Numerical analysis on blade failure induced by strut wake in axial compressor

-

摘要:

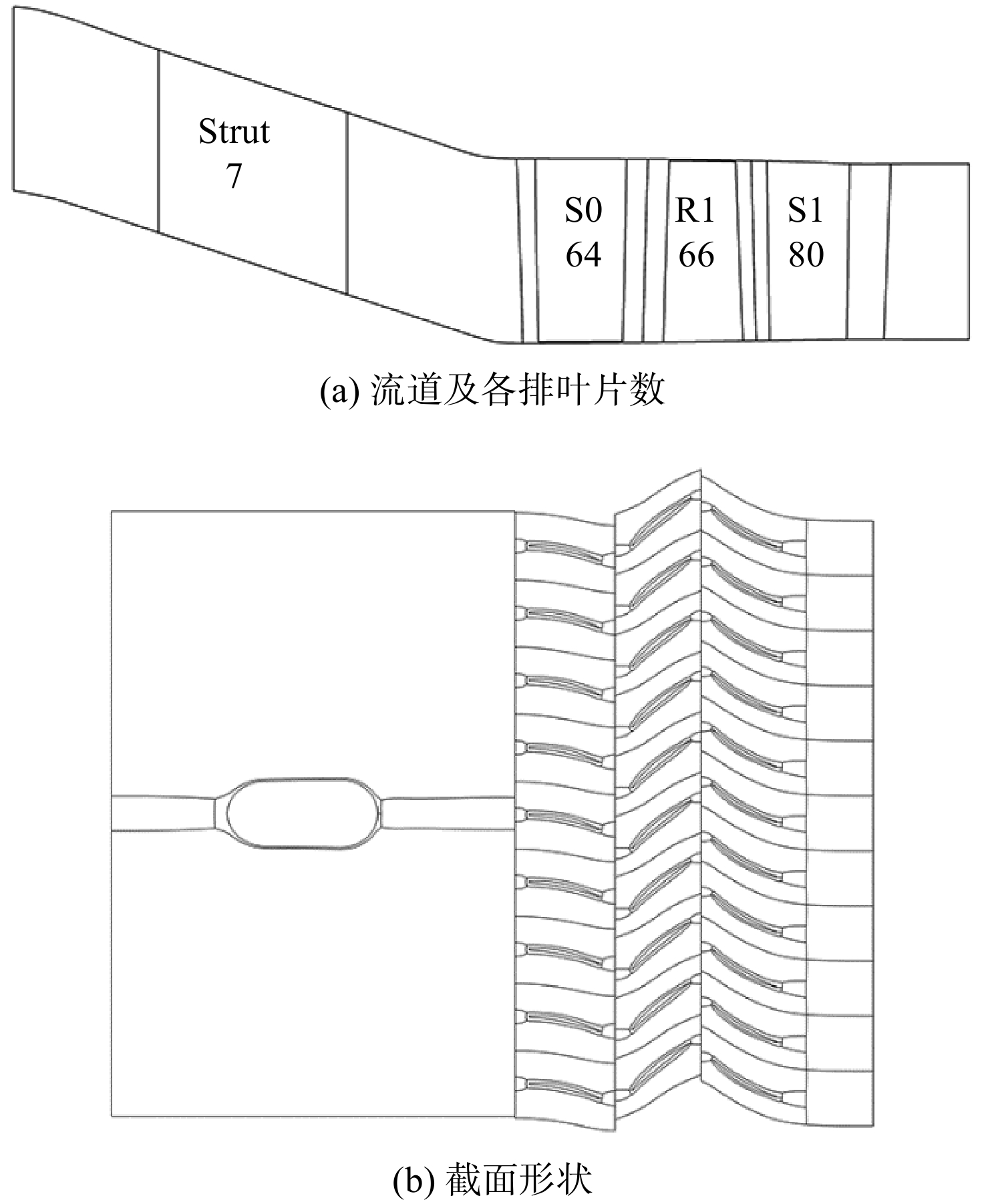

为探究某燃气轮机压气机过渡段支板后方导叶发生疲劳失效的原因,以带支板过渡段及高压压气机前1.5级为研究对象,利用非定常数值模拟及单向流固耦合方法,分析支板对压气机非定常流场的影响及导叶的强迫响应特征,并通过疲劳强度实验对分析结果进行了校核。结果表明:支板的存在使压气机设计点等熵效率下降3.6个百分点;支板尾缘交替脱落的涡使导叶进口攻角偏离设计值,造成气动性能下降,叶表压力脉动大幅增加;随着导叶与支板周向距离增大,支板对导叶的影响先增大后迅速减小;支板脱落涡引起的扰动频率比较分散,其低频分量引起的低阶共振是造成导叶疲劳失效的根本原因,其振动应力可达400 MPa;数值计算与实验结果吻合,证明了计算的可靠性。

Abstract:To explore the reasons for fatigue failure of inlet guide vane (IGV) downstream the strut in the transition section of a gas turbine compressor, unsteady numerical simulation and one-way fluid-structure coupling methods were used to analyze the effects of strut on unsteady flow in 1.5 stages high-pressure compressor and forced response characteristics of the IGV. Furthermore, the analysis results were checked by fatigue strength experiments. The results showed that the isentropic efficiency in the design point of compressor was reduced by 3.6 percent points compared with the model without strut. Vortex shedding alternately at the trailing edge of the strut caused the inlet attack angle of the IGV to deviate from the design value, resulting in a decrease in aerodynamic performance and a significant increase in the unsteady pressure pulsation on the IGV surface. With the increase of circumferential distance between IGV and strut, the influence of strut on IGV first increased and then decreased rapidly. The perturbation frequency resulted from the shedding vortex was relatively disperse, and the low-order resonance of IGV induced by the low frequency component was the fundamental reason of the fatigue failure of IGV; the maximum vibration stress can reach 400 MPa. The numerical simulation results were consistent with the experiment, proving the reliability of the simulation.

-

Key words:

- strut /

- unsteady /

- axial compressor /

- forced response /

- fluid-structure coupling /

- spectrum

-

表 1 模态分析结果

Table 1. Results of mode analysis

阶次 固有频率/Hz 振型 1 554.0 一弯 2 1622.0 一扭 3 2581.7 二弯 4 3608.2 5 5920.0 6 6237.9 7 7571.5 8 8281.4 9 10684.0 10 11548.0 表 2 压气机进口参数

Table 2. Compressor inlet parameters

归一化叶高/% 总压/kPa 总温/K 10 531.65 454.575 30 551.65 446.150 50 556.75 446.775 70 560.00 451.675 90 559.05 458.500 表 3 疲劳强度实验结果

Table 3. Results of fatigue strength test

叶片序号 频率/Hz 应力/MPa 寿命/106 实验时间/h 1 511.3 350 4.69 2.5 2 494.3 300 9.57 5.4 3 512.4 250 14.00 7.6 -

[1] NORRIS G,DOMINY R G,SMITH A D. Strut influences within a diffusing annular S-shaped duct[R]. ASME 98-GT-425,1998. [2] BAILEY D W,BRITCHFORD K M,CARROTTE J F,et al. Performance assessment of an annular S-shaped duct[J]. Journal of Turbomachinery,1997,119(1): 149-156. doi: 10.1115/1.2841003 [3] FELDCAMP G K,BIRK A M. Strut losses in a diverging annular diffuser with swirling flow[R]. ASME GT2006-90566,2006. [4] SENOO Y,KAWAGUCHI N,KOJIMA T,et al. Optimum strut-configuration for downstream annular diffusers with variable swirling inlet flow[J]. Journal of Fluids Engineering,1981,103(2): 294-298. doi: 10.1115/1.3241736 [5] 卜焕先,谭慧俊,何小明,等. 带支板轴对称弯曲管道的流动特性[J]. 航空动力学报,2016,31(5): 1252-1259.BU Huanxian,TAN Huijun,HE Xiaoming,et al. Flow field characteristics in an axisymmetric bend duct with struts[J]. Journal of Aerospace Power,2016,31(5): 1252-1259. (in Chinese) [6] NAYLOR E M J,DUEÑAS C O,MILLER R J,et al. Optimization of nonaxisymmetric endwalls in compressor S-shaped ducts[J]. Journal of Turbomachinery,2010,132(1): 011011.1-011011.10. [7] GRÄSEL J,PIERRÉ M,DEMOLIS J. Parametric inter-turbine duct design and optimisation[R]. Hamburg,Germany:25th International Congress of the Aeronautical Sciences,2006. [8] CHEN Y,HU W. Optimized aerodynamic design of aggressive intermediate turbine duct with strut fairings using genetic algorithms[R]. ASME GT2016-56639,2016. [9] 吴思宇,朱品武,汪作心,等. 过渡段部分对某高压压气机性能影响研究[J]. 热能动力工程,2021,36(9): 42-50.WU Siyu,ZHU Pinwu,WANG Zuoxin,et al. Research on the effect of transition section on performance of high pressure compressor[J]. Journal of Engineering for Thermal Energy and Power,2021,36(9): 42-50. (in Chinese) [10] HUBINKA J,SANTNER C,PARADISO B,et al. Design and construction of a two shaft test turbine for investigation of mid turbine frame flows[R]. ISABE-2009-1293,2009. [11] WALKER A D,BARKER A G,CARROTTE J F,et al. Integrated outlet guide vane design for an aggressive S-shaped compressor transition duct[J]. Journal of Turbomachinery,2013,135(1): 011035.1-011035.11. [12] WALKER A D,MARIAH I,HALL C. An experimental aerodynamic evaluation of design choices for a low-pressure compressor transition duct[J]. Journal of Turbomachinery,2021,143(9): 091004.1-091004.12. [13] ZHOU X D,WOLFF J M. Transonic compressor IGV/rotor interaction analysis including fluid structure interaction[R]. AIAA-2004-5292,2004. [14] MONK D,MURRAY W,KEY N L,et al. Experimental and computational study of forced response in a multistage axial compressor[R]. AIAA-2015-1342,2015. [15] MIURA T,SAKAI N,KANAZAWA N,et al. Forced response excitation due to the stator vanes of two and three compressor stages away[J]. Journal of Engineering for Gas Turbines and Power,2021,143(11): 111018.1-111018.9. [16] 田少杰,漆文凯,许正华. 气流激励下叶片振动响应分析方法[J]. 航空动力学报,2021,36(4): 826-838.TIAN Shaojie,QI Wenkai,XU Zhenghua. Method of blade vibration response analysis under airflow excitation[J]. Journal of Aerospace Power,2021,36(4): 826-838. (in Chinese) [17] 杨荣菲,刘氦旭,向宏辉,等. 进口探针支杆尾迹诱发压气机转子叶片共振的数值研究[J]. 推进技术,2021,42(5): 1002-1012.YANG Rongfei,LIU Haixu,XIANG Honghui,et al. Numerical study of compressor rotor blade resonance induced by wake of inlet probe support[J]. Journal of Propulsion Technology,2021,42(5): 1002-1012. (in Chinese) [18] NG W F,O’BRIEN W F,OLSEN T L. Experimental investigation of unsteady fan flow interaction with downstream struts[J]. Journal of Propulsion and Power,1987,3(2): 157-163. doi: 10.2514/3.22968 [19] CHIANG H-W D,TURNER M G. Compressor blade forced response due to downstream vane-strut potential interaction[J]. Journal of Turbomachinery,1996,118(1): 134-142. doi: 10.1115/1.2836594 [20] 王豪. 叶片流固耦合模拟方法研究[D]. 北京:北京航空航天大学,2020.WANG Hao. Investigation on fluid-structure interaction simulation of blades[D]. Beijing:Beihang University,2020.(in Chinese) [21] BENRA F K,DOHMEN H J,PEI J,et al. A comparison of one-way and two-way coupling methods for numerical analysis of fluid-structure interactions[J]. Journal of Applied Mathematics,2011,2011: 1-16. [22] KIELB R,CHIANG H W. Recent advancements in turbo-machinery forced response analyses[R]. Reno,US:30th Aerospace Sciences Meeting and Exhibit,1992. [23] MOFFATT S,HE L. Blade forced response prediction for industrial gas turbines: Part Ⅰ methodologies[R]. ASME GT2003-38640,2003. -

下载:

下载: