Notched fatigue strength prediction of SiCp/Al composites based on the three-dimensional space vector stress field intensity method

-

摘要:

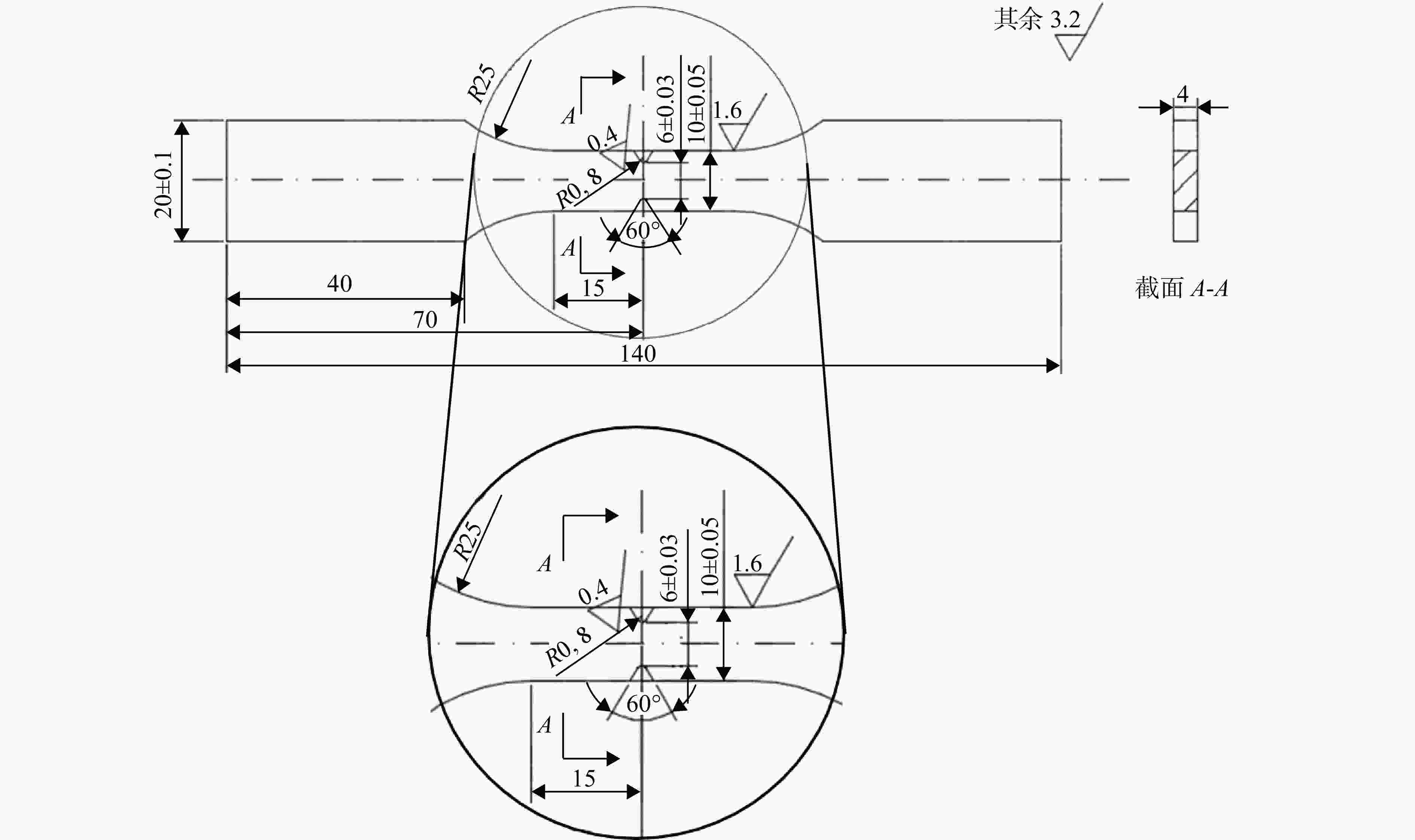

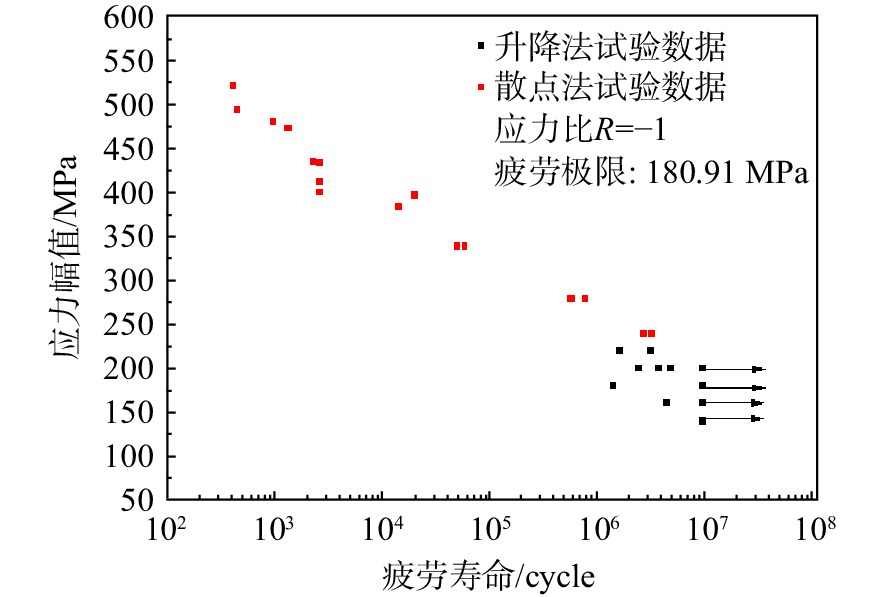

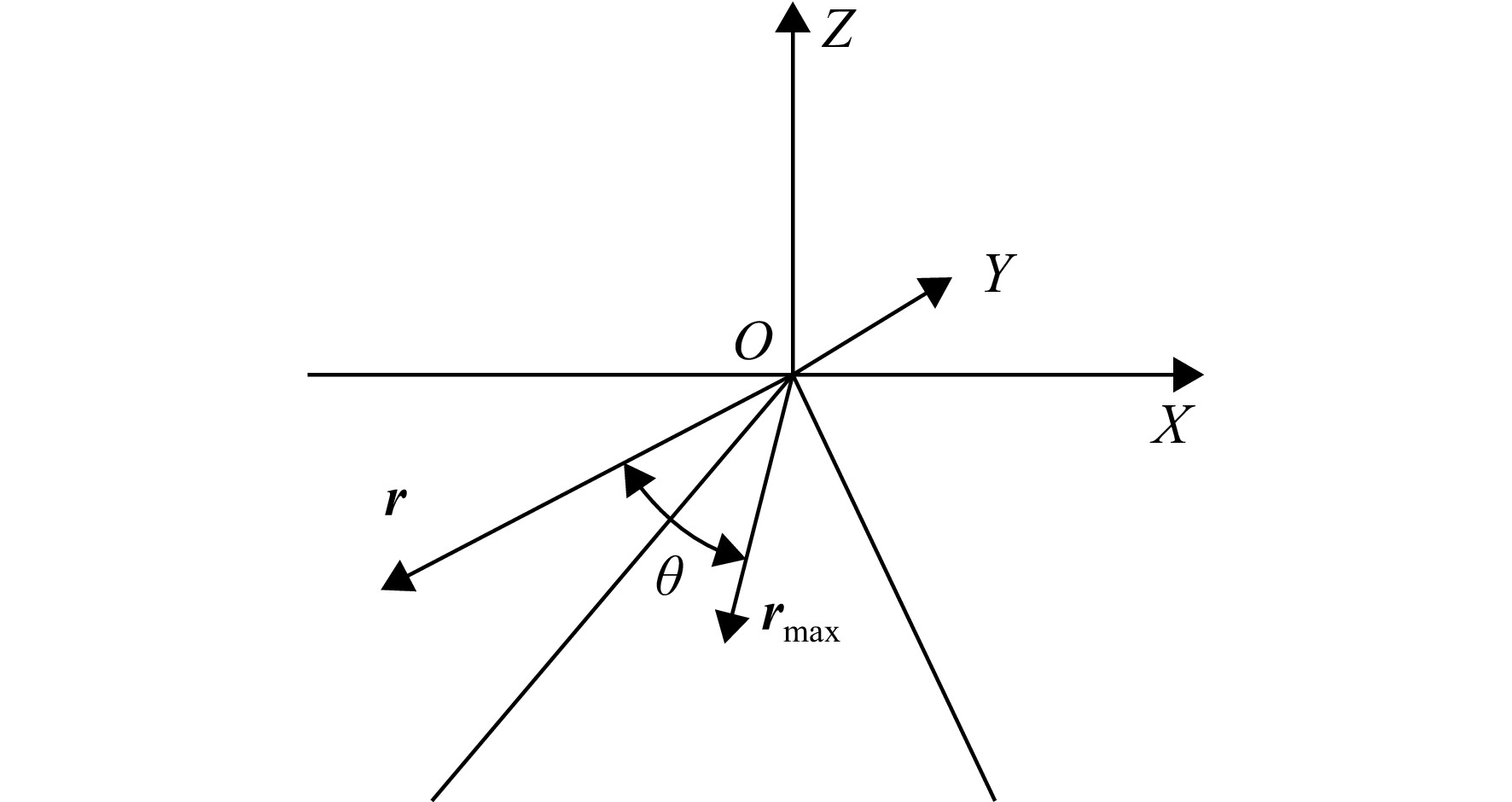

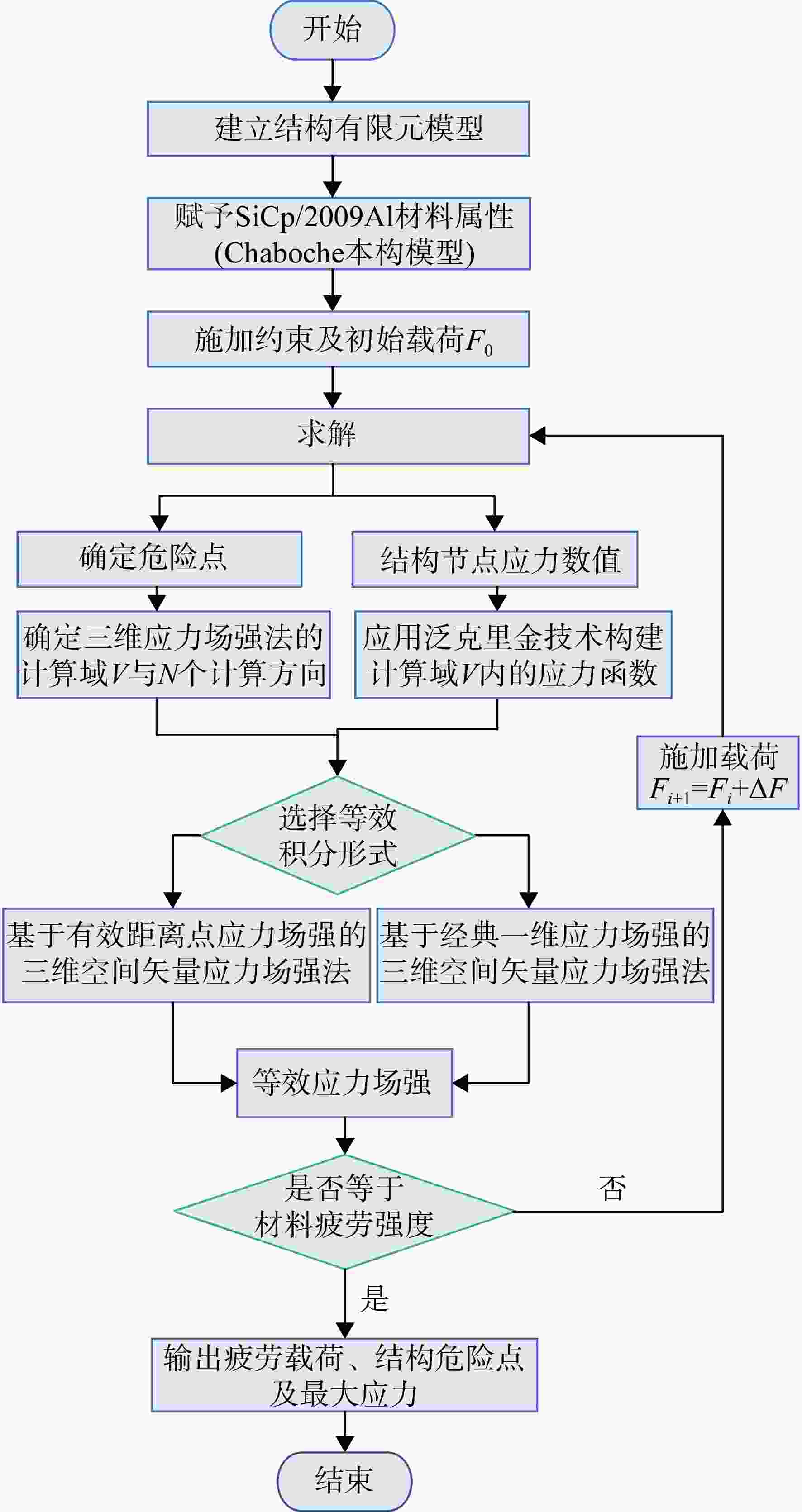

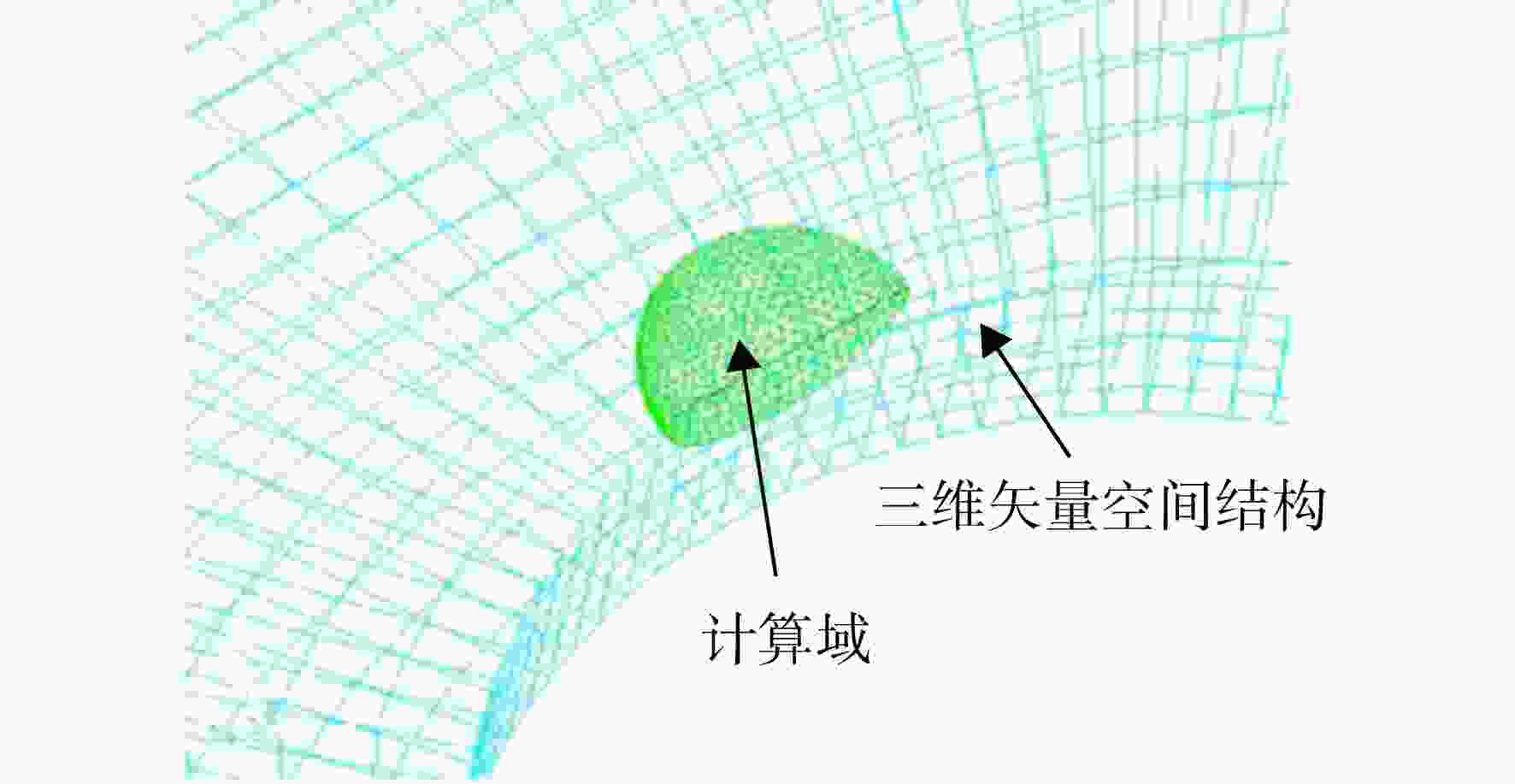

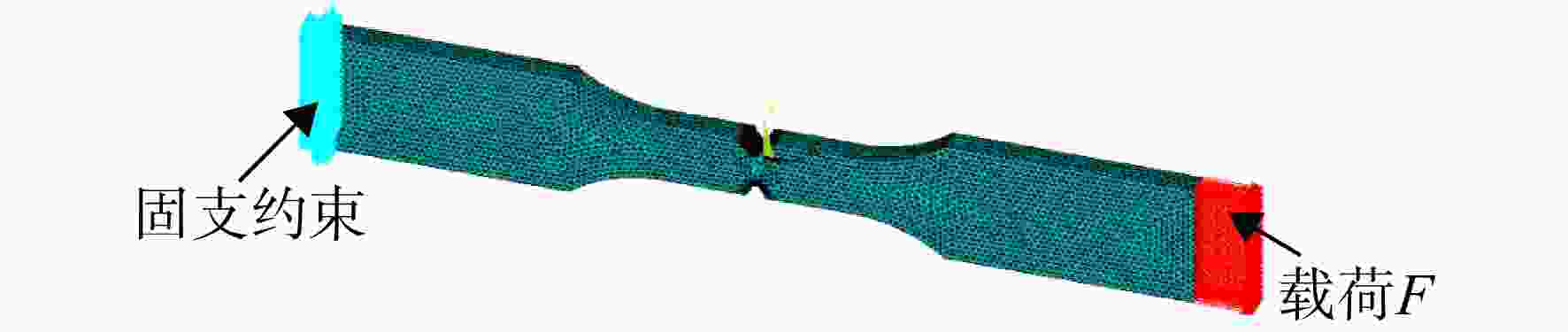

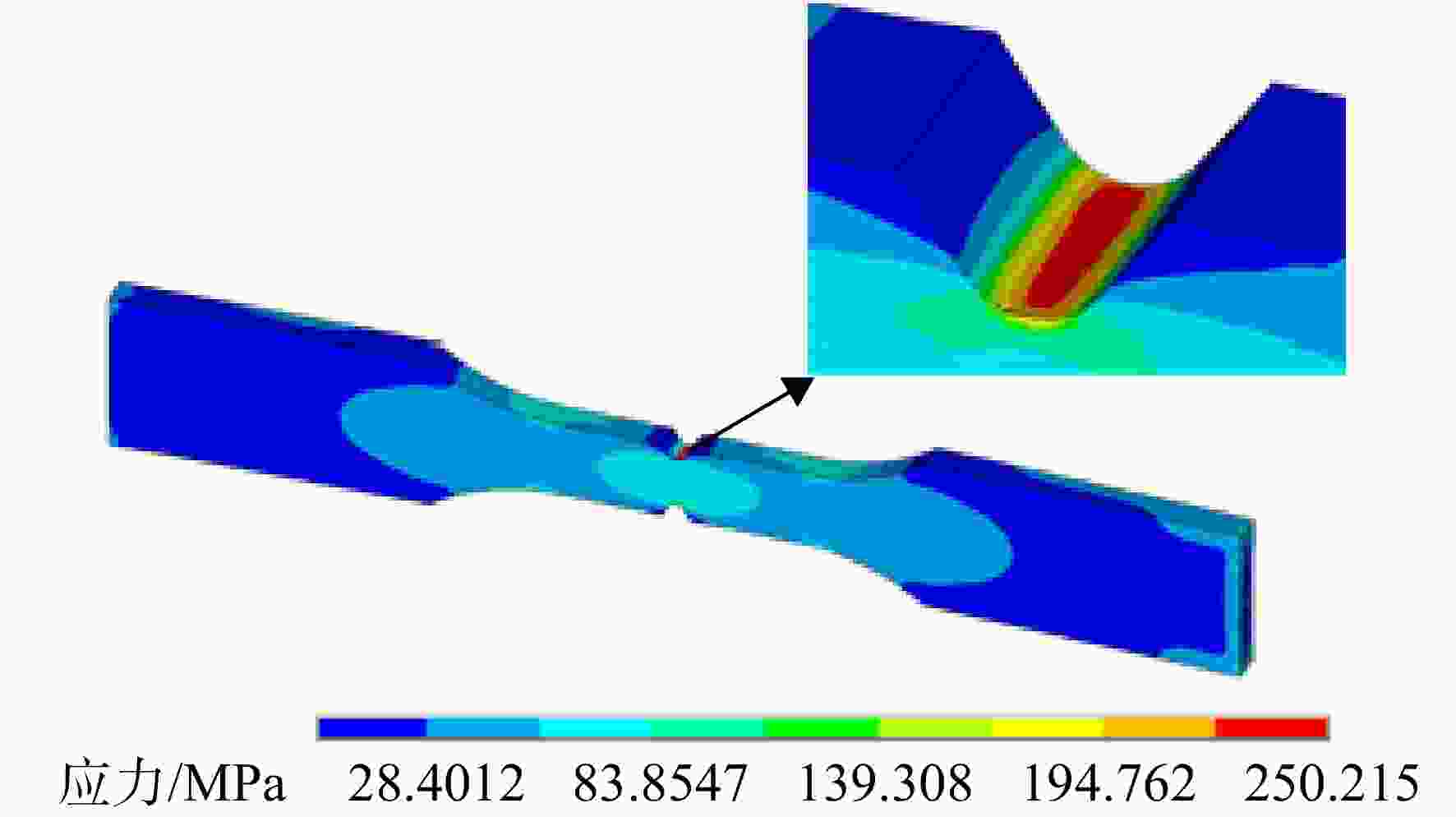

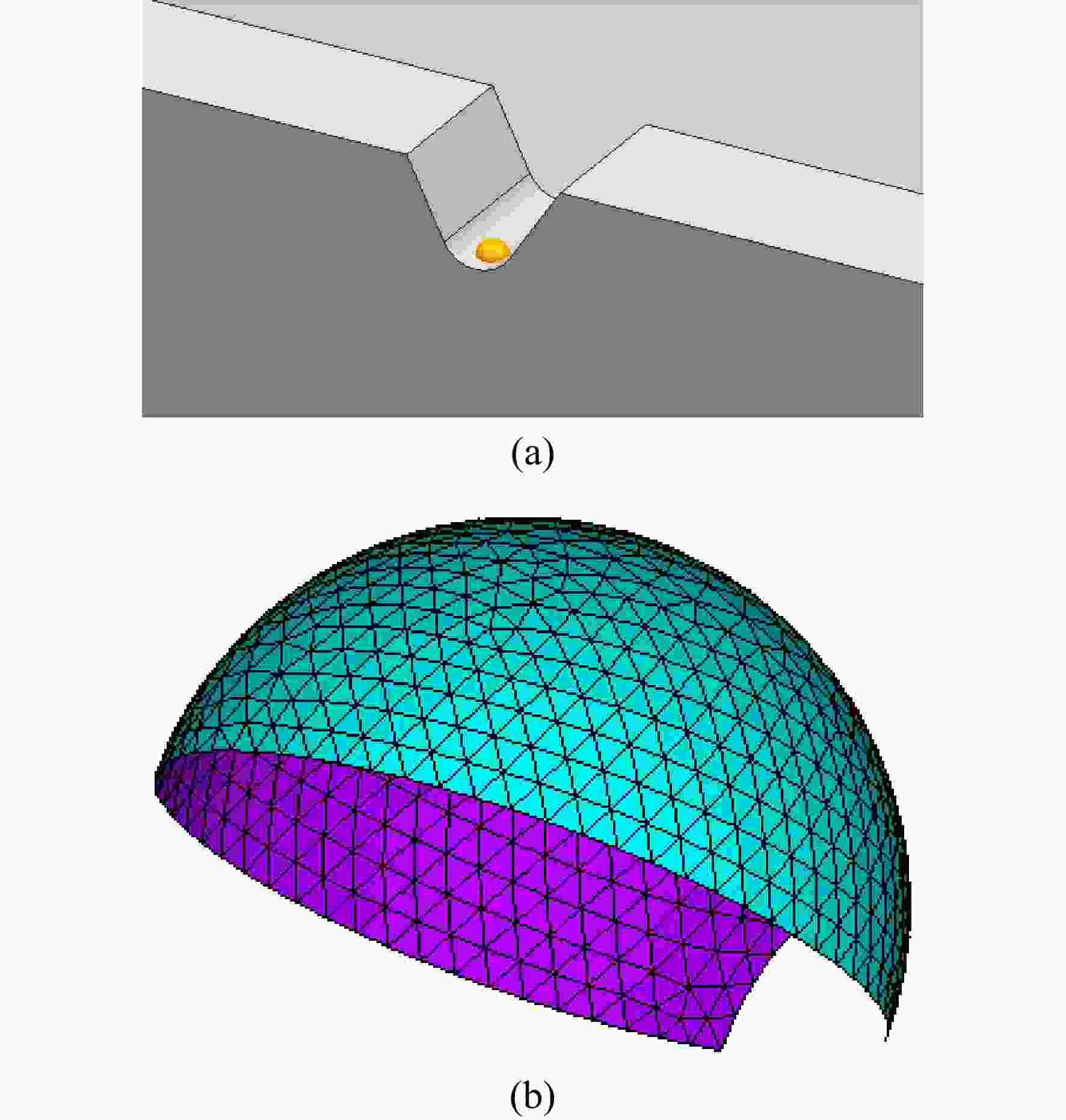

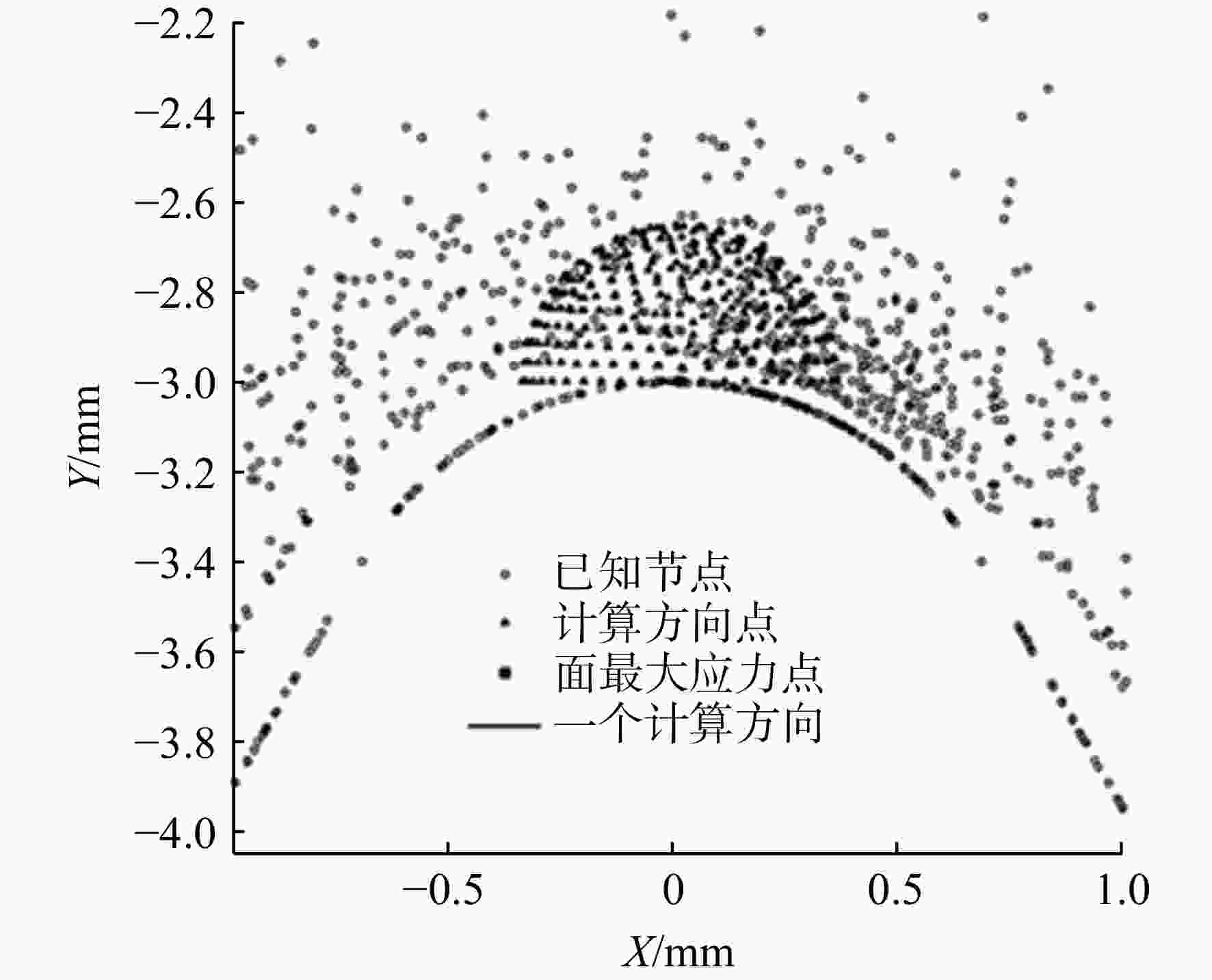

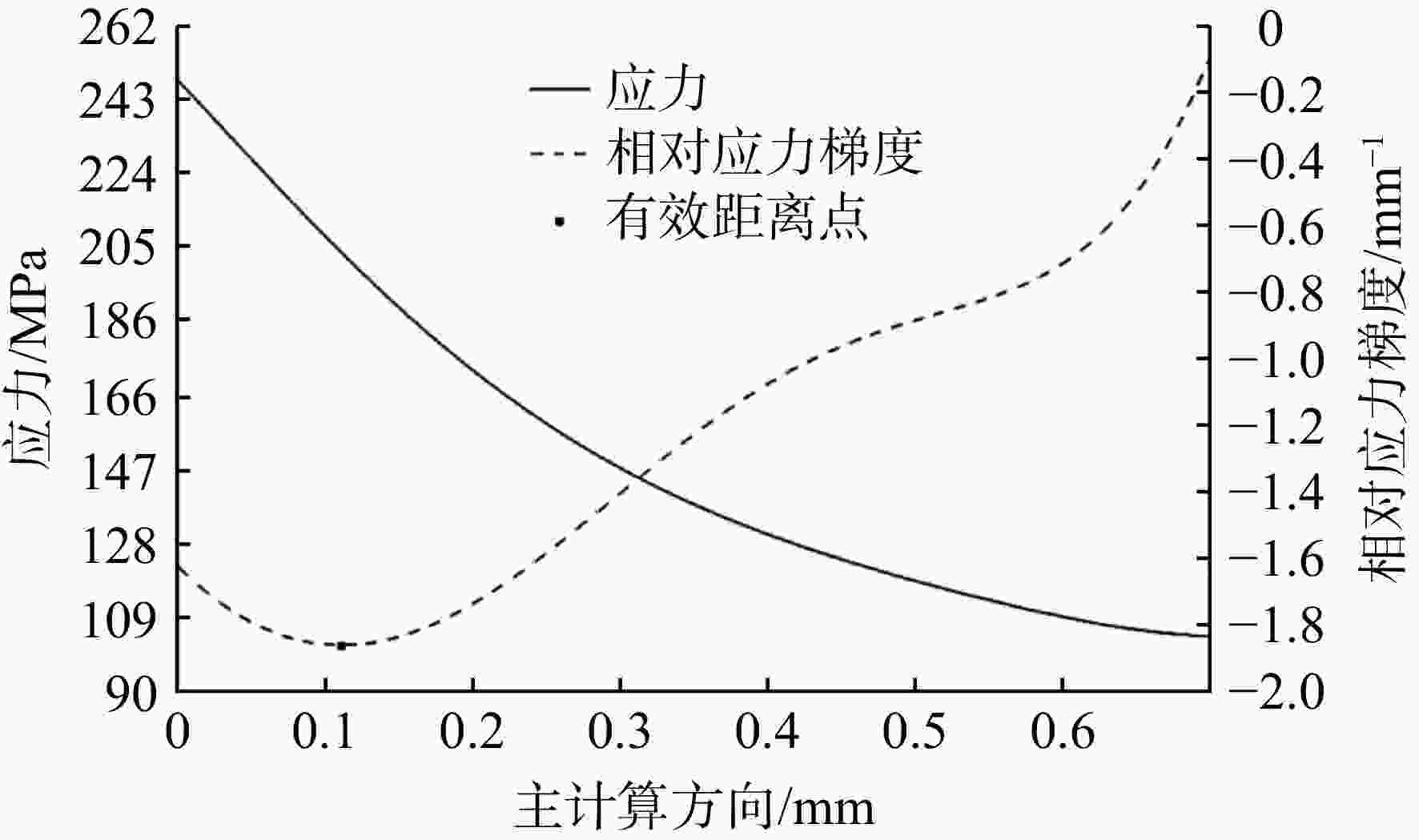

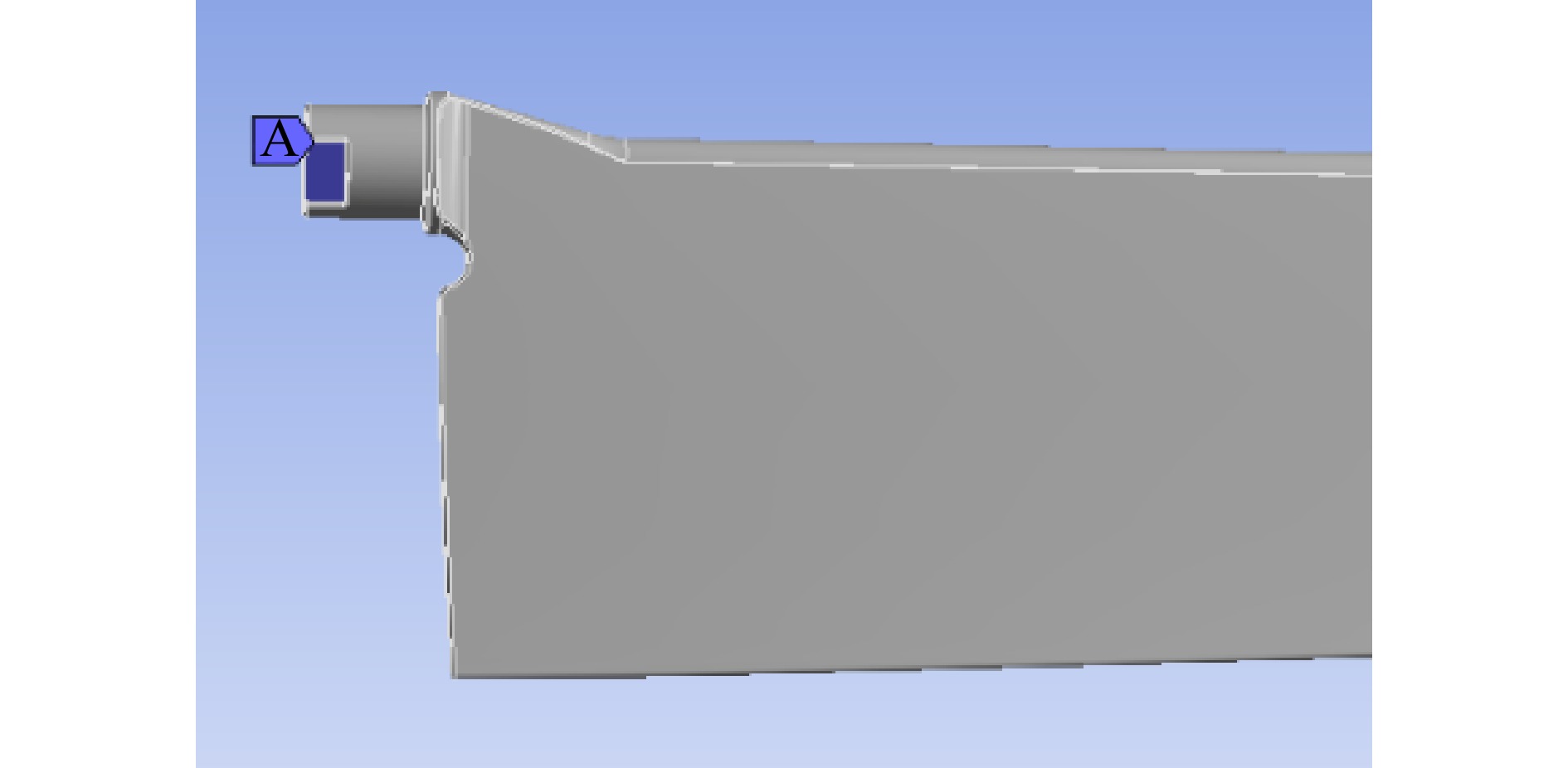

为了考虑应力梯度对SiCp/Al复合材料结构疲劳强度的影响,基于三维空间矢量应力场强法和光滑件疲劳强度,发展了一种SiCp/Al复合材料缺口疲劳强度预测方法,其中三维空间矢量应力场强法计算中分别应用了经典一维应力场强与有效距离点应力场强的等效应力积分形式,避免了构建三维权函数和人为确定疲劳损伤区域。采用升降法制定了SiCp/2009Al复合材料光滑件疲劳试验方案,获得了SiCp/2009Al复合材料107循环周次对应的轴向(

R =−1)疲劳强度为180.91 MPa,并以散点法开展疲劳试验获得了SiCp/2009Al疲劳寿命分布,光滑件疲劳试验结果显示SiCp/2009Al复合材料应力-寿命关系存在明显的平台区。采用逐级加载法开展了SiCp/2009Al复合材料缺口件轴向(R =−1)疲劳试验,获得了缺口件的疲劳强度为82.2 MPa。缺口件疲劳强度预测结果与试验结果吻合较好,最大误差在10%以内,其中基于有效距离点应力场强的三维空间矢量应力场强法建立的SiCp/Al复合材料缺口疲劳强度预测方法预测精度更高。-

关键词:

- SiCp/Al复合材料 /

- 疲劳强度 /

- 缺口疲劳 /

- 三维应力场强 /

- 高周疲劳试验

Abstract:In order to consider the influence of stress gradient on the fatigue strength of SiCp/Al composite structure, a notched fatigue strength prediction method of SiCp/Al composite was developed based on the three-dimensional space vector stress field intensity method (TSVFM) and the fatigue strength of smooth specimen. In the TSVFM, the equivalent stress integral forms of classic one-dimensional stress field intensity method and effective distance point stress field intensity method were applied respectively, which avoided the construction of three-dimensional weight function and artificial determination of fatigue damage region. The fatigue test scheme of SiCp/2009Al composite smooth specimen was determined by up-and-down method, and the axial (

R =−1) fatigue strength corresponding to 107 cycles of SiCp/2009Al composite was 180.91 MPa. The fatigue life distribution of SiCp/2009Al was obtained by the scattered point method. The fatigue test results of smooth specimen showed that there was an obvious platform area in the stress-life relationship of SiCp/2009Al composite. The axial (R =−1) fatigue test of notched specimen of SiCp/2009Al composite was carried out by step-by-step loading method, and the fatigue strength of notched specimen was 82.2 MPa. The fatigue strength prediction results of notched specimen were in good agreement with the test results, and the maximum error was within 10%. The notched fatigue strength prediction method of SiCp/Al composites based on the ETSVFM was better than the CTSVFM. -

屈服强度$ {\sigma }_{ {\rm{s} } } $/MPa 抗拉强度${\sigma }_{{\rm{b}}}$/MPa 弹性模量E/GPa 419.2 541.5 103.8 表 2 升降法试验数据

Table 2. Test results measured by up-and-down method

应力Si/MPa 试样系列号 1 2 3 4 5 6 7 8 9 10 11 12 220 × × 200 × × ○ ○ × 180 ○ ○ ○ × 160 ○ 140 注:○表示通过;×表示失效。 表 3 试验数据分析

Table 3. Test data analysis

应力/MPa 应力水平i fi ifi i2fi 220 2 2 4 8 200 1 3 3 3 180 0 1 0 0 总和 6 7 11 表 4 缺口件疲劳强度试验结果

Table 4. Fatigue strength test results of notched specimens

编号 加载级数 ${{\sigma } }_{\rm{f} }$/MPa ${{N} }_{\rm{f} }$/107 ${ {\sigma } }_{\rm{es} }$/MPa V1 2 83 0.986 80.30 V2 4 86 0.717 83.33 V3 6 80 0.352 78.06 V4 8 89 0.367 87.10 均值 82.20 表 5 缺口试件疲劳强度预测结果

Table 5. Fatigue strength prediction results of notched specimen

参数 试验值 基于经典一维的

三维空间矢量

应力场强法基于有效距离点的

三维空间矢量

应力场强法疲劳强度/MPa 82.20 86.74 82.16 误差/% 5.52 0.05 -

[1] 叶俊青, 王东, 张荣霞, 等. SiC颗粒增强铝基复合材料叶片锻件及其性能研究[C]//2019年(第四届)中国航空科学技术大会论文集. 沈阳: 中国航空学会, 2019: 510-518. [2] 吴琼,邓瑛,姚罡,等. 颗粒增强铝基复合材料结构高阶振型疲劳试验技术研究[J]. 航空制造技术,2021,64(22): 91-96.WU Qiong,DENG Ying,YAO Gang,et al. Research on high order vibration mode fatigue test technology of particle reinforced aluminum matrix composite structure[J]. Aeronautical Manufacturing Technology,2021,64(22): 91-96. (in Chinese) [3] 赵丙峰,谢里阳,赵志强,等. 基于应力场强法的缺口构件场强值算法[J]. 机械工程学报,2018,54(24): 88-97. doi: 10.3901/JME.2018.24.088ZHAO Bingfeng,XIE Liyang,ZHAO Zhiqiang,et al. Field stress intensity calculation of notched component specimens based on field intensity method[J]. Journal of Mechanical Engineering,2018,54(24): 88-97. (in Chinese) doi: 10.3901/JME.2018.24.088 [4] 奚蔚,姚卫星. 缺口件疲劳寿命分布预测的有效应力法[J]. 固体力学学报,2013,34(2): 205-212.XI Wei,YAO Weixing. Effective stress model for fatigue life distribution of notched specimen[J]. Chinese Journal of Solid Mechanics,2013,34(2): 205-212. (in Chinese) [5] 姚卫星. 金属材料疲劳行为的应力场强法描述[J]. 固体力学学报,1997,18(1): 38-48.YAO Weixing. The description for fatigue behaviours of metals by stress field intensity approach[J]. Acta Mechanica Solida Sinica,1997,18(1): 38-48. (in Chinese) [6] 郑楚鸿. 高周疲劳设计方法: 应力场强法的研究[D]. 北京: 清华大学, 1984.ZHENG Chuhong. High cycle fatigue design method: research on stress field strength method[D]. Beijing: Tsinghua University, 1984. (in Chinese) [7] YAO Weixing. Stress field intensity approach for predicting fatigue life[J]. International Journal of Fatigue,1993,15(3): 243-246. doi: 10.1016/0142-1123(93)90182-P [8] YAO Weixing,XIA Kaiquan,GU Yi. On the fatigue Notch factor, Kf[J]. International Journal of Fatigue,1995,17(4): 245-251. doi: 10.1016/0142-1123(95)93538-D [9] YAO Weixing,YE Bin,ZHENG Lichun. A verification of the assumption of anti-fatigue design[J]. International Journal of Fatigue,2001,23(3): 271-277. doi: 10.1016/S0142-1123(00)00083-9 [10] LOU Guokang,WEN Weidong,WU Fuxian,et al. Vibration fatigue probabilistic life prediction model and method for blade[J]. Transactions of Nanjing University of Aeronautics and Astronautics,2018,35(3): 494-506. [11] 刘晓丰,何欣,刘强. 遥感仪器光机系统用高体分SiCp/Al复合材料的疲劳研究[J]. 红外,2013,34(10): 20-25.LIU Xiaofeng,HE Xin,LIU Qiang. Research on fatigue of high volume fraction SiCp/Al composite material used in opto-mechanical system of remote sensing instrument[J]. Infrared,2013,34(10): 20-25. (in Chinese) [12] 于维成,袁金才,王中光. SiCp/6061Al复合材料的疲劳行为[J]. 金属学报,1990,26(6): 127-131.YU Weicheng,YUAN Jincai,WANG Zhongguang. Fatigue behaviour of SiCp/6061Al composite[J]. Acta Metallrugica Sinica,1990,26(6): 127-131. (in Chinese) [13] 左涛,樊建中,肖伯律,等. 颗粒增强铝基复合材料疲劳断裂研究[J]. 稀有金属,2007,31(4): 569-572.ZUO Tao,FAN Jianzhong,XIAO Bolü,et al. Fatigue fracture of particle reinforced aluminum matrix composites[J]. Chinese Journal of Rare Metals,2007,31(4): 569-572. (in Chinese) [14] UEMATSU Y,TOKAJI K,KAWAMURA M. Fatigue behaviour of SiC-particulate-reinforced aluminium alloy composites with different particle sizes at elevated temperatures[J]. Composites Science and Technology,2008,68(13): 2785-2791. doi: 10.1016/j.compscitech.2008.06.005 [15] LORCA J. High temperature fatigue of discontinuously-reinforced metal-matrix composites[J]. International Journal of Fatigue,2002,24(2/3/4): 233-240. [16] TOKAJI,SHIOTA,KOBAYASHI. Effect of particle size on fatigue behaviour in SiC particulate-reinforced aluminium alloy composites[J]. Fatigue & Fracture of Engineering Materials & Structures,1999,22(4): 281-288. [17] 蒋鹏琛,徐颖. 基于黏塑性本构理论的SiCp/2009Al循环本构模型研究[J]. 机械制造与自动化,2021,50(3): 95-98, 117.JIANG Pengchen,XU Ying. Research on SiCp/2009Al cycle constitutive model based on viscoplastic theory[J]. Machine Building & Automation,2021,50(3): 95-98, 117. (in Chinese) [18] 邹利华,樊建中,左涛,等. 粉末冶金15%SiCp/2009Al复合材料的高周疲劳性能[J]. 中国有色金属学报,2010,20(10): 1955-1961.ZOU Lihua,FAN Jianzhong,ZUO Tao,et al. High-cycle fatigue behavior of 15%SiCp/2009Al composite prepared by powder metallurgy process[J]. The Chinese Journal of Nonferrous Metals,2010,20(10): 1955-1961. (in Chinese) [19] QYLAFKU G,AZARI Z,KADI N,et al. Application of a new model proposal for fatigue life prediction on notches and key-seats[J]. International Journal of Fatigue,1999,21(8): 753-760. doi: 10.1016/S0142-1123(99)00046-8 [20] ADIB-RAMEZANI H,JEONG J. Advanced volumetric method for fatigue life prediction using stress gradient effects at Notch roots[J]. Computational Materials Science,2007,39(3): 649-663. doi: 10.1016/j.commatsci.2006.08.017 [21] KAYMAZ I. Application of kriging method to structural reliability problems[J]. Structural Safety,2005,27(2): 133-151. doi: 10.1016/j.strusafe.2004.09.001 -

下载:

下载: