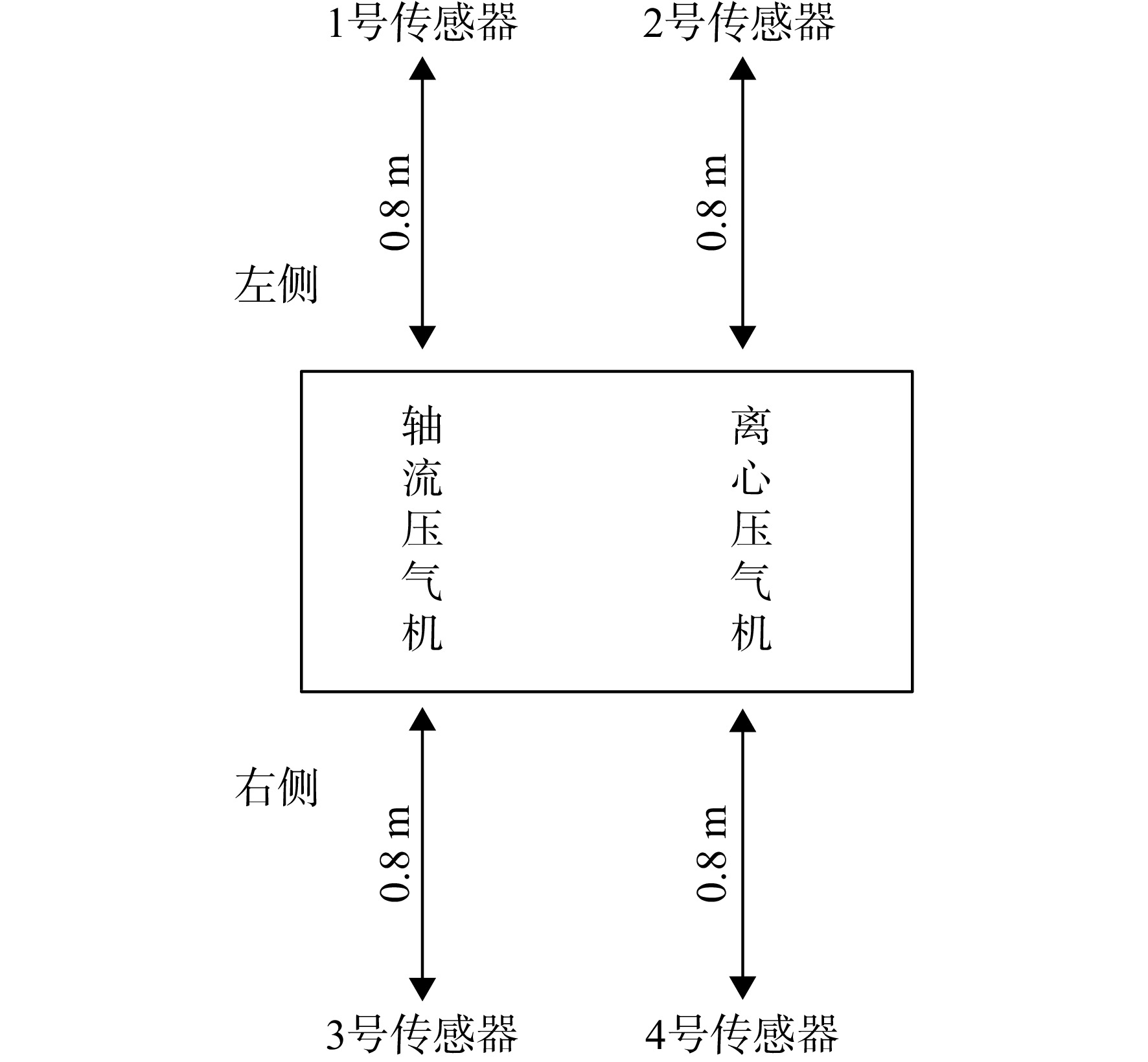

为了识别某型涡轴发动机喘振时的特征,通过进气畸变方式开展了某型发动机台架试车逼喘试验,利用声压传感器测量采集了轴流压气机和离心压气机两侧的声压信号。对声压信号进行测试环境与背景噪声修正,再采用时频分析方法实现了对由于进气减少引起的压气机叶片失速团特征和低频喘振特征的检测,并采用小波低频重构声压信号方法实现了某型涡轴发动机喘振信号的提取与识别。结果表明:随着进气的增加,轴流压气机和离心压气机转子频率处声压信号幅值会降低,同时会产生失速团,轴流压气机右侧能最先监测到喘振,喘振频率约为60 Hz。

Abstract:In order to identify the characteristics of a turboshaft engine during surge, the bench test of a turboshaft engine was carried out by inlet distortion method, and the sound pressure signals on both sides of axial compressor and centrifugal compressor were measured and collected by sound pressure sensor. The test environment and background noise of sound pressure signal were corrected, the characteristics of compressor blade stall mass and low-frequency surge caused by intake reduction were detected by time-frequency analysis method, and the surge signal of a turboshaft engine was extracted and identified by wavelet low-frequency reconstruction of sound pressure signal. The results showed that with the increase of intake air, the amplitude of sound pressure signal at the rotor frequency of axial flow compressor and centrifugal compressor decreased, and stall mass was generated. Surge can be first detected on the right side of axial flow compressor, with the surge frequency about 60 Hz.

-

Key words:

- turboshaft engine /

- compressor /

- surge test /

- sound pressure signal /

- wavelet transform

-

表 1 转速为32400 r/min工况下插板变化

Table 1. Board change at rotational speed of 32400 r/min

插板变化次数 时间/s 插板相对高度/% 1 0 3.71 2 4.94 8.25 3 11.86 15.36 4 19.85 18.82 5 31.67 22.04 6 41.38 25.00 7 62.84 27.82 8 72.44 31.71 9 97.46 34.46 10 99.64 37.96 11 111.09 41.14 12 120.71 44.61 13 131.61 47.79 14 142.97 51.82 15 155.82 52.68 16 165.05 53.25 17 174.95 55.07 18 186.11 56.11 表 2 转速为32000 r/min工况下插板变化

Table 2. Board change at rotational speed of 32000 r/min

插板变化次数 时间/s 插板相对高度/% 1 0 3.96 2 3.99 8.00 3 18.6 12.64 4 28.54 17.18 5 40.23 23.93 6 50.16 28.36 7 61.27 32.14 8 72.76 35.57 9 85.03 38.64 10 98.38 42.21 11 110.07 44.25 12 120.2 46.43 13 132.86 48.36 14 145.72 50.32 15 156.92 51.82 16 166.76 53.39 17 176.89 54.46 18 187.99 55.11 表 3 转速为32400 r/min工况下喘振发生时间

Table 3. Time of surge at rotational speed of 32400 r/min

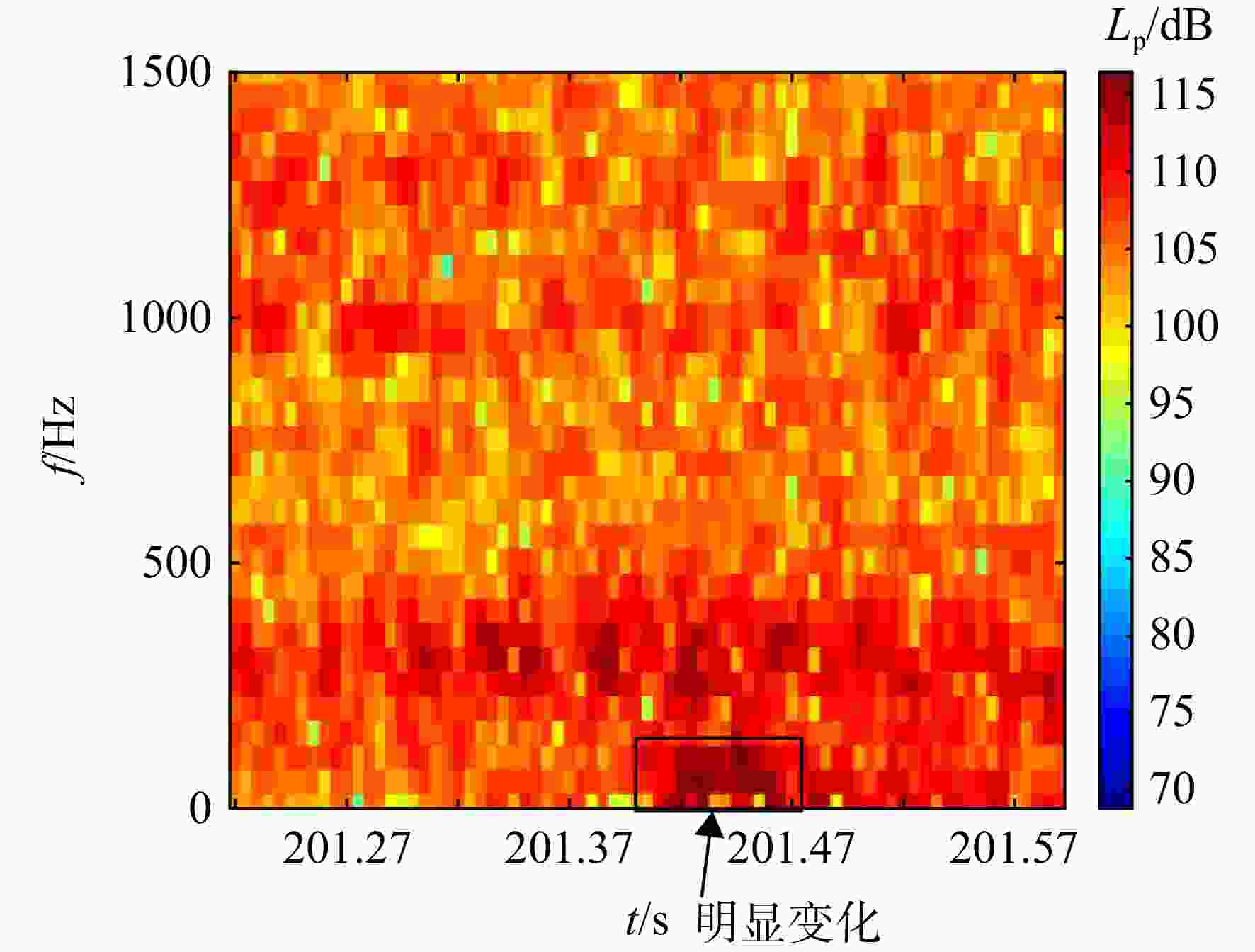

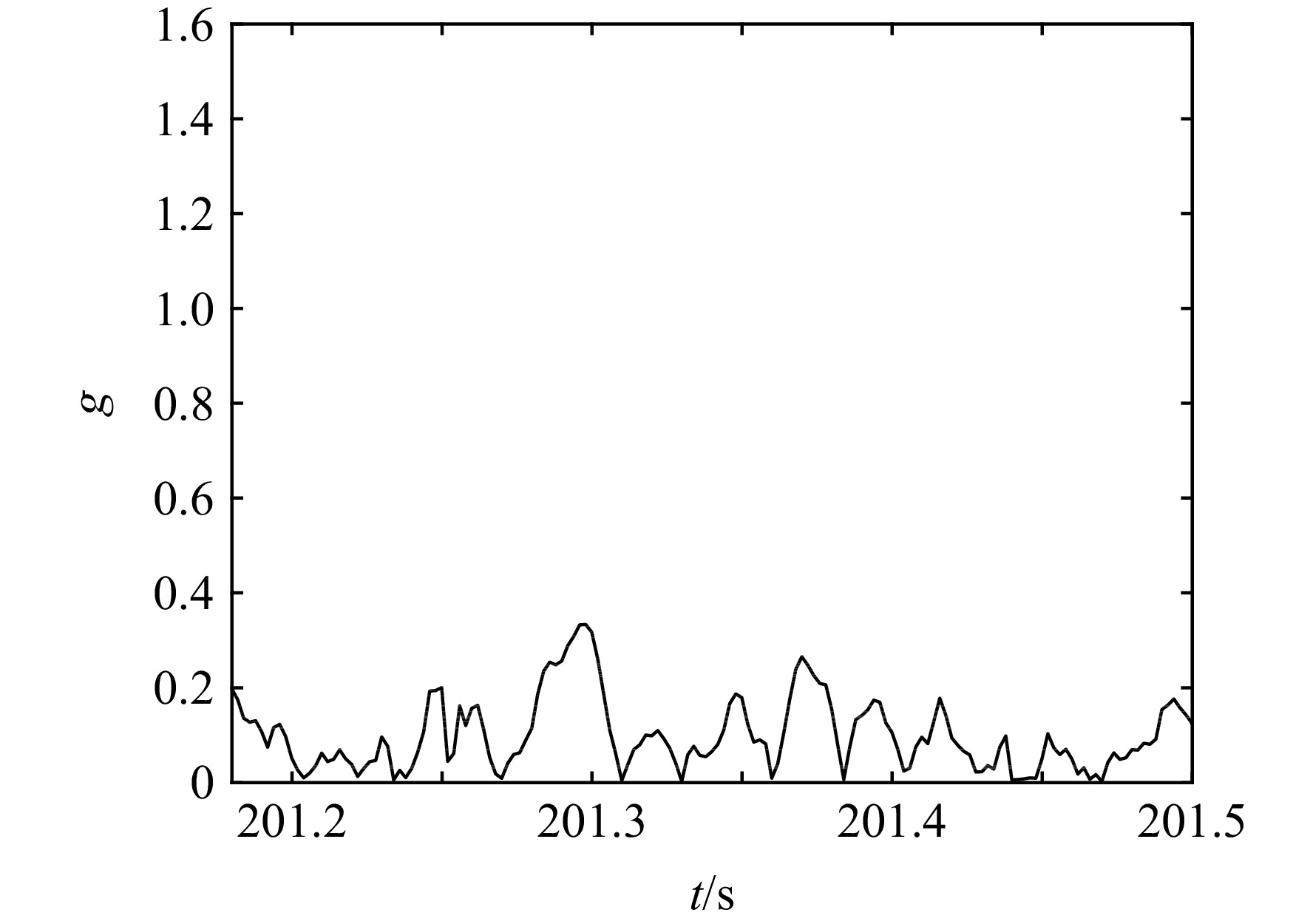

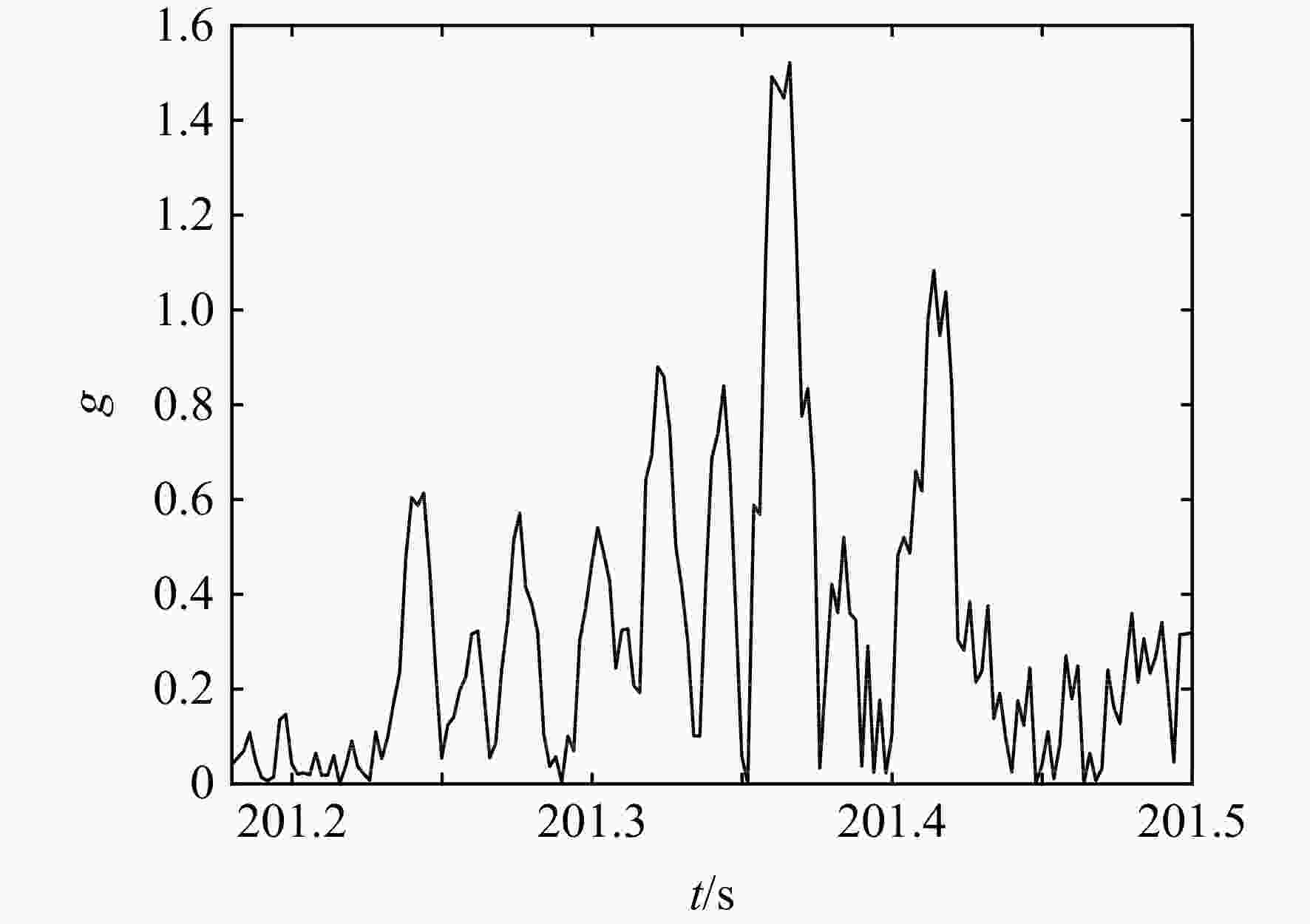

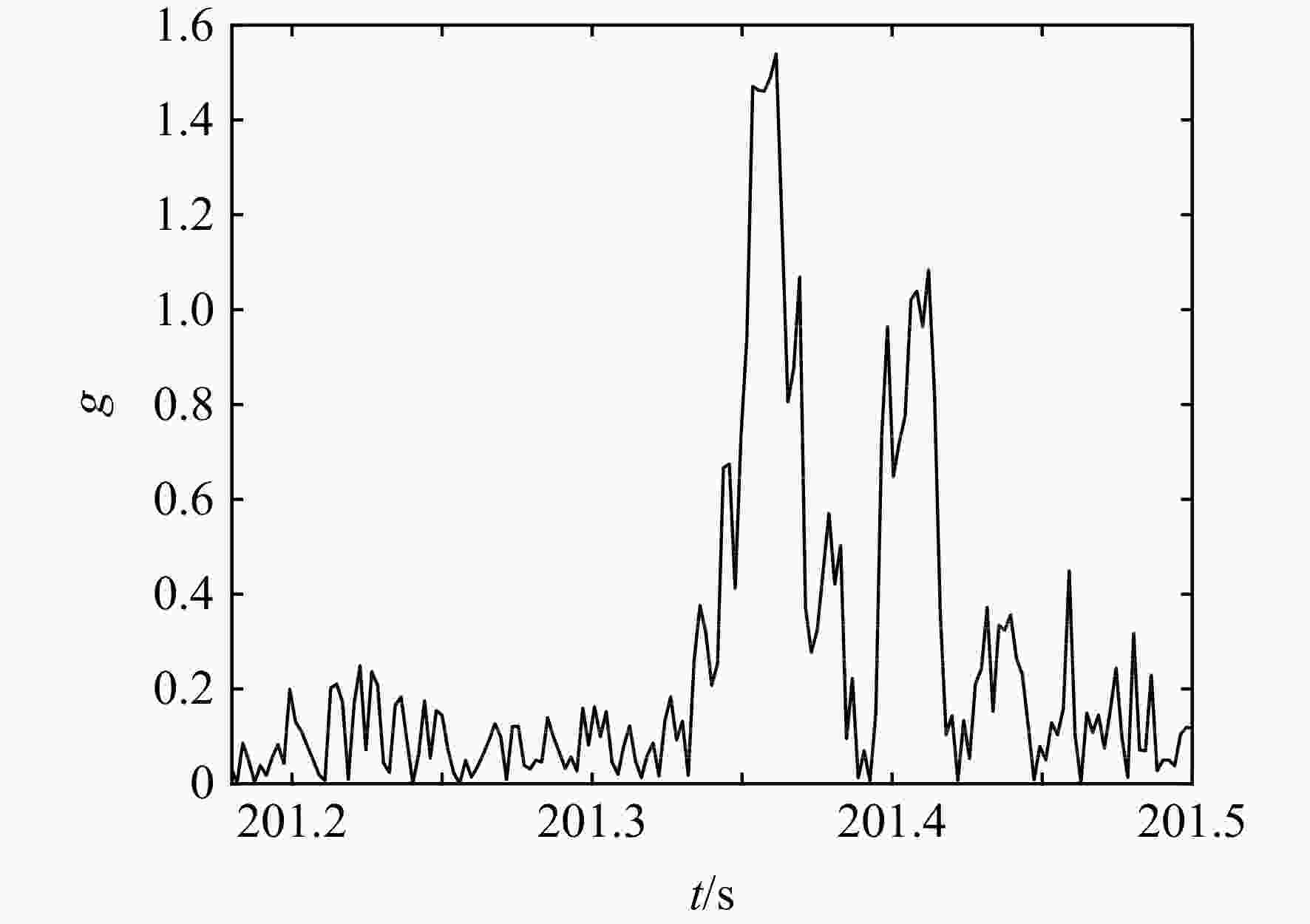

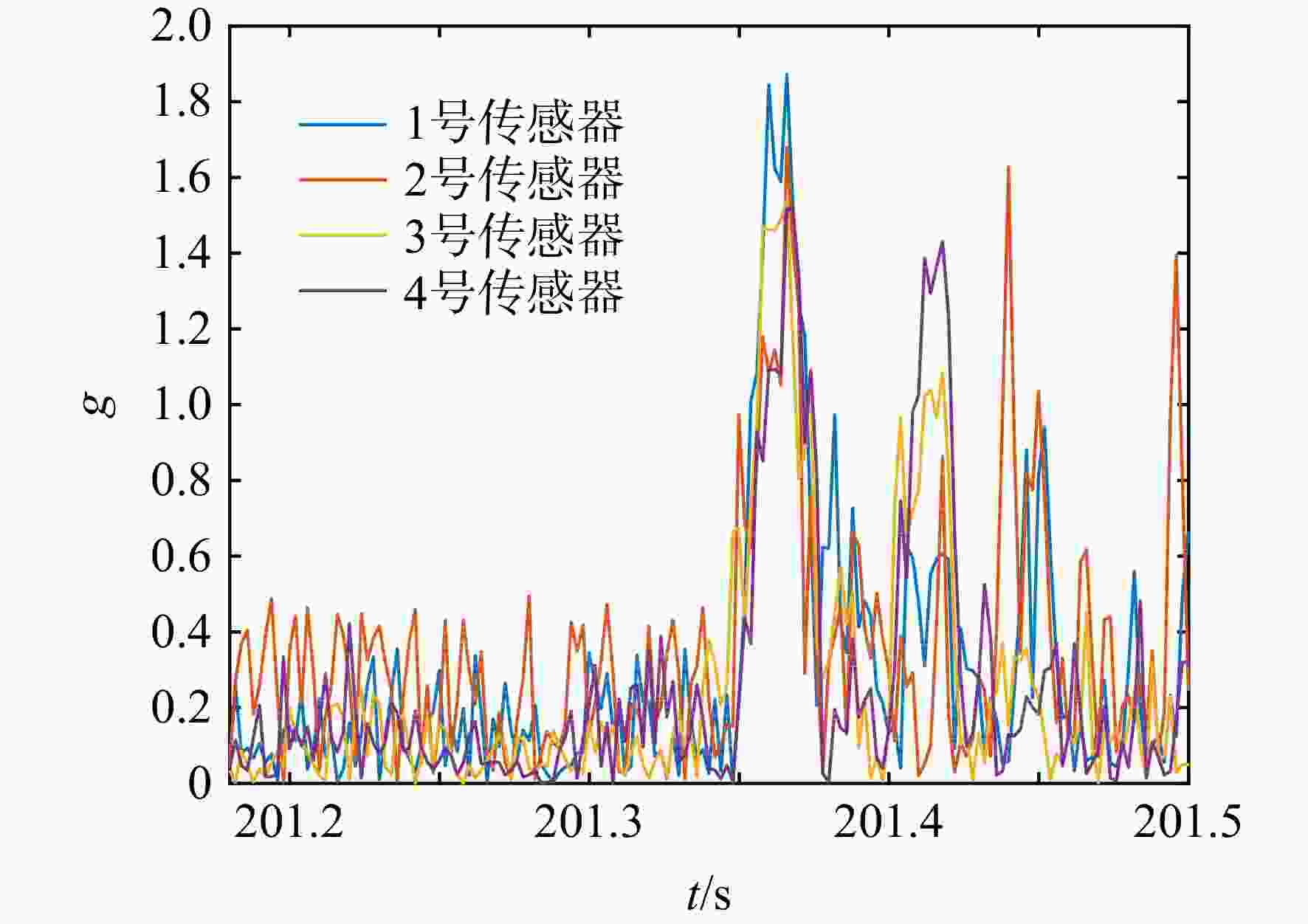

监测到喘振顺序 传感器位置 时间/s 1 3 201.3479 2 1 201.3539 3 4 201.3559 4 2 201.3579 表 4 转速为32000 r/min工况下喘振发生时间

Table 4. Time of surge at rotational speed of 32000 r/min

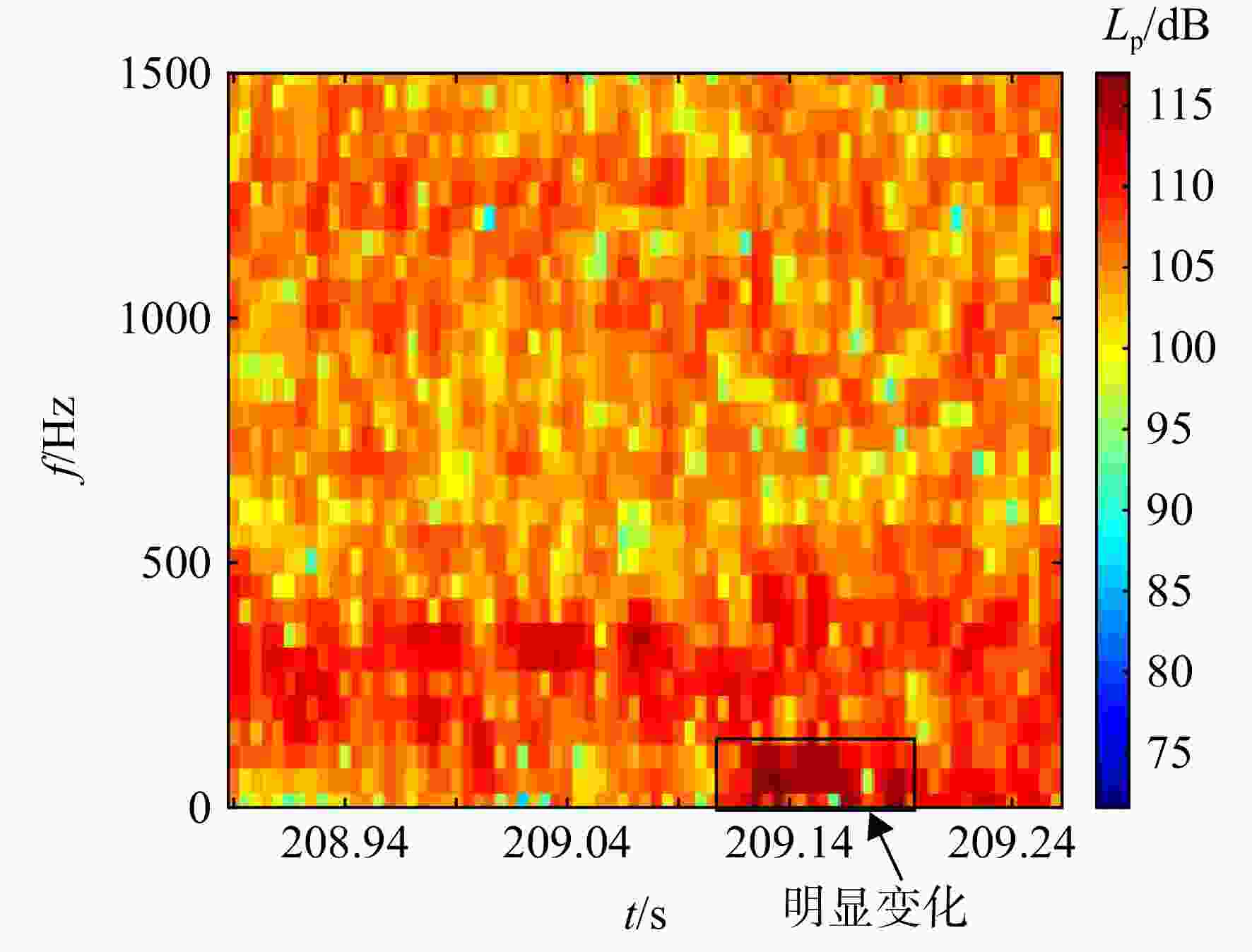

监测到喘振顺序 传感器位置 时间/s 1 3 209.1022 2 1 209.1062 3 4 209.1082 4 2 209.1102 -

[1] 王玉东. 基于压气机出口静压变化率的喘振检测方法[J]. 航空动力学报,2020,35(6): 1131-1139. doi: 10.13224/j.cnki.jasp.2020.06.002WANG Yudong. Surge detection method based on rate of change of compressor discharge static pressure[J]. Journal of Aerospace Power,2020,35(6): 1131-1139. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.06.002 [2] 李长征,熊兵,韩伟. 基于统计特征的轴流压气机喘振检测[J]. 航空动力学报,2010,25(12): 2656-2659. doi: 10.13224/j.cnki.jasp.2010.12.007LI Changzheng,XIONG Bing,HAN Wei. Surge detection of an axial compressor based on statistical characteristics[J]. Journal of Aerospace Power,2010,25(12): 2656-2659. (in Chinese) doi: 10.13224/j.cnki.jasp.2010.12.007 [3] 李长征,胡智琦,许思琦. 基于D-S证据融合的压气机气动失稳检测[J]. 推进技术,2017,38(8): 1870-1877.LI Changzheng,HU Zhiqi,XU Siqi. Aerodynamic instability detection for compressor based on D-S evidence fusion[J]. Journal of Propulsion Technology,2017,38(8): 1870-1877. (in Chinese) [4] 张海波,华伟,吴伟超. 一种基于发动机喘振实时模型的主动稳定性控制方法[J]. 航空动力学报,2013,28(5): 1150-1158.ZHANG Haibo,HUA Wei,WU Weichao. Active stability control method for turbofan engine based on post-stall model[J]. Journal of Aerospace Power,2013,28(5): 1150-1158. (in Chinese) [5] 彭生红,刘志友,张志林,等. 航空发动机气动失稳在线监测试验技术[J]. 航空动力学报,2021,36(9): 1880-1886. doi: 10.13224/j.cnki.jasp.20210106PENG Shenghong,LIU Zhiyou,ZHANG Zhilin,et al. Research for online detection of aerodynamic instability while aero-engine test[J]. Journal of Aerospace Power,2021,36(9): 1880-1886. (in Chinese) doi: 10.13224/j.cnki.jasp.20210106 [6] MUNARI E,MORINI M,PINELLI M,et al. Experimental investigation and modeling of surge in a multistage compressor[J]. Energy Procedia,2017,105: 1751-1756. doi: 10.1016/j.egypro.2017.03.503 [7] MUNARI E, MORINI M, PINELLI M, et al. Experimental investigation of stall and surge in a Multistage Compressor[R]. Seoul, South Korea: ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, 2016. [8] LI Changzheng,XU Siqi,HU Zhiqi. Experimental study of surge and rotating stall occurring in high-speed multistage axial compressor[J]. Procedia Engineering,2015,99: 1548-1560. doi: 10.1016/j.proeng.2014.12.707 [9] COURTIADE N,OTTAVY X. Experimental study of surge precursors in a high-speed multistage compressor[J]. Journal of Turbomachinery,2013,135(6): 061018.1-061018.9. [10] ZHENG Xinqian,SUN Zhenzhong,KAWAKUBO T,et al. Experimental investigation of surge and stall in a turbocharger centrifugal compressor with a vaned diffuser[J]. Experimental Thermal and Fluid Science,2017,82: 493-506. doi: 10.1016/j.expthermflusci.2016.11.036 [11] ZHENG Xinqian,LIU Anxiong. Phenomenon and mechanism of two-regime-surge in a centrifugal compressor[J]. Journal of Turbomachinery,2015,137(8): 081007.1-081007.7. [12] SUN Zhenzhong,ZHENG Xinqian,KAWAKUBO T. Experimental investigation of instability inducement and mechanism of centrifugal compressors with vaned diffuser[J]. Applied Thermal Engineering,2018,133: 464-471. doi: 10.1016/j.applthermaleng.2018.01.071 [13] LIU A X,ZHENG X Q. Methods of surge point judgment for compressor experiments[J]. Experimental Thermal and Fluid Science,2013,51: 204-213. doi: 10.1016/j.expthermflusci.2013.07.015 [14] CAMERON J D,MORRIS S C. Analysis of axial compressor stall inception using unsteady casing pressure measurements[J]. Journal of Turbomachinery,2013,135(2): 021036.1-021036.12. [15] LIU Yang,LI Jichao,DU Juan,et al. Application of fast wavelet analysis on early stall warning in axial compressors[J]. Journal of Thermal Science,2019,28(5): 837-849. doi: 10.1007/s11630-019-1207-4 [16] 国家质量监督检验检疫总局, 中国国家标准化管理委员会. 声学 声压法测定噪声源声功率级和声能量级 反射面上方近似自由场的工程法: GB/T 3767—2016[S]. 北京: 中国标准出版社, 2016: 41. [17] HAYNES J M,HENDRICKS G J,EPSTEIN A H. Active stabilization of rotating stall in a three-stage axial compressor[J]. Journal of Turbomachinery,1994,116(2): 226-239. doi: 10.1115/1.2928357 [18] PADUANO J D,GREITZER E M,EPSTEIN A H. Compression system stability and active control[J]. Annual Review of Fluid Mechanics,2001,33: 491-517. doi: 10.1146/annurev.fluid.33.1.491 [19] 贺象,马宏伟,银越千,等. 小尺寸多级轴流压气机喘振现象试验[J]. 航空动力学报,2016,31(8): 1957-1963. doi: 10.13224/j.cnki.jasp.2016.08.022HE Xiang,MA Hongwei,YIN Yueqian,et al. Experiment on surge phenomenon of small multi-stage axial compressor[J]. Journal of Aerospace Power,2016,31(8): 1957-1963. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.08.022 [20] 潘天宇,贺雷,王正鹤,等. 局部喘振频率特性及估算方法[J]. 航空动力学报,2015,30(11): 2666-2672.PAN Tianyu,HE Lei,WANG Zhenghe,et al. Study on the frequency of partial surge and a frequency prediction method[J]. Journal of Aerospace Power,2015,30(11): 2666-2672. (in Chinese) -

下载:

下载: