Significance of 40Cr laser quenching process parameters considering transformation induced plasticity

-

摘要:

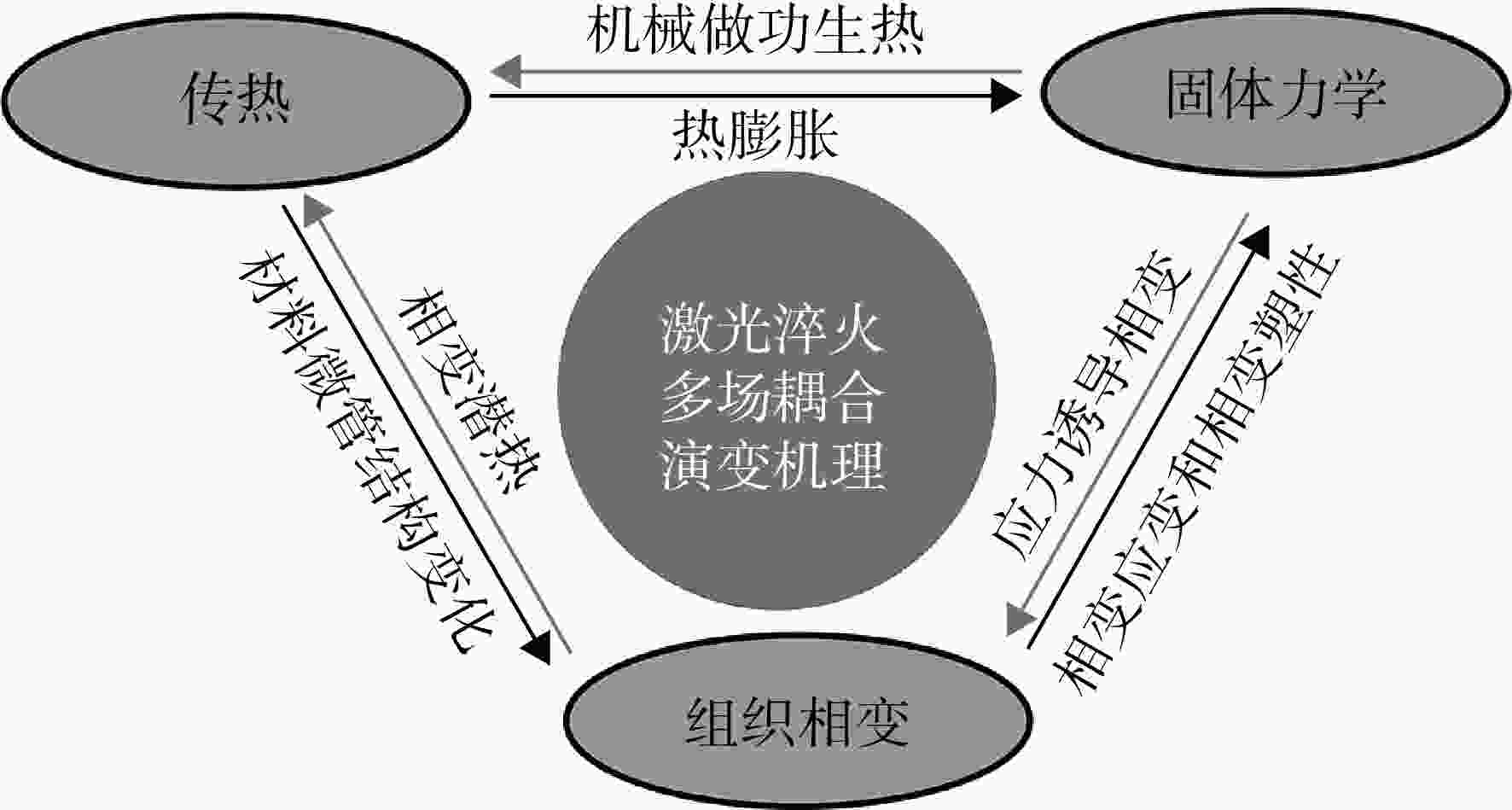

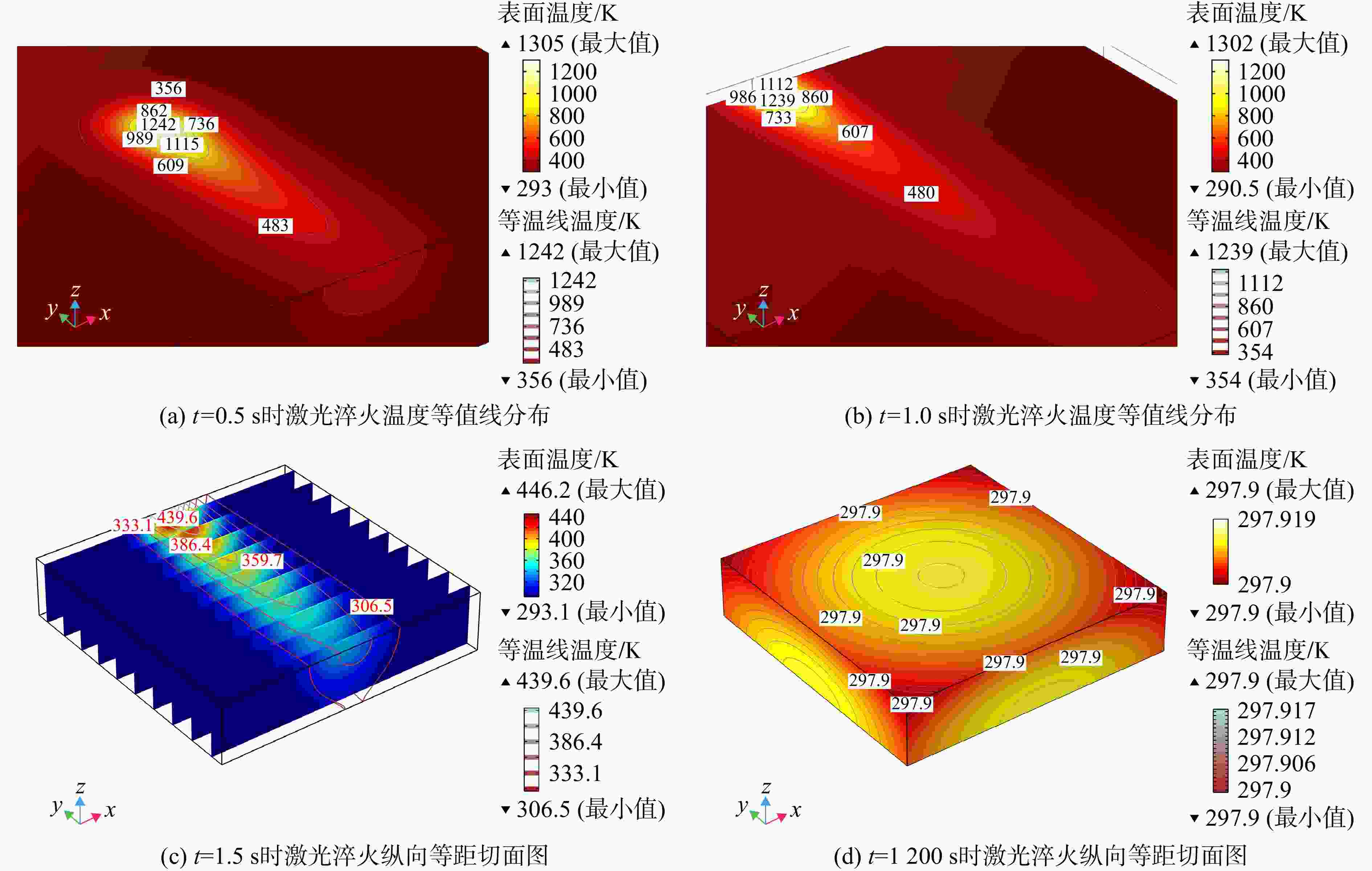

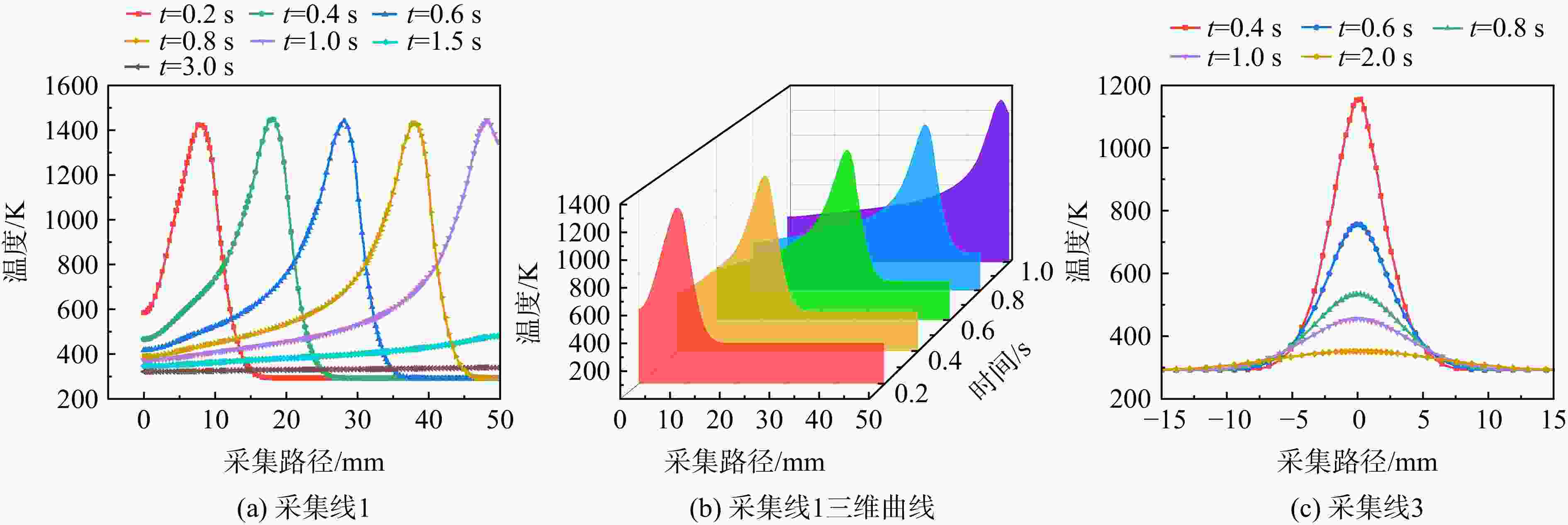

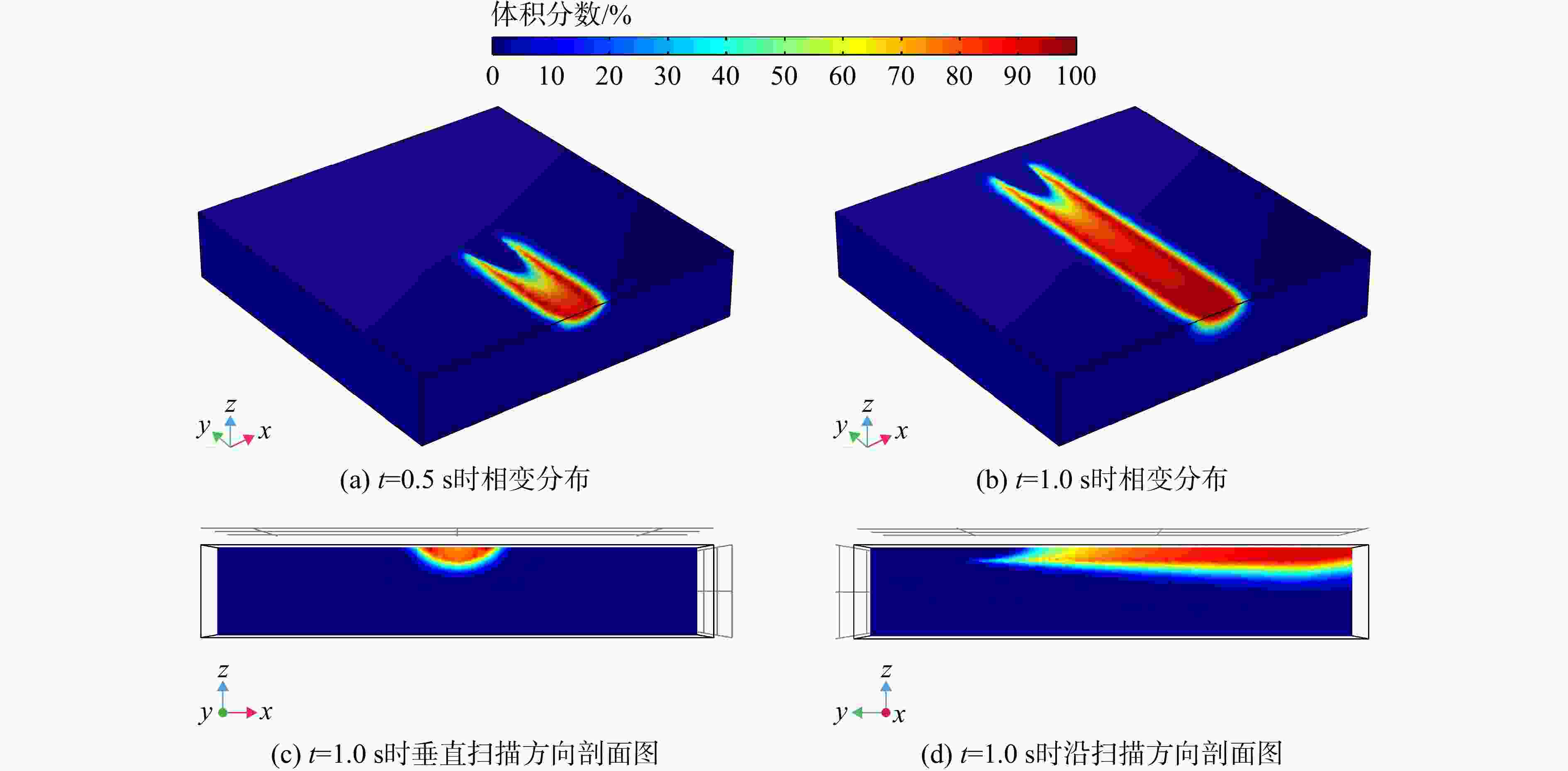

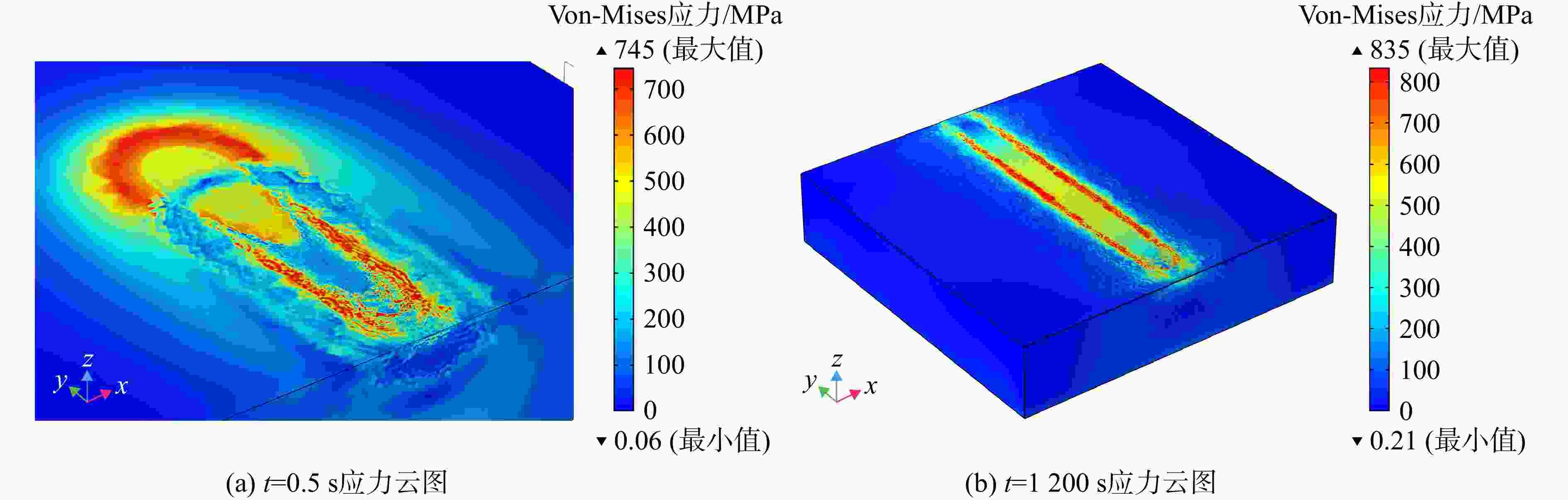

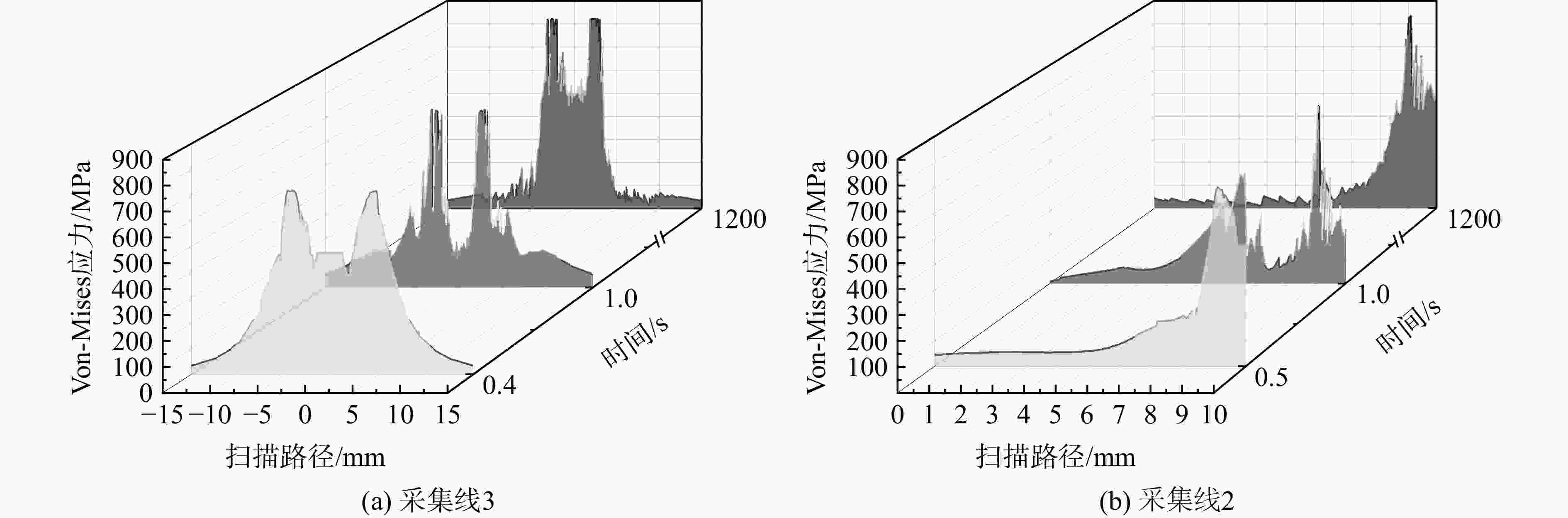

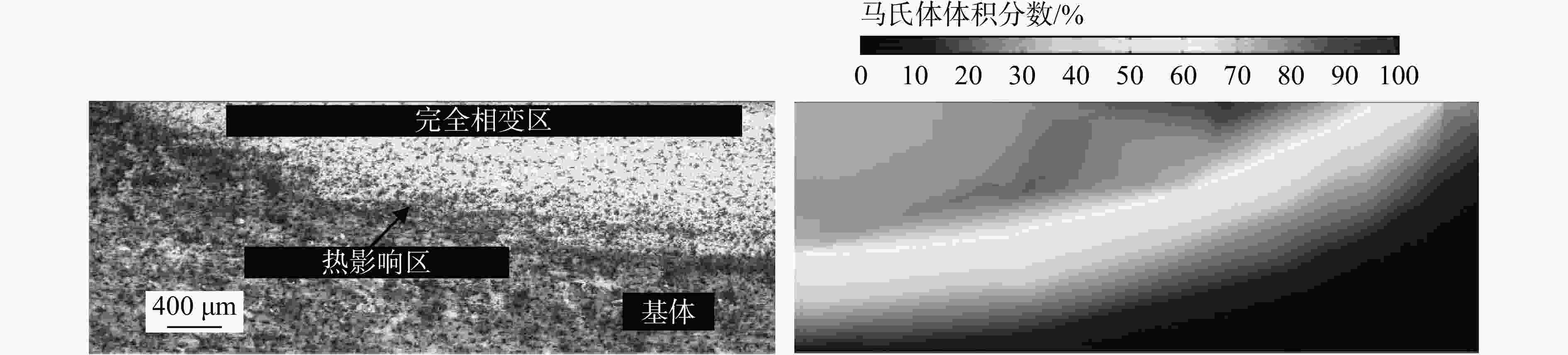

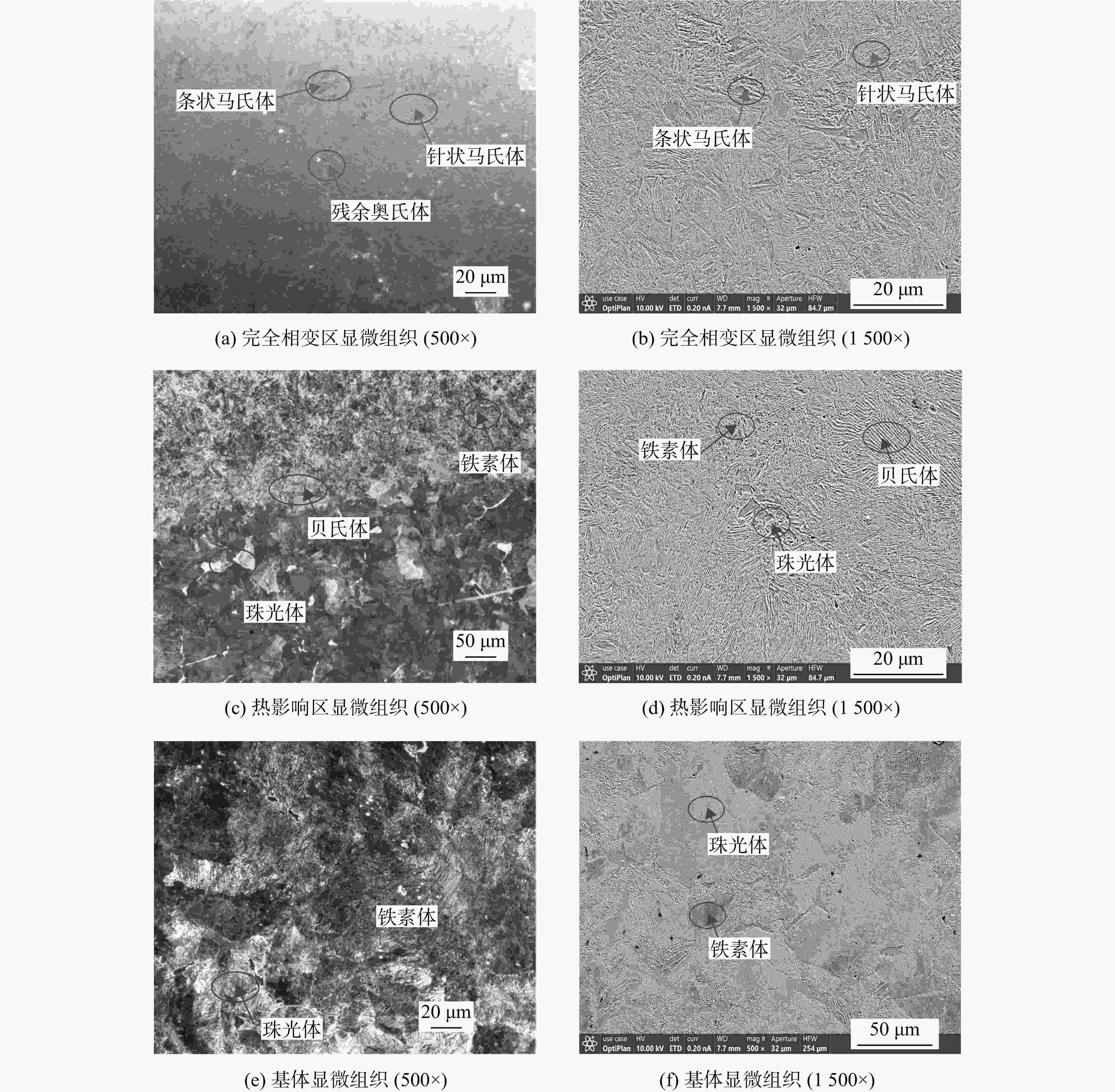

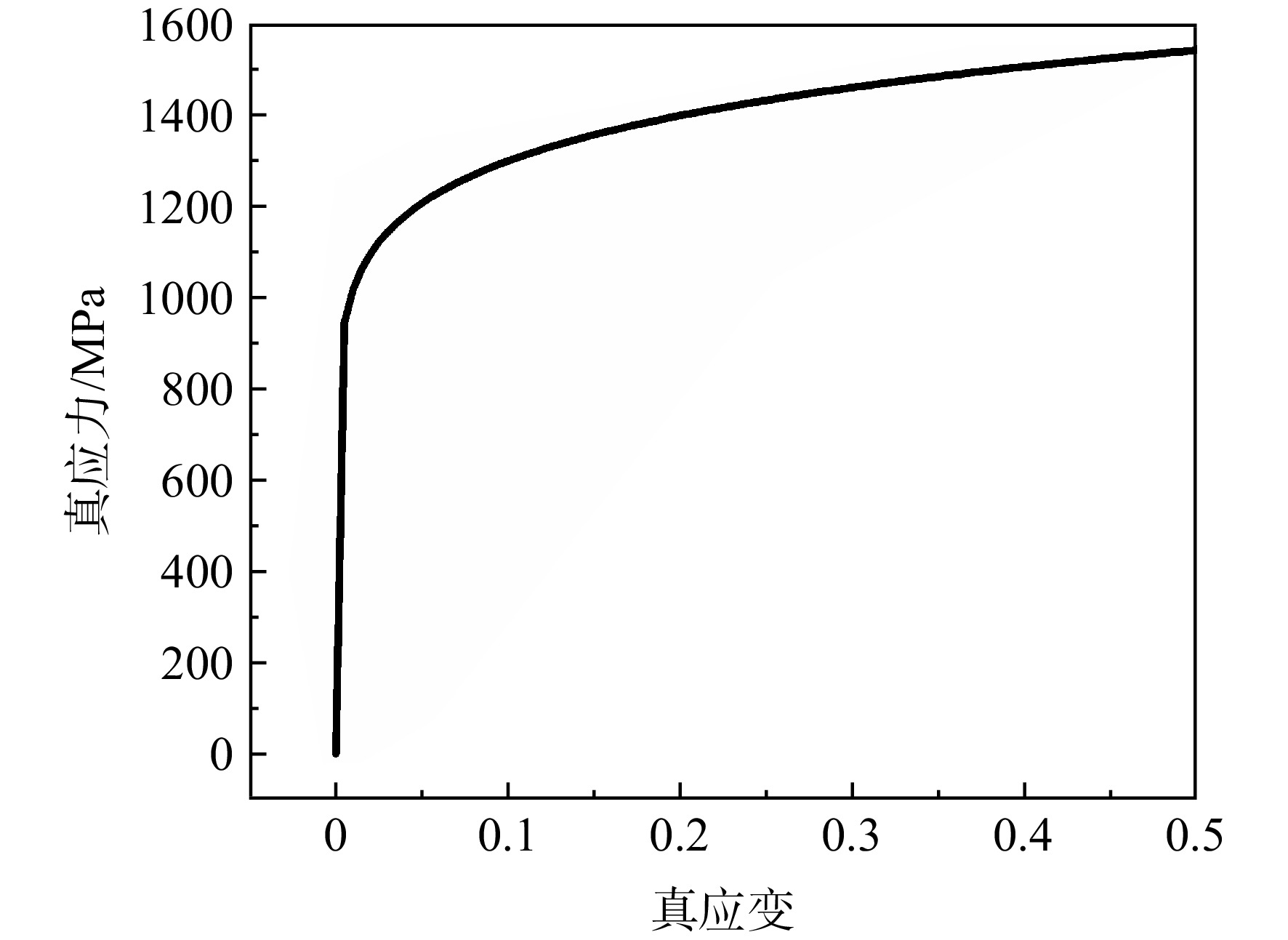

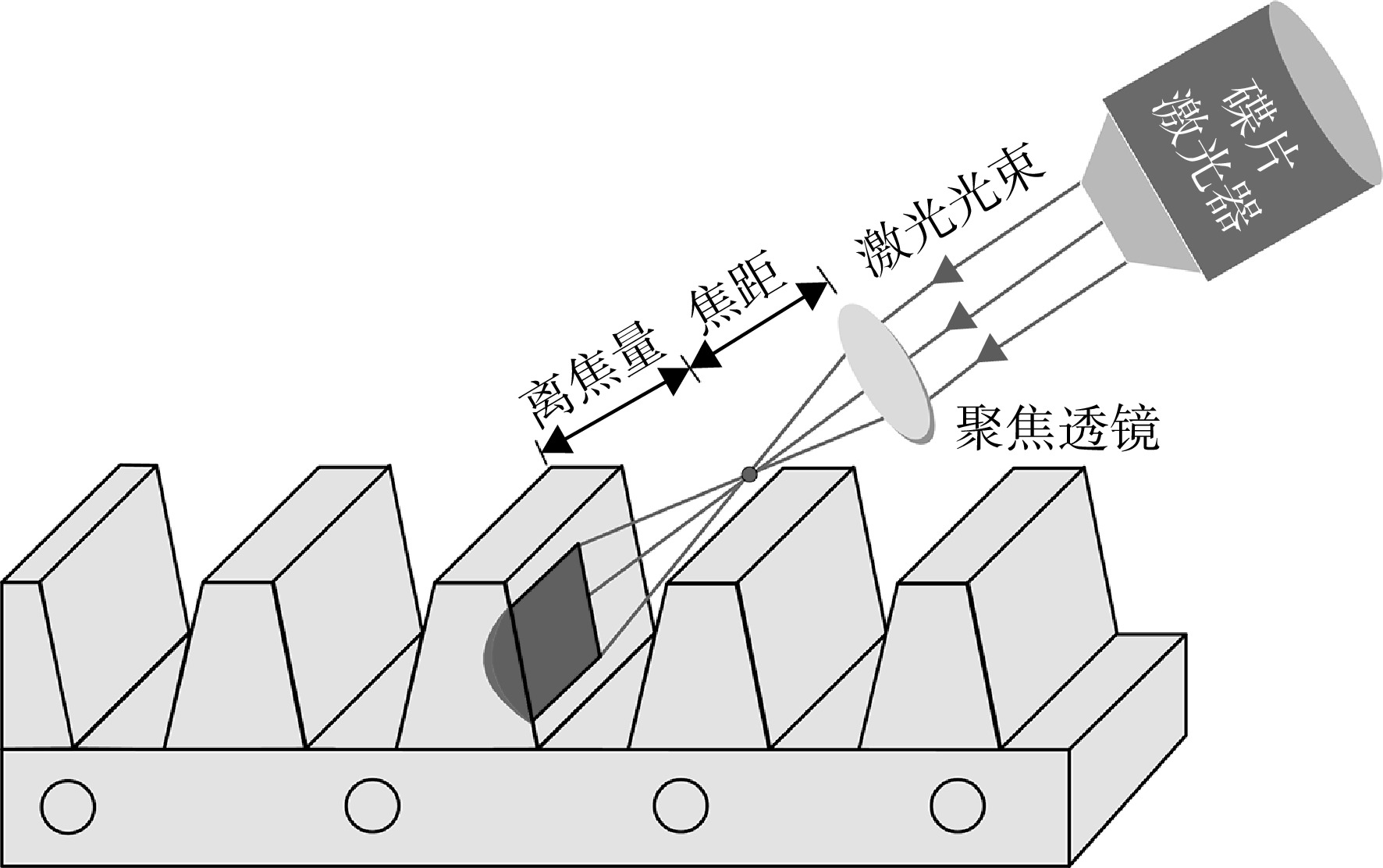

定量化揭示激光淬火过程多场耦合瞬时演变规律,进而实现40Cr激光淬火工艺参数显著性分析。基于相图计算法(CALPHAD)计算温变物性参数,建立40Cr齿轮钢激光淬火数值模型,对瞬态温度、相变以及应力分布进行数值计算,揭示相变行为与塑性应力之间的耦合作用机理。通过Axio Vert.A1显微镜、扫描电子显微镜(SEM)、超景深3D显微镜和显微硬度仪进行分析。基于正交试验,分析了激光半径、激光功率、扫描速度对淬火质量的显著性影响。结果表明:影响最高温度和相变深度的显著工艺参数依次为光斑直径、扫描速度、激光功率;残余应力成“驼峰”分布,影响残余拉应力的显著工艺参数依次为光斑直径、激光功率、扫描速度。该研究为有效控制淬火残余应力,优化工艺参数提供重要理论依据。

Abstract:The multi-field coupling instantaneous evolution law of laser quenching process was quantitatively revealed, then the significance analysis of 40Cr laser quenching process parameters was carried out. Based on the calculation of phase diagram (CALPHAD) method, the temperature changes physical properties of the material were calculated, and the coupled numerical model of 40Cr gear steel during laser quenching was established. Numerical calculations of the transient temperature, phase transition, and stress distribution of 40Cr laser quenching revealed the interaction mechanism between phase transition behavior and plastic stress. Axio Vert.A1 microscope, scanning electron microscope (SEM), super depth of field 3D microscope, and microhardness tester were used for analysis. The significant effects of laser radius, laser power, and scanning speed on quenching quality were analyzed based on orthogonal experiments. The results showed that the significant process parameters affecting the maximum temperature and phase transformation depth were spot diameter, scanning speed and laser power. The distribution of residual stress was “hump”, and the significant process parameters affecting the residual tensile stress were spot diameter, laser power and scanning speed. This research provides an essential theoretical basis for effectively controlling residual quenching stress and optimizing quenching process parameters.

-

表 1 40Cr元素组成

Table 1. Element composition of 40Cr

元素 质量分数/% C 0.37~0.45 Cr 0.8~1.1 Mn 0.5~0.8 Si 0.17~0.37 Cu ≤0.020 Ni ≤0.034 S ≤0.030 P ≤0.030 表 2 数值模拟与试验测量结果

Table 2. Numerical simulation and experimental measurement results

序号 激光功率/W 扫描速度/(mm/s) 光斑直径/mm 数值模拟残余应变 数值模拟显微硬度/HV0.2 试验数据/HV0.2 1 2800 45 9 0.393 856.22 851 2 2800 50 10 0.370 774.08 789 3 2800 55 11 0.331 725.66 717 4 2900 45 10 0.394 779.91 795 5 2900 50 11 0.422 710.57 703 6 2900 55 9 0.385 832.89 831 7 3000 45 11 0.403 946.16 729 8 3000 50 9 0.410 820.02 834 9 3000 55 10 0.427 801.24 788 表 3 数值模拟与试验测量硬度值对比

Table 3. Comparison of hardness values by numerical simulation and experiment measurement

序号 等效塑性

应变数值模拟显微

硬度/HV0.2试验数据/

HV0.2误差/% 1 0.297 756 780 2.97 2 0.368 774.08 760 1.85 3 0.327 839.66 863 3.05 4 0.42 779.91 807 3.35 5 0.424 780.57 751 3.94 表 4 40Cr激光淬火试验参数

Table 4. 40Cr laser quenching test parameters

参数 因素 水平 1 2 3 激光功率/W A 2800 2900 3000 扫描速度/(mm/s) B 45 50 55 光斑直径/mm C 9 10 11 表 5 激光淬火正交试验方案设计和极差分析

Table 5. Laser quenching orthogonal test scheme design and range analysis

序号 因素A 因素B 因素C 空列 温度/K 相变深度/μm 残余拉应力/MPa 1 2800 45 9 1 1683 223.847 541 2 2800 50 10 2 1340 187.256 469 3 2800 55 11 3 1006 141.003 393 4 2900 45 10 3 1481 212.514 507 5 2900 50 11 1 1164 171.804 429 6 2900 55 9 2 1580 216.906 536 7 3000 45 11 2 1293 179.297 458 8 3000 50 9 3 1805 229.036 557 9 3000 55 10 1 1377 190.944 496 K1j 1343.000 1485.667 1689.333 1408.000 K2j 1408.333 1436.333 1399.333 1404.333 K3j 1491.667 1321.000 1154.333 1430.667 Rj 148.667 164.667 535.000 U1j 184.035 205.219 223.263 195.532 U2j 200.408 196.032 196.905 194.486 U3j 199.759 182.951 164.035 194.184 Tj 16.373 22.268 59.228 M1j 467.667 502.000 544.667 488.667 M2j 490.667 485.000 490.667 487.667 M3j 503.667 475.000 426.667 485.667 Sj 36.000 27.000 118.000 表 6 温度的方差分析

Table 6. Temperature analysis of variance

方差来源 离差平方和 自由度 均方和 F比 Fa 显著性 A 33314.667 2 16657.334 27.292 F0.05(2,2)=19.000 * B 42850.667 2 21425.334 35.104 F0.05(2,2)=19.000 * C 430350.000 2 215175.000 352.553 F0.01(2,2)=99.000 ** 表 7 相变深度方差分析表

Table 7. Phase transition depth analysis of variance table

方差来源 离差平方和 自由度 均方和 F比 Fa 显著性 A 515.719 2 257.8595 171.964 F0.01(2,2)=99.000 ** B 751.398 2 375.699 250.550 F0.01(2,2)=99.000 ** C 5283.194 2 2641.597 1761.652 F0.01(2,2)=99.000 ** 表 8 残余拉应力方差分析表

Table 8. Residual tensile stress variance analysis table

方差来源 离差平方和 自由度 均方和 F比 Fa 显著性 A 1994.000 2 997.000 142.429 F0.01(2,2)=99.000 ** B 1118.000 2 559.000 79.857 F0.05(2,2)=19.000 * C 20936.000 2 10468.000 1495.429 F0.01(2,2)=99.000 ** -

[1] CHEN Zhaoyun,ZHOU Guijuan,CHEN Zhonghua. Microstructure and hardness investigation of 17-4PH stainless steel by laser quenching[J]. Materials Science and Engineering: A,2012,534: 536-541. doi: 10.1016/j.msea.2011.12.004 [2] SARVESTANI E S,REZAEIZADEH M,JOMEHZADEH E,et al. Early detection of industrial-scale gear tooth surface pitting using vibration analysis[J]. Journal of Failure Analysis and Prevention,2020,20(3): 768-788. doi: 10.1007/s11668-020-00874-1 [3] 张国祥,姚东伟. 激光淬火基体对镀铬层界面剪切强度的影响[J]. 激光技术,2012,36(4): 527-531. ZHANG Guoxiang,YAO Dongwei. Effect of laser-quenching substrate on interfacial shear strength of chromium plated coatings[J]. Laser Technology,2012,36(4): 527-531. (in Chinese ZHANG Guoxiang, YAO Dongwei . Effect of laser-quenching substrate on interfacial shear strength of chromium plated coatings[J]. Laser Technology,2012 ,36 (4 ):527 -531 . (in Chinese)[4] 郭卫,张汉杰,柴蓉霞. 27SiMn钢表面激光淬火数值模拟及实验验证[J]. 应用激光,2019,39(3): 482-489. GUO Wei,ZHANG Hanjie,CHAI Rongxia. Numerical simulation and experimental verification of laser quenching on 27SiMn steel surface[J]. Applied Laser,2019,39(3): 482-489. (in Chinese doi: 10.14128/j.cnki.al.20193903.482 GUO Wei, ZHANG Hanjie, CHAI Rongxia . Numerical simulation and experimental verification of laser quenching on 27SiMn steel surface[J]. Applied Laser,2019 ,39 (3 ):482 -489 . (in Chinese) doi: 10.14128/j.cnki.al.20193903.482[5] LESYK D A,MARTINEZ S,MORDYUK B N,et al. Combining laser transformation hardening and ultrasonic impact strain hardening for enhanced wear resistance of AISI 1045 steel[J]. Wear,2020,462/463: 203494. doi: 10.1016/j.wear.2020.203494 [6] BIRYUKOV V P,SOKOLOV S N,SAVIN A P,et al. Influence of laser quenching modes on tribological characteristics of 40Cr steel[J]. IOP Conference Series: Materials Science and Engineering,2020,996(1): 012004. doi: 10.1088/1757-899X/996/1/012004 [7] 陈正威,李昌,高兴,等. 考虑晶粒不均匀性的不锈钢激光淬火数值模拟[J]. 中国激光,2021,48(10): 1002109. CHEN Zhengwei,LI Chang,GAO Xing,et al. Numerical simulation on laser quenching of stainless steels with grain heterogeneity[J]. Chinese Journal of Lasers,2021,48(10): 1002109. (in Chinese doi: 10.3788/CJL202148.1002109 CHEN Zhengwei, LI Chang, GAO Xing, et al . Numerical simulation on laser quenching of stainless steels with grain heterogeneity[J]. Chinese Journal of Lasers,2021 ,48 (10 ):1002109 . (in Chinese) doi: 10.3788/CJL202148.1002109[8] MUTHUKUMARAN G,DINESH BABU P. Laser transformation hardening of various steel grades using different laser types[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2021,43(2): 103. doi: 10.1007/s40430-021-02854-4 [9] SIDI-AHMED K,MAOUCHE B,GABI Y,et al. Numerical simulations and experimental investigation of laser hardening depth investigation via 3MA-eddy current technique[J]. Journal of Magnetism and Magnetic Materials,2022,550: 169046. doi: 10.1016/j.jmmm.2022.169046 [10] 罗心磊,刘美红,黎振华,等. 不同热源模型对选区激光熔化18Ni300温度场计算结果的影响[J]. 中国激光,2021,48(14): 1402005. LUO Xinlei,LIU Meihong,LI Zhenhua,et al. Effect of different heat-source models on calculated temperature field of selective laser melted 18Ni300[J]. Chinese Journal of Lasers,2021,48(14): 1402005. (in Chinese doi: 10.3788/CJL202148.1402005 LUO Xinlei, LIU Meihong, LI Zhenhua, et al . Effect of different heat-source models on calculated temperature field of selective laser melted 18Ni300[J]. Chinese Journal of Lasers,2021 ,48 (14 ):1402005 . (in Chinese) doi: 10.3788/CJL202148.1402005[11] COLOMBINI E,SOLA R,PARIGI G,et al. Laser quenching of ionic nitrided steel: effect of process parameters on microstructure and optimization[J]. Metallurgical and Materials Transactions A,2014,45(12): 5562-5573. doi: 10.1007/s11661-014-2490-z [12] DA SILVA S L E F. Newton’s cooling law in generalised statistical mechanics[J]. Physica A: Statistical Mechanics and Its Applications,2021,565: 125539. doi: 10.1016/j.physa.2020.125539 [13] 孙文强. 5CrNiMo钢激光表面淬火温度场数值模拟及硬化层均匀性研究[D]. 天津: 天津理工大学,2013. SUN Wenqiang. Simulation of temperature field during laser surface quenching and analysis of the homogeneity of hardened layer for 5CrNiMo[D]. Tianjin: Tianjin University of Technology,2013. (in ChineseSUN Wenqiang. Simulation of temperature field during laser surface quenching and analysis of the homogeneity of hardened layer for 5CrNiMo[D]. Tianjin: Tianjin University of Technology, 2013. (in Chinese) [14] 刘玉. 中碳钢淬火应力分布的测定和有限元模拟[D]. 上海: 上海交通大学,2017. LIU Yu. Measurements and finite element simulation of quenching stress distribution in medium carbon steels[D]. Shanghai: Shanghai Jiao Tong University,2017. (in ChineseLIU Yu. Measurements and finite element simulation of quenching stress distribution in medium carbon steels[D]. Shanghai: Shanghai Jiao Tong University, 2017. (in Chinese) [15] KOHOUT J. Simple and precise description of the transformation kinetics and final structure of dual phase steels[J]. Materials,2021,14(7): 1781. doi: 10.3390/ma14071781 [16] BUBNOFF D V,CARVALHO M M O,XAVIER C R,et al. Evaluation of martensite fraction in 1026 steel by infrared thermography combined with the koistinen-marburger model[J]. Materials Science Forum,2016,869: 411-415. doi: 10.4028/www.scientific.net/MSF.869.411 [17] LEBLOND J B,DEVAUX J,DEVAUX J C. Mathematical modelling of transformation plasticity in steels I: Case of ideal-plastic phases[J]. International Journal of Plasticity,1989,5(6): 551-572. doi: 10.1016/0749-6419(89)90001-6 [18] KHANNA K,GUPTA V K,NIGAM S P. Creep analysis in functionally graded rotating disc using tresca criterion and comparison with von-mises criterion[J]. Materials Today: Proceedings,2017,4(2): 2431-2438. doi: 10.1016/j.matpr.2017.02.094 [19] MOCHIZUKI M,HAYASHI M,HATTORI T. Numerical analysis of welding residual stress and its verification using neutron diffraction measurement[J]. Journal of Engineering Materials and Technology,2000,122(1): 98-103. doi: 10.1115/1.482772 [20] BADRISH C A,KOTKUNDE N,MAHALLE G,et al. Analysis of hot anisotropic tensile flow stress and strain hardening behavior for inconel 625 alloy[J]. Journal of Materials Engineering and Performance,2019,28(12): 7537-7553. doi: 10.1007/s11665-019-04475-4 [21] TABOR D. The hardness of metals[M]. Oxford,UK: Oxford University Press,2000. [22] 边舫,苏国跃,孔凡亚,等. Inconel718合金的加工硬化行为[J]. 有色金属,2005(1): 1-3. BIAN Fang,SU Guoyue,KONG Fanya,et al. Work hardening behavior of inconel 718[J]. Nonferrous Metals,2005(1): 1-3. (in Chinese BIAN Fang, SU Guoyue, KONG Fanya, et al . Work hardening behavior of inconel 718[J]. Nonferrous Metals,2005 (1 ):1 -3 . (in Chinese)[23] 路彦君. 镍基高温合金Inconel718微铣削残余应力与加工硬化研究[D]. 大连: 大连理工大学,2016. LU Yanjun. Researches on residual stress and work hardening on micro-milling nickel-base superalloy Inconel718[D]. Dalian: Dalian University of Technology,2016. (in ChineseLU Yanjun. Researches on residual stress and work hardening on micro-milling nickel-base superalloy Inconel718[D]. Dalian: Dalian University of Technology, 2016. (in Chinese) -

下载:

下载: