Overview of experimental research on non-synchronous vibration in aero-engine axial compressor

-

摘要:

从非整阶振动的实验、非整阶振动信息获取、非整阶振动机理三个方面进行了概述,总结了近些年对非整阶振动研究的重要成果。平面叶栅和压气机实验台,结合叶尖定时技术和应变片测振及粒子测速(particle image velocimetry,PIV)技术进行非整阶振动的研究,主动控制旋转叶片振动实现流场与叶片振动耦合机理研究等。叶尖定时、应变片、PIV、主动控制叶片振动技术为非整阶振动的研究提供了先进的技术支撑,应用多物理场测试技术获得更加准确的非整阶振动条件下的流场和叶片振动信息。

Abstract:Important research results of non-synchronous vibration were summarized through its experiment, non-synchronous vibration signal obtaining, and mechanism of non-synchronous vibration. The basic research of non-synchronous vibration, and research on blade tip timing technology combined strain gauge and PIV (particle image velocimetry) to obtain the mechanism of non-synchronous vibration, compressed sensing blade tip timing to capture non-synchronous vibration signal and rotor blade vibration active control to research the coupling mechanism. Blade tip timing technology and strain gauge, PIV and active control blade vibration technology provide advanced brace for non-synchronous vibration phenomenon research. In a long run, multi-physics experimental research will still be a mainstream research method for the non-synchronous vibration.

-

-

[1] 马宏伟,蒋浩康. 压气机转子通道内尖区三维平均流场[J]. 航空动力学报,1997,12(2): 167-171. doi: 10.13224/j.cnki.jasp.1997.02.016MA Hongwei,JIANG Haokang. Three-dimensinal flow field inside a compressor rotor tip region[J]. Journal of Aerospace Power,1997,12(2): 167-171. (in Chinese) doi: 10.13224/j.cnki.jasp.1997.02.016 [2] 马宏伟,蒋浩康. 压气机不同状态下转子出口三维紊流流场[J]. 航空动力学报,1997,12(3): 268-272.MA Hongwei,JIANG Haokang. 3D turbulent flow at compressor rotor exit under different flow conditions[J]. Journal of Aerospace Power,1997,12(3): 268-272. (in Chinese) [3] MA Hongwei,WEI Wei,XAVIER O. Experimental investigation of flow field in a laboratory-scale compressor[J]. Chinese Journal of Aeronautics,2017,30(1): 31-46. doi: 10.1016/j.cja.2016.09.016 [4] IM H S, ZHA Gecheng. Effects of rotor tip clearance on tip clearance flow potentially leading to NSV in an axial compressor[R]. ASME GT2012-68148, 2012. [5] ESPINAL D,IM H S,ZHA Gecheng. Full-annulus simulation of nonsynchronous blade vibration excitation of an axial compressor[J]. Journal of Turbomachinery,2018,140: 031008.1-031008. [6] GAN Jiaye, IM H S, ESPINAL D. Investigation of a compressor rotor non-synchronous vibration with and without fluid-structure interaction[R]. ASME GT2014-26478, 2014. [7] CLARK S T,BESEM F M,KIELB R E. Developing a reduced-order model of nonsynchronous vibration in turbomachinery using proper-orthogonal decomposition methods[J]. Journal of Turbomachinery,2015,137: 052501.1-052501.11. [8] PATEL P, YANG Yunchao, ZHA Gecheng. Improved delayed detached eddy simulation (IDDES) of a 1.5 stage axial compressor non-synchronous vibration[R]. ASME GT2020-15073, 2020. [9] ZHANG Mingming,HOU Anping. Investigation on the flow field entropy structure of non-synchronous blade vibration in an axial turbocompressor[J]. Entropy,2020,22(12): 1372.1-1372.17. [10] ZHANG Mingming,HOU Anping,HAN Yadong. Investigation on the mechanism and parametric description of non-synchronous blade vibration[J]. Entropy,2021,23(4): 383.1-383.18. [11] HOLLENBACH R, KIELB R, HALL K. Extending a Van der Pol based reduced-order model for fluid-structure interaction applied to non-synchronous vibrations in turbomachinery[R]. ASME GT2021-58965, 2021. [12] BRANDSTETTER C,STAPELFELDT S. Analysis of a linear model for non-synchronous vibrations near stall[J]. International Journal of Turbomachinery Propulsion and Power,2021,6(3): 26.1-26.14. [13] SPIKER M A. Development of an efficient design method for non-synchronous vibrations[D]. Durham, US: Duke University, 2008. [14] CLARK S T, KIELB R E, HALL K C. Developing a reduced-order model to understand non-synchronous vibration(NSV) in turbomachinery[R]. ASME GT2012-68145, 2012. [15] 王丹. 航空发动机压气机叶片流固耦合振动动力学特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.WANG Dan. Study on the dynamics of vibrations for the aero-engine compressor blades considered the fluid-structure interactions[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese) [16] HOSKOTI L,MISRA A,SUCHEENDRAN M M. Frequency lock-in during vortex induced vibration of a rotating blade[J]. Journal of Fluid and Vibration,2018,80: 145-164. [17] LIU J M, HOLSTE F, NEISE W. On the azimuthal mode structure of rotating blade flow instabilities in axial turbomachines[R]. AIAA 96-1741, 1996. [18] BAUMGARTNER M, KAMEIER F, HOURMOUZIADIS J. Non-engine order blade vibration in a high pressure compressor[R]. Melbourne, Australia: 12th International Symposium on Airbreathing Engines, 1995. [19] BLEVINS R D. 流体诱发振动[M]. 吴恕三, 王觉, 译. 北京: 机械工业出版社, 1983. [20] SPIKER M A, KIELB R E. Efficient design method for non-synchronous vibrations using enforced motion[R]. ASME GT2008-50599, 2008. [21] KIELB R E, BARTER J W, THOMAS J P. Blade excitation by aerodynamic instabilities: a compressor blade study[R]. ASME GT2003-38634, 2003. [22] HAN Le, WEI Dasheng, WANG Yanrong. Locked-in phenomenon between tip clearance flow instabilities and enforced blade motion in axial transonic compressor rotors[R]. ASME GT2020-16050, 2020. [23] STAPELFELDT S,BRANDSTETTER C. Non-synchronous vibration in axial compressors: lock-in mechanism and semi-analytical model[J]. Journal of Sound and Vibration,2020,488(8): 115649.1-115649.10. [24] MOLLER D, SCHIFFER H P. On the mechanism of spike stall inception and near stall nonsynchronous vibration in an axial compressor[R]. ASME GT2020-14711, 2020. [25] THOMASSIN J, HUU D V. Blade tip clearance flow and compressor NSV: the jet core feedback theory as the coupling mechanism[R]. ASME GT2007-27286, 2007. [26] HO Chiming,NOSSIER N S. Dynamics of an impinging jet: Part 1 the feedback phenomenon[J]. Journal of Fluid Mechanics,1981,105: 119-142. doi: 10.1017/S0022112081003133 [27] HUU D V. Role of tip clearance flow in rotating instabilities and nonsynchronous vibration[J]. Journal of Propulsion and Power,2010,26: 556-561. doi: 10.2514/1.26709 [28] CAMP T R. A study of acoustic resonance in a low-speed multistage compressor[J]. Journal of Turbomachinery,1999,121: 36-43. doi: 10.1115/1.2841232 [29] DROLET M, HUU D V, THOMASSIN J. Numerical investigation into non-synchronous vibrations of axial flow compressors by the resonant tip clearance flow[R]. ASME GT2009-59074, 2009. [30] 杨明绥,刘思远,王德友,等. 航空发动机压气机声共振现象初探[J]. 航空发动机,2012,38(5): 36-42. doi: 10.3969/j.issn.1672-3147.2012.05.009YANG Mingsui,LIU Siyuan,WANG Deyou,et al. Study of acoustic resonance for aeroengine compressors[J]. Aeroengine,2012,38(5): 36-42. (in Chinese) doi: 10.3969/j.issn.1672-3147.2012.05.009 [31] 洪志亮,赵国昌,杨明绥,等. 航空发动机压气机内部流体诱发声共振研究进展[J]. 航空学报,2019,40(11): 023139.1-023139.12. doi: 10.7527/S1000-6893.2018.23139HONG Zhiliang,ZHAO Guochang,YANG Mingsui,et al. Development of flow-induced acoustic resonance in aeroengine compressors[J]. Acta Aeronautica et Astronautica Sinica,2019,40(11): 023139.1-023139.12. (in Chinese) doi: 10.7527/S1000-6893.2018.23139 [32] SUGENE F,FIEDLER K. An experimental investigation into unsteady blade forces and blade losses in axial compressor blade cascade[J]. Journal of Engineering for Gas Turbines and Power,1986,108: 47-52. doi: 10.1115/1.3239884 [33] 杨慧,郑赟. 测量叶轮机振动叶片表面非定常气动响应的实验技术——影响系数法[J]. 实验流体力学,2011,25(3): 71-77. doi: 10.3969/j.issn.1672-9897.2011.03.016YANG Hui,ZHENG Yun. Experimental technique for measuring unsteady aerodynamics of vibrating blade in turbomachinery: influence coefficient method (ICM)[J]. Journal of Experiments in Fluid Mechanics,2011,25(3): 71-77. (in Chinese) doi: 10.3969/j.issn.1672-9897.2011.03.016 [34] HANAMURA Y,HIDEO T,KAZUO Y. A simplified method to measure unsteady forces acting on the vibrating blades in cascade[J]. Bulletin of the Japan Society of Mechanical Engineers,1980,23(180): 880-887. doi: 10.1299/jsme1958.23.880 [35] WATANABE T,KAJI S. Experimental study on unsteady aerodynamic characterisics of an oscillating cascade with tip clearance[J]. Japan Society of Mechanical Engineers International Journal,1988,31(4): 660-667. [36] EHRLICH D A,FLEETER S. Incidence effects on chordwise bending cascade unsteady aerodynamics[J]. AIAA Journal,2000,38(2): 284-291. [37] NOWINSKI M, PANOVSKY J. Flutter mechanisms in low pressure turbine blades[R]. ASME 1998-GT-573, 1998. [38] BELL D L,HE Li. Three-dimensional unsteady flow for an oscillating turbine blade and the influence of tip leakage[J]. Journal of Turbomachinery,2000,122: 93-101. doi: 10.1115/1.555432 [39] 杨慧,何力,王延荣. 压气机线性振荡叶栅气弹试验研究二: 叶尖间隙的影响[J]. 航空学报,2008,29(4): 804-810. doi: 10.3321/j.issn:1000-6893.2008.04.006YANG Hui,HE Li,WANG Yanrong. Experimental study on aeroelasticity in linear oscillating compressor cascade: Part 2 tip clearance effect[J]. Acta Aeronautica et Astronautica Sinica,2008,29(4): 804-810. (in Chinese) doi: 10.3321/j.issn:1000-6893.2008.04.006 [40] HOLLENBACH R, KIELB R, HALL K. Unsteady pressures analysis of an oscillating airfoil exhibiting nonsynchronous vibrations as applied to turbomachinery[R]. San Diego, US: AIAA SciTech Forum, 2022. [41] HAN Le,WEI Dasheng,WANG Yanrong. Lock-in phenomenon of tip clearance flow and its influence on aerodynamic damping under specified vibration on an axial transonic compressor rotor[J]. Chinese Journal of Aeronautics,2021,35(3): 185-200. [42] 魏巍. 叶顶几何对轴流压气机气动性能及尖区非定常流动的影响[D]. 北京: 北京航空航天大学, 2015.WEI Wei. Experimental investigation of the effects of tip geometry on the performance and unsteady flow field in a large-scale compressor[D]. Beijing: Beihang University, 2015. (in Chinese) [43] 王理想. 压气机平面叶栅尖区流动及其与叶片振动耦合机理的研究[D]. 北京: 北京航空航天大学, 2017.WANG Lixiang. Investigation of the flow in the tip region of a compressor cascade and its coupling with blade vibration[D]. Beijing: Beihang University, 2017. (in Chinese) [44] SHI Lei,MA Hongwei,YU Xinghang. POD analysis of the unsteady behavior of blade wake under the influence of laminar separation vortex shedding in a compressor cascade[J]. Aerospace Science and Technology,2020,105: 106056.1-106056.15. [45] SCHOENENBORN H, CHENAUX V, OTT P. Aeroelasticity at reversed flow conditions: Part 1 numerical and experimental investigations of a compressor cascade with controlled vibration[R]. ASME GT2011-45034, 2011. [46] KEERTHI M C, KUSHARI A. Experimental study of the unsteady blade forces in an oscillating annular compressor cascade[R]. ASME GTINDIA2015-1333, 2015. [47] BRANDSTETTER C, JUNGST C M, SCHIFFER H P. Measurement of radial vortices, spill forward and vortex breakdown in a transonic compressor[R]. ASME GT2017-64576, 2017. [48] HOLZINGER F,WARTZEK F. Self-excited blade vibration experimentally investigated in transonic compressors: rotating instabilities and flutter[J]. Journal of Turbomachinery,2016,138: 041006.1-041006.9. [49] BRANDSTETTER C,PAGES V. Project phare 2: a high speed UHBR fan test facility for a new open-test case[J]. Journal of Turbomachinery,2019,141: 101004.1-101004.9. [50] BRANDSTETTER C,PAOLETTI B,OTTAVY X. Compressible modal instability onset in an aerodynamically mistuned transonic fan[J]. Journal of Turbomachinery,2019,141: 031004.1-031004.11. [51] RODRIGUES M,SOULAT L,PAOLETTI B,et al. Aerodynamic investigation of a composite low-speed fan for UHBR application[J]. Journal of Turbomachinery,2021,143: 101004.1-101004.12. [52] 贺象. 轴流压气机非定常扰动及失速先兆的数值模拟和实验研究[D] . 北京: 北京航空航天大学, 2012.HE Xiang. Numerical and experimental investigation of unsteady disturbance and stall inception in axial compressors[D]. Beijing: Beihang University, 2012. (in Chinese) [53] LENG Yujun,KEY N L. Utilization of fast response pressure measurements to non-intrusively monitor blade vibration in axial compressor[J]. Journal of Turbomachinery,2020,142(3): 031001.1-031001.12. [54] MURRAY III W L,KEY N L. Experimental investigation of a forced-response condition in a multistage compressor[J]. Journal of Propulsion and Power,2015,31(5): 1320-1329. doi: 10.2514/1.B35525 [55] FAN C, RUSSHARD P, WANG A. Analysis of blade tip timing data from fan blades with synchronous and non-synchronous vibration[R]. Ancona, Italy: 13th International Conference on Vibration Measurements by Laser and Noncontact Techniques, 2018. [56] CARASSALE L, COLETTI F, GUIDA R. Multi-channel spectral analysis of non-synchronous vibrations of bladed disks measured by blade tip timing[R]. ASME GT2020-15512, 2020. [57] 段发阶,李刚,叶德超,等. 基于叶尖定时的叶片动应力反演方法[J]. 纳米技术与精密工程,2016,14(3): 161-166. doi: 10.13494/j.npe.20150077DUAN Fajie,LI Gang,YE Dechao,et al. Method for inversing dynamic stress of blade based on tip-timing[J]. Nano-technology and Precision Engineering,2016,14(3): 161-166. (in Chinese) doi: 10.13494/j.npe.20150077 [58] 敖春燕, 乔百杰, 刘美茹, 等. 基于非接触式测量的旋转叶片动应变重构方法[J]. 航空动力学报, 2020, 35(3): 569-580.AO Chunyan, QIAO Baijie, LIU Meiru, et al. Dynamic strain reconstruction method of rotating blades based on no-contact measurement, 2020, 35(3): 569-580. (in Chinese) [59] RUSSHARD P. Blade tip timing (BTT) uncertainties[J]. AIP Conference Proceedings,2016,1740(1): 020003.1-020003.13. [60] 王维民,任三群,陈立芳,等. 涡轮机叶片同步振动参数辨识方法研究(实验研究)[J]. 振动与冲击,2017,36(17): 127-133.WANG Weimin,REN Sanqun,CHEN Lifang,et al. Tests for synchronous vibration parametric identification method of a turbine’s blades[J]. Journal of Vibration and Shock,2017,36(17): 127-133. (in Chinese) [61] 许敬晖,乔百杰,滕光蓉,等. 基于压缩感知的叶端定时信号参数辨识方法[J]. 航空学报,2021,42(5): 524229.1-524229.11.XU Jinghui,QIAO Baijie,TENG Guangrong,et al. Parameter identification of blade tip timing signal using compressed sensing[J]. Acta Aeronautica Astronautica Sinica,2021,42(5): 524229.1-524229.11. (in Chinese) [62] 徐海龙,杨拥民,胡海峰,等. 基于压缩感知的叶端定时欠采样多品叶片振动盲重构研究[J]. 机械工程学报,2019,55(13): 113-121. doi: 10.3901/JME.2019.13.113XU Hailong,YANG Yongmin,HU Haifeng,et al. Compressed sensing-based blind reconstruction of multi-frequency blade vibration from under-sampled BTT signals[J]. Journal of Mechanical Engineering,2019,55(13): 113-121. (in Chinese) doi: 10.3901/JME.2019.13.113 [63] 张智伟,柴鹏飞,孙宗翰,等. 高可靠小条件数压缩感知叶尖定时信号辨识[J]. 航空动力学报,2021,36(3): 509-519.ZHANG Zhiwei,CHAI Pengfei,SUN Zonghan,et al. High reliability identification method of blade tip timing signals based on compressed sensing under small condition number[J]. Journal of Aerospace Power,2021,36(3): 509-519. (in Chinese) [64] BOUCHAIN A, PICHERAL J, LAHALLE E, et al. New possibilities for analyzing complex asynchronous blade vibrations from tip-timing data using a sparse spectral analysis method[R]. ASME GT2019-91573, 2019. [65] DIAMOND D H,HEYNS P S. A novel method for the design of proximity sensor configuration for rotor blade tip timing[J]. Journal of Vibration and Acoustic,2018,140(6): 061003.1-061003.8. [66] CHEN S S,DONOHO D L,SAUNDERS M A. Atomic decomposition by basis pursuit[J]. Society for Industrial and Applied Mathematics Review,2001,43(1): 129-159. [67] 梁道森,潘云璨,张誉瀚,等. 基于压缩感知的整体叶盘多模态振动叶尖定时信号重构方法[J]. 推进技术,2021,42(11): 2578-2589. doi: 10.13675/j.cnki.tjjs.200028LIANG Daosen,PAN Yuncan,ZHANG Yuhan,et al. Multi-modal vibration tip timing signal reconstruction method for blisk based on compressed sensing[J]. Journal of Propulsion Technology,2021,42(11): 2578-2589. (in Chinese) doi: 10.13675/j.cnki.tjjs.200028 [68] BELZ J, MAY M, SIEMANN J, et al. Excited blade vibration for aeroelastic investigations of a rotating blisk piezo-electric macro fiber composites[R]. ASME GT2013-95735, 2013. -

下载:

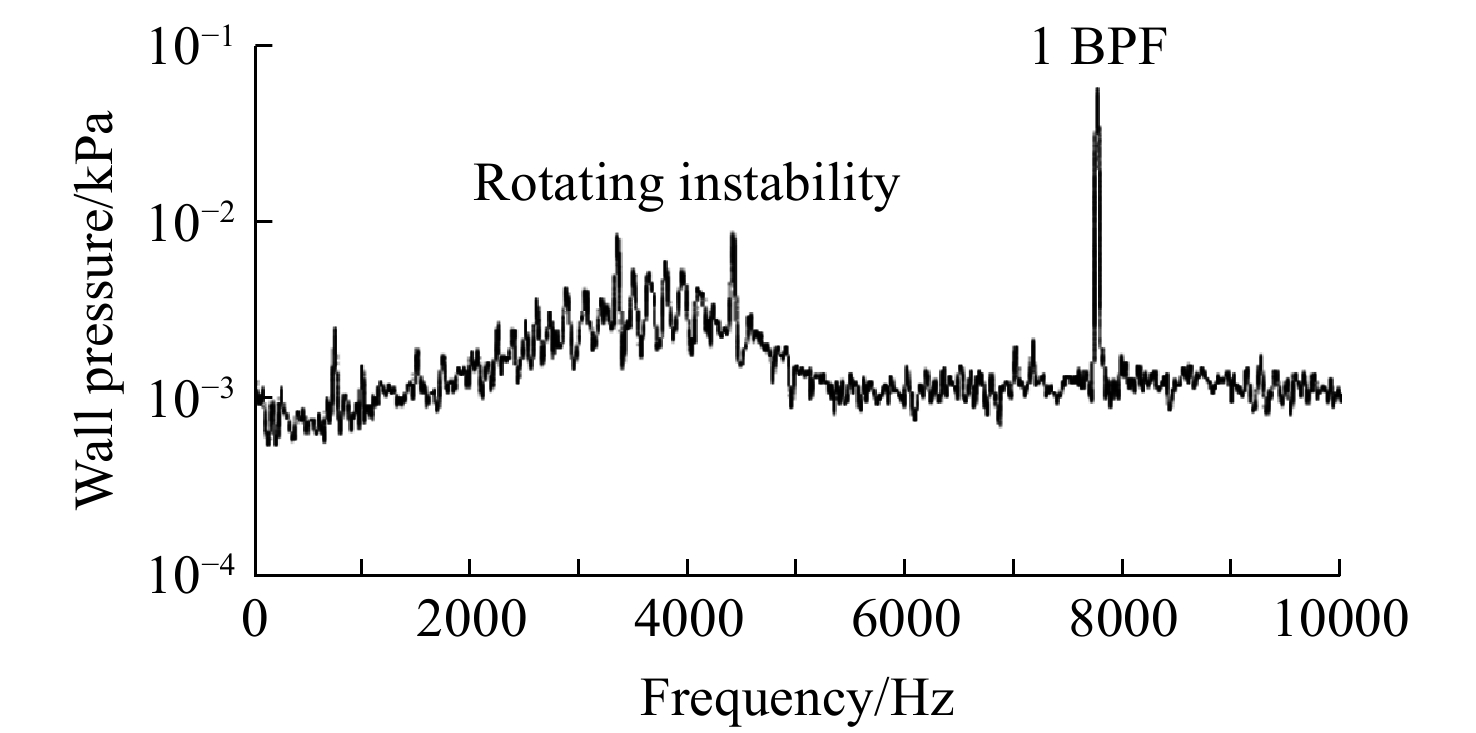

下载: