Research on horizontal assembly technology of low pressure turbine unit based on deformation control

-

摘要:

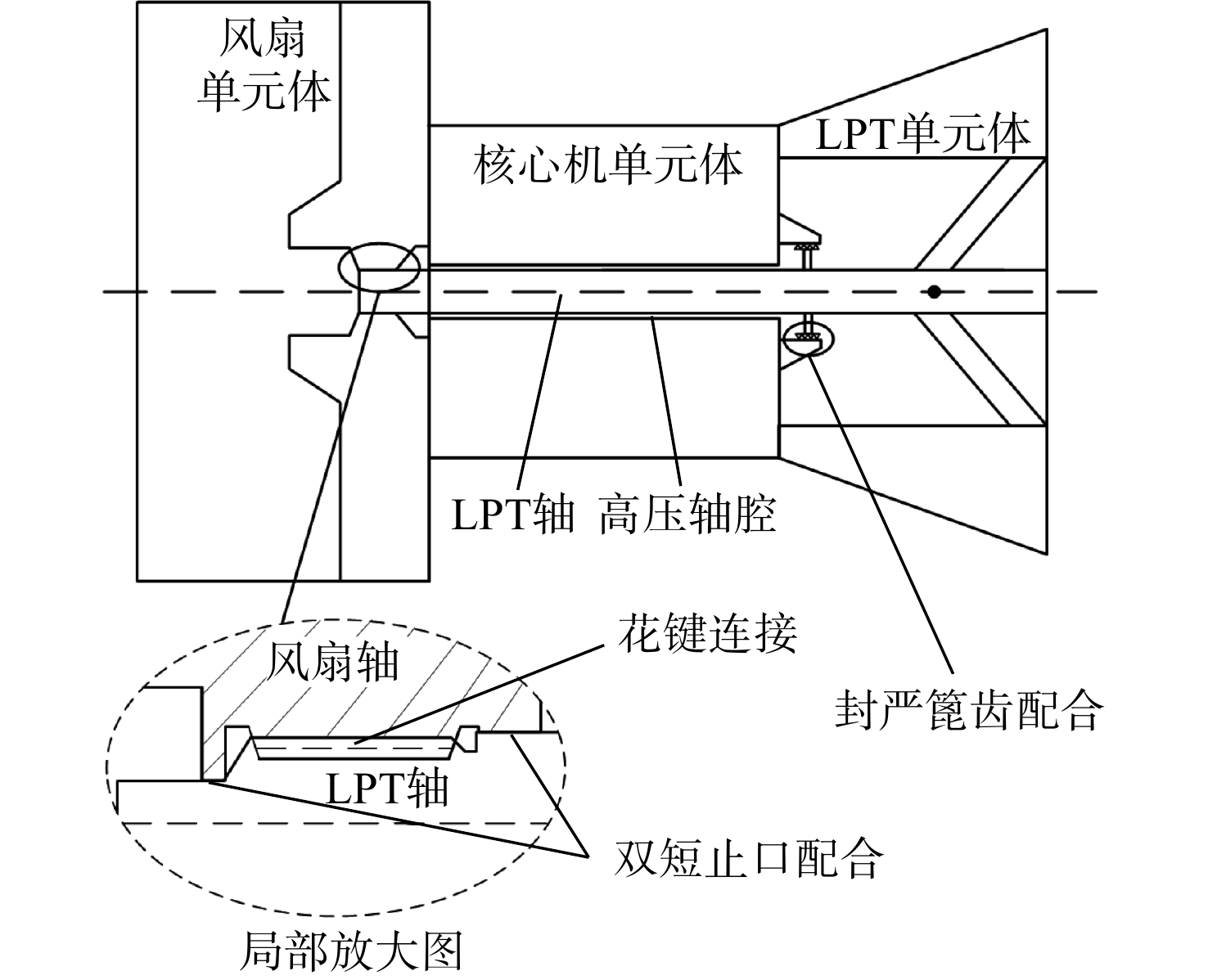

应用装配力学的理念对商用大涵道比航空发动机低压涡轮单元体传统水平装配技术进行改进,开展了低压涡轮单元体水平对接过程力学仿真分析,开发了基于变形控制的水平装配技术,实现了低压涡轮单元体数字化、高效率、高可靠性的安装。相较传统水平装配,引导工装结构更简洁,质量降低约70%;极大降低了对接难度,装配效率提高60%以上,一次对接成功率提升至100%。

Abstract:The concept of assembly mechanics was applied to improve the traditional horizontal assembly technology of low pressure turbine unit of commercial high bypass ratio aero-engine. An advanced horizontal assembly technology was developed based on deformation control by mechanical simulation analysis of the horizontal docking process of low pressure turbine unit. The result demonstrated that this technology realized the installation of low pressure turbine unit with high precision, high efficiency and high reliability. In addition, compared with traditional experience assembly, the guided tool structure was more concise by contributing to around 70% reduction of the weight, and the docking difficulty was greatly reduced by contributing to more than 60% increase of the assembly efficiency and 100% increase of the success rate of one-time docking.

-

Key words:

- aero-engine /

- low pressure turbine /

- assembly technology /

- deformation control /

- simulation /

- digitalization

-

表 1 引导工装结构设计参数对比

Table 1. Comparison of guide tool structural design parameters

结构参数 传统 优化 X-01 X-02 X-03 前/后

引导环轴向间距L1/mm 2696 2307 2307 与引导轴配合方式 滑动 滚动 滚动 与引导轴配合/mm 0.1 0.05 0.05 引导轴 材料 45#钢 45#钢 45#钢 壁厚限值[$\tilde B $]/mm 0 4 长度Lg/mm 3032 1485 1004 外径D/mm 90 80 82 内径d/mm 80 75 74 质量Ψ/kg 31.76 7.09 7.72 表 2 LPT单元体装配效果对比

Table 2. Comparison of LPT unit assembly effect

装配效果 传统

装配技术基于变形控制的

装配技术装配难度 高 低 磕碰/卡滞 有 无 装配时长/h 约为3 约为1 一次对接

成功率/%约为30 100 引导安装

贴合程度不到位 到位 -

[1] 刘大响, 陈光. 航空发动机: 飞机的心脏[M]. 北京: 航空工业出版社, 2003. [2] 石宏. 航空发动机装配工艺技术[M]. 北京: 北京航空航天大学出版社, 2015. [3] 周烁,汪俊熙,刘宜胜,等. 大型商用航空发动机整机装配工艺浅析[J]. 航空制造技术,2014,57(5): 92-96. doi: 10.3969/j.issn.1671-833X.2014.05.015ZHOU Shuo,WANG Junxi,LIU Yisheng,et al. Brief review on assembly process of large commercial aeroengine[J]. Aeronautical Manufacturing Technology,2014,57(5): 92-96. (in Chinese) doi: 10.3969/j.issn.1671-833X.2014.05.015 [4] 魏小红,陈贵林,田小京,等. 航空发动机数字化脉动总装线规划技术研究[J]. 航空制造技术,2015(21): 155-157,162. doi: 10.16080/j.issn1671-833x.2015.21.155WEI Xiaohong,CHEN Guilin,TIAN Xiaojing,et al. Study on aeroengine digital pulsation final assembly line planning technology[J]. Aeronautical Manufacturing Technology,2015(21): 155-157,162. (in Chinese) doi: 10.16080/j.issn1671-833x.2015.21.155 [5] 魏小红,颜建兴,金梅,等. 基于航空发动机脉动装配的智能管控技术研究[J]. 航空制造技术,2020,63(6): 43-50. doi: 10.16080/j.issn1671-833x.2020.06.043WEI Xiaohong,YAN Jianxing,JIN Mei,et al. Investigation on intelligent controlling-management system of aero-engines pulsation assembly line[J]. Aeronautical Manufacturing Technology,2020,63(6): 43-50. (in Chinese) doi: 10.16080/j.issn1671-833x.2020.06.043 [6] 王岭. 航空发动机低压涡轮单元体智能对接技术研究[J]. 燃气涡轮试验与研究,2018,31(5): 1-5. doi: 10.3969/j.issn.1672-2620.2018.05.001WANG Ling. Study on automatic docking technology for aero-engine low pressure turbine installation[J]. Gas Turbine Experiment and Research,2018,31(5): 1-5. (in Chinese) doi: 10.3969/j.issn.1672-2620.2018.05.001 [7] SUN Y,GUO J,HONG J,et al. Modeling of rotation accuracy of multi-support rotating machinery considering geometric errors and part deformation[J]. Assembly Automation,2020,40(5): 665-673. doi: 10.1108/AA-07-2018-099 [8] MU X,WANG Y,YUAN B,et al. A new assembly precision prediction method of aeroengine high-pressure rotor system considering manufacturing error and deformation of parts[J]. Journal of Manufacturing Systems,2021,61: 112-124. doi: 10.1016/j.jmsy.2021.08.010 [9] 丁司懿,金隼,李志敏,等. 航空发动机转子装配同心度的偏差传递模型与优化[J]. 上海交通大学学报,2018,52(1): 54-62. doi: 10.16183/j.cnki.jsjtu.2018.01.009DING Siyi,JIN Sun,LI Zhimin,et al. Deviation propagation model and optimization of concentricity for aero-engine rotor assembly[J]. Journal of Shanghai Jiao Tong University,2018,52(1): 54-62. (in Chinese) doi: 10.16183/j.cnki.jsjtu.2018.01.009 [10] 张子豪,郭俊康,洪军,等. 航空发动机高压转子装配偏心预测和相位优化的智能算法应用研究[J]. 西安交通大学学报,2021,55(2): 47-54. doi: 10.7652/xjtuxb202102006ZHANG Zihao,GUO Junkang,HONG Jun,et al. Research on application of intelligent algorithm for assembly eccentricity prediction and phase optimization of aero engine high pressure rotor[J]. Journal of Xi’an Jiao Tong University,2021,55(2): 47-54. (in Chinese) doi: 10.7652/xjtuxb202102006 [11] 邓王倩,莫蓉,陈凯,等. 基于实测数据的航空发动机转子叶尖装配间隙预测[J]. 航空动力学报,2022,37(6): 1272-1283.DENG Wangqian,MO Rong,CHEN Kai,el al. Prediction of rotor tip assembly clearance based on measured data for aero-engine[J]. Journal of Aerospace Power,2022,37(6): 1272-1283. (in Chinese) [12] 张龙,韩鹏卓,刘忠奎,等. 航空发动机转子叶尖间隙及同心度变化规律研究[J]. 燃气涡轮试验与研究,2017,30(1): 44-47. doi: 10.3969/j.issn.1672-2620.2017.01.010ZHANG Long,HAN Pengzhuo,LIU Zhongkui,et al. Research on the variation of rotor blade tip clearance and concentricity for aero-engine[J]. Gas Turbine Experiment and Research,2017,30(1): 44-47. (in Chinese) doi: 10.3969/j.issn.1672-2620.2017.01.010 [13] 詹江正,张光,宋文艳,等. 某型高压压气机12 级转子叶尖间隙理论分析与数值模拟[J]. 机械科学与技术,2019,38(10): 1632-1640.ZHAN Jiangzheng,ZHANG Guang,SONG Wenyan,et al. Theoretical analysis and numerical simulation of tip clearance of 12-stage high-pressure compressor rotor[J]. Mechanical Science and Technology for Aerospace Engineering,2019,38(10): 1632-1640. (in Chinese) [14] 焦俊杰,莫蓉,徐广庆,等. 螺栓孔的位置度误差对短精密螺栓连接结构装配力学特性的影响[J]. 航空动力学报,2021,36(5): 935-947. doi: 10.13224/j.cnki.jasp.2021.05.005JIAO Junjie,MO Rong,XU Guangqing,et al. Influence of position error of bolt hole on assemble mechanical characteristics of short precision bolted connection structure[J]. Journal of Aerospace Power,2021,36(5): 935-947. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.05.005 [15] LI T,YANG D,ZHAO B,et al. Measured and investigated nonlinear dynamics parameters on bolted flange joints of combined rotor[J]. Journal of Mechanical Science and Technology,2021,35(5): 1841-1850. doi: 10.1007/s12206-021-0404-8 [16] 李小强,孟庆阔,杜一凡,等. 拧紧策略对航空发动机单螺栓连接预紧力的影响[J]. 机械工程学报,2020,56(13): 231-241. doi: 10.3901/JME.2020.13.231LI Xiaoqiang,MENG Qingkuo,DU Yifan,et al. Influence of tightening strategy on pre-tightening force of aero-engine single-bolt connection[J]. Journal of Mechanical Engineering,2020,56(13): 231-241. (in Chinese) doi: 10.3901/JME.2020.13.231 [17] 张志贤,刘检华,宁汝新. 虚拟装配中基于多刚体动力学的物性装配过程仿真[J]. 机械工程学报,2013,49(5): 90-98. doi: 10.3901/JME.2013.05.090ZHANG Zhixian,LIU Jianhua,NING Nuxin,el al. Physical assembly process simulation based on multi-rigid-body dynamics in virtual assembly[J]. Journal of Mechanical Engineering,2013,49(5): 90-98. (in Chinese) doi: 10.3901/JME.2013.05.090 [18] 岳普煜,王建梅,黄庆学,等. 弹性结合油膜轴承锥套的装配力学行为研究[J]. 中北大学学报(自然科学版),2008(5): 405-408.YUE Puyu,WANG Jianmei,HUANG Qingxue,el al. Research on assembly mechanical behaviors of oil-film bearing taper sleeve with elastic cohesion[J]. Journal of North University of China (Nature Science Edition),2008(5): 405-408. (in Chinese) [19] 濮良贵, 陈国定, 吴立宣. 机械设计[M]. 北京: 高等教育出版社, 2015. -

下载:

下载: