Dynamic characteristics of angular contact ball bearings under different preloading mechanisms and interference amount

-

摘要:

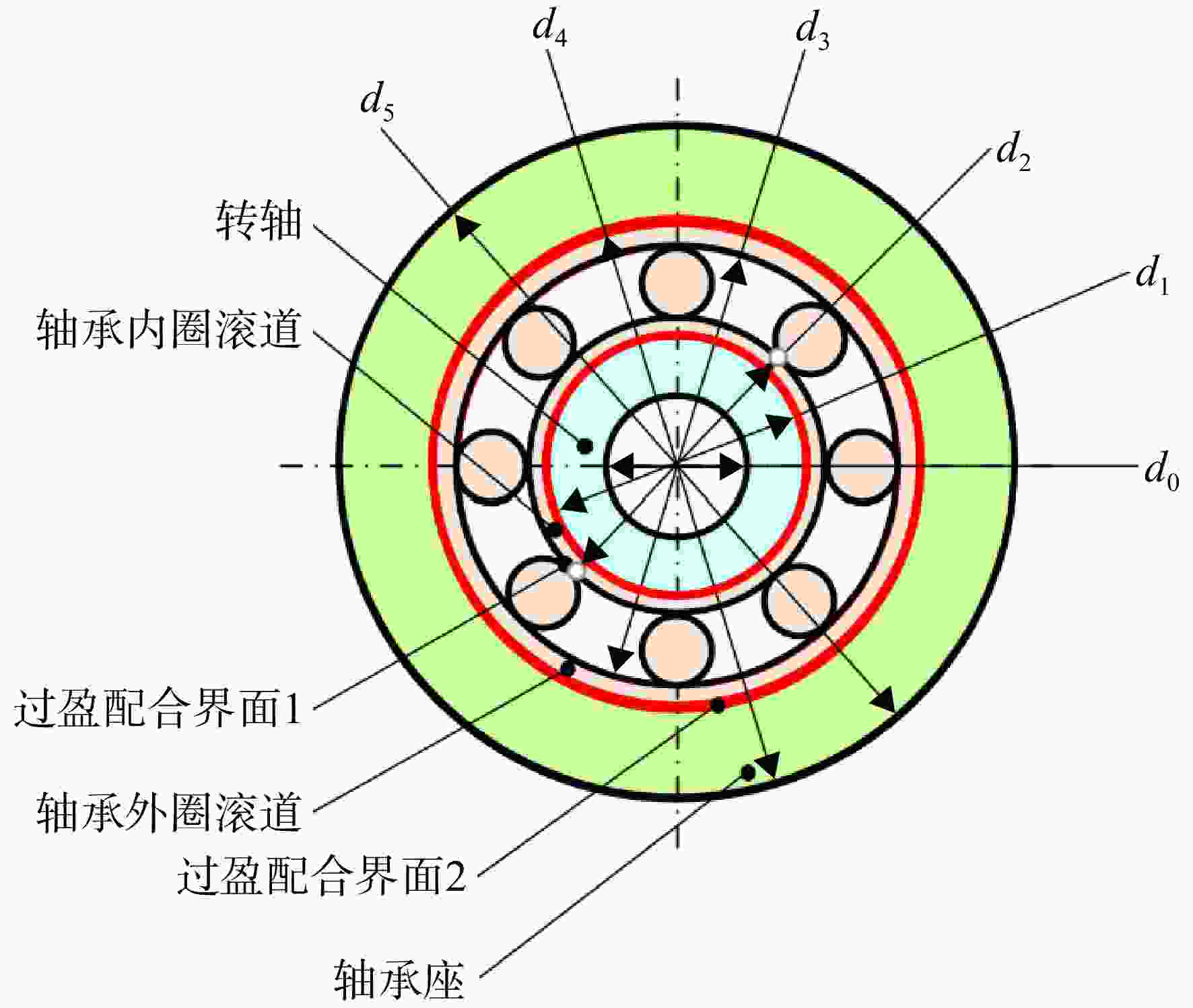

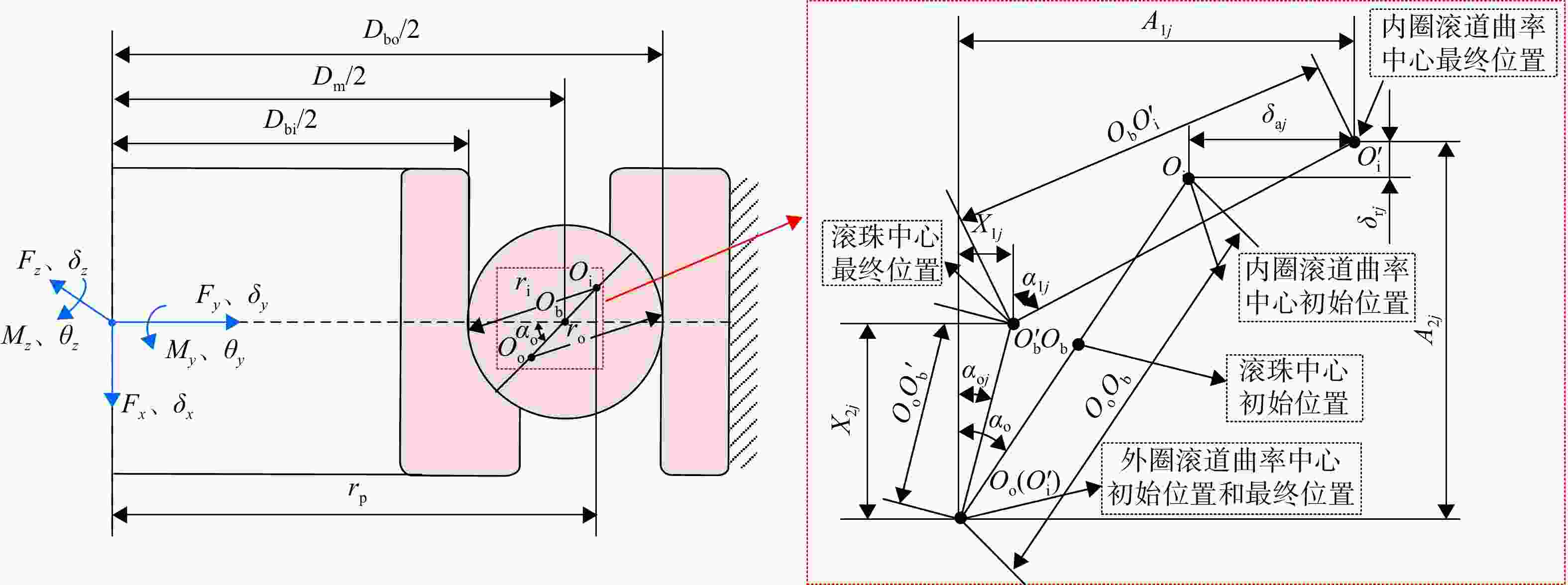

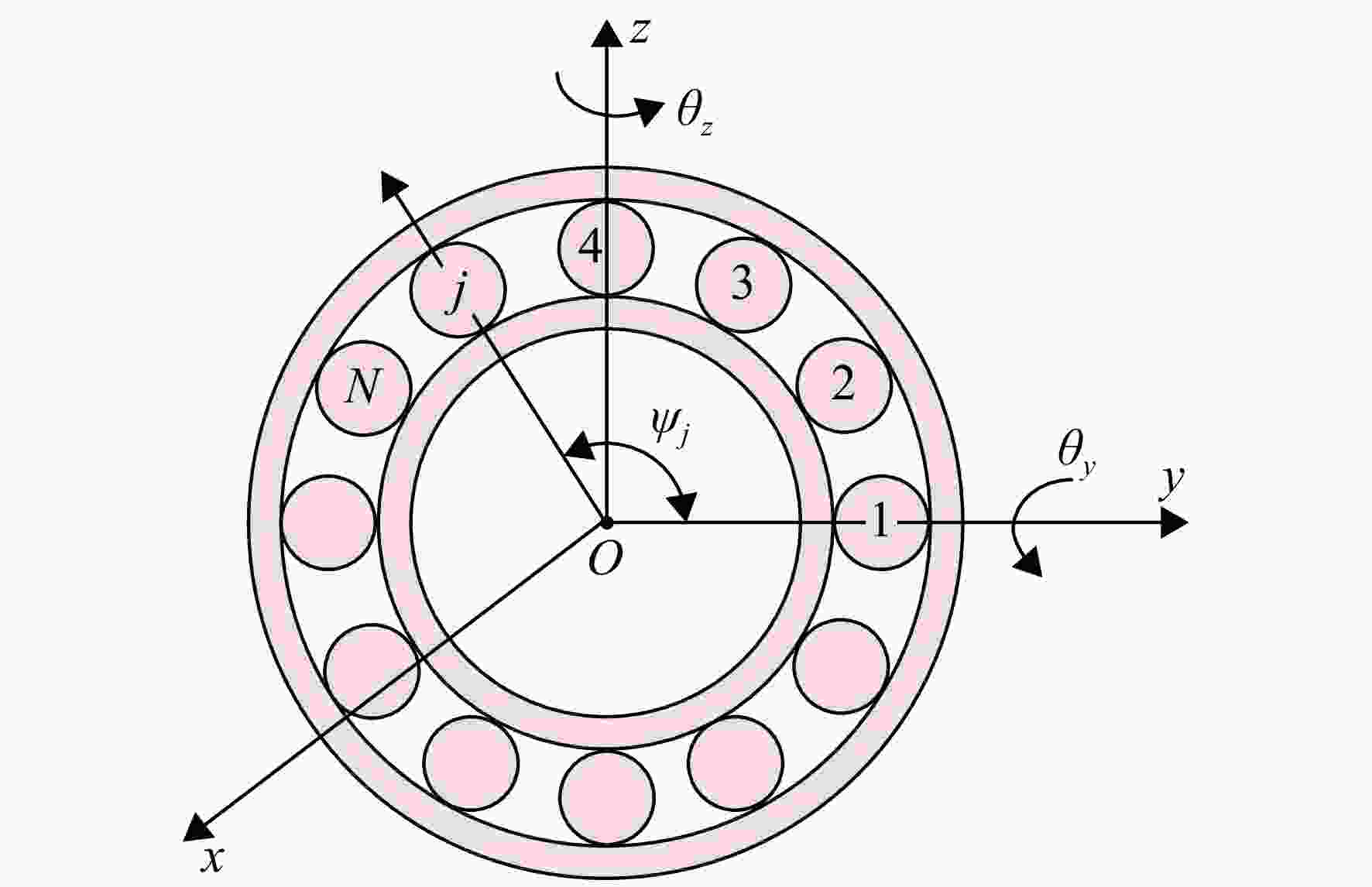

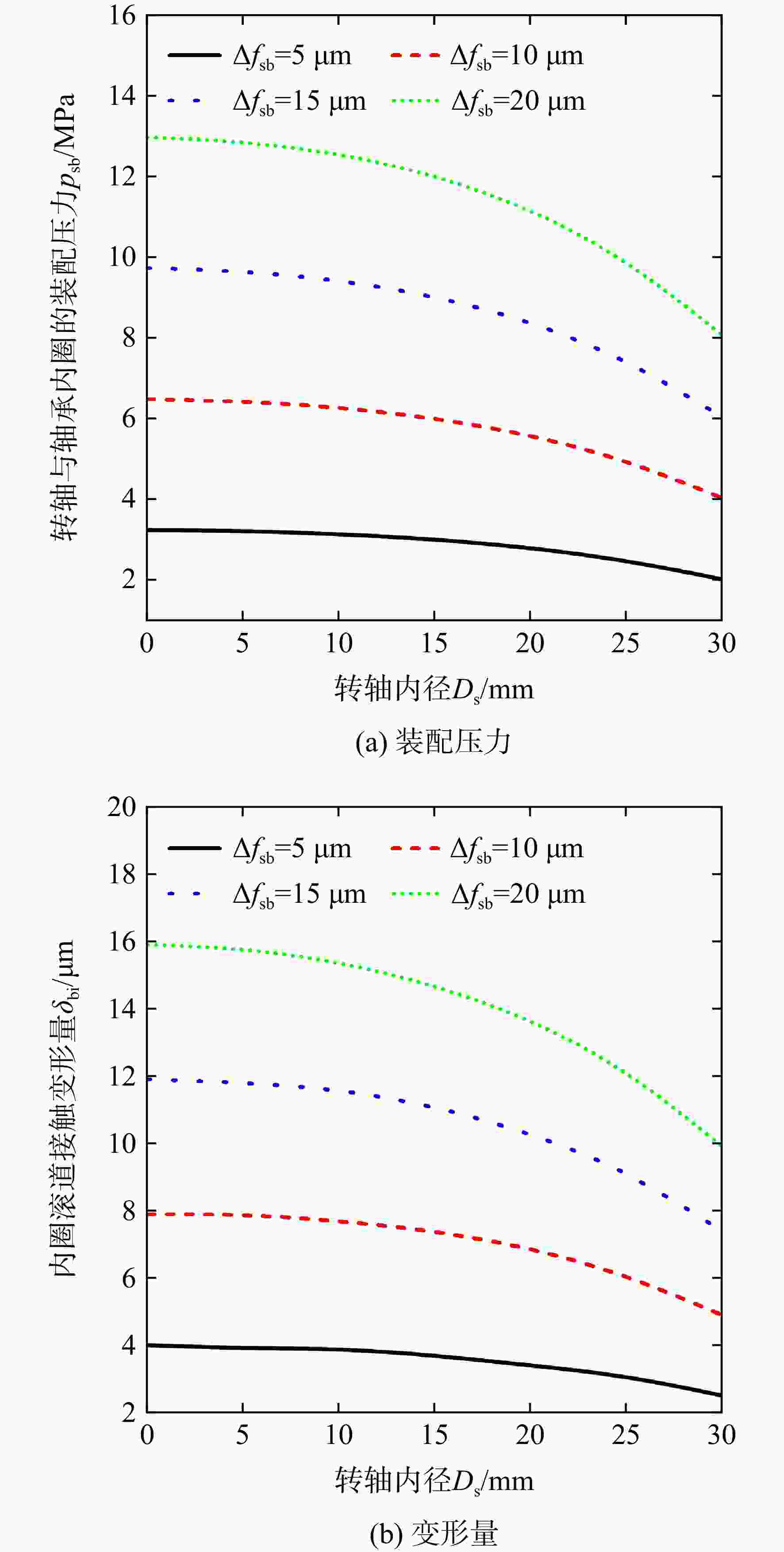

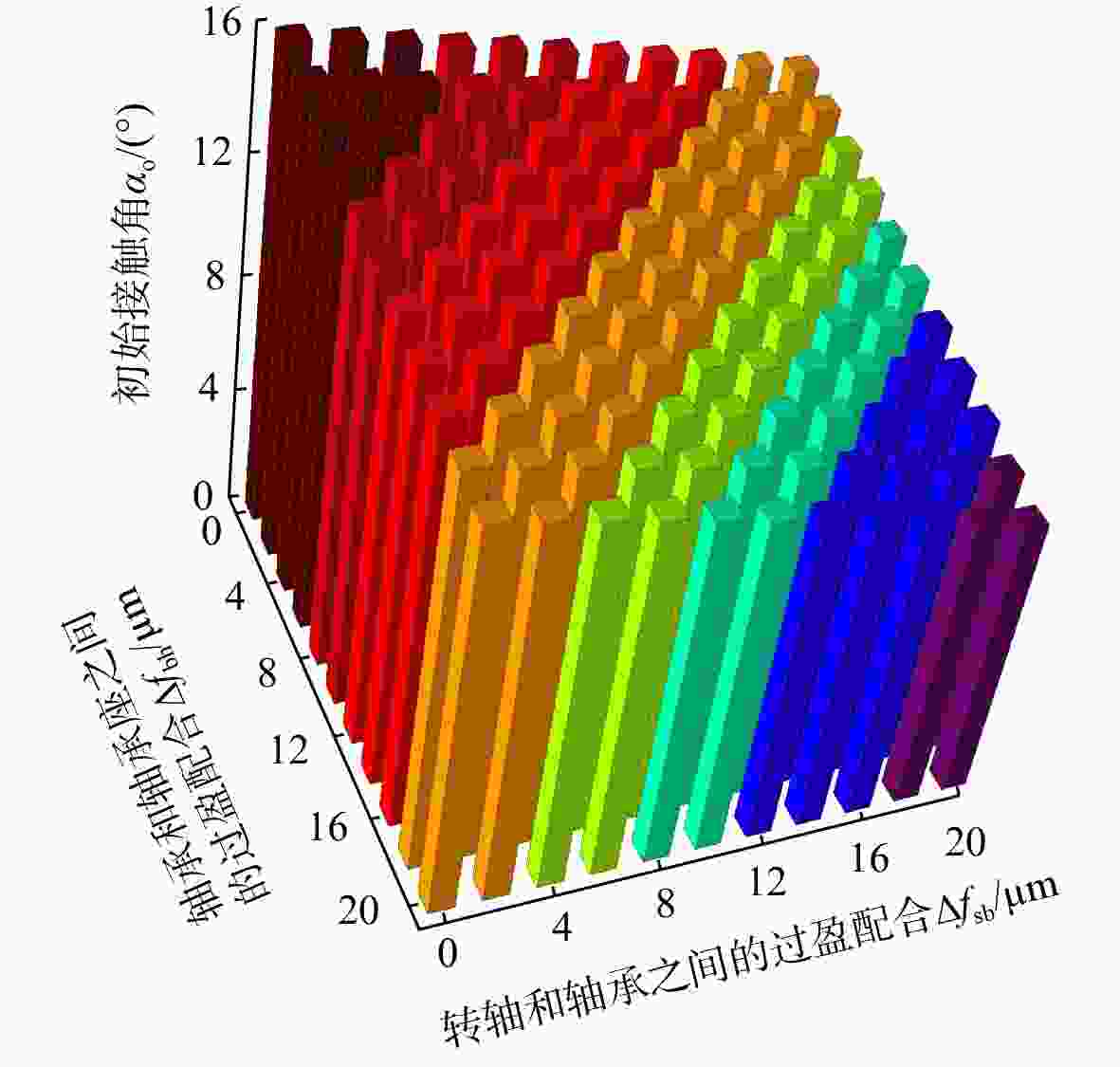

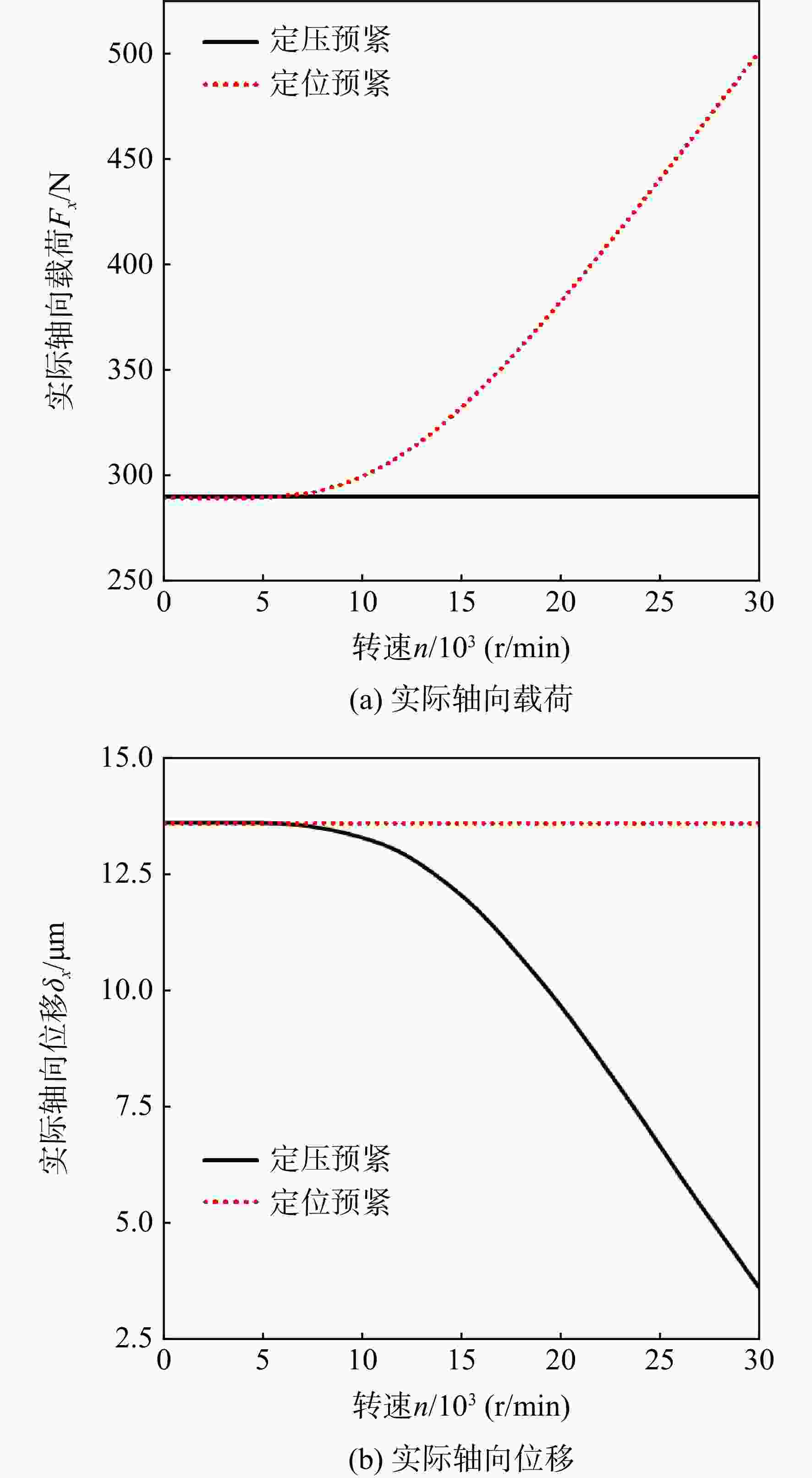

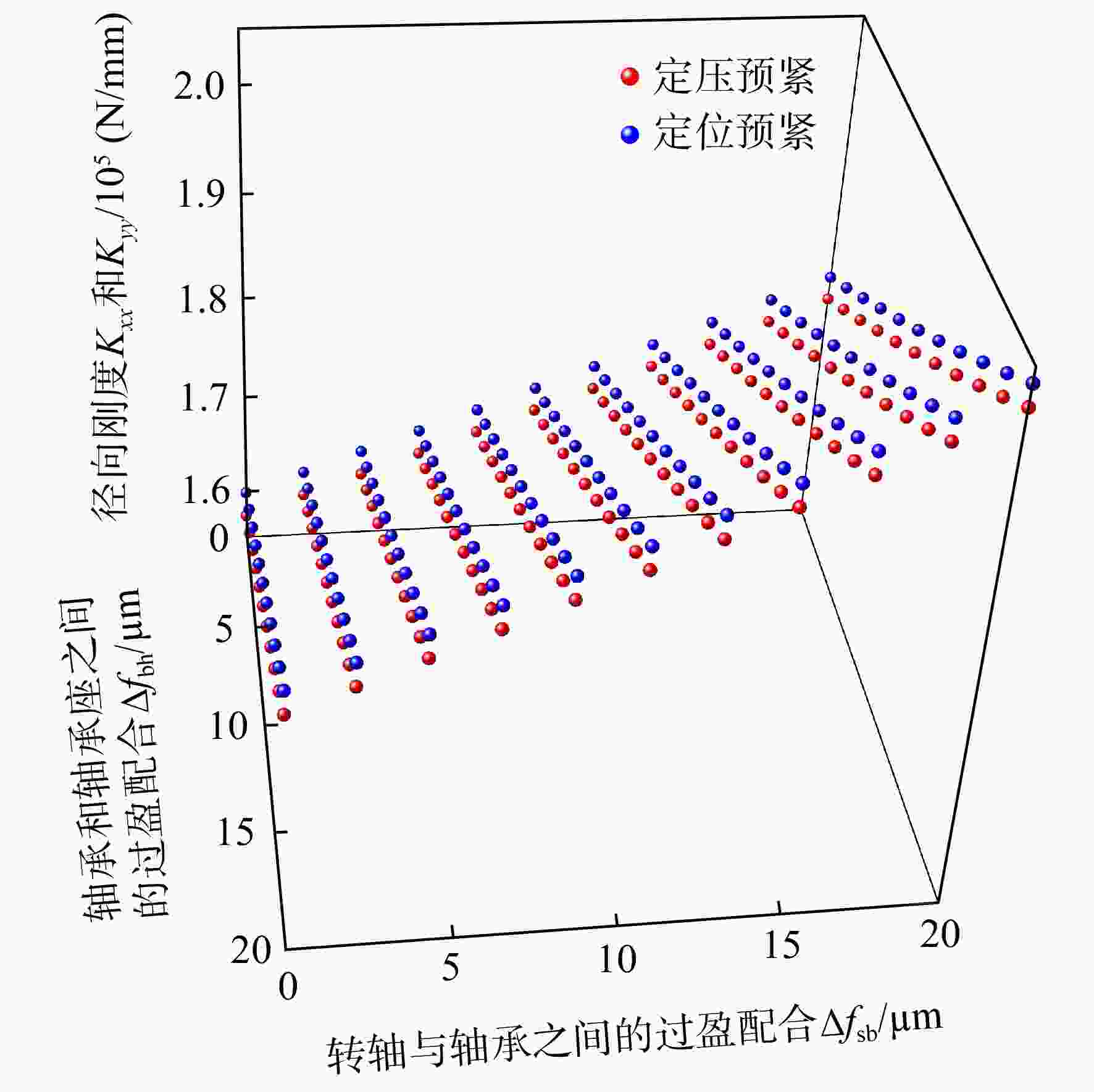

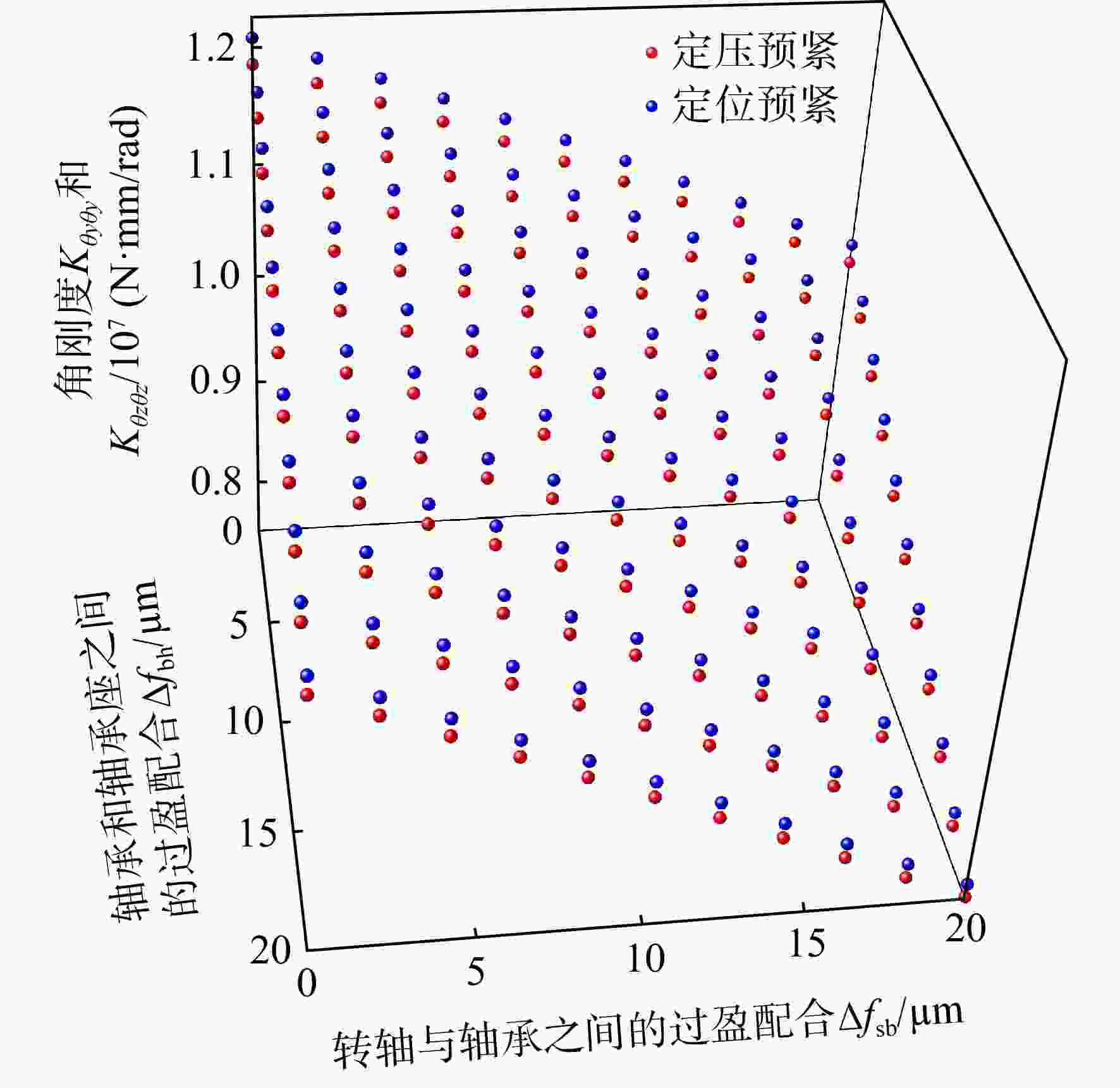

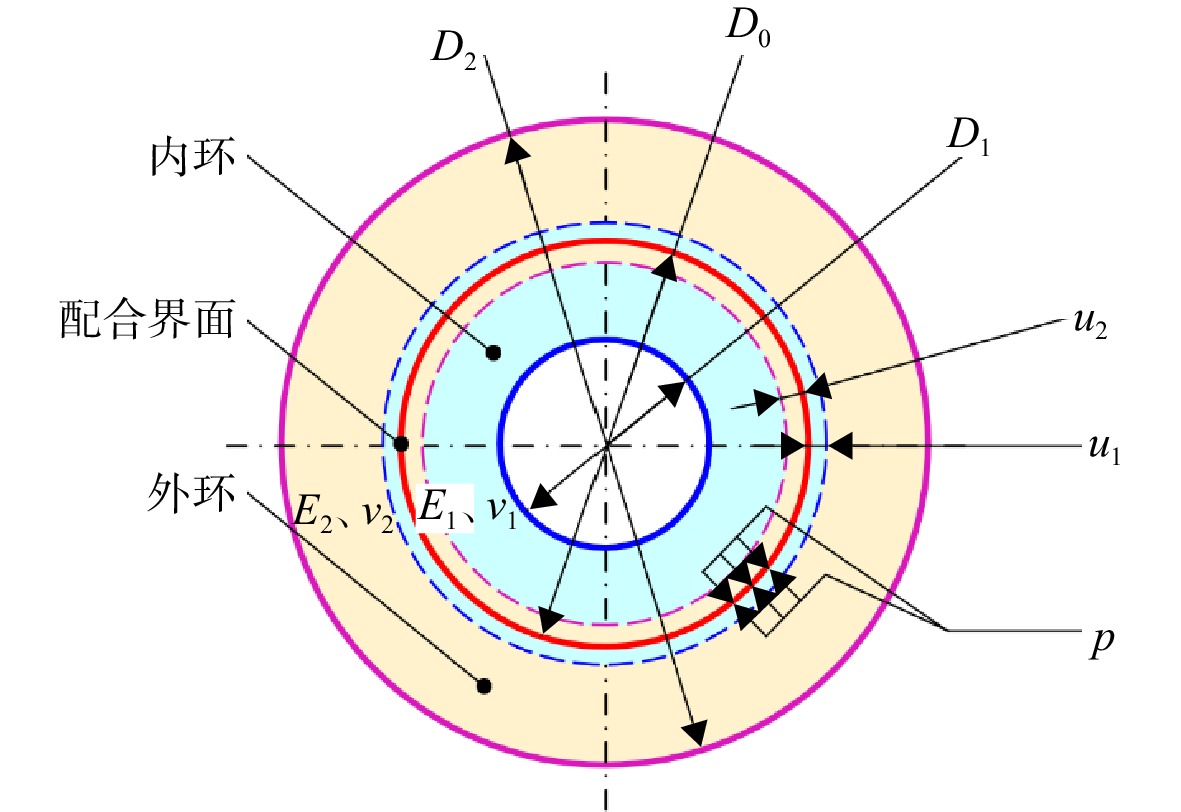

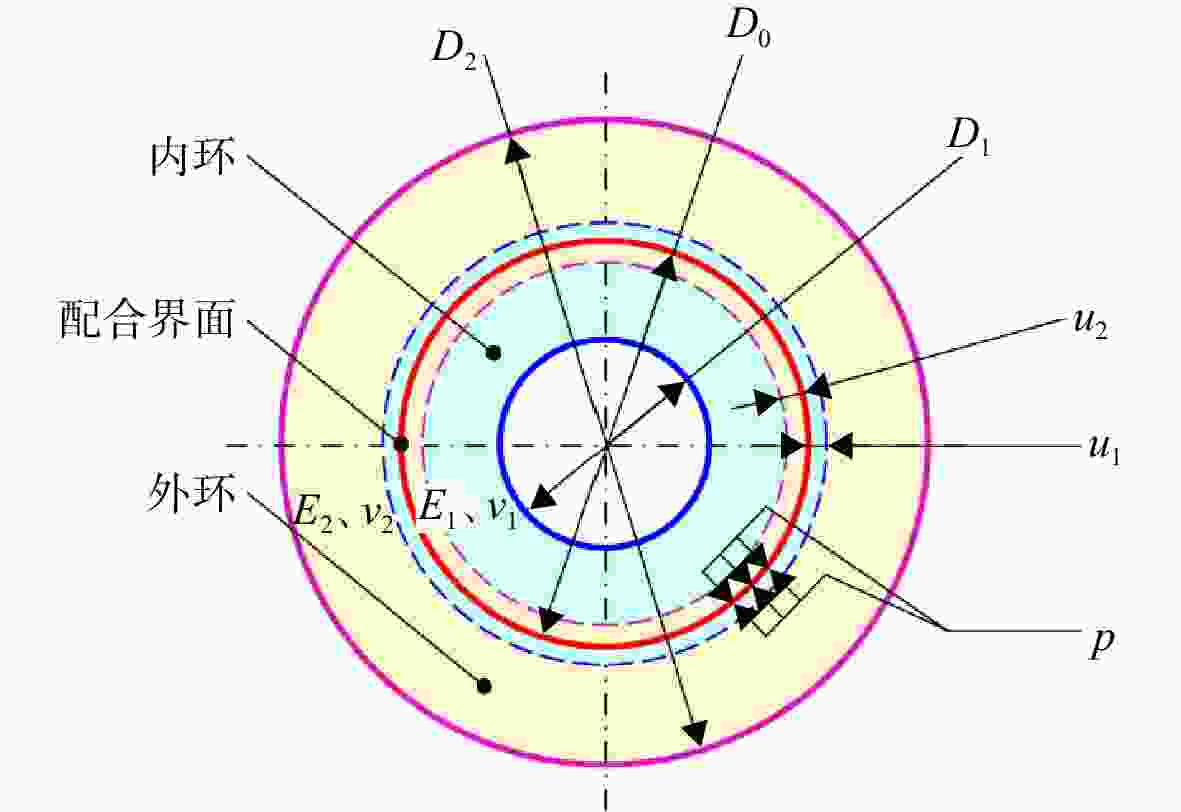

基于Hertz弹性接触理论和无滚道控制理论,建立了不同预载机制下五自由度角接触球轴承拟静力学分析模型,采用牛顿拉夫逊法对已建立的模型进行数值求解,探究预载机制和过盈量对角接触球轴承动力学特性的影响。通过将已建立模型求解接触角和轴承刚度结果与已有文献结果进行对比,验证模型的有效性。分别探究了过盈量对内外圈装配压力和滚道接触变形量的影响以及过盈量和预载机制对轴承刚度的影响。结果表明:随过盈量增加,内外圈装配压力增加,初始接触角减小;随着过盈量增加,轴承径向刚度增加,轴向刚度和角刚度减小;与定压预紧相比,定位预紧能够提高轴承刚度;探究转速对接触变形和装配压力的影响,确定了松脱旋转速度约为40 000 r/min。

Abstract:Based on Hertz elastic contact theory and raceless control theory, a quasi-static analysis model of angular contact ball bearings with five degrees of freedom under different preloading mechanisms was established. Newton Raphson method was used to numerically solve the established model for exploring the influences of preloading mechanisms and interference amount on the dynamic characteristics of angular contact ball bearings. The effectiveness of the model was verified by comparing the results of contact angle and bearing stiffness of the established model with those of existing literature. The influences of the interference amount on the assembly pressure of the inner and outer rings and the contact deformation of the raceway as well as the influences of the interference amount and the preloading mechanisms on the bearing stiffness were explored. The results showed that with the increase of interference, the assembly pressure of inner and outer rings decreased and the initial contact angle decreased; with the increase of interference, the radial stiffness of the bearing increased, while the axial stiffness and angular stiffness decreased; compared with constant pressure preloading, positioning preloading can improve the bearing stiffness; ghe influence of rotation speed on contact deformation and assembly pressure was investigated, and the release rotation speed was determined to be about 40000 r/min.

-

Key words:

- interference amount /

- preloading mechanism /

- Newton Raphson /

- bearing stiffness /

- contact angle

-

表 1 FAG B7014AC轴承参数

Table 1. Bearing parameters of FAG B7014AC

参数 数值 弹性模量E/105 (N/mm2) 2.06 泊松比ν 0.3 滚珠密度ρ/(kg/m3) 7850 滚珠直径d/mm 12.5 内圈滚道曲率半径ri/mm 6.54 外圈滚道曲率半径ro/mm 6.54 内圈滚道接触直径d2/mm 77 外圈滚道接触直径d3/mm 102 滚珠个数N 19 表 2 SKF EEB3-2Z轴承参数

Table 2. Bearing parameters of SKF EEB3-2Z

参数 数值 弹性模量E/105 (N/mm2) 2.06 泊松比ν 0.3 滚珠密度ρ/(kg/m3) 7850 滚珠直径d/mm 3.969 内圈滚道曲率半径ri/mm 2.064 外圈滚道曲率半径ro/mm 2.064 内圈滚道接触直径d2/mm 13.06 外圈滚道接触直径d3/mm 18.21 滚珠个数N 7 表 3 B7008C相关材料参数

Table 3. Material parameters of B7008C

参数 材料 弹性模量/

105 (N/mm2)泊松比ν 密度 /

(kg/m3)转轴 TC4 1.1 0.3 4510 轴承 9Cr18 2.06 0.3 7850 轴承座 TC4 1.1 0.3 4510 表 4 B7008C轴承参数

Table 4. Bearing parameters of B7008C

参数 数值 转轴和轴承过盈配合直径d1/mm 40 轴承和轴承座过盈配合直径d4/mm 68 轴承座外径d5/mm ∞ 滚珠直径d/mm 7.144 内圈滚道曲率半径ri/mm 4.0 外圈滚道曲率半径ro/mm 3.79 内圈滚道接触直径d2/mm 46.838 外圈滚道接触直径d3/mm 61.176 滚珠个数N 19 -

[1] ALFARES M A,ELSHARKAWY A A. Effects of axial preloading of angular contact ball bearings on the dynamics of a grinding machine spindle system[J]. Journal of Materials Processing Technology,2003,136(1/2/3): 48-59. [2] GUNDUZ A,DREYER J T,SINGH R. Effect of bearing preloads on the modal characteristics of a shaft-bearing assembly: experiments on double row angular contact ball bearings[J]. Mechanical Systems and Signal Processing,2012,31: 176-195. doi: 10.1016/j.ymssp.2012.03.013 [3] ZHANG Jinhua,FANG Bin,HONG Jun,et al. A general model for preload calculation and stiffness analysis for combined angular contact ball bearings[J]. Journal of Sound and Vibration,2017,411: 435-449. doi: 10.1016/j.jsv.2017.09.019 [4] ZHANG Jinhua,FANG Bin,ZHU Yongsheng,et al. A comparative study and stiffness analysis of angular contact ball bearings under different preload mechanisms[J]. Mechanism and Machine Theory,2017,115: 1-17. doi: 10.1016/j.mechmachtheory.2017.03.012 [5] FANG Bin,YAN Ke,HONG Jun,et al. A comprehensive study on the off-diagonal coupling elements in the stiffness matrix of the angular contact ball bearing and their influence on the dynamic characteristics of the rotor system[J]. Mechanism and Machine Theory,2021,158: 104251. doi: 10.1016/j.mechmachtheory.2021.104251 [6] 王硕桂,夏源明. 过盈配合量和预紧力对高速角接触球轴承刚度的影响[J]. 中国科学技术大学学报,2006,36(12): 1314-1320. doi: 10.3969/j.issn.0253-2778.2006.12.011WANG Shuogui,XIA Yuanming. Effect of the interference fit and axial preload in the stiffness of the high-speed angular contact ball bearing[J]. Journal of University of Science and Technology of China,2006,36(12): 1314-1320. (in Chinese) doi: 10.3969/j.issn.0253-2778.2006.12.011 [7] 李小虎,张燕飞,万少可,等. 定位预紧和定压预紧下角接触球轴承动态特性研究[J]. 轴承,2021(12): 1-7, 12. doi: 10.19533/j.issn1000-3762.2021.12.001LI Xiaohu,ZHANG Yanfei,WAN Shaoke,et al. Study on dynamic characteristics of angular contact ball bearings under fixed preload and constant pressure preload[J]. Bearing,2021(12): 1-7, 12. (in Chinese) doi: 10.19533/j.issn1000-3762.2021.12.001 [8] 李鸿亮,夏旎,邓四二,等. 配对角接触球轴承初始预紧力分析[J]. 轴承,2013(8): 1-3, 7. doi: 10.3969/j.issn.1000-3762.2013.08.001LI Hongliang,XIA Ni,DENG Sier,et al. Analysis on initial preload of paired angular contact ball bearings[J]. Bearing,2013(8): 1-3, 7. (in Chinese) doi: 10.3969/j.issn.1000-3762.2013.08.001 [9] 李鸿亮,贺红霞,刘良勇,等. 定位预紧配对角接触球轴承工作预紧力分析[J]. 轴承,2012(9): 37-39. doi: 10.3969/j.issn.1000-3762.2012.09.015LI Hongliang,HE Hongxia,LIU Liangyong,et al. Analysis of working preload of angular contact ball bearing with positioning preload pair[J]. Bearing,2012(9): 37-39. (in Chinese) doi: 10.3969/j.issn.1000-3762.2012.09.015 [10] LEE C M,WOO W S,KIM D H. The latest preload technology of machine tool spindles: a review[J]. International Journal of Precision Engineering and Manufacturing,2017,18(11): 1669-1679. doi: 10.1007/s12541-017-0195-0 [11] 王云龙,王文中,卿涛,等. 角接触球轴承-转子加减速过程动力学分析[J]. 机械工程学报,2018,54(9): 9-16.WANG Yunlong,WANG Wenzhong,QING Tao,et al. Dynamic analysis of angular contact ball bearing-rotor system during start up and shut down[J]. Journal of Mechanical Engineering,2018,54(9): 9-16. (in Chinese) [12] 邓四二,李兴林,汪久根,等. 角接触球轴承摩擦力矩特性研究[J]. 机械工程学报,2011,47(5): 114-120. doi: 10.3901/JME.2011.05.114DENG Sier,LI Xinglin,WANG Jiugen,et al. Frictional torque characteristic of angular contact ball bearings[J]. Journal of Mechanical Engineering,2011,47(5): 114-120. (in Chinese) doi: 10.3901/JME.2011.05.114 [13] 冈本纯三. 球轴承的设计计算[M]. 黄志强, 译. 北京: 机械工业出版社, 2003. [14] CAO Yuzhong,ALTINTAS Y. A general method for the modeling of spindle-bearing systems[J]. Journal of Mechanical Design,2004,126(6): 1089-1104. doi: 10.1115/1.1802311 [15] WANG Wenzhong,HU Lang,ZHANG Shengguang,et al. Modeling angular contact ball bearing without raceway control hypothesis[J]. Mechanism and Machine Theory,2014,82: 154-172. doi: 10.1016/j.mechmachtheory.2014.08.006 [16] XU Tengfei,YANG Lihua,WU Wei,et al. The stiffness characteristics analysis of the duplex angular contact ball bearings based on a comprehensive multi-degree-of-freedom mathematical model[J]. Applied Mathematical Modelling,2022,106: 601-626. doi: 10.1016/j.apm.2022.02.017 [17] 李震,关先磊,钟锐,等. 联合载荷下角接触球轴承的动态特性分析[J]. 机械工程学报,2020,56(17): 116-125. doi: 10.3901/JME.2020.17.116LI Zhen,GUAN Xianlei,ZHONG Rui,et al. Analysis of dynamic characteristics of angle contact bearings with combined loads[J]. Journal of Mechanical Engineering,2020,56(17): 116-125. (in Chinese) doi: 10.3901/JME.2020.17.116 [18] GUO Yi,PARKER R G. Stiffness matrix calculation of rolling element bearings using a finite element/contact mechanics model[J]. Mechanism and Machine Theory,2012,51: 32-45. doi: 10.1016/j.mechmachtheory.2011.12.006 [19] KRAUS J,BLECH J J,BRAUN S G. In situ determination of rolling bearing stiffness and damping by modal analysis[J]. Journal of Vibration and Acoustics,1987,109(3): 235-240. doi: 10.1115/1.3269426 -

下载:

下载: