Fast analysis of forced vibration response on intermediate stage compressor rotor blade

-

摘要:

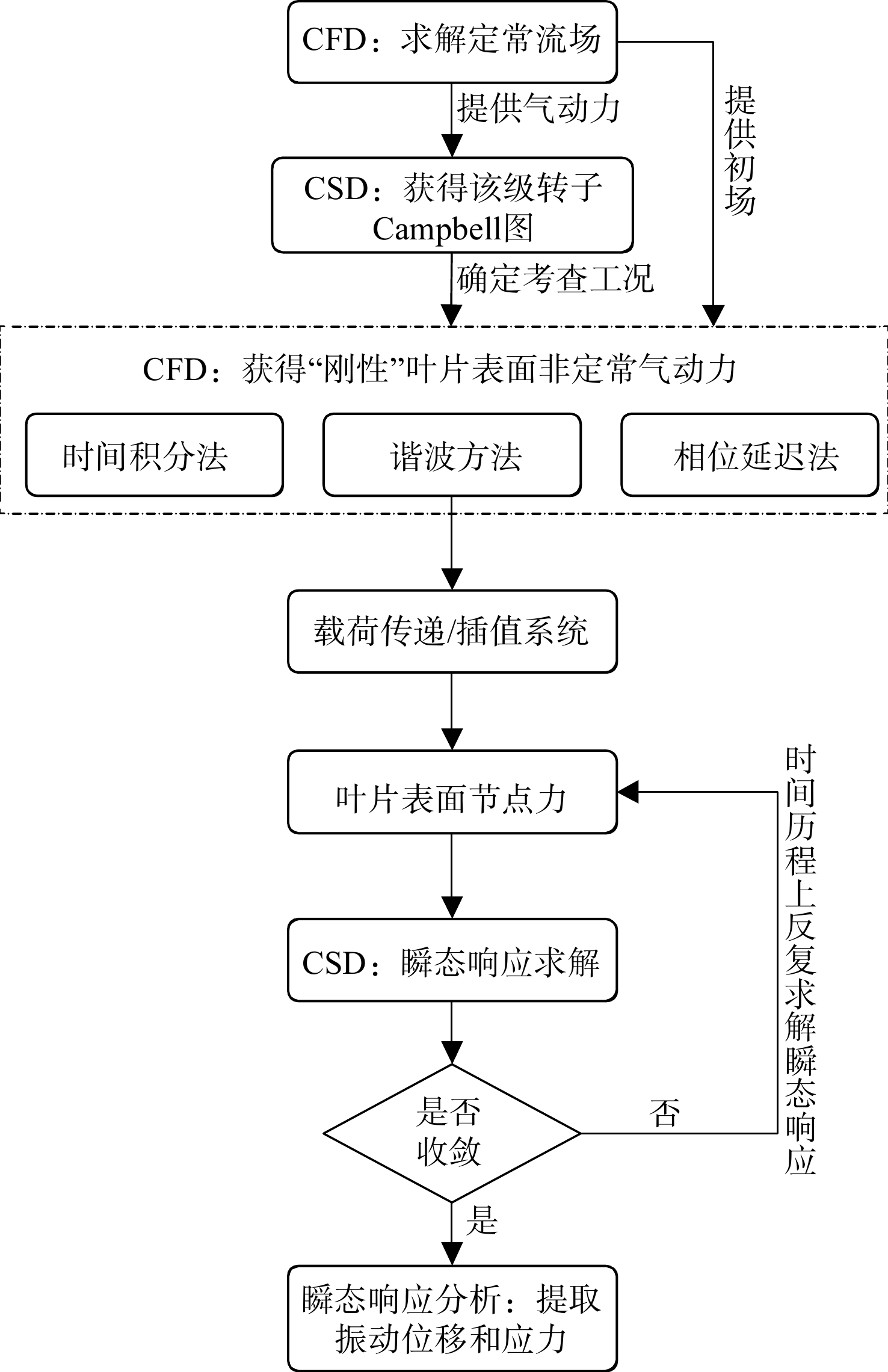

以多级压气机第二级转子叶片为例,对其共振时的振动特征进行了快速分析。一方面通过进口边界条件修正对压气机模型进行减缩,并结合谐波方法提高了非定常气动力计算效率,另一方面利用系统在模态空间的频响关系和扫频技术进一步提高了求解效率,特别是当工程上亟需开展非定常气动力作用下的强迫振动响应分析时,可高效评估共振时叶片振动特征。结果表明:第二级转子叶片主要受上游静子激励,下游静子的势扰动影响有限,在共振转速附近易激起第15阶模态共振,叶片尖区有较高的振动应力,经瞬态响应分析,在给定的阻尼和工况下,所考查位置和方向的振动应力约71 MPa,利用扫频等方式评估共振时非定常气动力引起的转子叶片振动应力约为92 MPa。所形成的分析方法与流程有一定的普适性。

Abstract:The second stage rotor blade of multi-stage compressor was investigated to efficiently calculate the response caused by aerodynamic excitation. The compressor was reduced through the inlet boundary correction, and combined with the harmonic method to improve the calculation efficiency of unsteady aerodynamic force. The relationship between frequency and response in modal space and the harmonic analysis method were used to further improve the solution efficiency. When the forced vibration response analysis under aerodynamic excitation was urgently required in engineering, the blade vibration features at resonance can be evaluated efficiently. The results showed that the excitations of the second rotor blade was mainly subject to the upstream stator passing frequencies, and the influence of the downstream stator was limited. The 15th modal shape was excited near the resonance condition and there was significant vibration stress in the blade tip area. Under the given damping and simulated working conditions, the vibration stress was about 71 MPa in the examined position and direction obtained by the transient response analysis, and it was about 92 MPa under the resonance condition evaluated by the harmonic analysis method.

-

Key words:

- multi-stage compressor /

- rotor blade /

- forced vibration response /

- resonance stress /

- fast analysis

-

图 3 非线性谐波法与时间推进法结果对比

Figure 3. Comparison between nonlinear harmonic method and time marching method[17]

表 1 S1、R2和S2无量纲设计参数

Table 1. Normalized design parameters of S1, R2 and S2

参数 S1 R2 S2 叶片数 46 37 62 叶尖前缘半径 1.014 1 0.982 叶尖尾缘半径 1.004 0.986 0.971 叶根前缘半径 0.628 0.653 0.7 叶根尾缘半径 0.650 0.697 0.718 叶尖弦长C 0.191 0.264 0.157 叶根弦长 0.123 0.224 0.101 叶尖间隙 0 0.28% C 0 表 2 不同转速下气动激励与100%转速下的偏差

Table 2. Deviation of aerodynamic excitation between different rotating speeds and 100% rotating speed

归一化转速 模态力/N 误差/% 0.95 32.23 −1.6 0.98 31.24 −4.5 1.0 32.74 0 1.02 34.58 5.6 1.05 30.86 −5.7 表 3 转子叶片表面监测点

Table 3. Monitors on blade surface of R2

模态阶次 最大主应力 监测点编号 主应力方向 nx ny nz 1 S1 1326 0.97 −0.17 −0.16 2 S1 874 0.96 0.15 −0.22 3 S1 1375 1.00 −0.02 −0.00 15 S1 1585 −0.16 0.93 0.33 16 S1 1585 0.06 0.91 0.41 表 4 第二级转子叶片100%转速各阶模态频率和阻尼比

Table 4. Modal frequencies and damping ratios of R2 at 100%rotating speed

模态阶次 频率/Hz ζi /% 1 709.46 0.030 2 1701.2 0.030 3 2116.5 0.033 15 11013 0.138 16 11817 0.148 表 5 不同方法的计算耗时

Table 5. Calculation time of different methods

方法 归一化时间 共振模态频响关系分析 1 扫频方法 10 瞬态分析 103~104 -

[1] 韩乐,王延荣. 转子叶片气弹稳定性与强迫响应分析[J]. 航空发动机,2021,47(4): 82-90.HAN Le,WANG Yanrong. Analysis of aeroelastic stability and forced response of rotor blades[J]. Aeroengine,2021,47(4): 82-90. (in Chinese) [2] HAN Le,WEI Dasheng,WANG Yanrong,et al. Analysis method of nonsynchronous vibration and influence of tip clearance flow instabilities on nonsynchronous vibration in an axial transonic compressor rotor[J]. Journal of Turbomachinery,2021,143(11): 111014.1-111014.15. [3] KIELB R E, CHIANG H D. Recent advancements in turbomachinery forced response analyses[R]. AIAA-92-0012, 1992. [4] VAHDATI M,SAYMA A I,IMREGUN M. An integrated nonlinear approach for turbomachinery forced response prediction: Part Ⅰ formulation[J]. Journal of Fluids and Structures,2000,14(1): 87-101. doi: 10.1006/jfls.1999.0253 [5] VAHDATI M,SAYMA A I,IMREGUN M. An Integrated nonlinear approach for turbomachinery forced response prediction: Part Ⅱ case studies[J]. Journal of Fluids and Structures,2000,14(1): 103-125. doi: 10.1006/jfls.1999.0254 [6] 徐可宁. 叶轮机叶盘结构气动弹性算法研究及程序实现[D]. 北京: 北京航空航天大学, 2011.XU Kening. On the algorithm of aeroelasticity and the program implementation of bladed disk assemblies in turbomachines[D]. Beijing: Beihang University, 2011. (in Chinese) [7] ESPINAL D,IM H S,ZHA G C. Full-annulus simulation of nonsynchronous blade vibration excitation of an axial compressor[J]. Journal of Turbomachinery,2018,140(3): 031008.1-031008.12. [8] HE L,DENTON J D. Three-dimensional time-marching inviscid and viscous solutions for unsteady flows around vibrating blades[J]. Journal of Turbomachinery,1994,116(3): 469-476. doi: 10.1115/1.2929436 [9] HALL K C,LORENCE C B. Calculation of three-dimensional unsteady flows in turbomachinery using the linearized harmonic euler equations[J]. Journal of Turbomachinery,1993,115(4): 800-809. doi: 10.1115/1.2929318 [10] NING W, HE L. Computation of unsteady flows around oscillating blades using linear and nonlinear harmonic euler methods[R]. ASME Paper 97-GT-229, 1997. [11] HE L. An Euler solution for unsteady flows around oscillating blades[J]. Journal of Turbomachinery,1990,112(4): 714-722. doi: 10.1115/1.2927714 [12] 张小博,王延荣,黄钟山,等. 转静干涉下转子叶片的非定常压力频谱[J]. 航空动力学报,2016,31(7): 1695-1703. doi: 10.13224/j.cnki.jasp.2016.07.019ZHANG Xiaobo,WANG Yanrong,HUANG Zhongshan,et al. Frequency spectrum of unsteady pressure on rotor blade with rotor-stator interaction[J]. Journal of Aerospace Power,2016,31(7): 1695-1703. (in Chinese) doi: 10.13224/j.cnki.jasp.2016.07.019 [13] 王翔鹏, 王延荣, 田爱梅. 转、静子轴向间距对转子叶片振动应力的影响[J]. 航空动力学报, 2016, 31(6): 1427-1434.WANG Xiangpeng, WANG Yanrong, TIAN Aimei. Effect of axial spacing between rotor-stator on vibration stress of blade[J]. Journal of Aerospace Power, 2016, 31(6): 1427-1434. (in Chinese) [14] 李雪峰. 轴流跨音风扇/压气机转静非定常气动力的数值研究[D]. 南京: 南京航空航天大学, 2019.LI Xuefeng. Numerical study on unsteady aerodynamic of axial flow transonic fan/compressor[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019. (in Chinese) [15] HALL K C,THOMAS J P,Clark W S. Computation of unsteady nonlinear flows in cascades using a harmonic balance technique[J]. AIAA Journal,2002,40(5): 879-886. doi: 10.2514/2.1754 [16] 张翔,黄秀全,张恒铭,等. 基于谐波平衡法的跨声速风扇颤振特性数值模拟[J]. 机械强度,2017,39(3): 493-499.ZHANG Xiang,HUANG Xiuquan,ZHANG Hengming,et al. Numerical simulation of flutter characteristics in transonic fan based on harmonic balance method[J]. Journal of Mechanical Strength,2017,39(3): 493-499. (in Chinese) [17] 杨唯超. 压气机转子叶片颤振及其影响因素分析[D]. 北京: 北京航空航天大学, 2019.YANG Weichao. Investigation on flutter of compressor rotor blade and its influencing factors[D]. Beijing: Beihang University, 2019. (in Chinese) [18] 王延荣,黄钟山,付志忠,等. 基于热态叶型的小轮毂比弯掠叶片结构保形设计与优化[J]. 航空动力学报,2015,30(10): 2305-2311.WANG Yanrong,HUANG Zhongshan,FU Zhizhong,et al. Structural design and optimization for the deformation approaching to hot profile of a swept fan blade with smaller hub-to-tip ratio[J]. Journal of Aerospace Power,2015,30(10): 2305-2311. (in Chinese) -

下载:

下载: