Experiment on lean blow-out performance of combustors with different atomization characteristics

-

摘要:

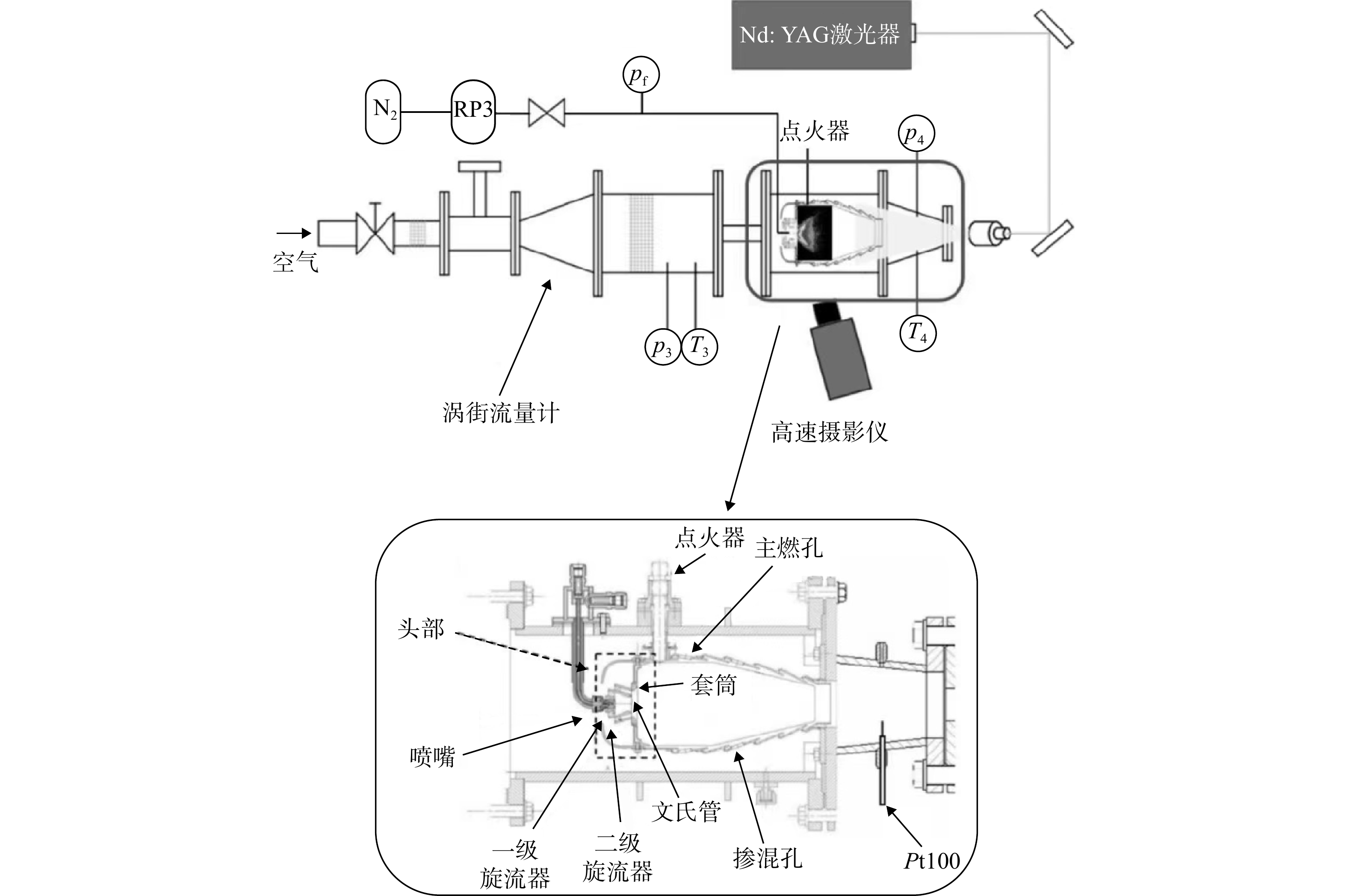

为了研究雾化特性对贫油熄火性能的影响,对喷雾火焰进行了试验研究。在双轴向和双径向旋流器燃烧室中,分别测量了不同喷嘴的熄火极限和出口温度,并估算了燃烧效率。结果表明:①不同结构和喷嘴的燃烧室熄火性能有很大差异,双径向燃烧室的熄火性能普遍优于双轴向;②雾化特性中的索太尔平均直径、液滴速度、喷雾空间分布等参数都影响着贫油熄火极限,仅靠索太尔平均直径无法代表所有雾化特性对贫油熄火性能的影响;③空心喷雾使得火焰根部远离回流区,实心喷雾使得火焰根部集中在回流区;④不同雾化特性的燃烧室在接近贫油熄火时的燃烧效率和出口温度有很大不同。熄火时的出口温度代表了理想的贫油熄火极限。燃烧效率反映了燃烧室实际贫油熄火极限与理想熄火极限之间的差距。

Abstract:In order to investigate the effects of atomization characteristics on the lean blow-out (LBO) performance, an experimental study was carried out on the spray and the combustion. The LBO limits and outlet temperatures near the LBO condition of different atomizers were measured and the combustion efficiency was estimated in a single dome rectangular model combustor with a dual-radial and a dual-axial swirl cup, respectively. The results showed that, (1) the LBO performance of the combustors with different structures and atomizers was very different. The LBO performance of the dual-radial combustors was generally better than that of the dual-axial combustors. (2)There was no obvious correlation between spray Sauter mean diameter (SMD)and LBO limit, and SMD alone cannot represent the influence of all atomization characteristics on LBO performance. (3)The hollow spray kept the flame base away from the recirculation zone, and the solid spray kept the flame base concentrated in the recirculation zone. (4)The combustion efficiency and outlet temperature of combustors with different atomization characteristics were very different near the LBO. The outlet temperature at LBO represented the ideal LBO limit. The combustion efficiency reflected the difference between the actual LBO limit and the ideal LBO limit.

-

表 1 燃烧室编号

Table 1. Combustor number

燃烧室编号 旋流器 喷嘴序号 A1 双轴向 1 A2 双轴向 2 A3 双轴向 3 A4 双轴向 4 A5 双轴向 5 A8 双轴向 8 R1 双径向 1 R6 双径向 6 R7 双径向 7 R8 双径向 8 R9 双径向 9 表 2 燃烧室详细尺寸参数

Table 2. Detailed configuration parameters of the combustors

部件 参数 双轴向旋流杯 参数 双径向旋流杯 一级旋流器 二级旋流器 一级旋流器 二级旋流器 旋流器 Dout/mm 26 34.5 B/mm 5.1 7 Din/mm 19 28 θb/(°) 64 70 θb/(°) 40 45 δ/mm 1.2 1.2 δ/mm 1 1 R/mm 12.5 15 Ae/mm2 147.5 186.6 Ae/mm2 146.7 190.7 n 12 12 n 12 12 Sn 0.992 1.126 Sn 1.09 1.25 文氏管 d/mm 18.5 d/mm 13 套筒 θ/(°) 45 θ/(°) 45 表 3 试验所用喷嘴

Table 3. Atomizer used in the experiment

喷嘴序号 参考体积流量/

(USgal/h)参考喷雾锥角/

(°)形态 1 2.00 80 实心 2 2.50 80 实心 3 3.00 45 实心 4 3.00 80 实心 5 3.50 45 实心 6 3.50 60 实心 7 4.00 60 实心 8 4.50 60 实心 9 5.00 60 实心 表 4 不同燃烧室平均LBO极限和方均根误差

Table 4. Average LBO limits and RMS errors of different combustors

燃烧室

编号熄火时喷嘴

压力降/kPaqlbo qlbo方均根

误差A1 345.9 0.011409 0.000096 A2 309.6 0.014029 0.000102 A3 222.3 0.014058 0.000062 A4 202.7 0.013325 0.000057 A5 174.0 0.014541 0.000053 A8 192.2 0.022234 0.000082 R1 144.8 0.007403 0.000107 R6 50.4 0.007925 0.000057 R7 44.0 0.008005 0.000076 R8 43.1 0.010612 0.000049 R9 34.9 0.010438 0.000108 -

[1] ZHANG Zhichao,CHEN Longfei,LU Yiji,et al. Lean ignition and blow-off behaviour of butyl butyrate and ethanol blends in a gas turbine combustor[J]. Fuel,2019,239(1): 1351-1362. [2] KUMAR A, CHATTERJEE K, MUKHOPADHYAY A, et al. Experimental characterization of premixed flame in gas turbine combustor with spectroscopy and RGB analysis[R]. Mumbai, India: ASME 2012 Gas Turbine India Conference, 2012. [3] JIN Yi,HE Xiaomin,ZHANG Jingyu,et al. Experimental study on emission performance of an LPP/TVC[J]. Chinese Journal of Aeronautics,2012,25(3): 335-341. doi: 10.1016/S1000-9361(11)60394-4 [4] LEFEBVRE A H. Gas turbine combustion[M]. New York, US: McGraw-Hill Book Company, 1983. [5] MANAMPATHY G, GIRIDHARA G, MONGIA H C, et al. Swirl cup modeling: Part Ⅷ spray combustion in CFM-56 single cup flame tube[R]. AIAA-2003-0319, 2003. [6] POLYMEROPOULOS C E,DAS S. The effect of droplet size on the burning velocity of kerosene-air sprays[J]. Combustion and Flame,1975,25(1): 247-257. [7] ALSULAMI R,WINDELL B,NATES S,et al. Investigating the role of atomization on flame stability of liquid fuels in an annular spray burner[J]. Fuel,2020,265(1): 116945.1-116945.11. [8] GONG J S,FU W B. The experimental study on the flow characteristics for a swirling gas-liquid spray atomizer[J]. Applied Thermal Engineering,2007,27(17): 2886-2892. [9] WAGNER H G. Soot formation in combustion[J]. Symposium (International) on Combustion,1979,17(1): 3-19. doi: 10.1016/S0082-0784(79)80005-3 [10] BAXTER M R,LEFEBVRE A H. Weak extinction limits of large scale flame holders[J]. Journal of Engineering for Gas Turbines and Power,1992,114(4): 776-782. doi: 10.1115/1.2906656 [11] STURGESS G J,HENEGHAN S P,VANGSNESS M D,et al. Effects of back-pressure in a lean blow-out research combustor[J]. Journal of Engineering for Gas Turbines and Power,1993,115(3): 486-498. doi: 10.1115/1.2906735 [12] LIEUWEN T,MCDONELL V,PETERSEN E,et al. Fuel flexibility influences on premixed combustor blow-out, flashback, auto ignition and stability[J]. Journal of Engineering for Gas Turbines and Power,2008,130(1): 011506.1-011506.10. [13] HAYASHI S,KUMAGAI S. Flame propagation in fuel droplet-vapor-air mixtures[J]. Symposium on Combustion,1975,15(1): 445-452. doi: 10.1016/S0082-0784(75)80318-3 [14] MIZUTANI Y,NAKAJIMA A. Combustion of fuel vapor-drop-air systems: Part Ⅱ spherical flames in a vessel[J]. Combustion and Flame,1973,20(3): 351-357. doi: 10.1016/0010-2180(73)90027-8 [15] MIZUTANI Y,NAKAJIMA A. Combustion of fuel vapor-drop-air systems: Part Ⅰ open burner flames[J]. Combustion and Flame,1973,20(3): 343-350. doi: 10.1016/0010-2180(73)90026-6 [16] LEVY Y,BULZAN D L. On the oscillation of combustion of a laminar spray[J]. Combustion and Flame,1995,100(4): 543-549. doi: 10.1016/0010-2180(94)00135-F [17] NICOLI C,HALDENWANG P,SUARD S. Effect of substituting fuel spray for fuel gas on flame stability in lean pre-mixtures[J]. Combustion and Flame,2007,149(3): 295-313. doi: 10.1016/j.combustflame.2006.12.018 [18] MUTHUSELVAN G,SURYANARAYANA R M,IYENGAR V S,et al. Effect of atomization quality on lean blow-out limits and acoustic oscillations in a swirl stabilized burner[J]. Combustion Science and Technology,2019,192(6): 1028-1052. [19] DUVVUR A,CHAING C H,SIRIGNANO W A. Oscillatory fuel droplet vaporization: driving mechanism for combustion instability[J]. Journal of Propulsion and Power,1996,12(2): 358-365. doi: 10.2514/3.24036 [20] LIU Cunxi,LIU Fuqiang,YANG Jinhu,et al. Investigations of the effects of spray characteristics on the flame pattern and combustion stability of a swirl-cup combustor[J]. Fuel,2015,139(1): 529-536. [21] ESCLAPEZ L, MA P C, MAYHEW E, et al. Large-eddy simulations of fuel effect on gas turbine lean blow-out[R]. AIAA 2017-1955, 2017. [22] SUN Lei,HUANG Yong,LIU Zhilin,et al. Investigation of effect of atomization performance on lean blowout limit for gas turbine combustors by comparison of utilizing aviation kerosene and methane as fuel[J]. International Journal of Turbo and Jet-Engines,2021,40(1): 1-10. [23] MISHRA R K,KUMAR S K,CHANDEL S. Effect of fuel particle size on the stability of swirl stabilized flame in a gas turbine combustor[J]. International Journal of Turbo and Jet-Engines,2015,32(2): 129-141. [24] MISHRA R K,KUMAR S K,CHANDEL S. Effect of spray cone angle on flame stability in an annular gas turbine combustor[J]. International Journal of Turbo and Jet-Engines,2016,33(1): 35-44. [25] MAYHEW E, MITSINGAS C M, MCGANN B, et al. Spray characteristics and flame structure of Jet A and alternative jet fuels[R]. AIAA 2017-0148,2017. [26] LEFEBVRE A H. Fuel effects on gas turbine combustion: ignition,stability, and combustion efficiency[J]. Journal of Engineering for Gas Turbines and Power,1985,107(1): 24-37. doi: 10.1115/1.3239693 [27] STOHR M,BOXX I,CARTER C,et al. Dynamics of lean blowout of a swirl-stabilized flame in a gas turbine model combustor[J]. Proceedings of the Combustion Institute,2011,33(2): 2953-2960. doi: 10.1016/j.proci.2010.06.103 [28] LONGWELL J P,FROST E E,WEISS M A. Flame stability in bluff body recirculation zones[J]. Industrial and Engineering Chemistry,1953,45(8): 1629-1633. doi: 10.1021/ie50524a019 [29] MUTHUSELVAN G,SURYANARAYANA R M,IYENGAR V S,et al. Effect of lean primary-zone operation on emissions and stability of non-premixed combustors[J]. Journal of Propulsion and Power,2021,37(1): 47-58. doi: 10.2514/1.B37942 -

下载:

下载: