Performance and aviation application of direct ammonia fuel SOFC-GT hybrid system

-

摘要:

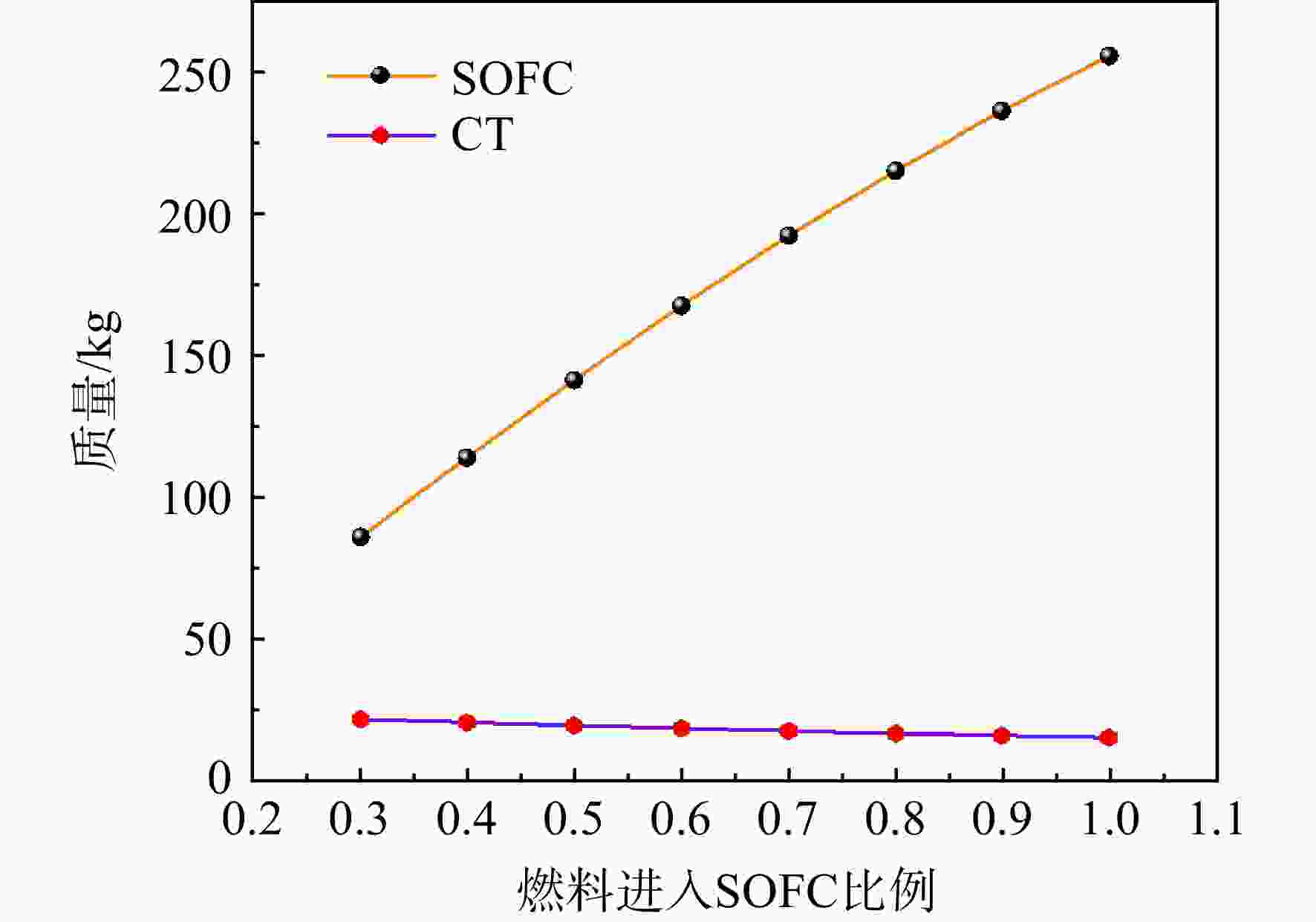

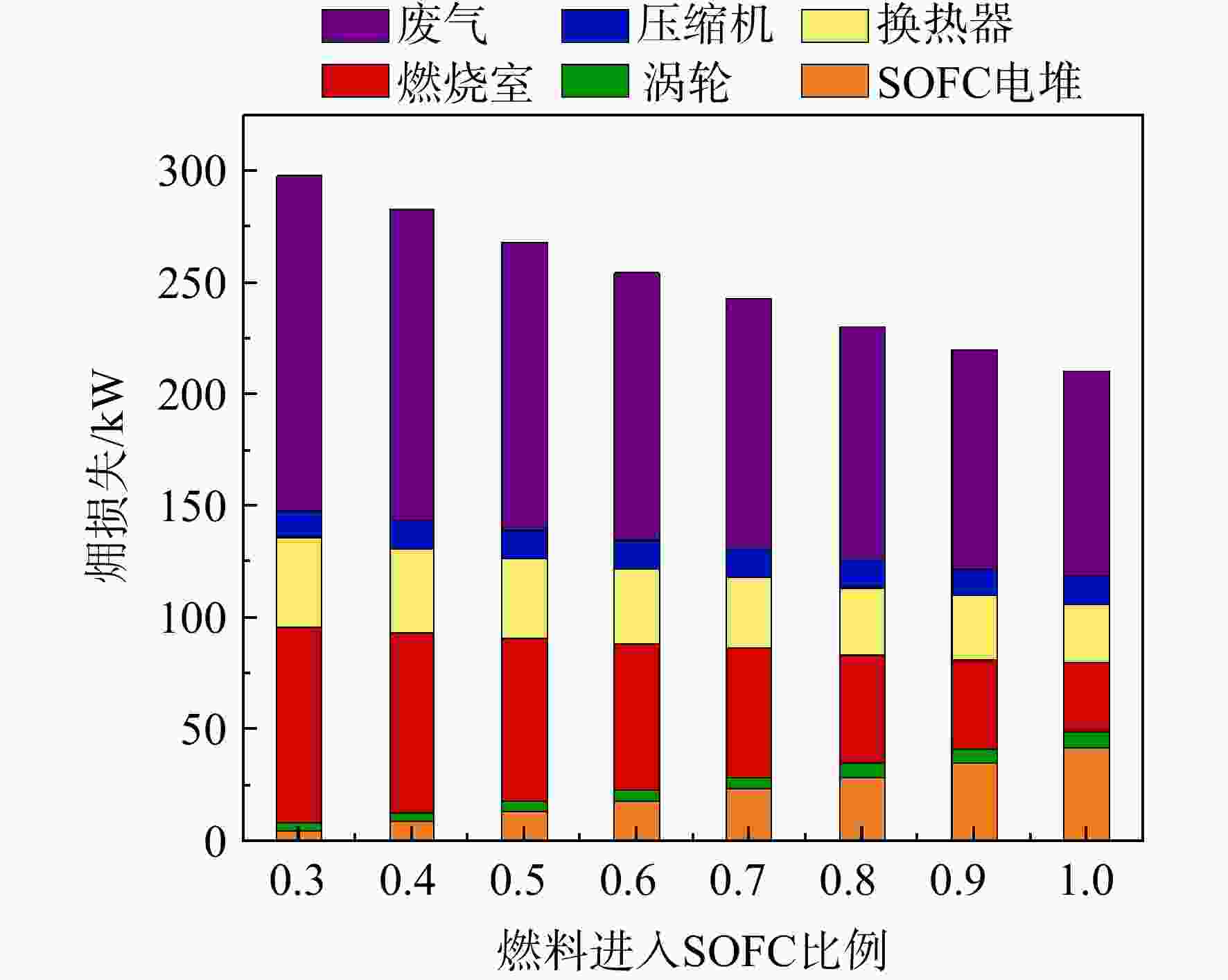

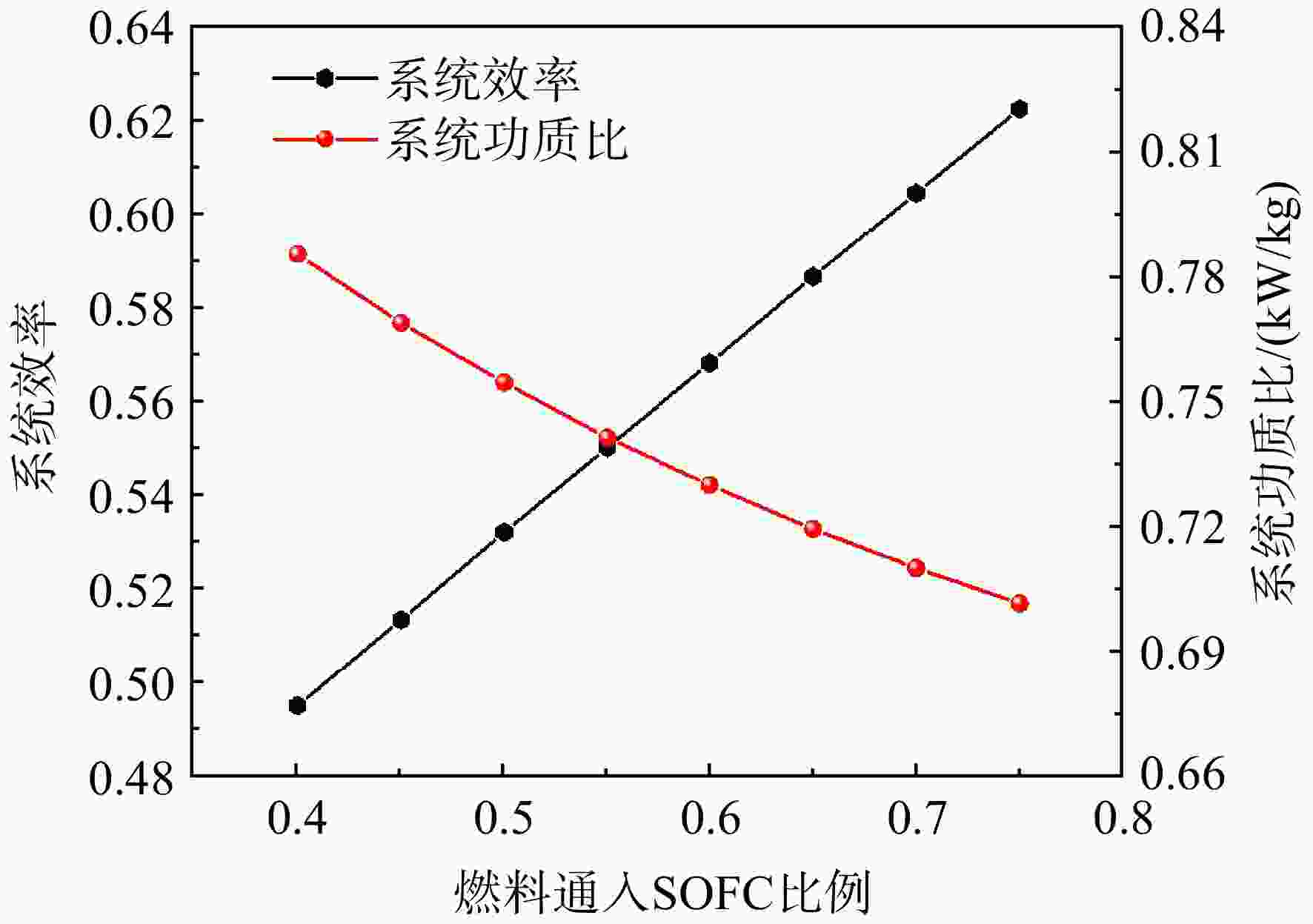

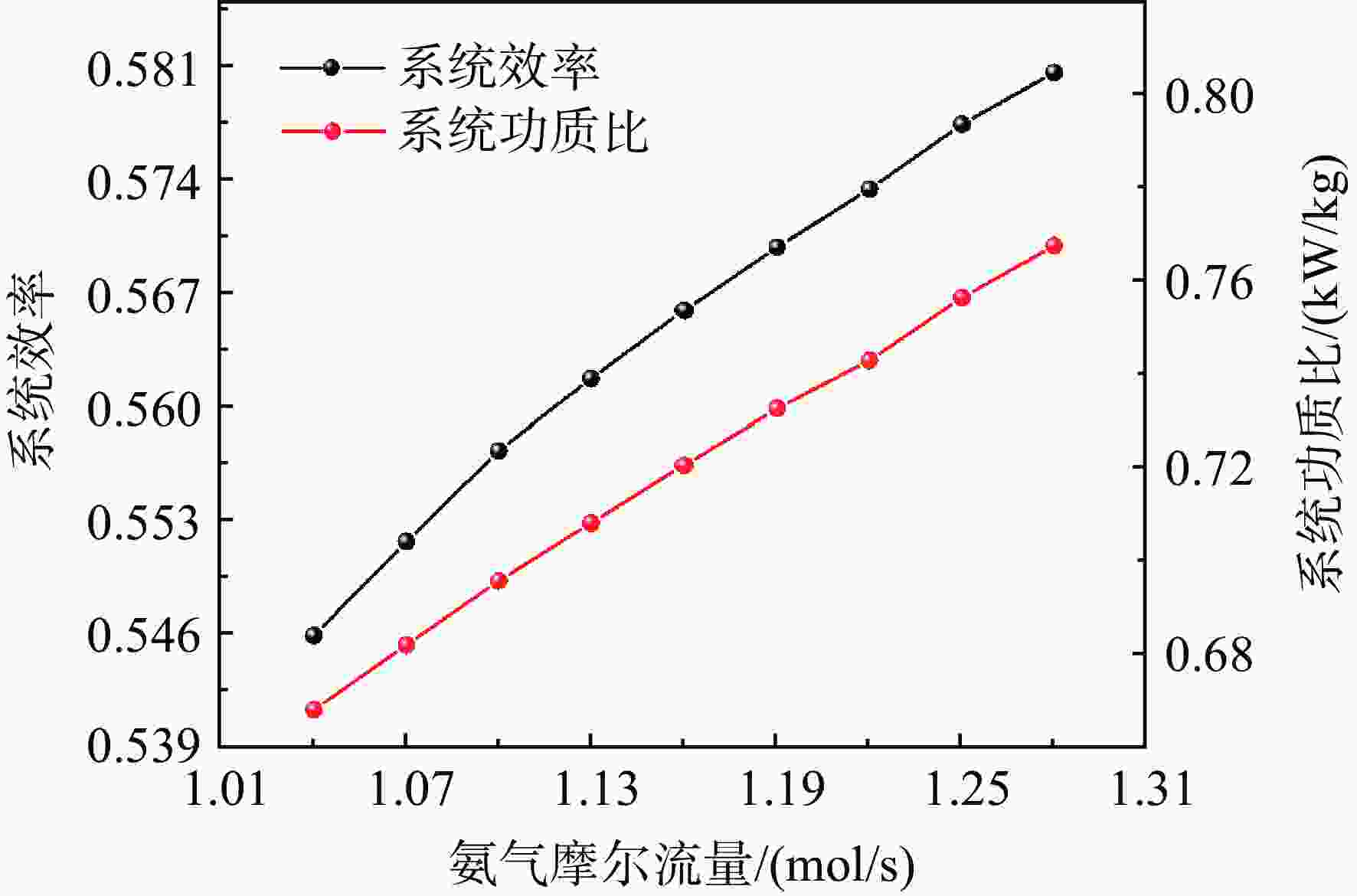

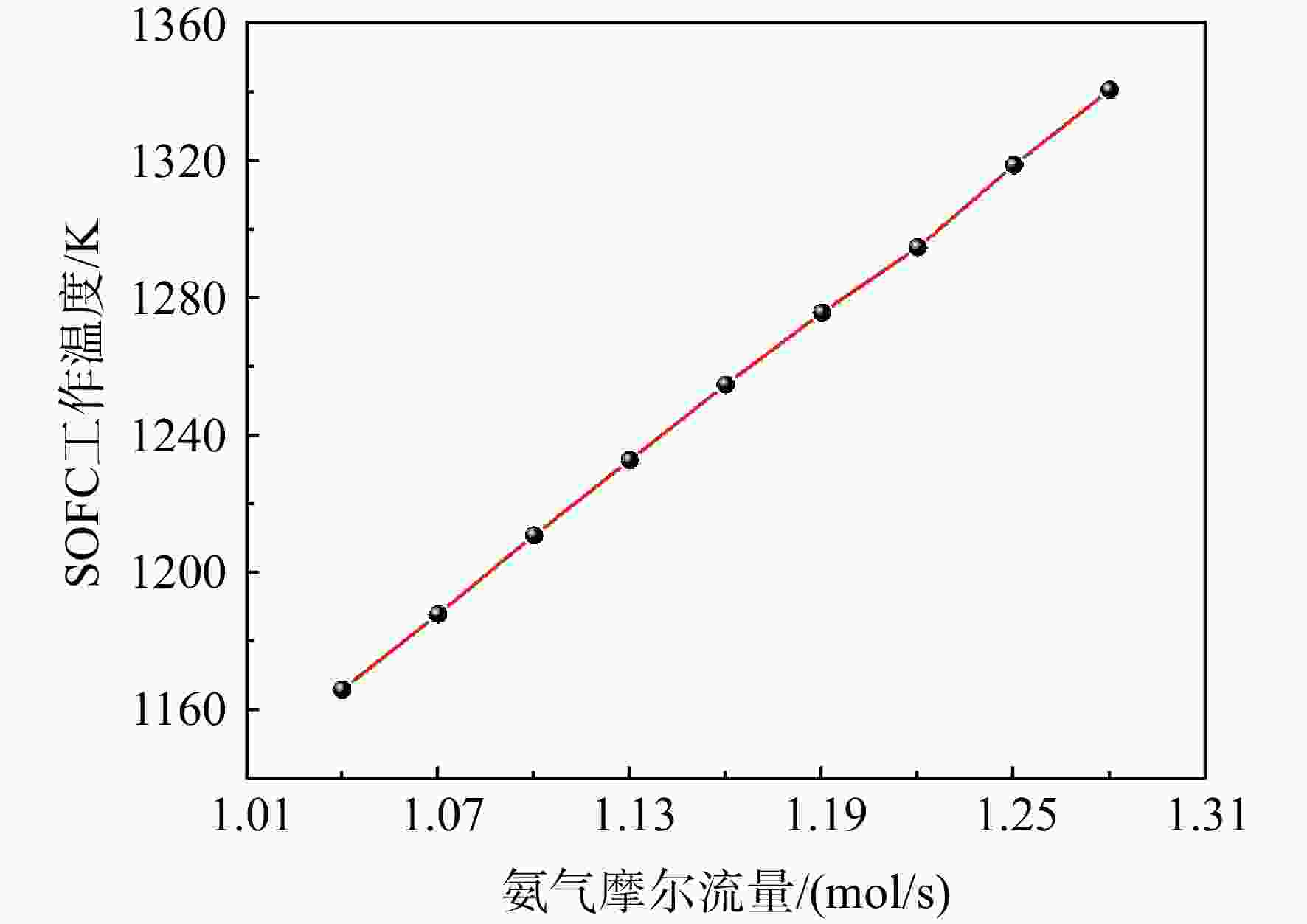

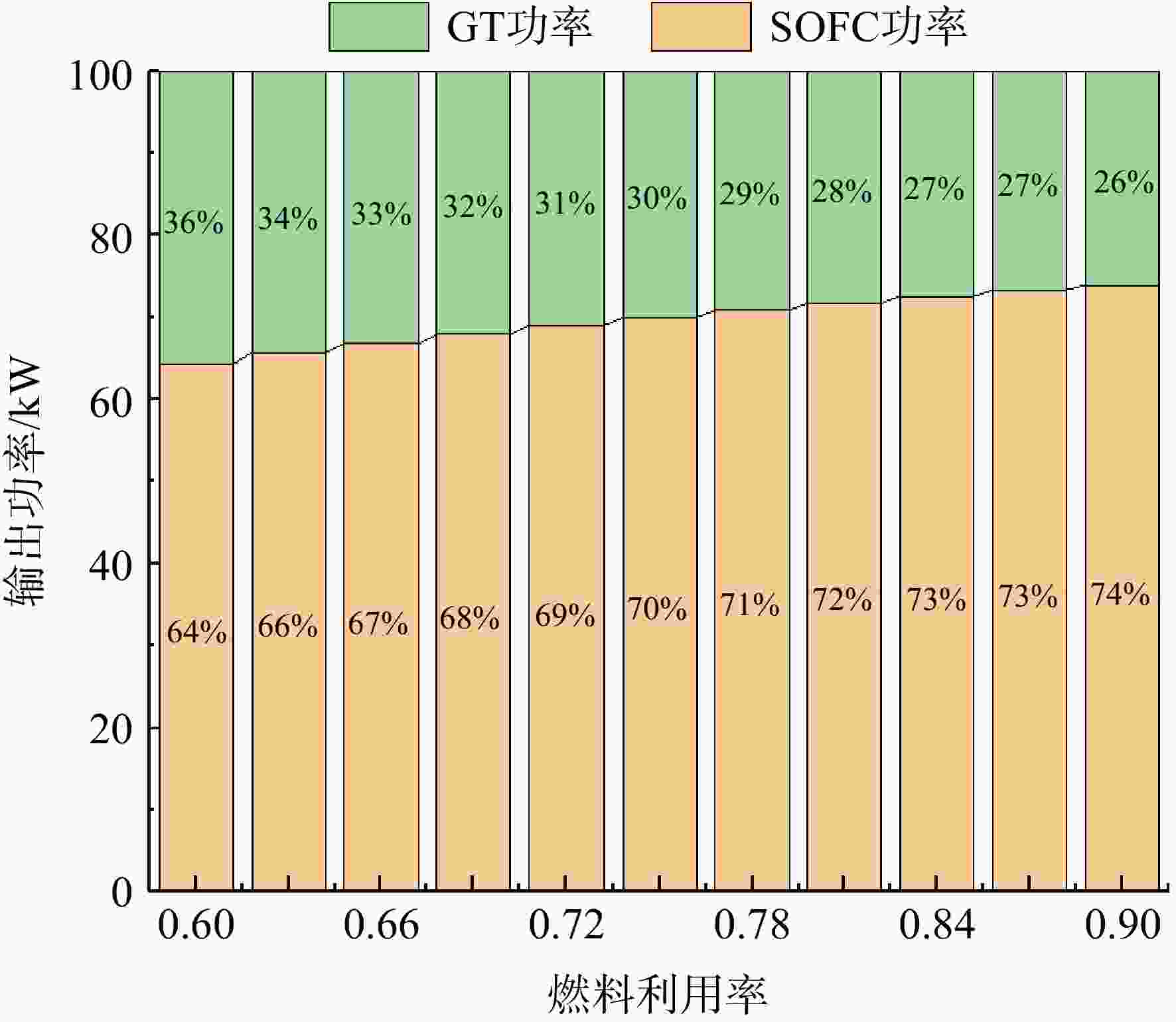

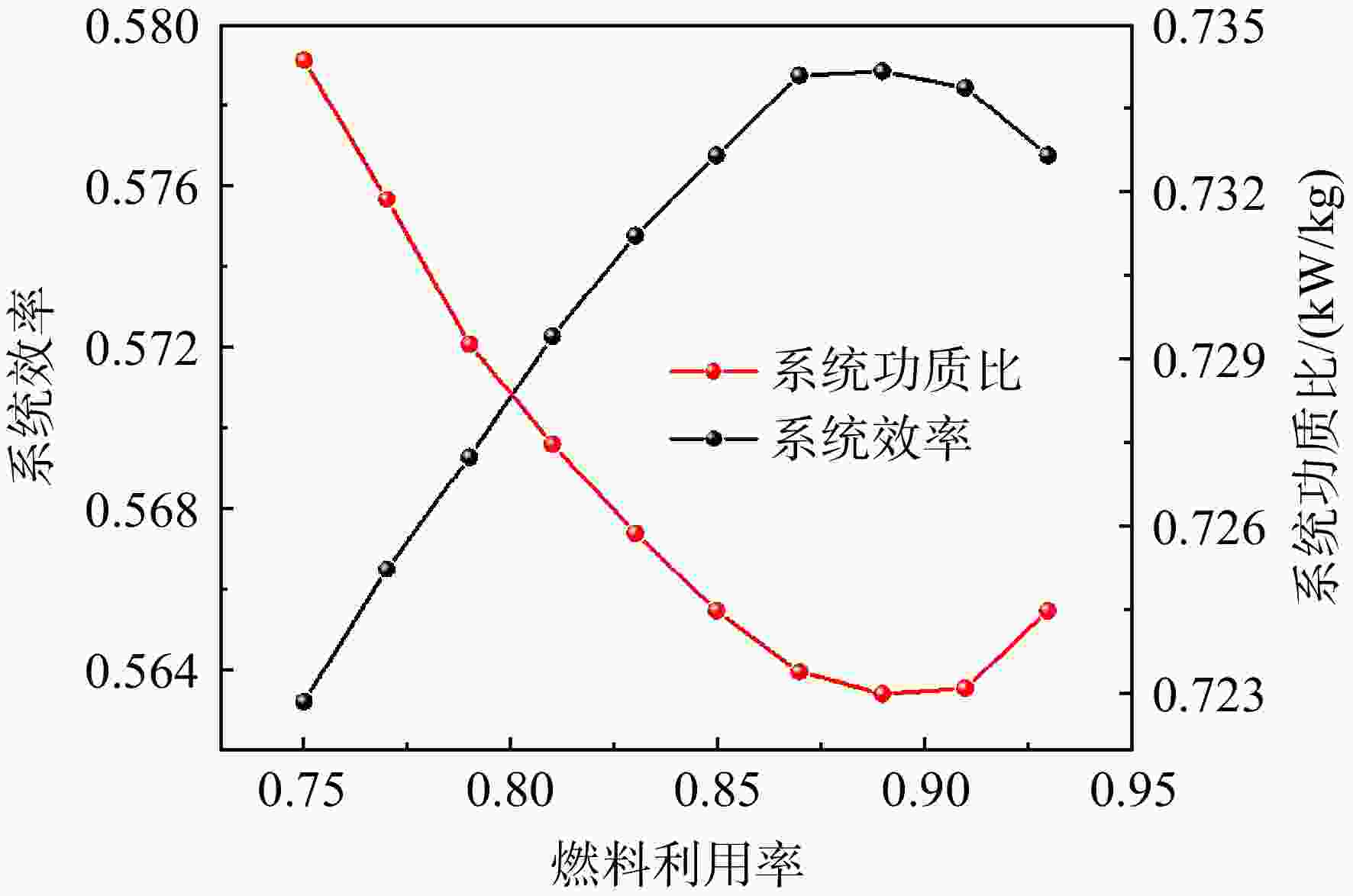

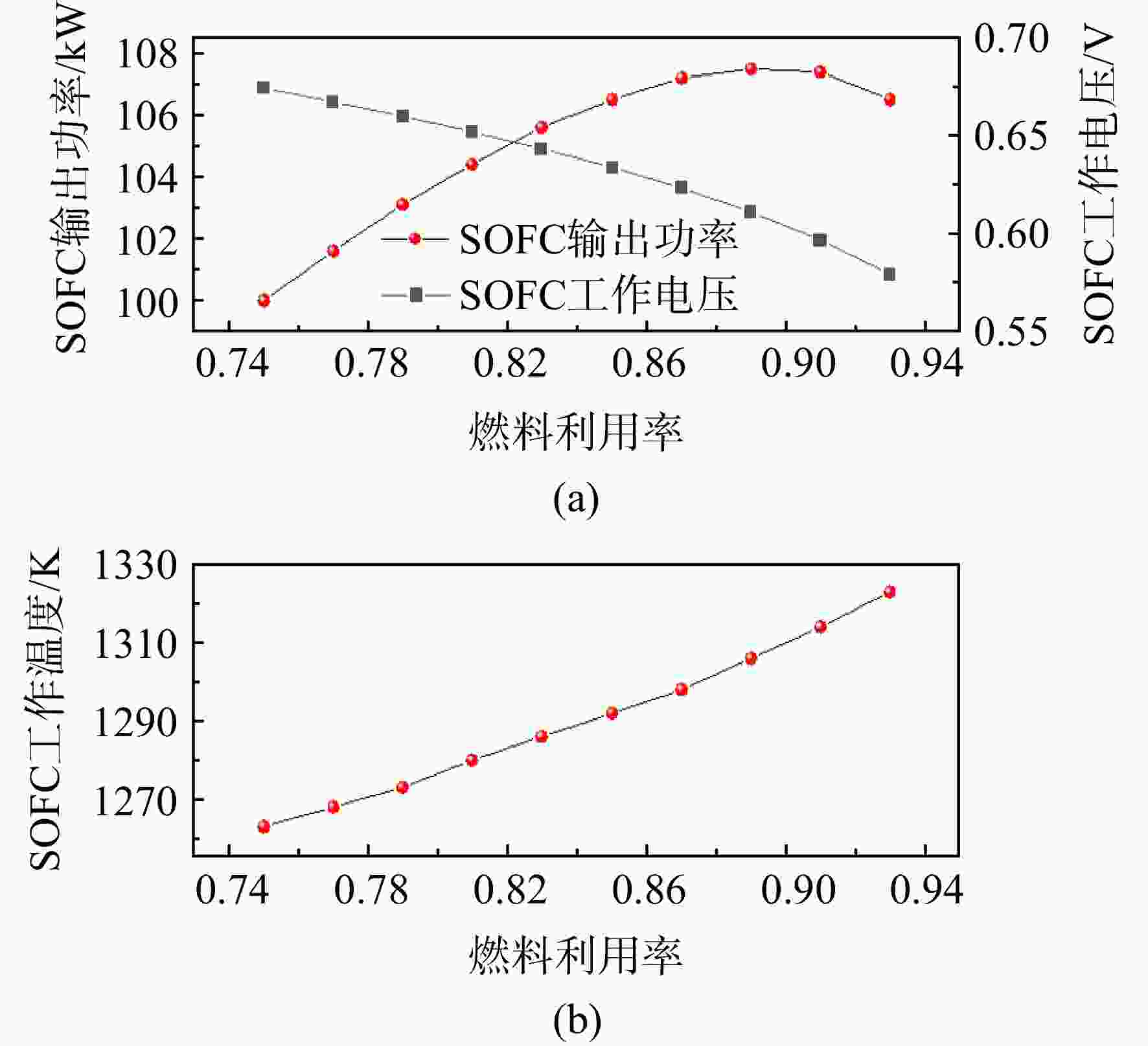

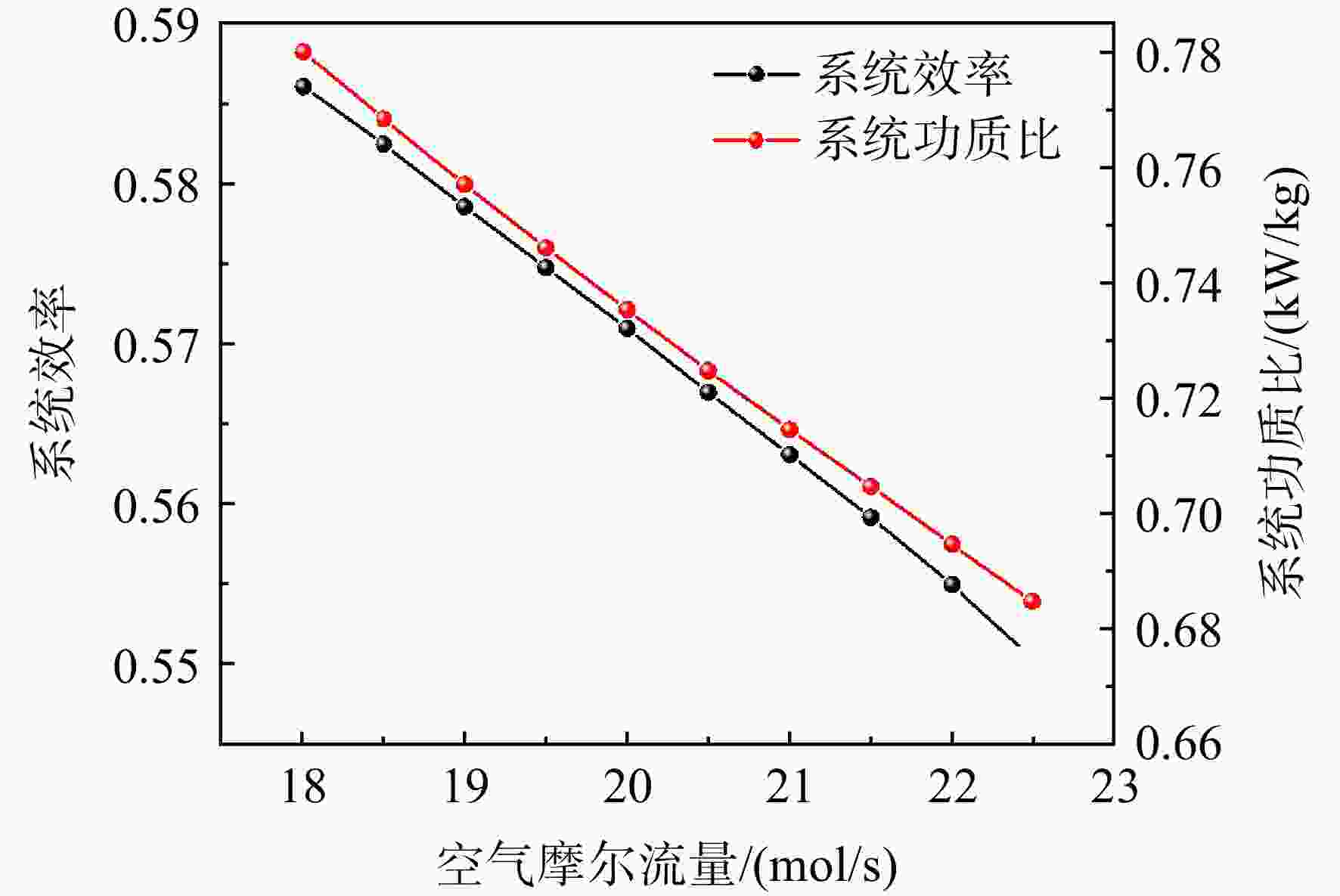

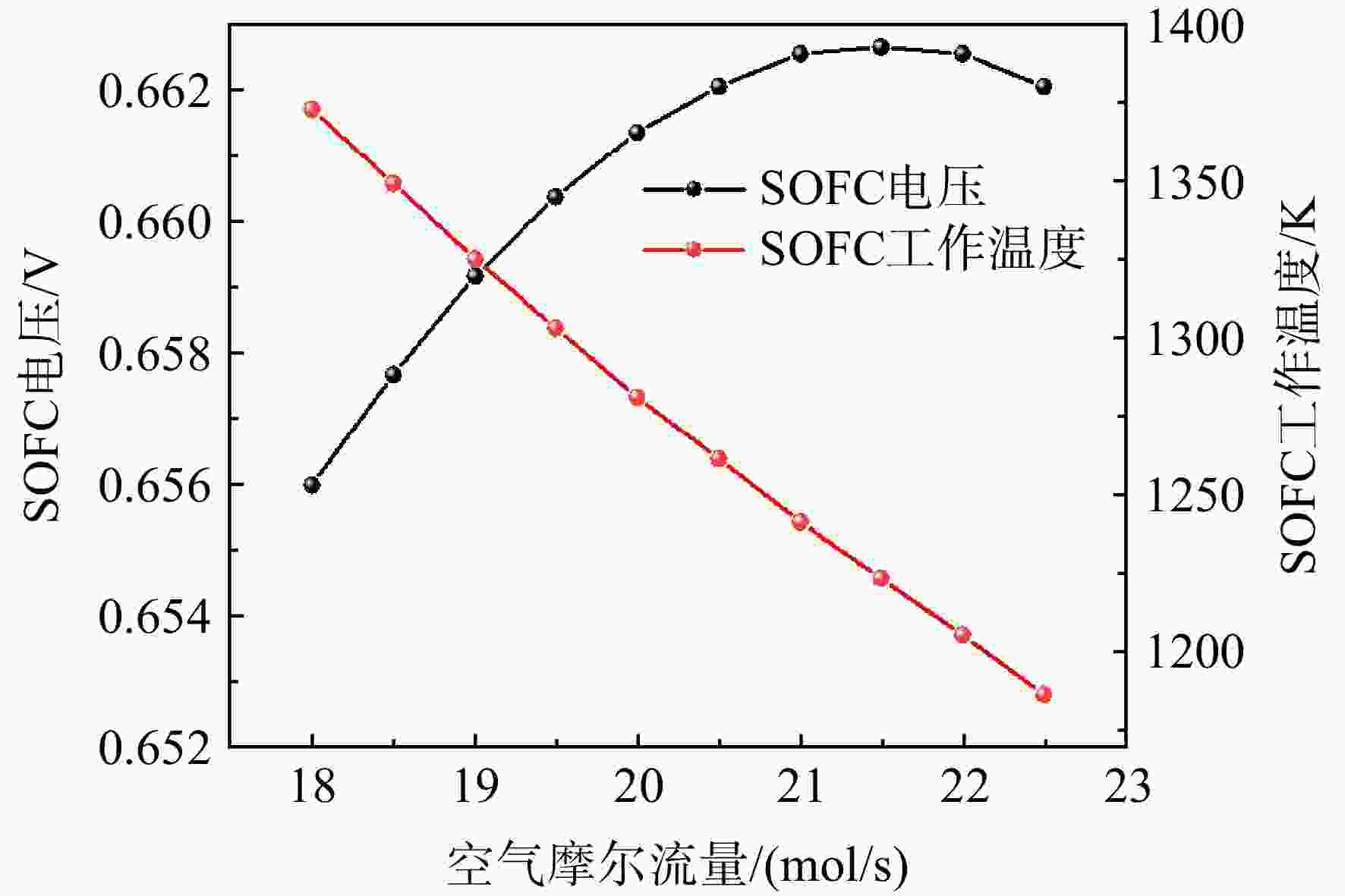

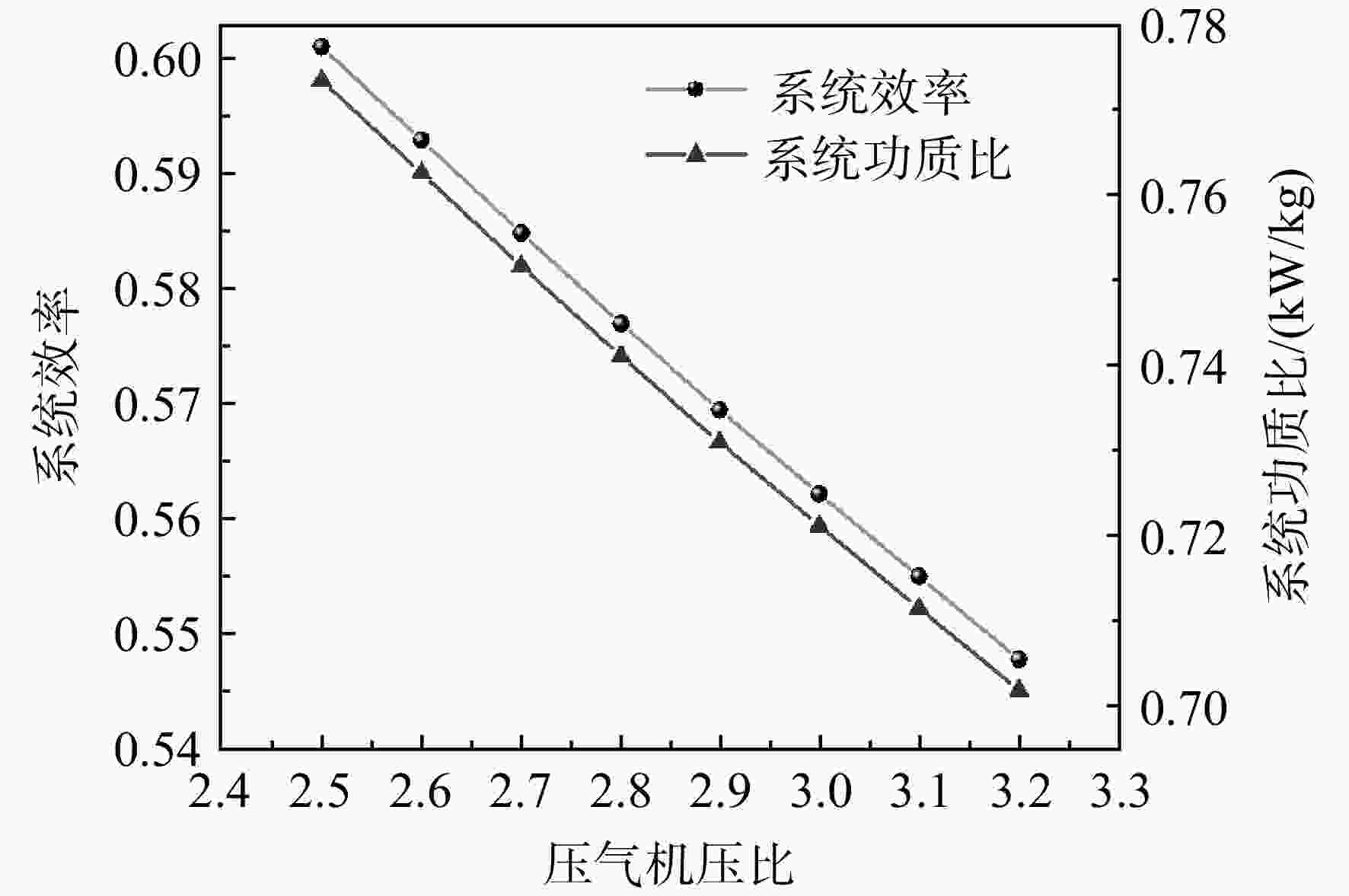

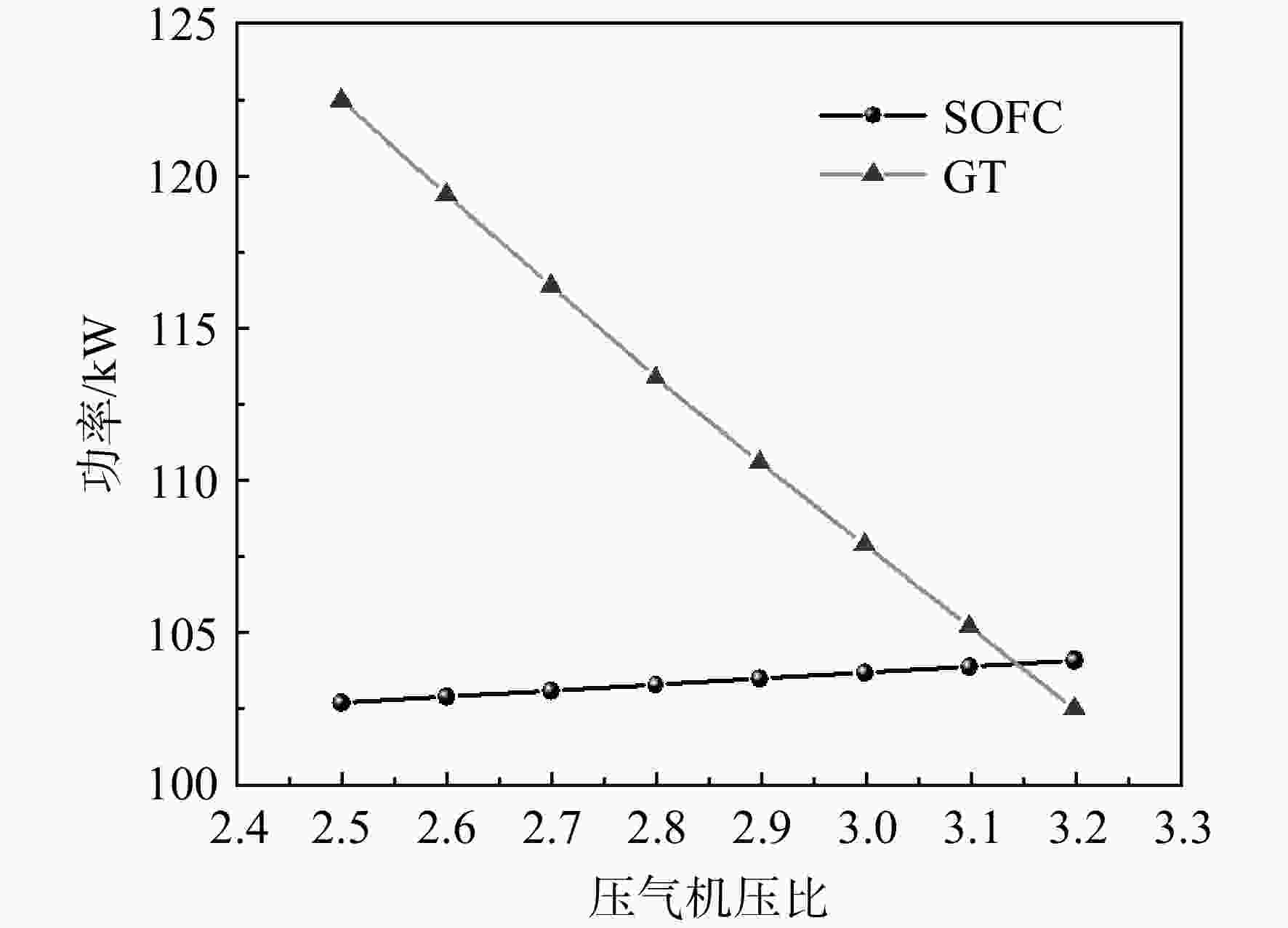

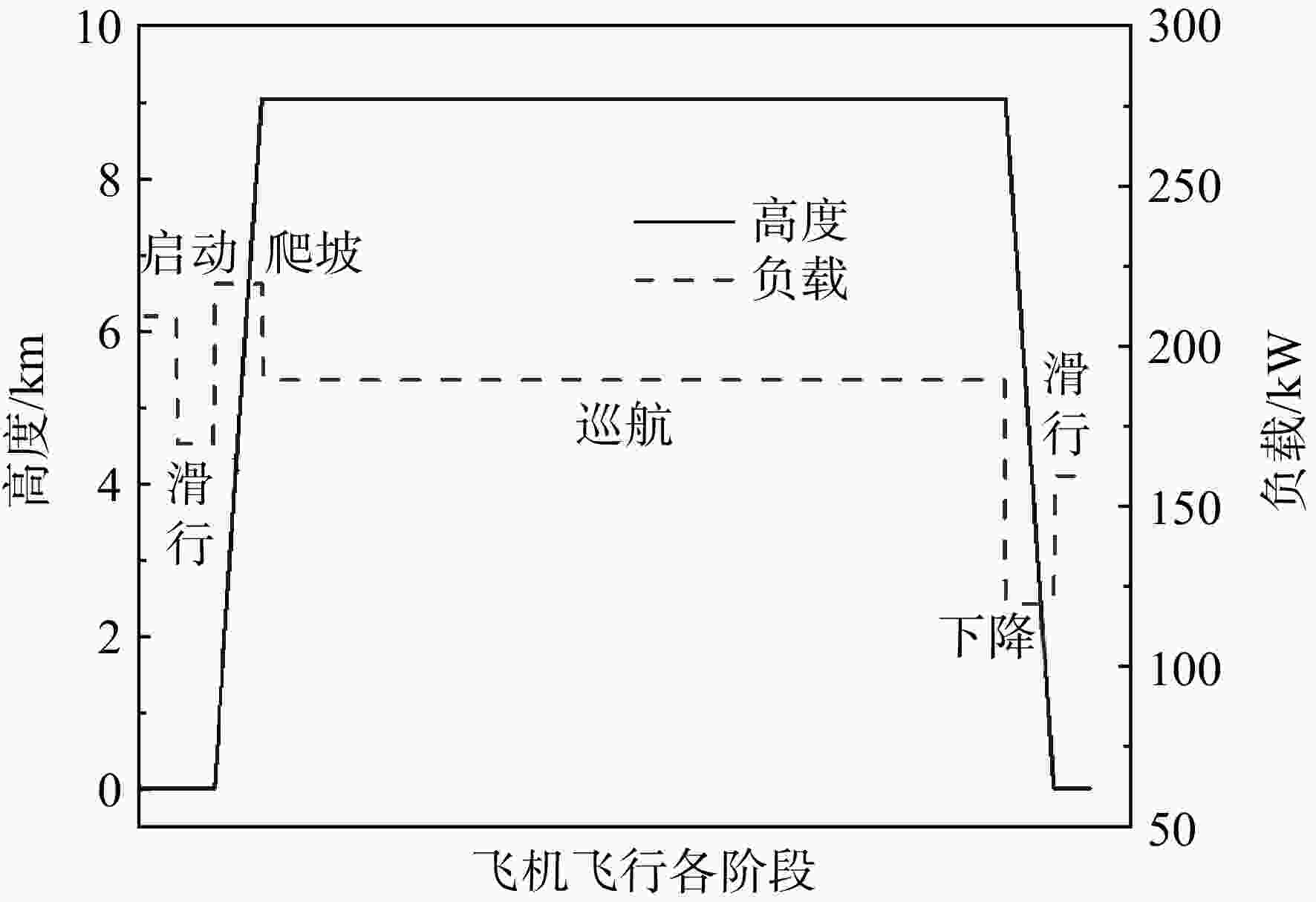

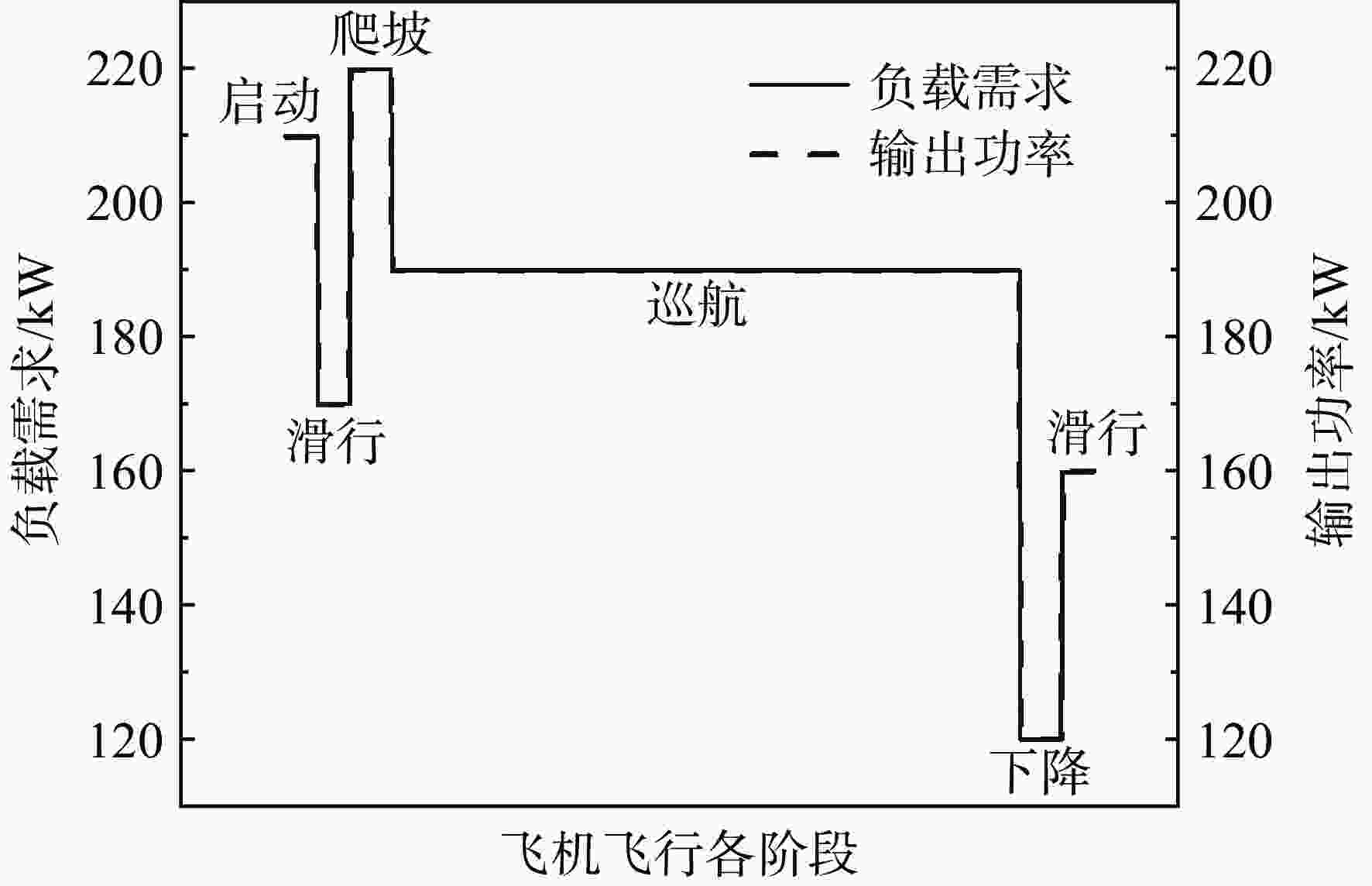

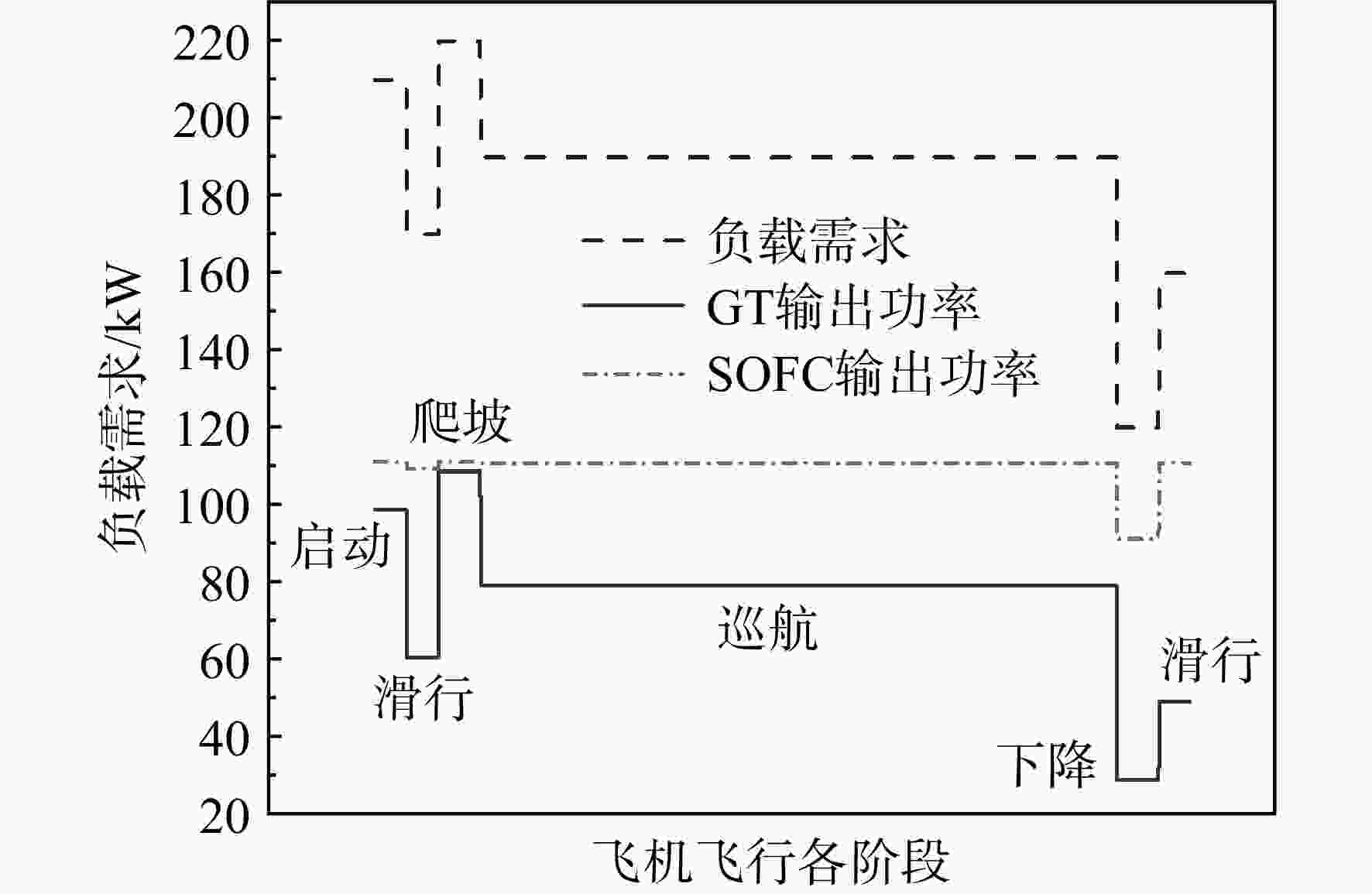

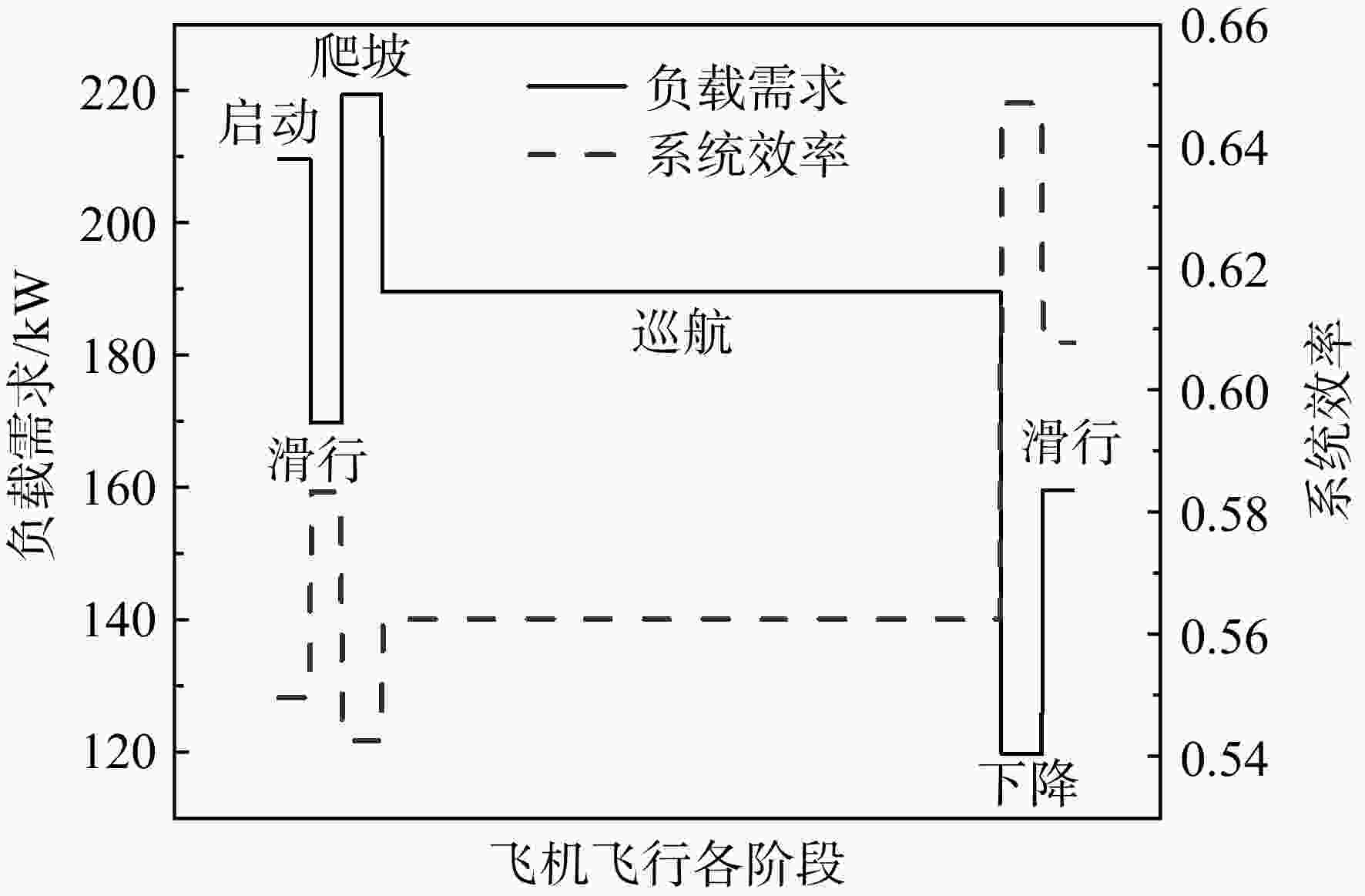

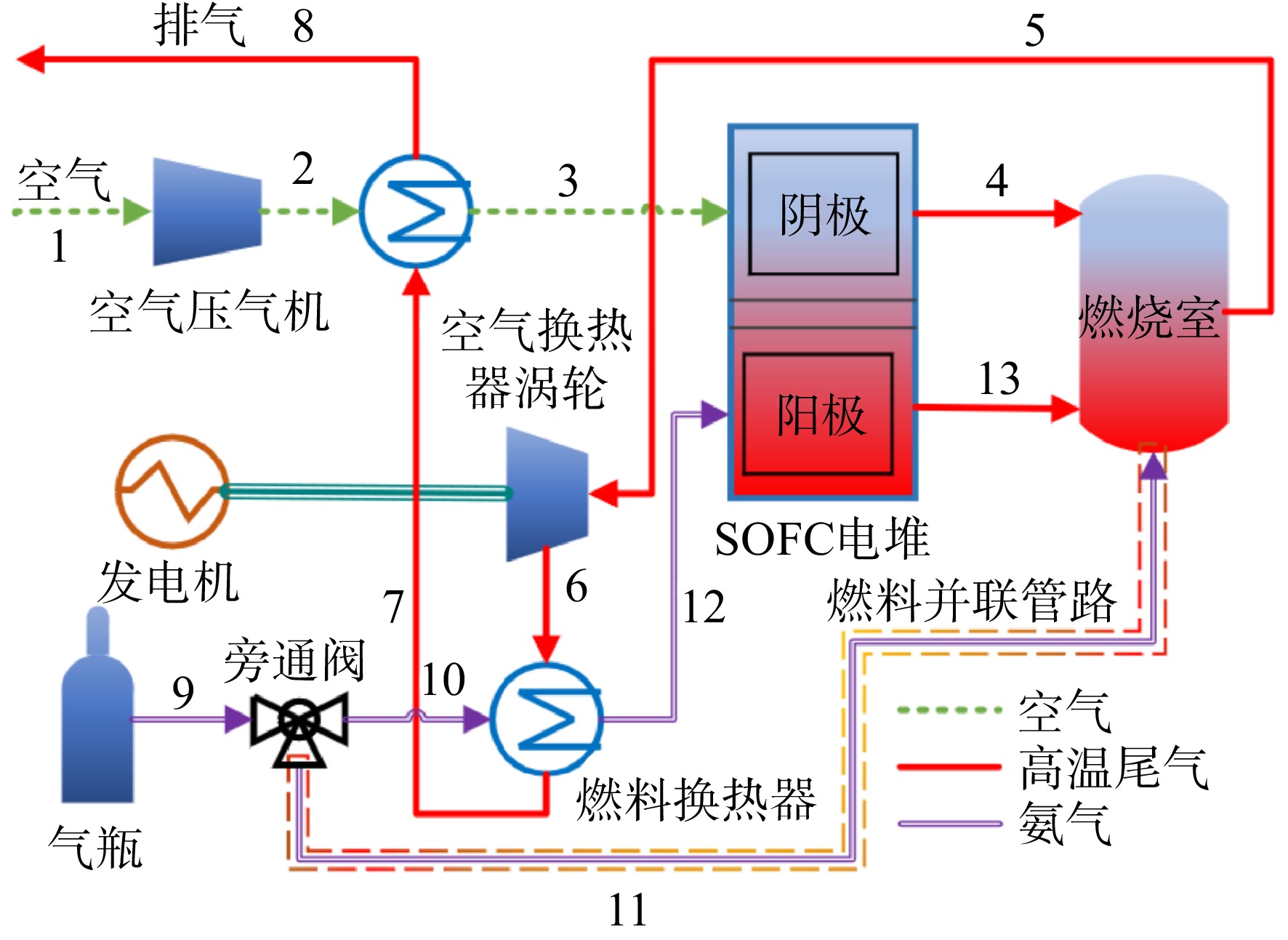

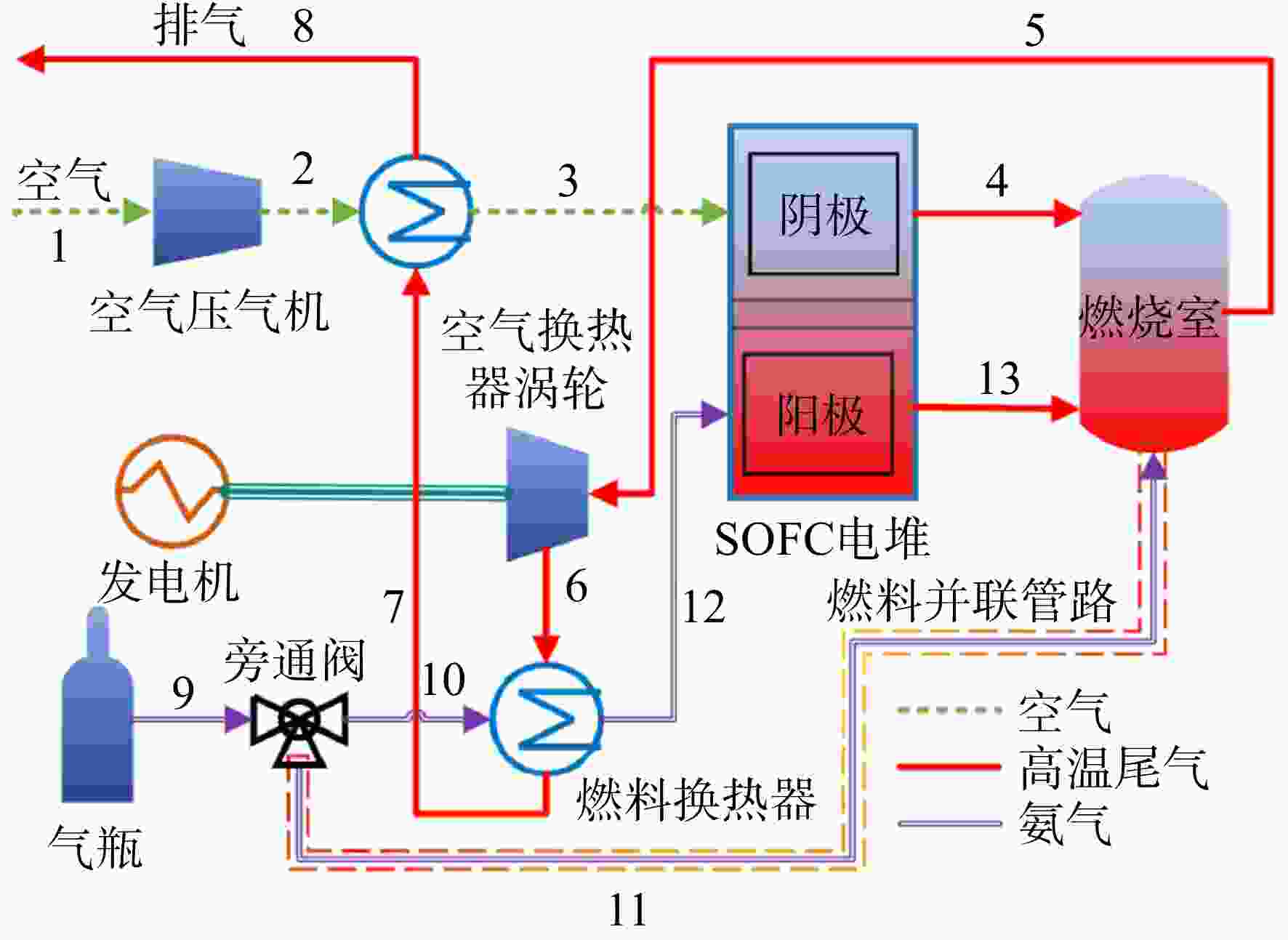

建立了基于直接氨燃料的固体氧化物燃料电池-燃气轮机(SOFC-GT)混合动力系统仿真模型,开发了一种架构优化的高功率-质量比的高效发电系统,并研究了燃料利用率和系统燃料分配对系统功率分配、各子部件质量以及其㶲损失等性能的影响。基于所建立的模型分析了压气机压比、燃料摩尔流量、空气摩尔流量等输入参数对系统性能的影响,在最优性能条件下对系统进行功率-质量比分析。仿真结果表明该系统的净发电效率为56.85%,㶲效率为50.71%,净发电量为213 kW,功率-质量比为0.7303 kW/kg,达到美国能源部太平洋西北国家实验室(PNNL)为SOFC-GT混合动力系统应用于航空航天领域制定的标准。在此基础上,讨论了该系统在商用飞机主动力和辅助动力上的应用,表明SOFC-GT混合动力系统在航空领域具有良好的应用前景。

Abstract:A simulation model of the solid oxide fuel cells-gas turbine (SOFC-GT) hybrid power system on the basis of direct ammonia fuel was established, to developed an efficient power generation system with a high power-mass ratio optimized by architecture, and studied the effects of fuel utilization and system fuel allocation on system power allocation, mass of various subcomponents, and energy losses. Then, the performance of the established SOFC-GT hybrid system was evaluated by changing parameters such as the compressor pressure ratio, fuel flow rate and air flow rate. The power-mass ratio analysis of the system was also carried out under the optimal performance condition. The simulation results showed that, the net power generation efficiency of the system can reach 56.85%, and the exergy efficiency can reach 50.71% at the design conditions. Meanwhile, the net power generation and the power-mass ratio reached 213 kW and 0.7303 kW/kg, respectively. So, this result can meet the power-mass ratio standard given by the Pacific Northwest National Laboratory (PNNL) for the SOFC-GT hybrid system used in the aerospace field. Finally, the application of the system on commercial aircraft as both main power system and auxiliary power unit was discussed, and the designed SOFC-GT hybrid system showed good aviation application prospects.

-

Key words:

- DA-SOFC /

- solid oxide fuel cells-gas turbine /

- hybrid system /

- system efficiency /

- power-mass ratio /

- aviation power

-

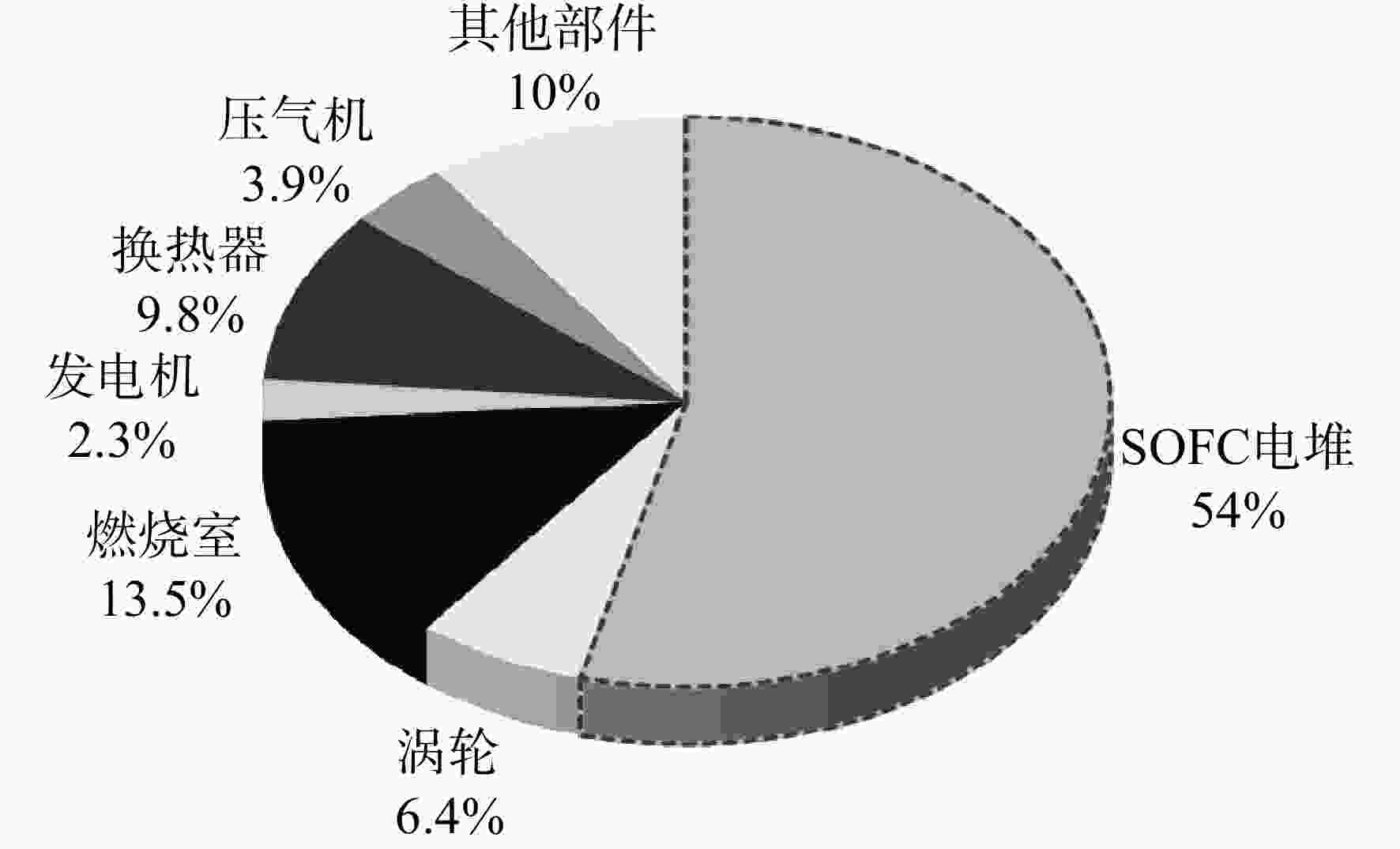

表 1 SOFC-GT混合动力系统各部件的质量模型

Table 1. Mass models of sub-components of the SOFC-GT hybrid system

部件 公式 压气机 ${m}_{ {\rm{comp} } }=1.588\;7 {\pi }_{\text{c} } ^{-0.305}$ 发电机 ${m}_{{\rm{afternater}}}=\dfrac{ {\dot{W} }_{{\rm{fc,stack}}} }{11.56}$ SOFC电堆 ${m}_{ {\rm{cell} } }=\dfrac{ {\dot{W} }_{ {\rm{fc,stack,ac} } } }{0.263\times 2.5}$ 燃烧室 ${m}_{{\rm{comb}}}=10.6+ (\dot{m}-0.1) \times 62.7$ 热交换器 ${m}_{{\rm{hx}}}={m}_{{\rm{a.hx}}}+{m}_{{\rm{f.hx}}}$

${m}_{ {\rm{a.hx} } }=-1.84{\xi }_{ {\rm{hx} } }+37.1$

${m}_{ {\rm{f.hx} } }=-1.84 {\xi }_{ {\rm{hx} } }+16.3$涡轮 ${m}_{{\rm{gt}}}=0.1\times {\dot{W} }_{{\rm{gt}}}$ 其他部件 ${m}_{ {\rm{others} } }=0.1 {m}_{ {\rm{total} } }$ 系统总质量 ${m}_{ {\rm{total} } }={m}_{ {\rm{comp} } }+{m}_{ {\rm{afternater} } }+{m}_{ {\rm{cell} } }+{m}_{ {\rm{comb} } }+$

${m}_{ {\rm{hx} } }+{m}_{ {\rm{gt} } } +{m}_{ {\rm{others} } } $注:表中$ {\xi }_{{\rm{hx}}} $表示换热器换热效率。 表 2 SOFC-GT混合动力系统对比结果

Table 2. Performance comparison of the SOFC-GT hybrid system

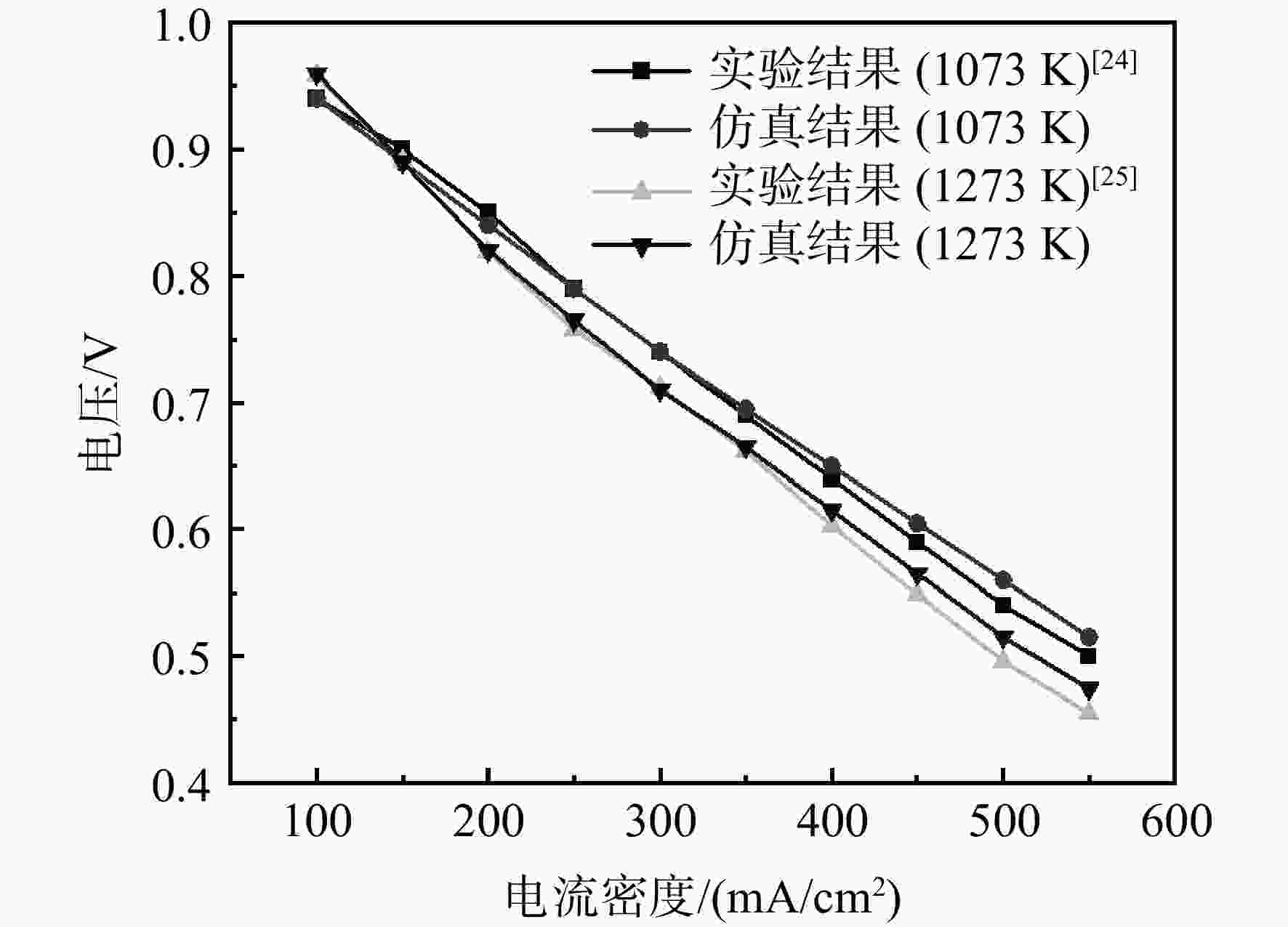

参数 本文结果 实验结果 误差/% 电压/V 0.614 0.61 0.6 总功率/kW 221.87 223 0.5 SOFC功率/kW 175.57 176 0.1 GT功率/kW 46.3 47 1.5 系统热效率 0.5922 0.5952 0.5 表 3 SOFC-GT混合动力系统运行参数

Table 3. Operation parameters of the SOFC-GT hybrid system

组件 参数 数值 SOFC 电池数量 1152 单电池有效面积/cm2 834 GT 压气机压比 2.9 压气机等熵效率 0.82 涡轮等熵效率 0.85 燃烧室绝热效率 0.98 其他参数 空气摩尔流量/(mol/s) 20.211 氨气摩尔流量/(mol/s) 1.186 燃料通入SOFC的比例 0.6 NH3的低位热值/(kJ/mol) 316 表 4 各工况点状态参数

Table 4. Parameters of each operating point

工况点 温度/K 压力/kPa 摩尔流量/(mol/s) 1 298.15 101.3 20.211 2 434.00 293.8 20.211 3 1177.00 285.0 20.211 4 1273.00 276.4 19.790 5 1519.00 268.1 21.690 6 1275.00 111.7 21.690 7 1245.00 108.3 21.690 8 614.00 105.1 21.690 9 298.15 293.8 1.186 10 298.15 293.8 0.7116 11 298.15 293.8 0.4744 12 1003.00 285.0 0.7116 13 1273.00 276.4 1.423 表 5 各工况点物质的摩尔分数

Table 5. Mole fraction at each operating point

工况点 摩尔分数/% NH3 H2 O2 N2 H2O 1 0 0 21.0 79.0 0 2 0 0 21.0 79.0 0 3 0 0 21.0 79.0 0 4 0 0 19.3 80.7 0 5 0 0 15.5 76.3 8.2 6 0 0 15.5 76.3 8.2 7 0 0 15.5 76.3 8.2 8 0 0 15.5 76.3 8.2 9 100 0 0 0 0 10 100 0 0 0 0 11 100 0 0 0 0 12 100 0 0 0 0 13 0 16.1 0 25 58.9 表 6 SOFC-GT混合动力系统计算结果

Table 6. Performance comparison of the SOFC-GT hybrid system

参数 本文结果 文献[7]结果 燃料利用率 0.785 0.8286 工作电压/V 0.6618 0.5763 总功率/kW 213 200.5 SOFC功率/kW 102.7 170.2 GT功率/kW 110.3 30.27 系统热效率 0.5685 0.4881 系统㶲效率 0.5071 0.4045 表 7 SOFC-GT混合动力系统计算结果

Table 7. Performance comparison of the SOFC-GT hybrid system

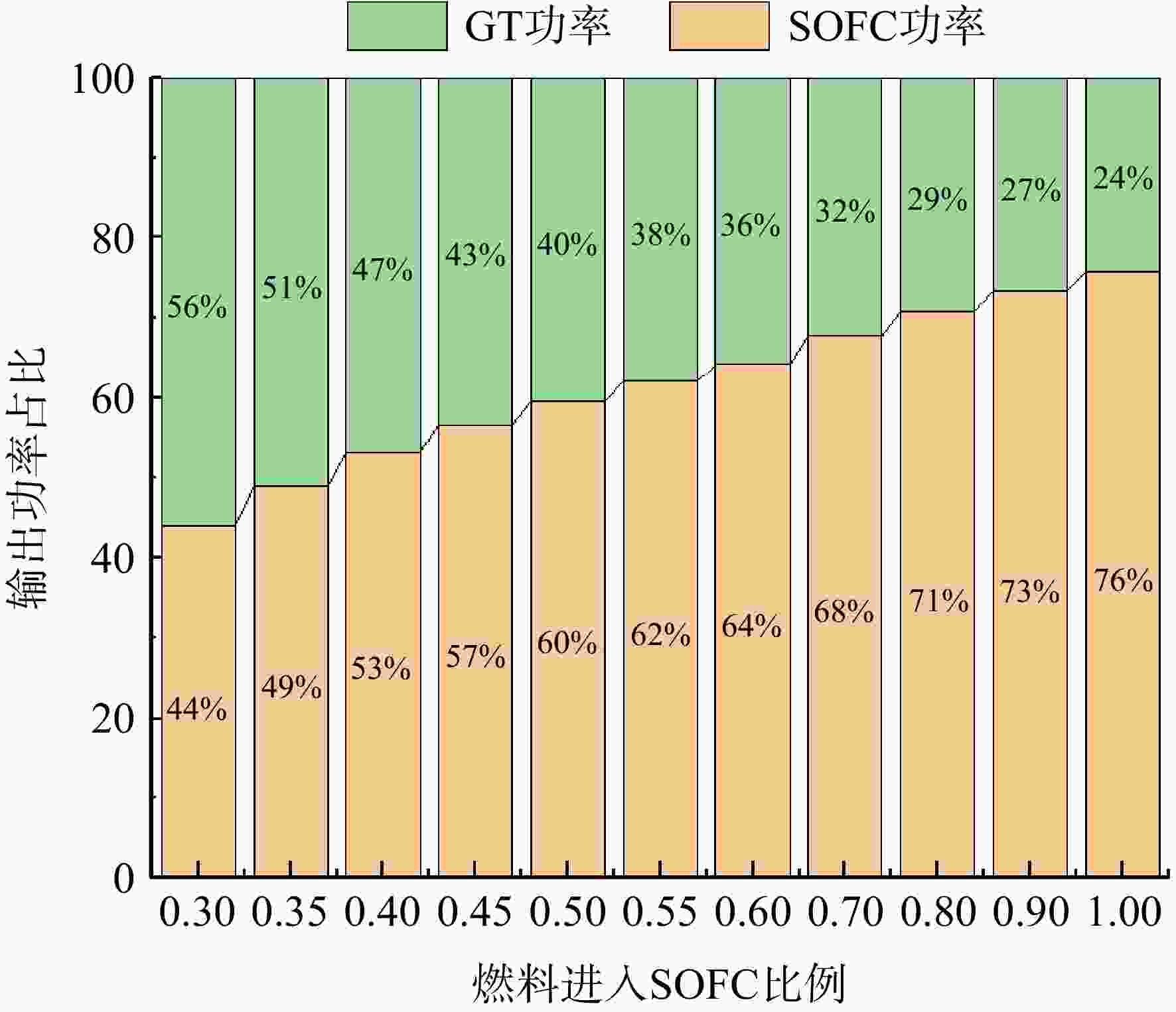

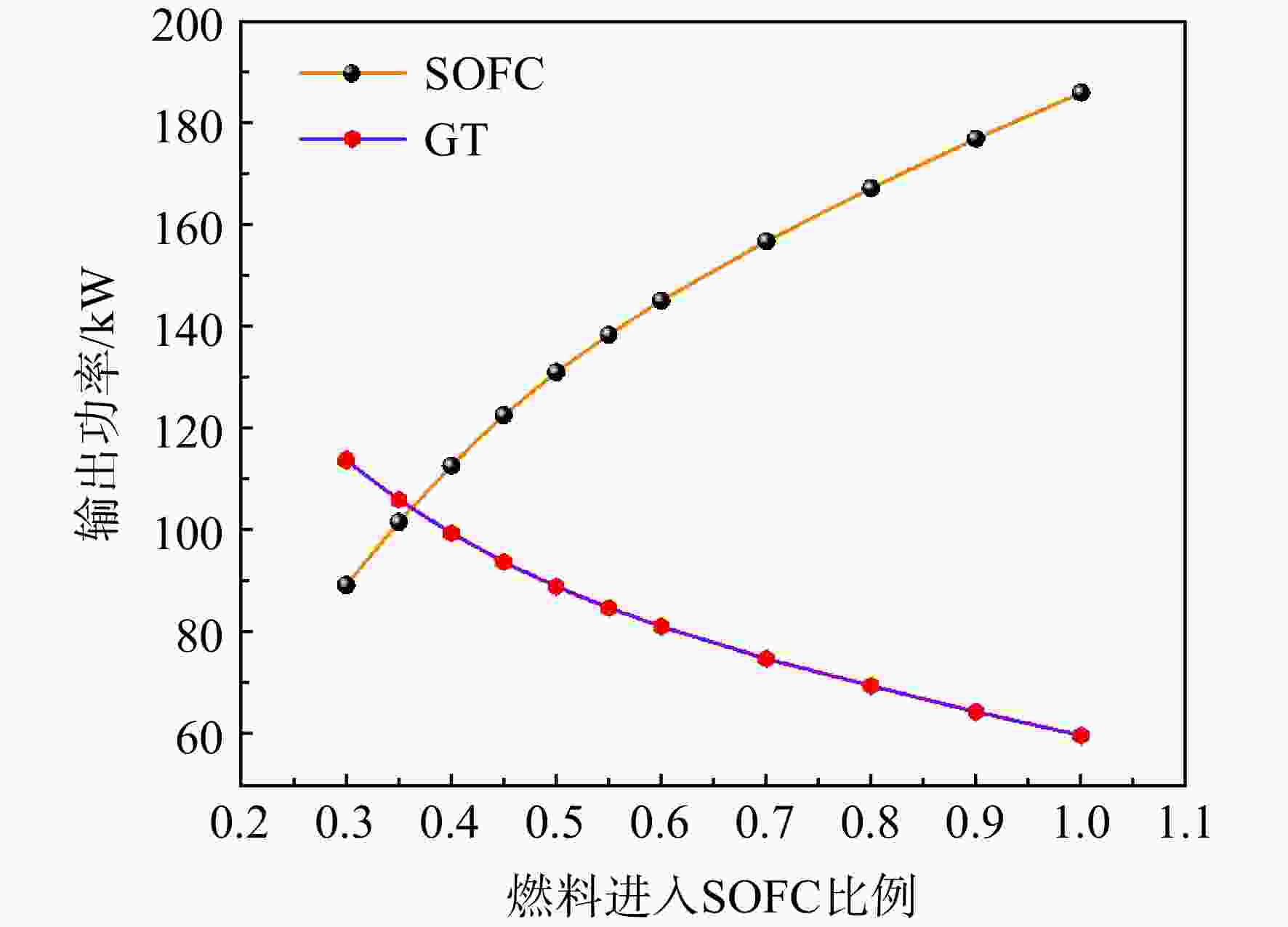

参数 数值 工作电压/V 0.6630 总功率/kW 214.3 SOFC功率/kW 104.2 GT功率/kW 110.1 系统热效率 0.57197 表 8 燃料并联管路对SOFC-GT混合动力系统性能的影响

Table 8. Influence of fuel parallel pipeline on SOFC-GT hybrid system performance

参数 数值 有 无 系统效率 0.5693 0.6356 SOFC输出功率/kW 102.8 163.1 GT输出功率/kW 110.50 75.08 SOFC质量/kg 159.6 253.2 GT质量/kg 19.05 15.51 系统功质比/(kW/kg) 0.7303 0.6089 表 9 SOFC-GT混合动力系统性能参数

Table 9. SOFC-GT hybrid system parameters

参数 数值 系统输出功率/kW 220 系统效率 0.54286 燃料进入SOFC比例 0.56103 燃料利用率 0.73928 SOFC输出功率/kW 112.01 GT输出功率/kW 107.99 系统功质比/(kW/kg) 0.7302 -

[1] SMITH H J. The PACE of clean energy development[J]. Science,2017,355(6328): 921-922. doi: 10.1126/science.2017.355.6328.twil [2] MALE J L,KINTNER-MEYER M C W,WEBER R S. The U. S. energy system and the production of sustainable aviation fuel from clean electricity[J]. Frontiers in Energy Research,2021,9(3): 765360.1-765360.13. [3] JEONG W,YU W,LEE M S,et al. Ultrathin sputtered platinum-gadolinium doped ceria cathodic interlayer for enhanced performance of low temperature solid oxide fuel cells[J]. International Journal of Hydrogen Energy,2020,45(56): 32442-32448. doi: 10.1016/j.ijhydene.2020.08.239 [4] 刘少名,邓占锋,徐桂芝,等. 欧洲固体氧化物燃料电池(SOFC)产业化现状[J]. 工程科学学报,2020,42(3): 278-288.LIU Shaoming,DENG Zhanfeng,XU Guizhi,et al. Commercialization and future development of the solid oxide fuel cell (SOFC) in Europe[J]. Chinese Journal of Engineering,2020,42(3): 278-288. (in Chinese) [5] LIN P H,HONG C W. Cold start dynamics and temperature sliding observer design of an automotive SOFC APU[J]. Journal of Power Sources,2009,187(2): 517-526. doi: 10.1016/j.jpowsour.2008.11.043 [6] CHOUDHARY T, SAHU M, KRISHNA S. Thermodynamic analysis of solid oxide fuel cell gas turbine hybrid system for aircraft power generation[R]. SAE Technical Paper-01-2062, 2017. [7] 胡焦英,毛军逵,贺振宗. 基于航空煤油重整的SOFC-GT混合动力系统性能[J]. 航空动力学报,2020,35(2): 325-336. doi: 10.13224/j.cnki.jasp.2020.02.012HU Jiaoying,MAO Junkui,HE Zhenzong. Performance of the SOFC-GT hybrid system based on aviation kerosene reforming[J]. Journal of Aerospace Power,2020,35(2): 325-336. (in Chinese) doi: 10.13224/j.cnki.jasp.2020.02.012 [8] 秦江,姬志行,郭发福,等. 航空用燃料电池及混合电推进系统发展综述[J]. 推进技术,2022,43(7): 6-23.QIN Jiang,JI Zhixing,GUO Fafu,et al. Review of aviation fuel cell and hybrid electric propulsion systems[J]. Journal of Propulsion Technology,2022,43(7): 6-23. (in Chinese) [9] SANZ O,VELASCO I,PÉREZ-MIQUEO I,et al. Intensification of hydrogen production by methanol steam reforming[J]. International Journal of Hydrogen Energy,2016,41(10): 5250-5259. doi: 10.1016/j.ijhydene.2016.01.084 [10] DOLAN R H,ANDERSON J E,WALLINGTON T J. Outlook for ammonia as a sustainable transportation fuel[J]. Sustainable Energy & Fuels,2021,5(19): 4830-4841. [11] LAN Rong,TAO Shanwen. Ammonia as a suitable fuel for fuel cells[J]. Frontiers in Energy Research,2014,2(3): 35-47. [12] MIYAZAKI K,OKANISHI T,MUROYAMA H,et al. Development of Ni-Ba (Zr, Y) O3 cermet anodes for direct ammonia-fueled solid oxide fuel cells[J]. Journal of Power Sources,2017,365: 148-154. doi: 10.1016/j.jpowsour.2017.08.085 [13] ISHAK F,DINCER I,ZAMFIRESCU C. Energy and exergy analyses of direct ammonia solid oxide fuel cell integrated with gas turbine power cycle[J]. Journal of Power Sources,2012,212: 73-85. doi: 10.1016/j.jpowsour.2012.03.083 [14] EZZAT M F,DINCER I. Energy and exergy analyses of a novel ammonia combined power plant operating with gas turbine and solid oxide fuel cell systems[J]. Energy,2020,194: 116750-116764. doi: 10.1016/j.energy.2019.116750 [15] COLLINS J M,MCLARTY D. All-electric commercial aviation with solid oxide fuel cell-gas turbine-battery hybrids[J]. Applied Energy,2020,265: 114787.1-114787.9. [16] WOJCIK A,MIDDLETON H,DAMOPOULOS I,et al. Ammonia as a fuel in solid oxide fuel cells[J]. Journal of Power Sources,2003,118(1/2): 342-348. [17] GUO Fafu,QIN Jiang,JI Zhixing,et al. Performance analysis of a turbofan engine integrated with solid oxide fuel cells based on Al-H2O hydrogen production for more electric long-endurance UAVs[J]. Energy Conversion and Management,2021,235(5): 113999.1-113999.16. [18] 刘强,段远源. 超临界600MW火电机组热力系统的火用分析[J]. 中国电机工程学报,2010,30(32): 8-12. doi: 10.13334/j.0258-8013.pcsee.2010.32.020LIU Qiang,DUAN Yuanyuan. Exergy analysis for thermal power system of a 600 MW supercritical power unit[J]. Proceedings of the CSEE,2010,30(32): 8-12. (in Chinese) doi: 10.13334/j.0258-8013.pcsee.2010.32.020 [19] SHAMOUSHAKI M,EHYAEI M A,GHANATIR F. Exergy, economic and environmental analysis and multi-objective optimization of a SOFC-GT power plant[J]. Energy,2017,134: 515-531. doi: 10.1016/j.energy.2017.06.058 [20] JI Zhixing,QIN Jiang,CHENG Kunlin,et al. Design and performance of a compact air-breathing jet hybrid-electric engine coupled with solid oxide fuel cells[J]. Frontiers in Energy Research,2021,8: 613205.1-613205.14. [21] JI Zhixing,ROKNI M M,QIN Jiang,et al. Energy and configuration management strategy for battery/fuel cell/jet engine hybrid propulsion and power systems on aircraft[J]. Energy Conversion and Management,2020,225: 113393.1-113393.16. [22] CIRIGLIANO D,FRISCH A M,LIU Feng,et al. Diesel, spark-ignition, and turboprop engines for long-duration unmanned air flights[J]. Journal of Propulsion and Power,2018,34(4): 878-892. doi: 10.2514/1.B36547 [23] TORNABENE R, WANG X Y, STEFFEN C J Jr, et al. Development of parametric mass and volume models for an aerospace SOFC/gas turbine hybrid system[C]// Turbo Expo 2005 ASMEDC. Reno-Tahoe, US : NASA, 2005: 135-144. [24] LUO Yu,LIAO Shuting,CHEN Shuai,et al. Optimized coupling of ammonia decomposition and electrochemical oxidation in a tubular direct ammonia solid oxide fuel cell for high-efficiency power generation[J]. Applied Energy,2022,307(2): 118158.1-118158.14. [25] MOLOUK A F S,YANG Jun,OKANISHI T,et al. Electrochemical and catalytic behavior of Ni-based cermet anode for ammonia-fueled SOFCs[J]. ECS Transactions,2015,68(1): 2751-2762. doi: 10.1149/06801.2751ecst [26] 吴小娟. 固体氧化物燃料电池/微型燃气轮机混合发电系统的建模与控制[D]. 上海: 上海交通大学, 2009.WU Xiaojuan. Modeling and control of solid oxide fuel cell/micro gas turbine hybrid power generation system[D]. Shanghai: Shanghai Jiao Tong University, 2009. (in Chinese) [27] JI Zhixing,QIN Jiang,CHENG Kunlin,et al. Comparative performance analysis of solid oxide fuel cell turbine-less jet engines for electric propulsion airplanes: application of alternative fuel[J]. Aerospace Science and Technology,2019(10): 105286.1-105286.14. [28] SEYAM S,DINCER I,AGELIN-CHAAB M. Investigation of two hybrid aircraft propulsion and powering systems using alternative fuels[J]. Energy,2021,232(1): 121037.1-121037.12. [29] LI Y H,CHOI S S,RAJAKARUNA S. An analysis of the control and operation of a solid oxide fuel-cell power plant in an isolated system[J]. IEEE Transactions on Energy Conversion,2005,20(2): 381-387. doi: 10.1109/TEC.2005.847998 [30] 钱煜平,张扬军. 航空混合电推进系统中的热管理问题分析[J]. 航空动力,2019(6): 36-40.QIAN Yuping,ZHANG Yangjun. Analysis of thermal management in aviation hybrid electric propulsion system[J]. Aerospace Power,2019(6): 36-40. (in Chinese) [31] VALENCIA E A, HIDALGO V, PANAGIOTIS L, et al. Design point analysis of an hybrid fuel cell gas turbine cycle for advanced distributed propulsion systems[C]//Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference. Reston, Virginia, US: AIAA, 2015: 3802-3802. [32] FERNANDES M D,DE P ANDRADE S T,BISTRITZKI V N,et al. SOFC-APU systems for aircraft: a review[J]. International Journal of Hydrogen Energy,2018,43(33): 16311-16333. doi: 10.1016/j.ijhydene.2018.07.004 [33] DAGGETT D, EELMAN S, KRISTIANSSON G. Fuel cell APU[R]. AIAA 2003-2660, 2003. [34] BRAUN R J,GUMMALLA M,YAMANIS J. System architectures for solid oxide fuel cell-based auxiliary power units in future commercial aircraft applications[J]. Journal of Fuel Cell Science and Technology,2009,6(3): 268-271. -

下载:

下载: