Review on efficient algorithm of failure probability for aero-engine life limited parts

-

摘要:

综述了为提高失效概率计算效率的研究成果,包括基于抽样的高效失效概率算法和基于积分的高效失效概率算法。其中,基于抽样的高效失效概率算法在传统蒙特卡洛模拟方法的基础上,通过重要性抽样方法在失效域抽样、最优抽样技术优化分区样本量、分区细化技术减少分区数量,从而减少蒙特卡洛模拟样本量。另外,基于积分的高效失效概率算法通过建立

N 次飞行循环与初始循环(N = 0)随机变量空间的映射关系,解决了时变失效区域中概率密度函数难以求解的困难。在与蒙特卡洛相对误差小于5% 条件下,积分算法时间成本降低了数十倍。Abstract:The research results for improving the efficiency of failure probability calculation, including the efficient sampling-based algorithms and the efficient integration-based algorithms, were summarized. Among them, based on the traditional Monte Carlo simulation method, the importance sampling algorithm generated samples in the failure domain. The optimal sampling technology optimized the zone sample size. The zone refinement technology reduced the number of zones, thus reducing the Monte Carlo simulation sample size. In addition, the direct integration was realized by establishing the mapping relationship of failure domain at

N flight cycles and the initial (N = 0) flight cycles based on the probability density theory. When the relative error with Monte Carlo was less than 5%, the calculation time cost was reduced by at least tens of times. -

-

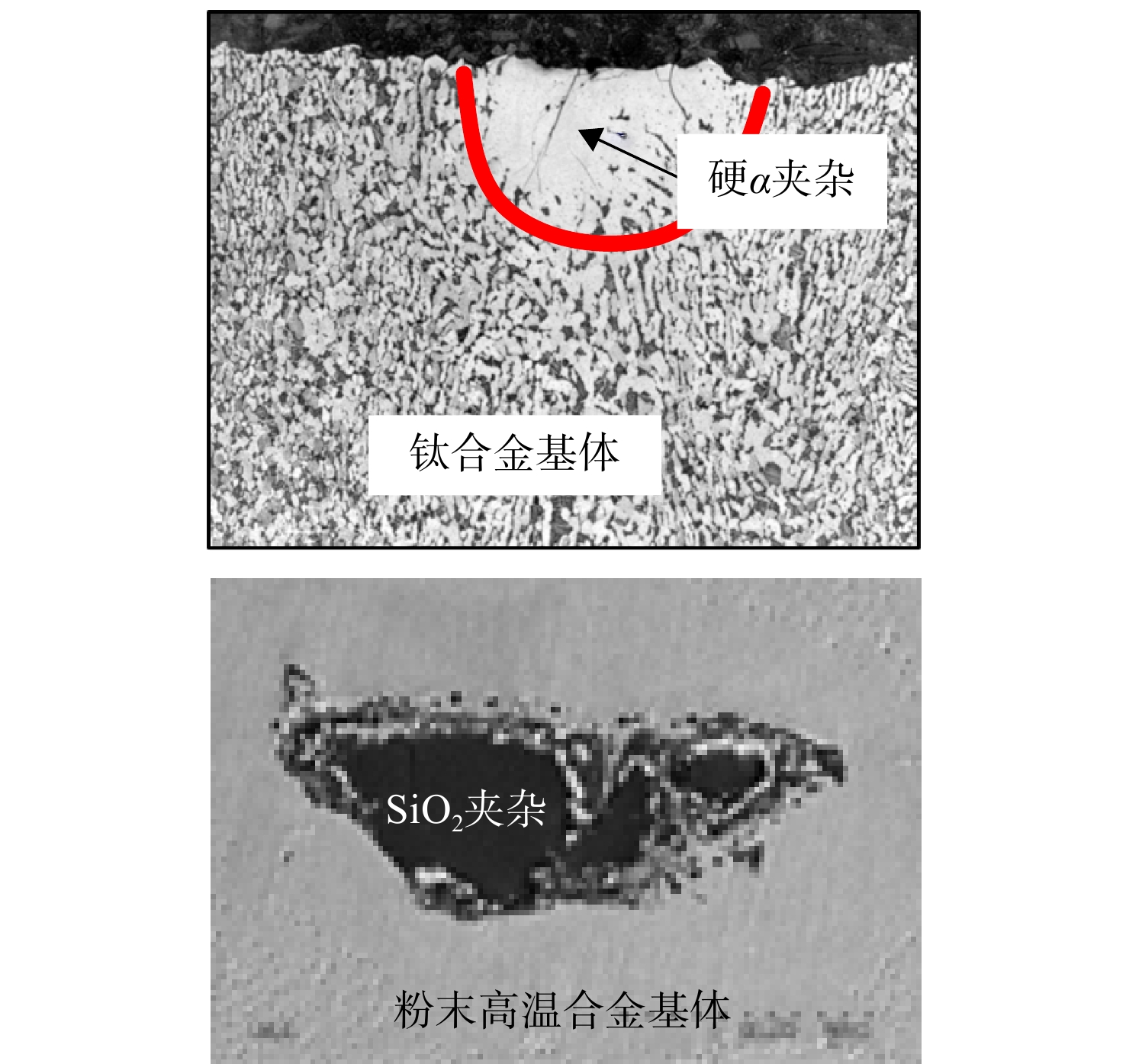

[1] CHAMIS C C. Damage tolerance and reliability of turbine engine components[R]. NASA/TP-1999-209878, 1999. [2] WU Y T,ENRIGHT M P,MILLWATER H R. Probabilistic methods for design assessment of reliability with inspection[J]. AIAA Journal,2002,40(5): 937-946. doi: 10.2514/2.1730 [3] ENRIGHT M P,HUYSE L. Methodology for probabilistic life prediction of multiple-anomaly materials[J]. AIAA Journal,2006,44(4): 787-793. doi: 10.2514/1.17142 [4] ENRIGHT M P,HUDAK S J,MCCLUNG R C,et al. Application of probabilistic fracture mechanics to prognosis of aircraft engine components[J]. AIAA Journal,2006,44(2): 311-316. doi: 10.2514/1.13142 [5] Federal Aviation Administration. Advisory circular 33.70-1: guidance material for aircraft engine-life-limited parts requirements[R]. Washington, US: Department of Transportation, 2009. [6] Federal Aviation Administration. Advisory circular 33.70-2: damage tolerance of hole features in high-energy turbine engine rotors[R]. Washington, US: Department of Transportation, 2009. [7] Federal Aviation Administration. Advisory circular 33.14-1: damage tolerance for high energy turbine engine rotors[R]. Washington, US: Department of Transportation, 2009. [8] 李家祥. 航空发动机适航规定: CCAR-33R2[S]. 北京: 中国民用航空局, 2011. [9] European Aviation Safety Agency. Certification specifications and acceptable means of compliance for large aero planes, amendment[EB/OL]. [2022-04-29]. https://www.easa.europa.eu/document-library/certification-specifications/cs-e-amendment. [10] 丁水汀,周惠敏,刘俊博,等. 航空发动机限寿件表面特征概率损伤容限评估[J]. 航空动力学报,2021,36(2): 421-430. doi: 10.13224/j.cnki.jasp.2021.02.021DING Shuiting,ZHOU Huimin,LIU Junbo,et al. Probabilistic damage tolerance assessment of the surface features of aero engine life limited parts[J]. Journal of Aerospace Power,2021,36(2): 421-430. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.02.021 [11] LEVERANT G R,MILLWATER H R,MCCLUNG R C,et al. A new tool for design and certification of aircraft turbine rotors[J]. Journal of Engineering for Gas Turbines and Power,2004,126(1): 155-159. doi: 10.1115/1.1622409 [12] Sub-team to the Aerospace Industries Association Rotor Integrity Sub-committee. The development of anomaly distributions for aircraft engine titanium disk alloys[R]. Kissimmee, US: 38th Structures, Structural Dynamics, and Materials Conference, 1997. [13] WU Y T, MILLWATER H R, ENRIGHT M P. Efficient and accurate methods for probabilistic analysis of titanium rotors[R]. South Bend, US: 8th ASCE Specialty Conference on Probabilistic Mechanics and Structural Reliability, 2000. [14] ENRIGHT M P, MCCLUNG R C, LIANG W, et al. A tool for probabilistic damage tolerance of hole features in turbine engine rotors[R]. Copenhagen, Denmark: ASME Turbo Expo: Turbine Technical Conference and Exposition, 2012. [15] HUYSE L, ENRIGHT M P. Efficient statistical analysis of failure risk in engine rotor disks using importance sampling techniques[R]. AIAA 2003-1838, 2003. [16] ENRIGHT M P,MILLWATER H R,HUYSE L. Adaptive optimal sampling methodology for reliability prediction of series systems[J]. AIAA Journal,2006,44(3): 523-528. doi: 10.2514/1.11290 [17] ENRIGHT M P, MILLWATER H R. Optimal sampling techniques for zone-based probabilistic fatigue life prediction[R]. AIAA 2002-1383, 2002. [18] MILLWATER H R, ENRIGHT M P, FITCH S. A convergent probabilistic technique for risk assessment of gas turbine disks subject to metallurgical defects[R]. AIAA 2002-1382, 2002. [19] YANG L,DING S,WANG Z,et al. Efficient probabilistic risk assessment for aeroengine turbine disks using probability density evolution[J]. AIAA Journal,2017,55(8): 2755-2761. doi: 10.2514/1.J055237 [20] LIU J B, DING S T, LI G. Influence of random variable dimension on the fast numerical integration method of aero engine rotor disk failure risk analysis[R]. Virtual: ASME International Mechanical Engineering Congress and Exposition, 2020. [21] DING S,WANG Z,QIU T,et al. Probabilistic failure risk assessment for aeroengine disks considering a transient process[J]. Aerospace Science and Technology,2018,78: 696-707. doi: 10.1016/j.ast.2018.05.017 [22] MILLWATER H R, FITCH S, WU Y T, et al. A probabilistically-based damage tolerance analysis computer program for hard alpha anomalies in titanium rotors[R]. Munich, Germany: ASME Turbo Expo: Power for Land, Sea, and Air, 2000. [23] TRYON R, MATTHEWS R. Integrated processing and probabilistic lifing models for superalloy turbine disks[R]. AIAA 2011-1739, 2011. [24] ENRIGHT M P,MCCLUNG R C. A probabilistic framework for gas turbine engine materials with multiple types of anomalies[J]. Journal of Engineering for Gas Turbines and Power,2011,133(8): 1-10. [25] CORRAN R, GORELIK M, LEHMANN D, et al. The development of anomaly distributions for machined holes in aircraft engine rotors[R]. Barcelona, Spain: ASME Turbo Expo: Power for Land, Sea, and Air, 2006. [26] MCCLUNG R C, ENRIGHT M P, LIANG W W. Integration of NASA-developed lifing technology for PM alloys into DARWIN®[R]. San Antonio, US: Southwest Research Institute, 2011. [27] 周晓明. 粉末高温合金中非金属夹杂物的遗传特征及损伤力学行为研究[D]. 北京: 北京航空材料研究院, 2006.ZHOU Xiaoming. Genetic characteristic and damage mechanical behavior of non-metallic inclusions in P/M superalloy[D]. Beijing: Beijing Institute of Aeronautical Materials, 2006. (in Chinese) [28] PARIS P,ERDOGAN F. A critical analysis of crack propagation laws[J]. Journal of Fluids Engineering,1963,85(4): 528-533. [29] NEWMAN J C. Stress-intensity factor equations for cracks in three-dimensional finite bodies subjected to tension and bending loads[M]. Hampton, US: Langley Research Center, National Aeronautics and Space Administration, 1984. [30] GLINKA G,SHEN G. Universal features of weight functions for cracks in mode I[J]. Engineering Fracture Mechanics,1991,40(6): 1135-1146. doi: 10.1016/0013-7944(91)90177-3 [31] ZHOU H M, DING S T, GUO L. Universal weight function method on the probabilistic surface damage tolerance assessment of aeroengine rotors[R]. Virtual: ASME International Mechanical Engineering Congress and Exposition, 2020. [32] WU X R. A review and verification of analytical weight function methods in fracture mechanics[J]. Fatigue Fracture Engineering Materials and Structure,2019,42(9): 1-26. [33] WU Y T J, ZHAO J, SHIAO M, et al. Efficient methods for probabilistic damage tolerance inspection optimization[R]. AIAA 2010-2518, 2010. [34] SHOOK B, MILLWATER H R, HU D K S, et al. Comparison of continual on-board inspections to a single mid-life inspection for gas turbine engine disks[R]. AIAA 2005-2215, 2005. [35] ENRIGHT M P,MCCLUNG R C. A probabilistic framework for gas turbine engine materials with multiple types of anomalies[J]. Journal of Engineering for Gas Turbines and Power,2011,133(8): 082502.1-082502.10. [36] 张弓,周燕佩,丁水汀. 面向适航要求的涡轮发动机限寿件概率失效风险评估方法[J]. 航空动力学报,2015,30(10): 2338-2042. doi: 10.13224/j.cnki.jasp.2015.10.006ZHANG Gong,ZHOU Yanpei,DING Shuiting. Probabilistic failure risk assessment method of turbine engine life limited parts for airworthiness requirements[J]. Journal of Aerospace Power,2015,30(10): 2338-2042. (in Chinese) doi: 10.13224/j.cnki.jasp.2015.10.006 [37] LI J,CHEN J. The principle of preservation of probability and the generalized density evolution equation[J]. Structural Safety,2008,30(1): 65-77. doi: 10.1016/j.strusafe.2006.08.001 [38] 李果, 丁水汀, 刘俊博, 等. 一种基于概率密度演化理论的概率失效风险评估高效计算方法: ZL 2018 1 1135082.5[P]. 2021-01-08. [39] LI G,LIU J,ZHOU H,et al. Efficient numerical integration algorithm of probabilistic risk assessment for aero-engine rotors considering in-service inspection uncertainties[J]. Aerospace,2022,9(9): 525.1-525.18. -

下载:

下载: