Numerical simulation and experimental verification on laser shock peening for turbine mortise

-

摘要:

提出了基于离散化思想的曲面结构激光冲击强化数值模拟方法,通过空间几何关系和能量守恒原理实现受冲击区域、压力的精准定义,可实现任意曲面、任意角度的激光冲击强化数值模拟,并依据网格无关性要求确定了靶材网格尺寸。利用该方法,探究了激光冲击强化后涡轮盘榫槽结构特征部位的残余应力分布规律,与试验结果相比预测误差在20%以内。研究表明:激光冲击强化后涡轮盘榫槽部位引入一定深度范围内的残余压应力,但因曲面结构特征导致的工艺可达性影响,残余应力数值低于相同工艺水平下的平面结构,且在不同方向上存在差异性。

-

关键词:

- 激光冲击强化 /

- 曲面结构 /

- 涡轮盘榫槽 /

- GH4720Li合金 /

- 残余应力

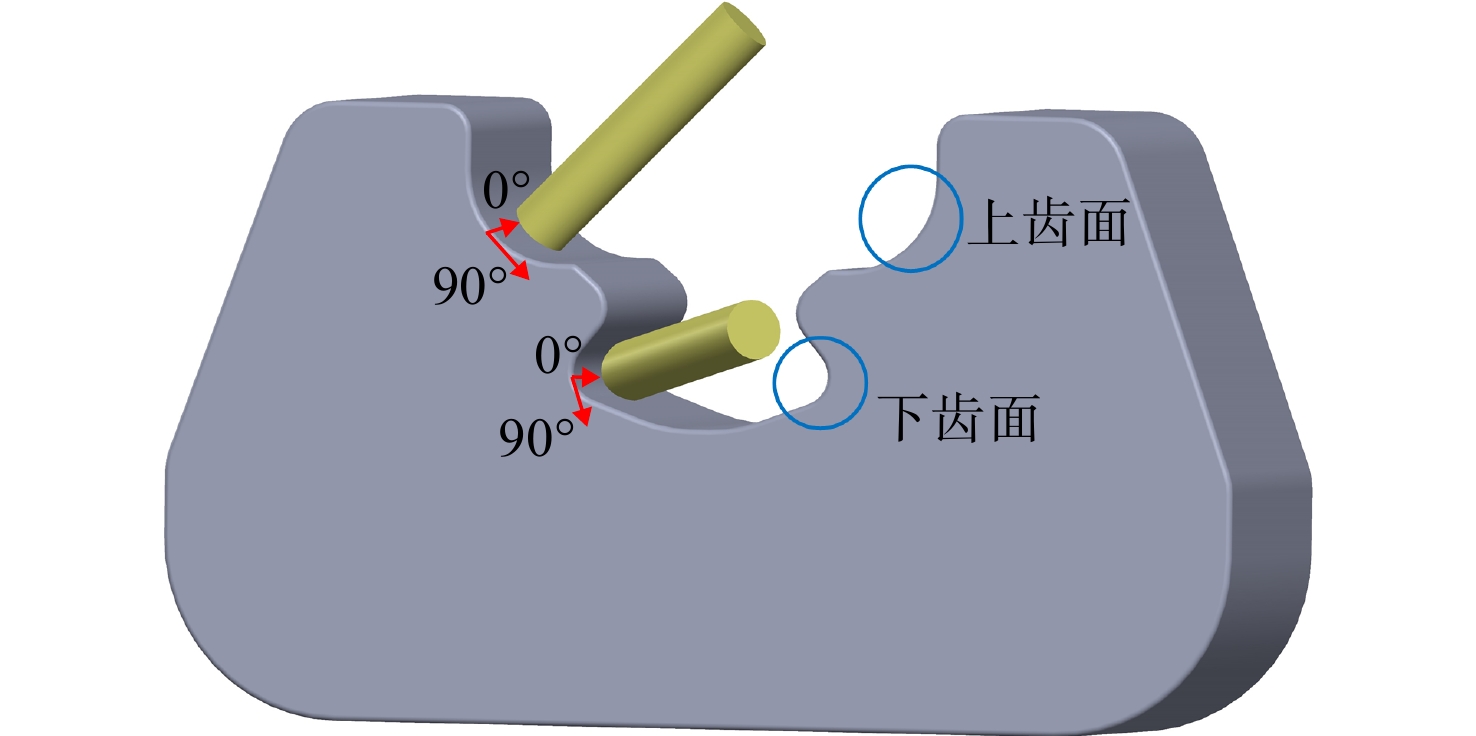

Abstract:A numerical simulation method of laser shock peening of curved structure based on the idea of discretization was proposed. The precise definition of the impacted area and pressure was realized through the spatial geometric relationship and the principle of energy conservation, and the numerical simulation of laser shock peening of any curved surface and any angle can be realized. Then the target mesh size was determined according to the requirements of mesh independence. Using this method, the residual stress distribution law of the characteristic for the turbine mortise structure after laser shock peening was explored. Compared with the experimental results, the prediction error was less than 20%. The research showed that the residual compressive stress in a certain depth range was introduced into the mortise of the turbine disk after laser shock peening, but due to the process accessibility caused by the structural characteristics of the curved surface, the residual stress value was lower than the plane structure at the same process level, and there were differences in different directions.

-

Key words:

- laser shock peening /

- curved surface structure /

- turbine mortise /

- GH4720Li superalloy /

- residual stress

-

E/GPa v A/MPa B/MPa C n 219 0.31 1142 1 947 0.026 0.882 表 2 不同结构表面残余应力

Table 2. Surface residual stress of different structures

$\varphi$ 残余应力/MPa 平面 上齿面 下齿面 0° −678.51 −668.89 −413.42 90° −677.93 −633.42 −338.03 -

[1] 江涛. 发动机叶片榫槽爬波原位检测系统研制[D]. 南京: 南京航空航天大学, 2012.JIANG Tao. Engine blade groove creeping wave detection system developed in situ[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012. (in Chinese) [2] 孙希泰. 材料表面强化技术[M]. 北京: 化学工业出版社材料科学与工程出版中心, 2005. [3] 段志勇. 激光冲击波及激光冲击处理技术的研究[D]. 合肥: 中国科学技术大学, 2000.DUAN Zhiyong. Study on laser shock wave and laser shock processing technology[D]. Hefei: University of Science and Technology of China, 2000. (in Chinese) [4] LI Songxia,QIAO Hongchao,ZHAO Jibin,et al. Research and development of laser shock processing technology[J]. Opto-Electronic Engineering,2017,44(6): 569-576. [5] MONTROSS C S,WEI T,LIN Y,et al. Laser shock processing and its effects on microstructure and properties of metal alloys: a review[J]. International Journal of Fatigue,2002,24(10): 1021-1036. doi: 10.1016/S0142-1123(02)00022-1 [6] OCANA J L,MORALES M,MOLPECERS C,et al. Numerical simulation of surface deformation and residual stresses fields in laser shock processing experiments[J]. Applied Surface Science,2004,238(1/2/3/4): 242-248. doi: 10.1016/j.apsusc.2004.05.232 [7] HU Yongxiang,YAO Zhenqiang,HU Jun. 3-D FEM simulation of laser shock processing[J]. Surface & Coatings Technology,2006,201(3/4): 1426-1435. [8] 张永康,高立. 钛合金板料激光冲击变形的数值模拟和实验[J]. 中国机械工程,2006,17(17): 1813-1817. doi: 10.3321/j.issn:1004-132X.2006.17.013ZHANG Yongkang,GAO Li. Numerical simulation and experimental study on the deformation of TA2 sheet metal by laser shock[J]. China Mechanical Engineering,2006,17(17): 1813-1817. (in Chinese) doi: 10.3321/j.issn:1004-132X.2006.17.013 [9] 胡永祥. 激光冲击处理工艺过程数值建模与冲击效应研究[D]. 上海: 上海交通大学, 2008.HU Yongxiang. Research on the numerical simulation and impact effects of laser shock processing[D]. Shanghai: Shanghai Jiao Tong University, 2008. (in Chinese) [10] GILL A S,TELANG A,VASUDEVAN V K. Characteristics of surface layers formed on inconel 718 by laser shock peening with and without a protective coating[J]. Journal of Materials Processing Tech,2015,225: 463-472. doi: 10.1016/j.jmatprotec.2015.06.026 [11] 汪璐. 激光冲击强化对GH4720Li力学性能的影响及热稳定性研究[D]. 广州: 广东工业大学, 2021.WANG Lu. Study on effect of laser shock processing on mechanical properties and thermal stability of GH4720Li[D] Guangzhou: Guangdong University of Technology, 2021. (in Chinese) [12] 朱然. 平顶光束多点激光冲击薄壁件的强化与变形研究[D]. 南京: 东南大学, 2019.ZHU Ran. Study on strengthening and deformation of thin-walled components under flattened beam multiple laser shock processing[D]. Nanjing: Southeast University, 2019. (in Chinese) [13] YANG Chunhui,HODGSON P D,LIU Qianchu,et al. Geometrical effects on residual stresses in 7050-T7451 aluminum alloy rods subject to laser shock peening[J]. Journal of Materials Processing Technology,2008,201(1): 303-309. [14] [15] 葛良辰,曹宇鹏,花国然,等. 表面曲率对激光冲击曲面材料表面残余应力场分布的影响[J]. 表面技术,2020,49(4): 284-291.GE Liangchen,CAO Yupeng,HUA Guoran,et al. The effect of surface curvature on surface residual stress field distribution of laser shock materials[J]. Surface Technology,2020,49(4): 284-291. (in Chinese) [16] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures[R]. Hague, Netherlands:Proceedings of the Seventh International Symposium on Ballistics, 1983. [17] HU Dianyin,TIAN Tengyue,WANG Xin,et al. Surface hardening analysis for shot peened GH4720Li superalloy using a DEM-FEM coupling RV simulation method[J]. International Journal of Mechanical Sciences,2021,209: 106689.1-106689.11. [18] FABBRO R,FOURNIER J,BALLARD P,et al. Physical study of laser produced plasma in confined geometry[J]. Journal of Applied Physics,1990,68(2): 775-784. doi: 10.1063/1.346783 [19] XU Gaofeng,LUO Kaiyu,DAI Fengze,et al. Effects of scanning path and overlapping rate on residual stress of 316L stainless steel blade subjected to massive laser shock peening treatment with square spots[J]. Applied Surface Science,2019,481: 1053-1063. doi: 10.1016/j.apsusc.2019.03.093 [20] SUN Boyu,ZHAO Jibin,QIAO Hongchao,et al. Effects of square spot size and beam quality on residual stress of 7050 aluminum alloy by laser shock peening[J]. Materials Chemistry and Physics,2022,284: 126023.1-126023.10. [21] 杨玉致. 机械噪声控制技术[M]. 北京: 中国农业机械出版社, 1983. [22] 中国金属学会高温材料分会. 中国高温合金手册[M]. 北京: 中国标准出版社, 2012. [23] 王瑞荣,陈伟民,谢东珠. 斜辐照激光等离子体辐射X光子特性[J]. 强激光与粒子束,2008,20(3): 387-390.WANG Ruirong,CHEN Weimin,XIE Dongzhu. Characteristics of X-ray photons in tilted incident laser-produced plasma[J]. High Power Laser and Particles Beams,2008,20(3): 387-390. (in Chinese) -

下载:

下载: