Thermal insulation mechanism analysis and effectiveness criterion of thermal barrier coating

-

摘要:

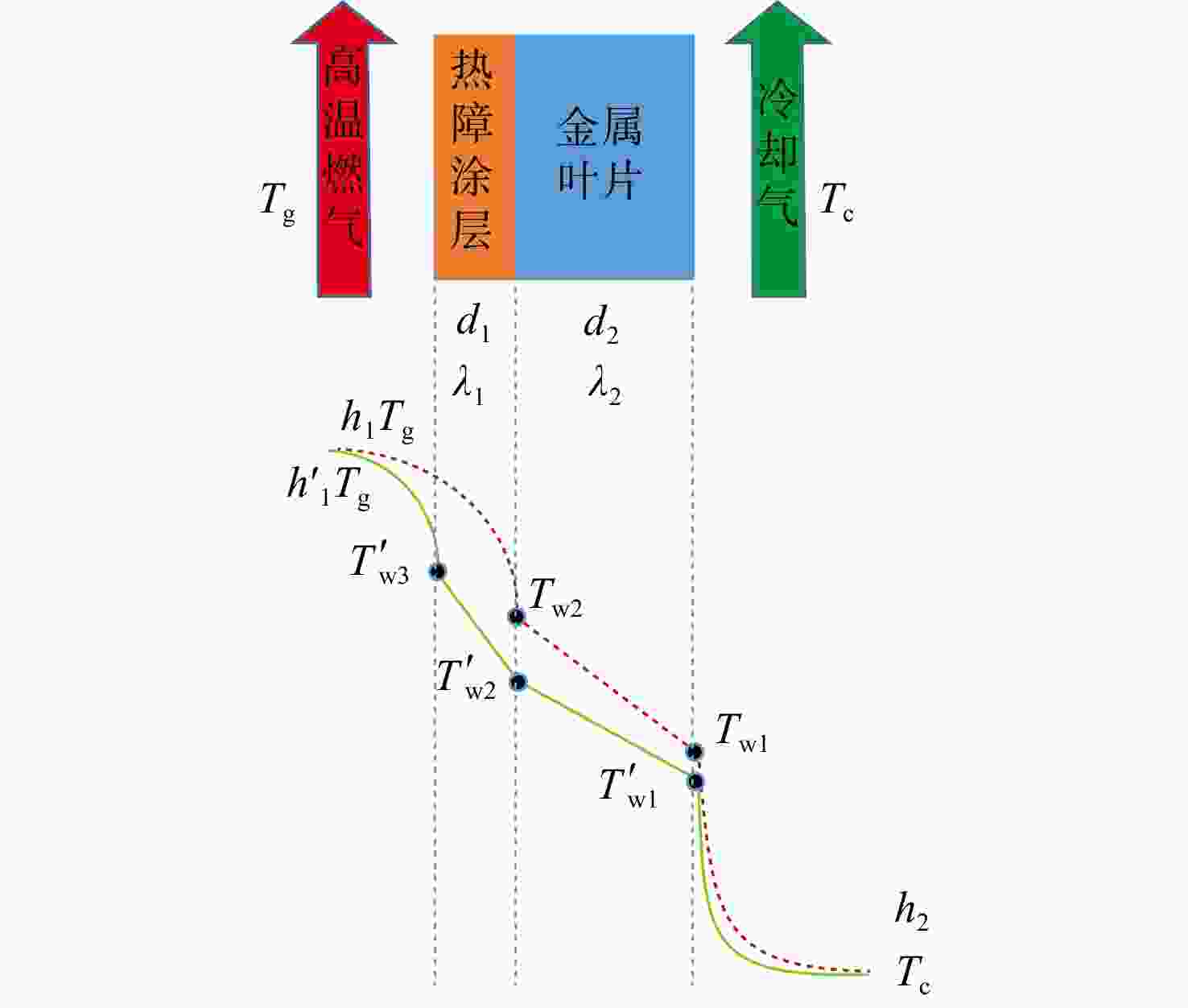

建立了一维对流-导热模型,经理论推导、分析验证得到了热障涂层隔热有效性判据:当涂层热阻大于无涂层时高温燃气侧换热热阻时,涂层总能使叶片金属基体外表面温度降低,起到隔热效果;反之,则喷涂热障涂层(TBC)后外部燃气侧表面传热系数存在临界值,只有该表面传热系数小于临界值,热障涂层才能起到隔热效果,否则涂层起不到隔热效果,甚至会恶化叶片换热。热障涂层自身温降与有无涂层前后叶片金属基体外表面温降成比例关系,建立了以叶片金属基体外表面温度为基础的新的涂层隔热效果评价机制。

Abstract:A one-dimensional convection-thermal conductivity model was established, and the thermal insulation effectiveness criterion of the thermal barrier coating was obtained through theoretical deduction and analysis. When the thermal resistance of the coating was greater than the heat transfer resistance of the high-temperature gas side without coating, the coating could generate a positive thermal insulation effect. On the contrary, the heat transfer coefficient for the external gas side after spraying the thermal barrier coating (TBC) had a maximum critical value. At this time, only when the external gas side heat transfer coefficient was smaller than this critical value after the TBC was sprayed, the TBC could have a thermal insulation effect, otherwise the thermal barrier coating couldn't work, even worsen the heat transfer of the blades. The temperature-drop of the TBC itself was proportional to the temperature-drop of the outer surface of metal blade with or without TBC. And a new evaluation standard of the thermal insulation effect of the coating based on the outer surface temperature of the blade metal substrate was proposed.

-

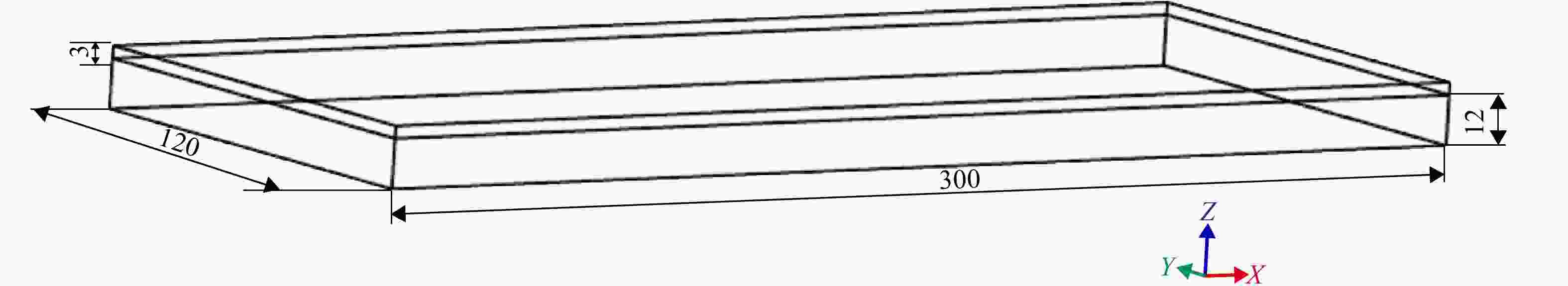

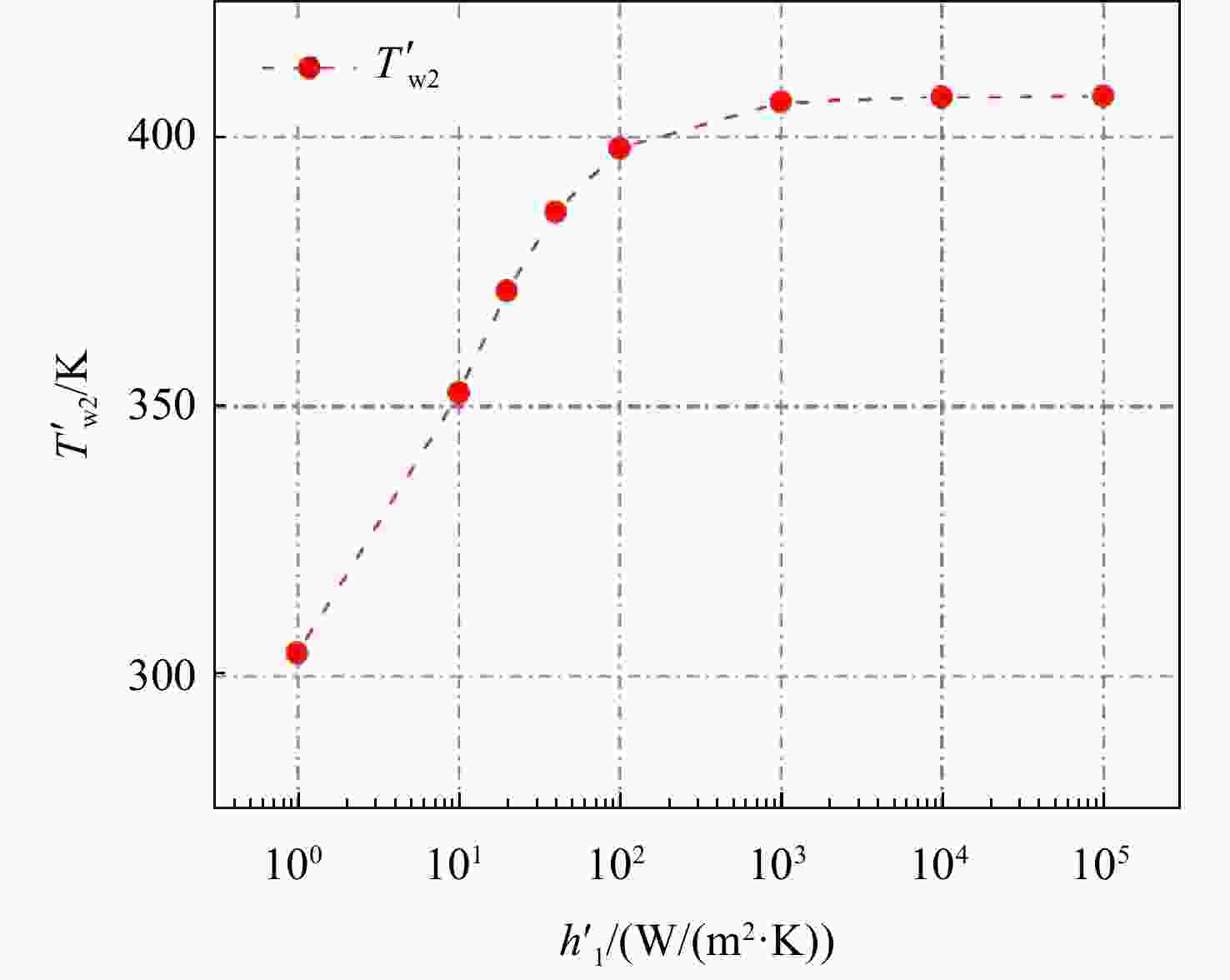

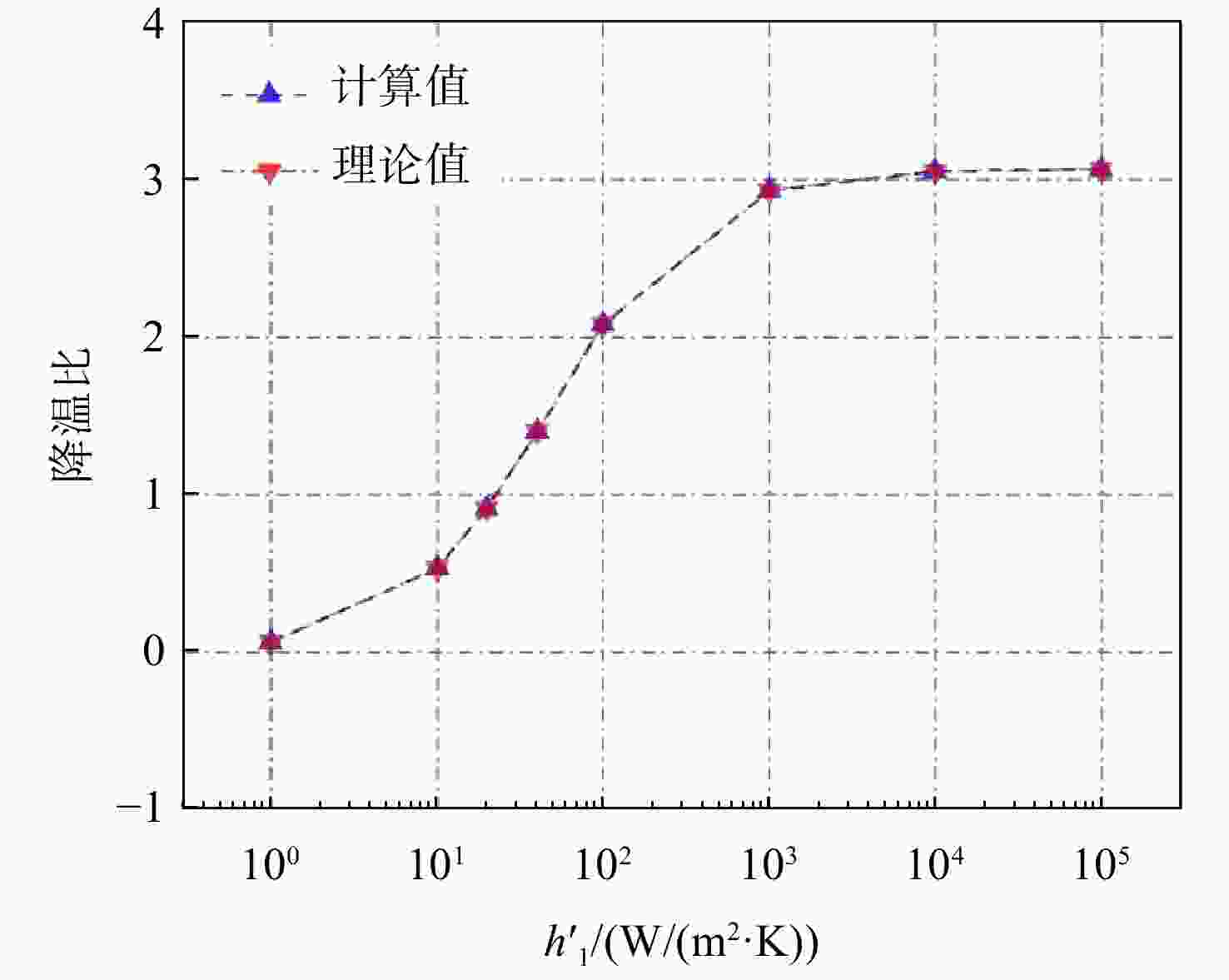

图 4 带热障涂层叶片金属基体外表面温度

${T'_{{\text{w}}2}}$ 随${h'_1}$ 变化曲线 (${h_1} = 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ){\text{ }}\;,{h'_1} = 1$ ~$ 100\;000\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ) $ )Figure 4. Curve of external surface temperature of blade metal substrate with thermal barrier coating

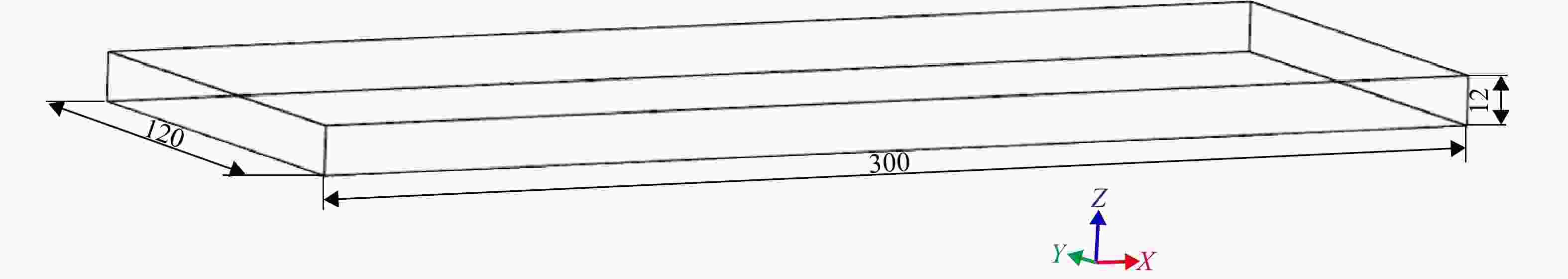

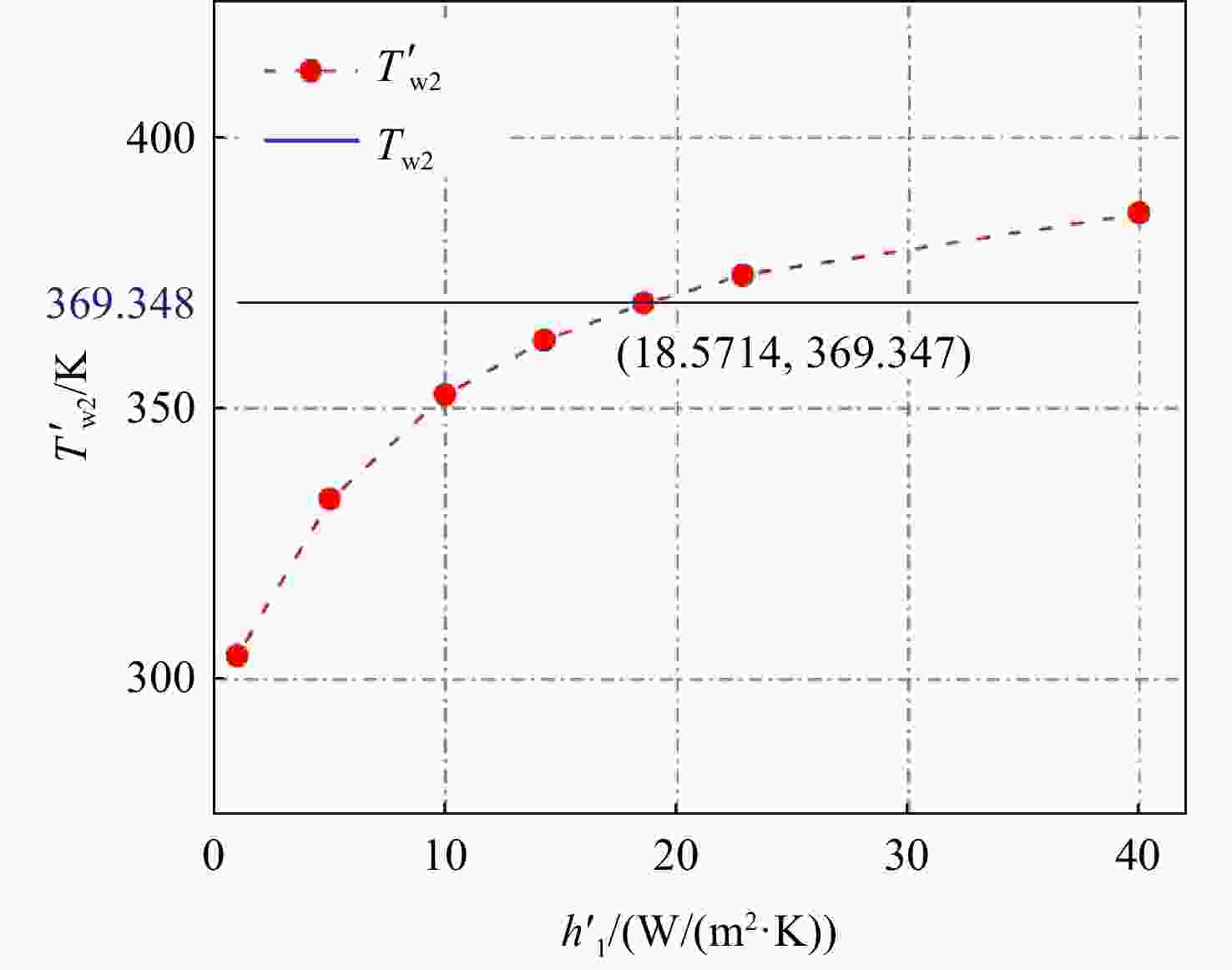

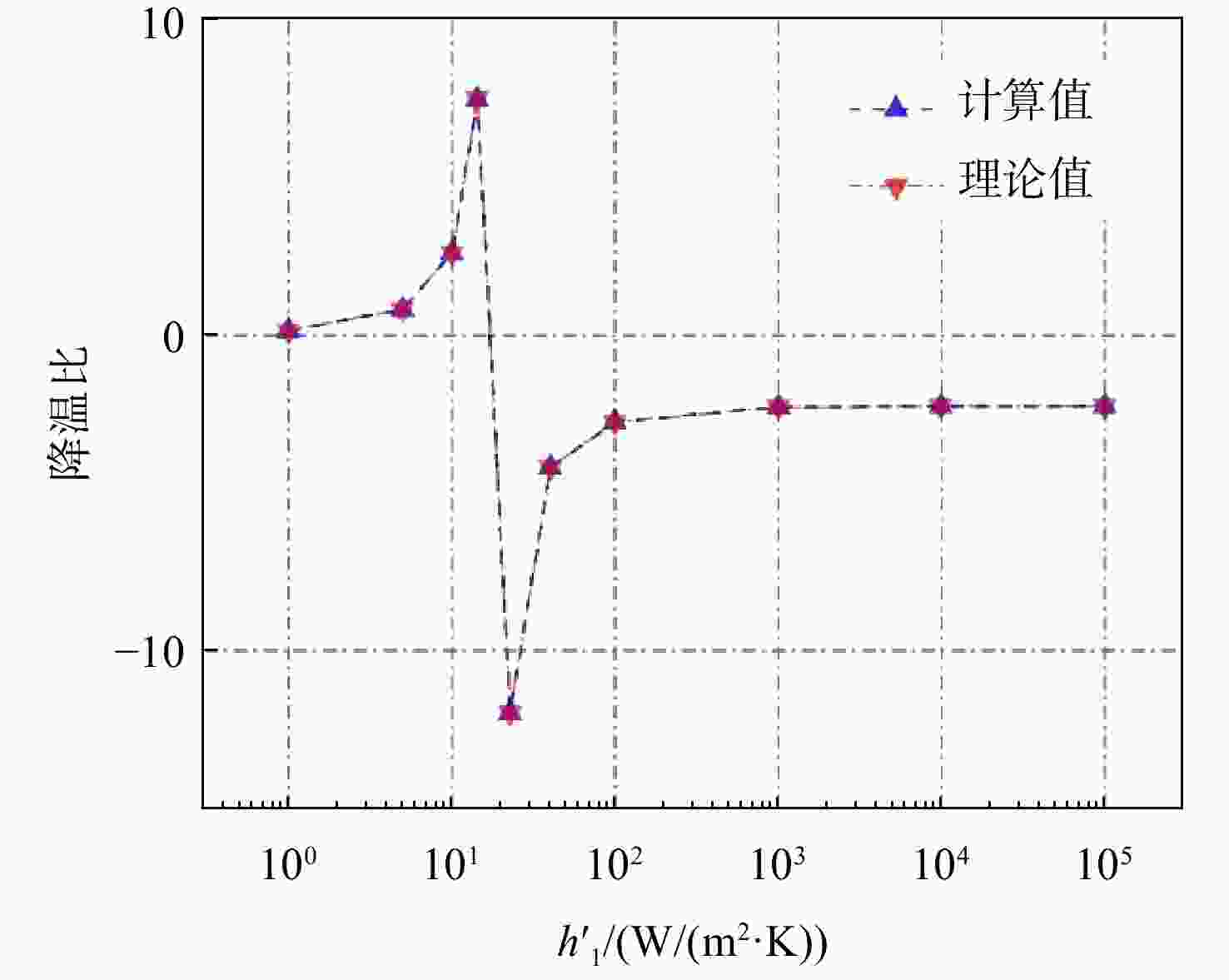

${T '_{{\text{w}}2}}$ varies with${h '_1}$ (${h_1} = 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ){\text{ }}\;,{h'_1} = 1$ −$100\;000\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } )$ )图 5 带热障涂层时叶片金属基体外表面温度

${T '_{{\text{w}}2}}$ 随${h '_1}$ 变化曲线 (${h_1} = 10\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } )\;,{h '_1} = 1$ ~$40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ) $ )Figure 5. Curve of external surface temperature of blade metal substrate with thermal barrier coating

${T '_{{\text{w}}2}}$ varies with${h '_1}$ (${h_1} = 10\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ){\text{ }},{h '_1} = 1$ −$ 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ) $ )表 1 换热模型参数

Table 1. Heat transfer model parameters

参数类型 真实叶片 设计模型 金属基体厚度/mm 1.5~3.0 12.00 涂层厚度/mm 0.1~0.7 3.00 金属基体

导热系数/(${ {\text{W} } / {( { {\text{m} } \cdot {\text{K} } })} }$)20~25 1.02 涂层导热系数/(${ {\text{W} } /{( { {\text{m} } \cdot {\text{K} } } )} }$) 0.8~2 0.065 涂层/金属基体

厚度比0.05~0.5 0.25 涂层/金属基体

导热系数比0.04~0.08 0.07 外换热系数/(${ {\text{W} } /{( { {\text{m} }^2 \cdot {\text{K} } })} }$) 103~104 10~40 金属基体/涂层

Bi数比0.1~1.5 数量级一致 叶片金属基体

表面粗糙度/μm1.20 尽可能光滑 涂层表面粗糙度/μm 4~7 3.2~8.0 表 2 边界条件

Table 2. Boundary conditions

边界 条件设置 无涂层高温燃气侧 对流边界条件: ${T_{\rm{g}}} = 493\;{\text{ K} }$, ${h_1} = { {10} / {40} }\;{ {\text{W} }/{( { { {\text{m} }^2} \cdot {\text{K} } } )} }$ 有涂层高温燃气侧 对流边界条件:${T_{\rm{g}}} = 493\;{\text{ K} }$, ${h'_1} = 1 {\text{~}} 100\;000\;{\text{W/} }( { { {\text{m} }^{\text{2} } } \cdot {\text{K} } } )$ 内部冷却气侧 对流边界条件:${T_{\rm{c}}} = 293\;{\text{ K} }$, ${h_2} = 20\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } )$ 其余边界 对称面为周期性边界条件 表 3

${T '_{{\text{w}}2}}$ 随${h'_1}$ 变化曲线 (${h_1} = 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ){\text{ }},{h '_1} = 1{\text{~}}100\;000\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}} )$ )Table 3.

${T '_{{\text{w}}2}}$ variation curve with${h '_1}$ (${h_1} = 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ),{\text{ }}{h'_1} = 1$ −$100\;000\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}} ) $ )${ { h'_1} } /({\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } }))$ ${ { { T '_{ {\text{w} }2} } } \mathord{\left/ {\vphantom { { { {T'}_{ {\text{w} }2} } } {\text{K} } } } \right. } {\text{K} } }$ 1 304.127 10 352.394 20 371.207 40 385.922 100 397.746 1000 406.403 10000 407.348 100000 407.443 表 4

${T '_{{\text{w}}2}}$ 随${h'_1}$ 变化曲线 (${h_1} = 10\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } )\;,{h'_1} = 1$ ~$ 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ) $ )Table 4.

${T'_{{\text{w}}2}}$ variation curve with${h'_1}$ (${h_1} = 10\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } )\;,{h'_1} = 1$ −$ 40\;{\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ) $ )${ {h'_1} }/({\text{W} }/( { { {\text{m} }^2} \cdot {\text{K} } } ))$ ${ { { T'_{ {\text{w} }2} } } \mathord{\left/ {\vphantom { { { {T {\text{'} } }_{ {\text{w} }2} } } {\text{K} } } } \right. } {\text{K} } }$ 1 304.127 5 333.099 10 352.394 14.2857 362.413 18.5714 369.347 22.8571 374.431 40 385.922 表 5 各参数随

${h' _1}$ 变化结果 (${h_1} = 40\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}} )$ )Table 5. Change results of each parameter with

${h' _1}$ (${h_1} = 40\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}})$ )${ { { h'_1} } /{( { {\text{W} }/( { { {\text{m} }^{\text{2} } } \cdot {\text{K} } })})} }$ ${ { { T'_{ {\text{w} }2} } } \mathord{\left/ {\vphantom { { { {T'}_{ {\text{w} }2} } } {\text{K} } } } \right. } {\text{K} } }$ ${ { { T'_{ {\text{w3} } } } } \mathord{\left/ {\vphantom { { { {T'}_{ {\text{w3} } } } } {\text{K} } } } \right. } {\text{K} } }$ $ {{\Delta {T_1}} \mathord{\left/ {\vphantom {{\Delta {T_1}} {\text{K}}}} \right. } {\text{K}}} $ $ {{\Delta {T_2}} \mathord{\left/ {\vphantom {{\Delta {T_2}} {\text{K}}}} \right. } {\text{K}}} $ 温降比计算值 温降比理论值 1 304.127 312.46 8.333 131.236 0.063496297 0.063492063 10 352.394 396.796 44.402 82.969 0.535163736 0.535147392 20 371.207 429.668 58.461 64.156 0.911231997 0.911196911 40 385.922 455.378 69.456 49.441 1.404825954 1.404761905 100 397.746 476.037 78.291 37.617 2.081266449 2.081128748 1000 406.403 491.164 84.761 28.96 2.926830110 2.926587302 10000 407.348 492.815 85.467 28.015 3.050758522 3.050514451 100000 407.443 492.982 85.539 27.92 3.063717765 3.063486871 表 6 各参数随

${h' _1}$ 变化结果 (${h_1} = 10\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}})$ )Table 6. Change results of each parameter with

${h' _1}$ (${h_1} = 10\;{\text{W/}}( {{{\text{m}}^{\text{2}}} \cdot {\text{K}}} )$ )${ { { h'_1} } /{({ {\text{W} }/( { { {\text{m} }^{\text{2} } } \cdot {\text{K} } } )} )} }$ ${ { { T'_{ {\text{w} }2} } } \mathord{\left/ {\vphantom { { { {T'}_{ {\text{w} }2} } } {\text{K} } } } \right. } {\text{K} } }$ ${ { { T'_{ {\text{w3} } } } } \mathord{\left/ {\vphantom { { { {T'}_{ {\text{w3} } } } } {\text{K} } } } \right. } {\text{K} } }$ $ {{\Delta {T_1}} \mathord{\left/ {\vphantom {{\Delta {T_1}} {\text{K}}}} \right. } {\text{K}}} $ $ {{\Delta {T_2}} \mathord{\left/ {\vphantom {{\Delta {T_2}} {\text{K}}}} \right. } {\text{K}}} $ 温降比计算值 温降比理论值 1 304.127 312.46 8.333 65.221 0.127766 0.127758 5 333.099 363.08 29.981 36.249 0.827085 0.827068 10 352.394 396.796 44.402 16.954 2.618969 2.619048 14.2857 362.413 414.302 51.889 6.935 7.482192 7.482961 18.5714 369.347 426.418 57.071 0.001 57071 1459181 22.8571 374.431 435.3 60.869 −5.083 −11.975 −11.9729 40 385.922 455.378 69.456 −16.574 −4.19066 −4.19048 100 397.746 476.037 78.291 −28.398 −2.75692 −2.75689 1000 406.403 491.164 84.761 −37.055 −2.28744 −2.28738 10000 407.348 492.815 85.467 −38 −2.24913 −2.24907 100000 407.443 492.982 85.539 −38.095 −2.24541 −2.24531 -

[1] 郭洪波,宫声凯,徐惠彬. 先进航空发动机热障涂层技术研究进展[J]. 中国材料进展,2009,28(9): 18-26.GUO Hongbo,GONG Shengkai,XU Huibin. Progress in thermal barrier coatings for advanced aeroengines[J]. Materials China,2009,28(9): 18-26. (in Chinese) [2] PRASERT P,XU H Z,YANG W S,et al. Numerical study of the effects of thermal barrier coating and turbulence intensity on cooling performances of a nozzle guide vane[J]. Energies,2017,10(3): 362-378. doi: 10.3390/en10030362 [3] MAIKELL J, BOGARD D, PIGGUSH J, et al. Experimental simulation of a film cooled turbine blade leading edge including thermal barrier coating effects[R]. Orlando, US: ASME, 2009. [4] 杨晓军,许诺然,刘智刚. 污染物沉积和热障涂层脱落对气膜冷却效率影响的数值研究[J]. 推进技术,2013,34(10): 1362-1368. doi: 10.13675/j.cnki.tjjs.2013.10.014YANG Xiaojun,XU Nuoran,LIU Zhigang. Effects of deposition and thermal barrier coating spallation on film cooling effectiveness: a numerical study[J]. Journal of Propulsion Technology,2013,34(10): 1362-1368. (in Chinese) doi: 10.13675/j.cnki.tjjs.2013.10.014 [5] LAWSON S A,THOLE K A,OKITA Y,et al. Simulations of multi-phase particle deposition on a showerhead with staggered film-cooling holes[J]. Journal of Turbomachinery,2012,134(5): 051041.1-051041.12. [6] ALBERT J E,BOGARD D G. Experimental simulation of contaminant deposition on a film cooled turbine vane pressure side with a trench[J]. Journal of Turbomachinery,2013,135(5): 051008.1-051008.11. [7] NEMDILI F,AZZI A,JUBRAN B A. Numerical investigation of the influence of a hole imperfection on film cooling effectiveness[J]. International Journal of Numerical Methods for Heat & Fluid Flow,2011,21(1): 46-60. [8] EKKAD S V,HAN J C. Heat transfer distributions on a cylinder with simulated thermal barrier coating spallation[J]. Journal of Thermophysics & Heat Transfer,2015,13(1): 76-81. [9] BUNKER R S. Effect of partial coating blockage on film cooling effectiveness[R]. ASME Paper 2000-GT-0244, 2000. [10] SOMAWARDHANA R P, BOGARD D G. Effects of obstructions and surface roughness on film cooling effectiveness with and without a transverse trench[R]. ASME Paper GT2007-28003, 2007. [11] WANG J,CUI P,VUJANOVIC M,et al. Effects of surface deposition and droplet injection on film cooling[J]. Energy Conversion and Management,2016,125: 51-58. doi: 10.1016/j.enconman.2016.03.038 [12] 郭云修,李广超,曾睿,等. 气膜孔堵塞对叶片吸力面气膜冷却的影响[J]. 动力工程学报,2021,41(1): 28-35. doi: 10.19805/j.cnki.jcspe.2021.01.005GUO Yunxiu,LI Guangchao,ZENG Rui,et al. Effect of hole blockage on the film cooling effectiveness of a blade on the suction side[J]. Journal of Chinese Society of Power Engineering,2021,41(1): 28-35. (in Chinese) doi: 10.19805/j.cnki.jcspe.2021.01.005 [13] SUNDARAM N,THOLE K A. Effects of surface deposition, hole blockage, and thermal barrier coating spallation on vane endwall film cooling[J]. Journal of Turbomachinery,2007,129(3): 599-607. [14] 宫声凯,邓亮,毕晓方,等. 陶瓷热障涂层的隔热效果研究[J]. 航空学报,2000,21(增刊1): 25-29. doi: 10.3321/j.issn:1000-6893.2000.Z1.006GONG Shengkai,DENG Liang,BI Xiaofang,et al. Thermal barrier effect of ceramic thermal barrier coatings[J]. Acta Aeronautica et Astronautica Sinica,2000,21(Suppl.1): 25-29. (in Chinese) doi: 10.3321/j.issn:1000-6893.2000.Z1.006 [15] PADTURE N P,GELL M,JORDAN E H. Thermal barrier coatings for gas-turbine engine apptications[J]. Science,2002,296(5566): 280-284. doi: 10.1126/science.1068609 [16] ZHU W,WANG J W,YANG L,et al. Modeling and simulation of the temperature and stress fields in a 3D turbine blade coated with thermal barrier coatings[J]. Surface & Coatings Technology,2017,315: 443-453. [17] LIU Z Y,ZHU W,YANG L,et al. Numerical prediction of thermal insulation performance and stress distribution of thermal barrier coatings coated on a turbine vane[J]. International Journal of Thermal Sciences,2020,158: 1-12. [18] HUANG X,PU J,WANG J H,et al. Sensitivity analysis of internal layout and coating thickness to overall cooling performances of laminated cooling configurations with surface thermal barrier coatings[J]. Applied Thermal Engineering,2020,181(1): 116020.1-116020.13. [19] DAVIDSON F T, DEES J E, BOGARD D G. An experimental study of thermal barrier coatings and film cooling on an internally cooled simulated turbine vane[R]. ASME Paper GT2011-46604, 2011. -

下载:

下载: