Multi-disciplinary optimization method for high-altitude propellers considering aero-structure

-

摘要:

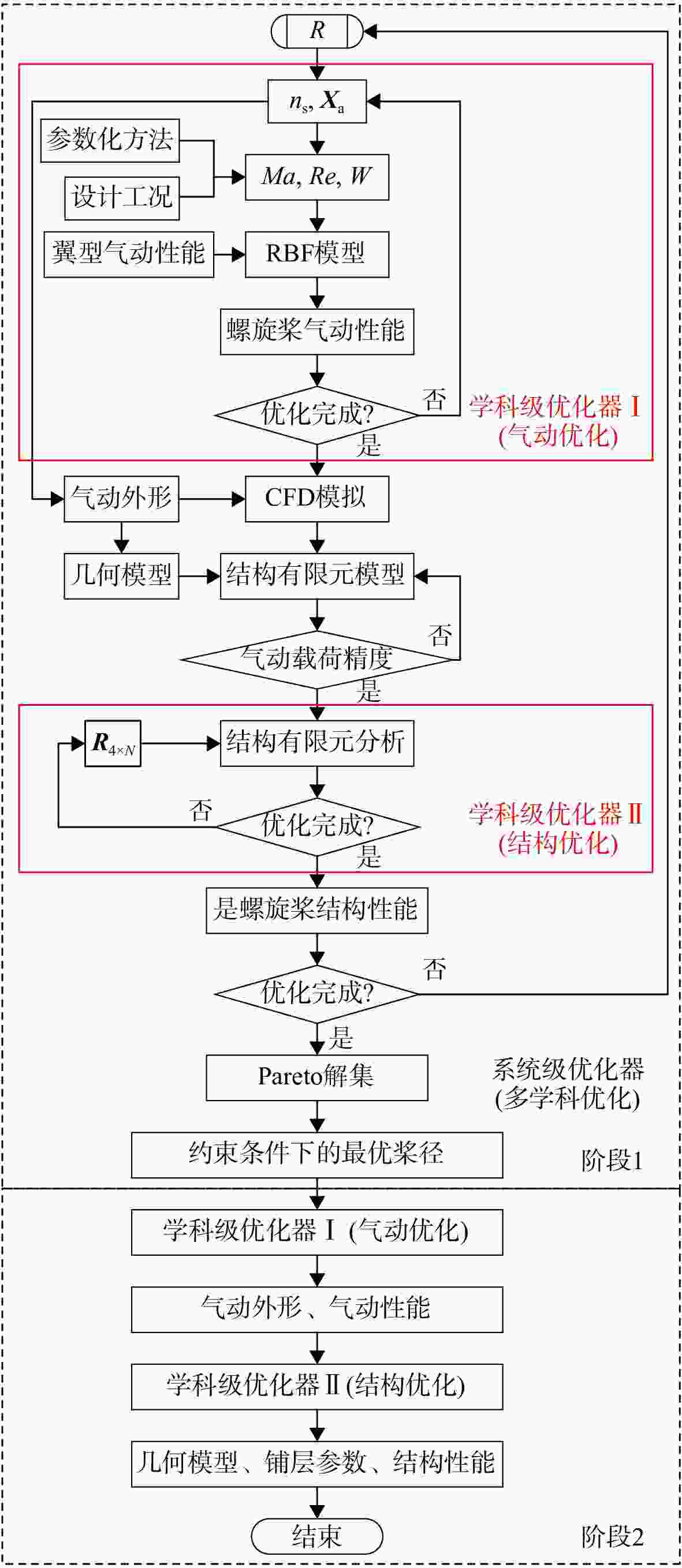

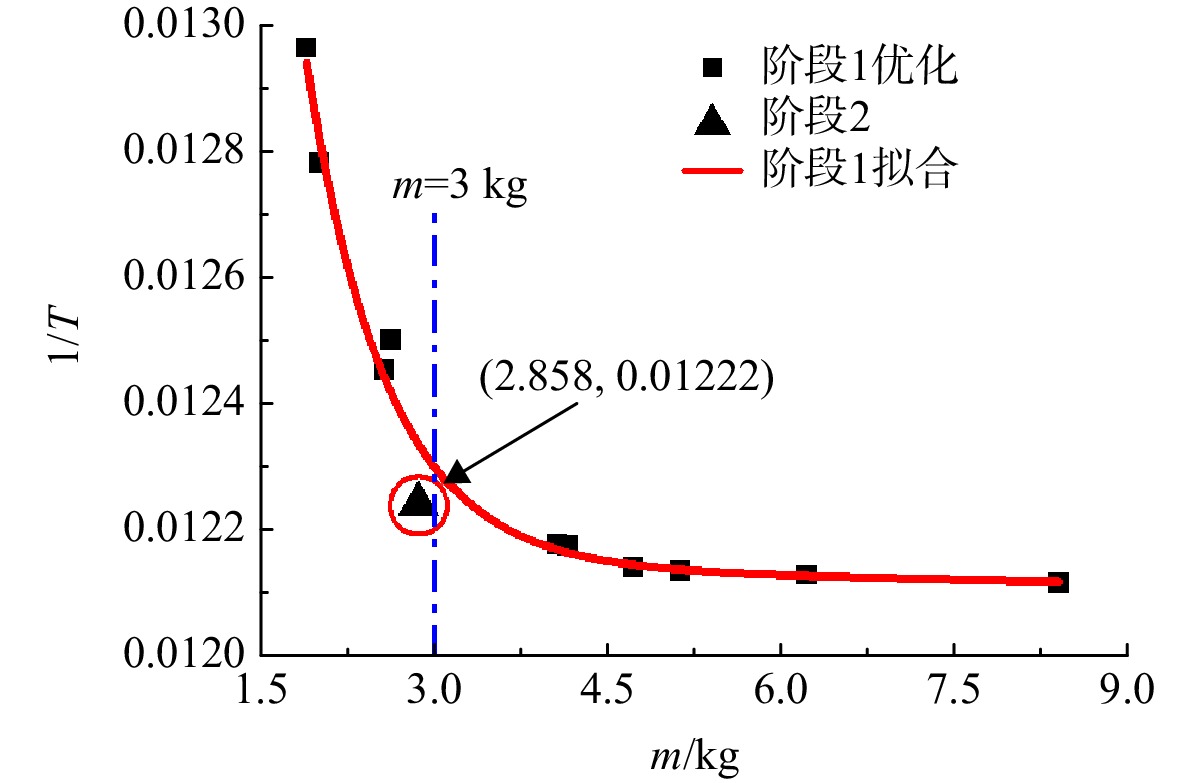

为实现高空螺旋桨高效率和轻质量之间的权衡设计,提出一种考虑螺旋桨气动-结构性能的多学科多目标优化设计方法,理论上可得到约束条件下推力最大和质量最小的Pareto解集。但工程应用中,变量太多,可接受时间内仅能获得Pareto解集拟合趋势。为避免优化周期太长,提出以下阶段性优化方法。阶段1:根据上述Pareto解集拟合趋势和平台约束,确定最优桨径;阶段2:进行基于最优桨径的气动优化获得气动外形,结构优化获得结构方案。使用该方法对高空太阳能无人机螺旋桨优化,两个阶段耗时分别为96 h和4 h。对获得螺旋桨制造,仿真和试验,对比结果表明:推力最大误差为10.9%,质量误差为6.9%,刚度误差为15.2%,固有频率误差为15.4%,试验结果也表明该方法的合理有效性。

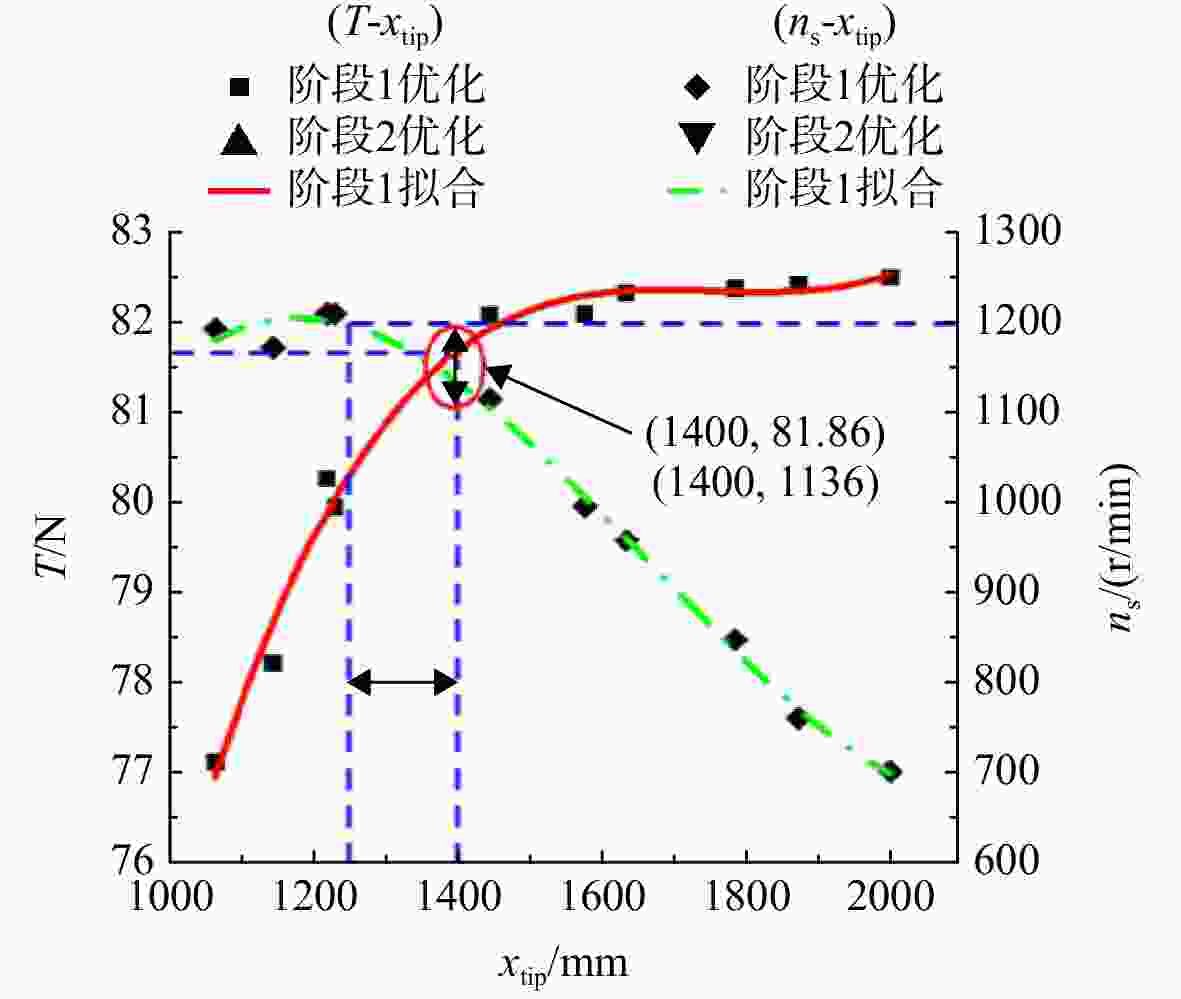

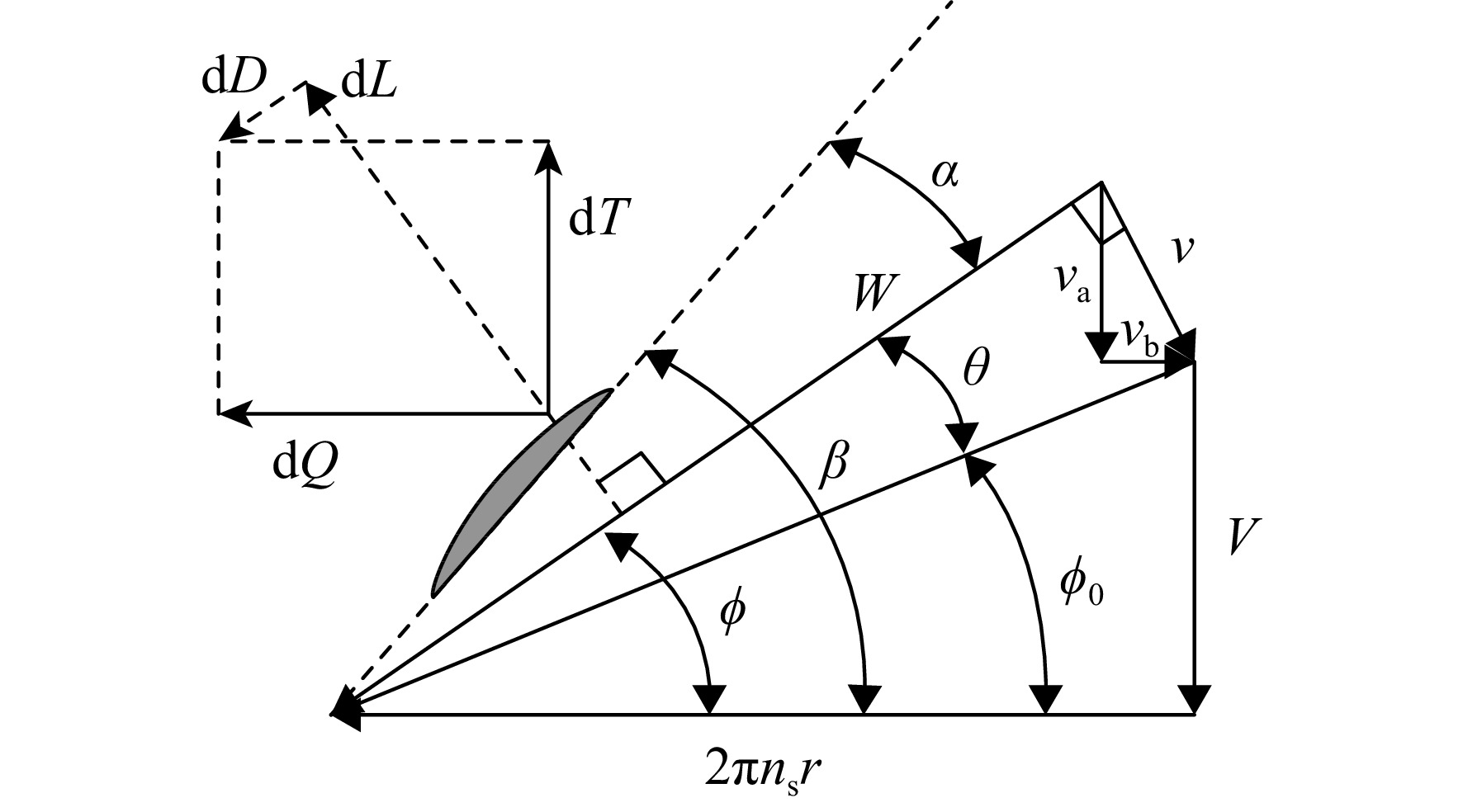

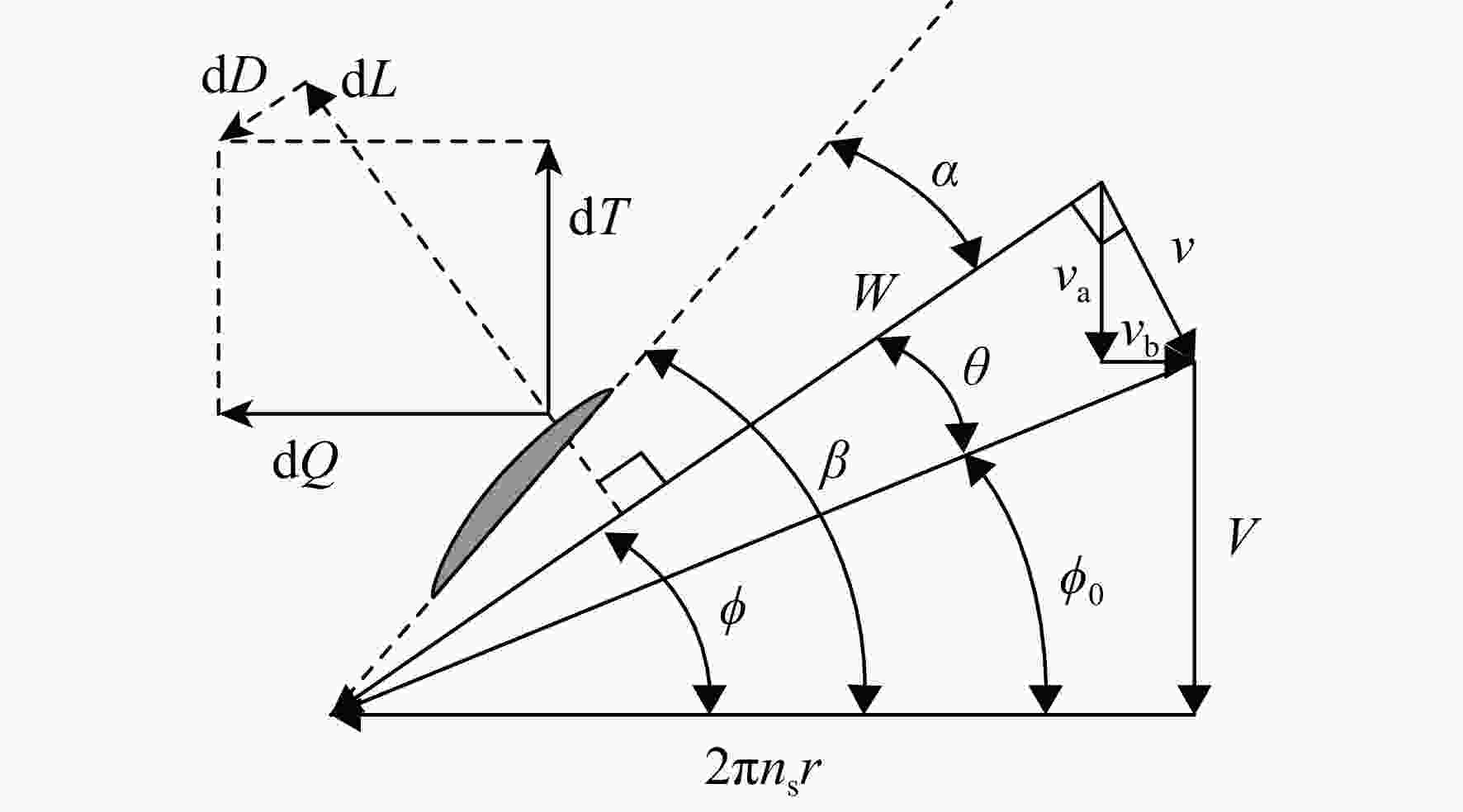

Abstract:To accomplish the trade-off design of high-altitude propellers with high efficiency and light mass, a multi-disciplinary and multi-objective optimization design method was proposed by considering both aero-structure of the propeller. Theoretically, Pareto solution set with the objective of maximum thrust and minimum mass can be obtained. However, in practical engineering applications, due to large amount of optimization variables, only the fitting trend of the Pareto solution set was obtained in acceptable time. To avoid overlong optimization period, the staged optimization approach was proposed. Stage 1: the optimal propeller diameter was decided by the Pareto solution set fitting trend and constraints; Stage 2: the aerodynamic shape was obtained by aerodynamic optimization based on the optimal propeller diameter; the structural scheme was obtained through structural optimization. This approach was used to optimize the propeller for a solar-powered unmanned aerial vehicle, the two stages took 96 h and 4 h, respectively, the propeller was manufactured, simulated and tested. The comparison results showed that the maximum thrust error was 10.9%, the mass error was 6.9%, the stiffness error was 15.2%, and the natural frequency error was 15.4%; so the test results also demonstrated its rationality and validity.

-

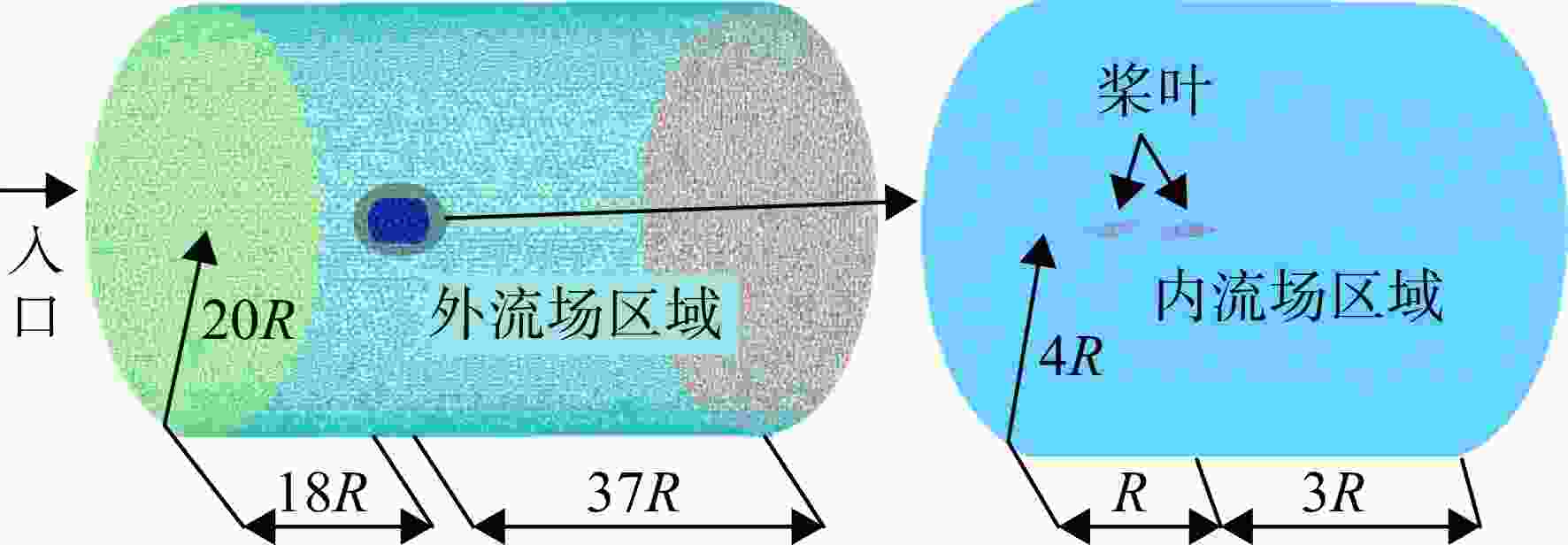

表 1 CFD计算参数设置

Table 1. CFD simulation parameters

项目 参数设置 分析类型 稳态 运动域 外流场:固定

内流场:旋转热量交换 总能量 湍流模型 SST (shear stress transport) 网格连接 GGI (general graphics interface) 表 2 设计工况

Table 2. Design condition

名称 参数 海拔高度/km 22 大气压力/Pa 4047.5 空气密度/m3 0.0645098 风速/(m/s) 47.3 声速/(m/s) 296.377 动力黏度/10−5 (N·s/m2) 1.43217 环境温度/℃ −70~80 表 3 材料属性

Table 3. Material properties

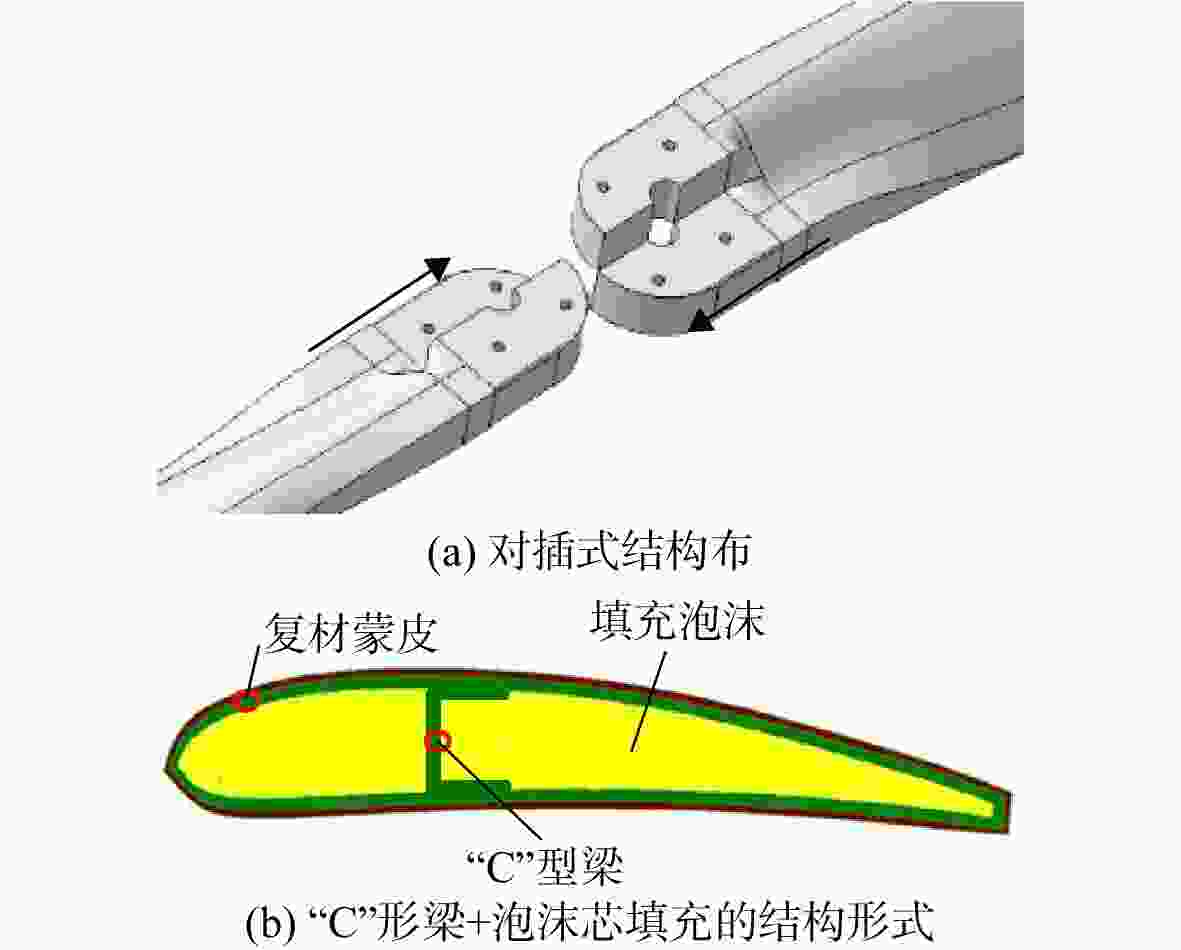

参数 UD Woven PMI 纵向弹性模量E1/GPa 120 70 0.05 横向弹性模量E2/GPa 7.3 70 0.05 切变模量G12/GPa 4.7 4.1 0.019 泊松比μ 0.32 0.062 0.25 密度ρ/(kg/m3) 1580 1650 45 单层厚度t/mm 0.125 0.20 表 4 螺旋桨优化结果

Table 4. Optimization results of the propeller

参数 数值 半径/mm 1400 推力/N 81.86 转速/(r/min) 1136 功率/kW 5 效率/% 77.43 质量/kg 2.858 最大位移/mm 6.92 复合材料应变 917.1 1阶固有频率/Hz 31.62 表 5 测试结果对比

Table 5. Comparison of the test results

参数 优化数据 仿真数据 测试数据 质量/kg 2.858 2.858 2.66 位移/mm 6.92 7.545 6.4 1阶固有频率/Hz 31.62 27.95 23.66 -

[1] ZHANG Sen,LI Huaxing,ABBASI A A. Design methodology using characteristic parameters control for low Reynolds number airfoils[J]. Aerospace Science and Technology,2019,86: 143-152. doi: 10.1016/j.ast.2019.01.003 [2] MORGADO J,ABDOLLAHZADEH M,SILVESTRE M A R,et al. High altitude propeller design and analysis[J]. Aerospace Science and Technology,2015,45: 398-407. doi: 10.1016/j.ast.2015.06.011 [3] MOUROUSIAS N, MALIM A, MARINUS B G, et al. Surrogate-based optimization of a high-altitude propeller[R]. AIAA 2021-2597, 2021. [4] GARCÍA-GUTIÉRREZ A,GONZALO J,DOMÍNGUEZ D,et al. Aerodynamic optimization of propellers for high altitude pseudo-satellites[J]. Aerospace Science and Technology,2020,96: 105562. doi: 10.1016/j.ast.2019.105562 [5] ADRIAN G G,JESUS G,DEIBI L,et al. Stochastic design of high-altitude propellers[J]. Aerospace Science and Technology,2020,107: 106283.1-106283.9. [6] MA Rong,ZHONG Bowen,LIU Peiqing. Optimization design study of low-Reynolds-number high-lift airfoils for the high-efficiency propeller of low-dynamic vehicles in stratosphere[J]. Science China Technological Sciences,2010,53(10): 2792-2807. doi: 10.1007/s11431-010-4087-0 [7] JIAO Jun,SONG Bifeng,ZHANG Yugang,et al. Optimal design and experiment of propellers for high altitude airship[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering,2018,232(10): 1887-1902. doi: 10.1177/0954410017704217 [8] DUAN Dengyan,WANG Zhigang,WANG Qiannan,et al. Research on integrated optimization design method of high-efficiency motor propeller system for UAVs with multi-states[J]. IEEE Access,2020,8: 165432-165443. doi: 10.1109/ACCESS.2020.3014411 [9] LIU Xinqiang,HE Weiliang,WEI Fengmei. Design of high altitude propeller using multilevel optimization[J]. International Journal of Computational Methods,2020,17(4): 1950004.1-1950004.32. [10] PARK D,LEE Y,CHO T,et al. Design and performance evaluation of propeller for solar-powered high-altitude long-endurance unmanned aerial vehicle[J]. International Journal of Aerospace Engineering,2018,2018: 1-23. [11] 程俊杰,王海峰,尚玲玲,等. 一种高空飞艇螺旋桨结构多目标优化设计方法[J]. 航空动力学报,2021,36(3): 584-591. doi: 10.13224/j.cnki.jasp.2021.03.014CHENG Junjie,WANG Haifeng,SHANG Lingling,et al. Multi-objective optimization design method for propeller structure of a high-altitude airship[J]. Journal of Aerospace Power,2021,36(3): 584-591. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.03.014 [12] 尚玲玲,王海峰,口启慧,等. 平流层飞艇三叶螺旋桨结构优化方法[J]. 航空动力学报,2022,37(8): 1714-1723. doi: 10.13224/j.cnki.jasp.20210334SHANG Lingling,WANG Haifeng,KOU Qihui,et al. Structure optimization method of three-blade propeller for stratospheric airship[J]. Journal of Aerospace Power,2022,37(8): 1714-1723. (in Chinese) doi: 10.13224/j.cnki.jasp.20210334 [13] MENG Junhui,HU Jie,XIAO Houdi,et al. Hierarchical optimization of the composite blade of a stratospheric airship propeller based on genetic algorithm[J]. Structural and Multidisciplinary Optimization,2017,56(6): 1341-1352. doi: 10.1007/s00158-017-1725-1 [14] GOLDSTEIN S. On the vortex theory of screw propellers[J]. Proceedings of the Royal Society of London Series A, Containing Papers of a Mathematical and Physical Character,1929,123(792): 440-465. doi: 10.1098/rspa.1929.0078 [15] REISSNER H. On the vortex theory of the screw propeller[J]. Journal of the Aeronautical Sciences,1937,5(1): 1-7. doi: 10.2514/8.496 [16] ARIF M,ASIF M,AHEMD I. Advanced composite material for aerospace application-a review[J]. International Journal of Engineering and Manufacturing Science,2017,7(2): 393-409. [17] SHUE B, MOREIRA A, FLOWERS G. Review of recent developments in composite material for aerospace applications[C]// Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference: Vol 1 Part B. San Diego, California, USA: ASME, 2010: 811-819. [18] AN Weigang,CHEN Dianyu,JIN Peng. A single-level composite structure optimization method based on a blending tapered model[J]. Chinese Journal of Aeronautics,2013,26(4): 943-947. doi: 10.1016/j.cja.2013.04.016 [19] TIAN Song,WANG Haifeng,SHANG Lingling,et al. Structural optimization and influence factors on reliability for composite wind turbine blade[J]. Journal of Failure Analysis and Prevention,2021,21(6): 2305-2319. doi: 10.1007/s11668-021-01292-7 -

下载:

下载: