Comparison for radial difference of film cooling performance on suction surface of a rotor blade

-

摘要:

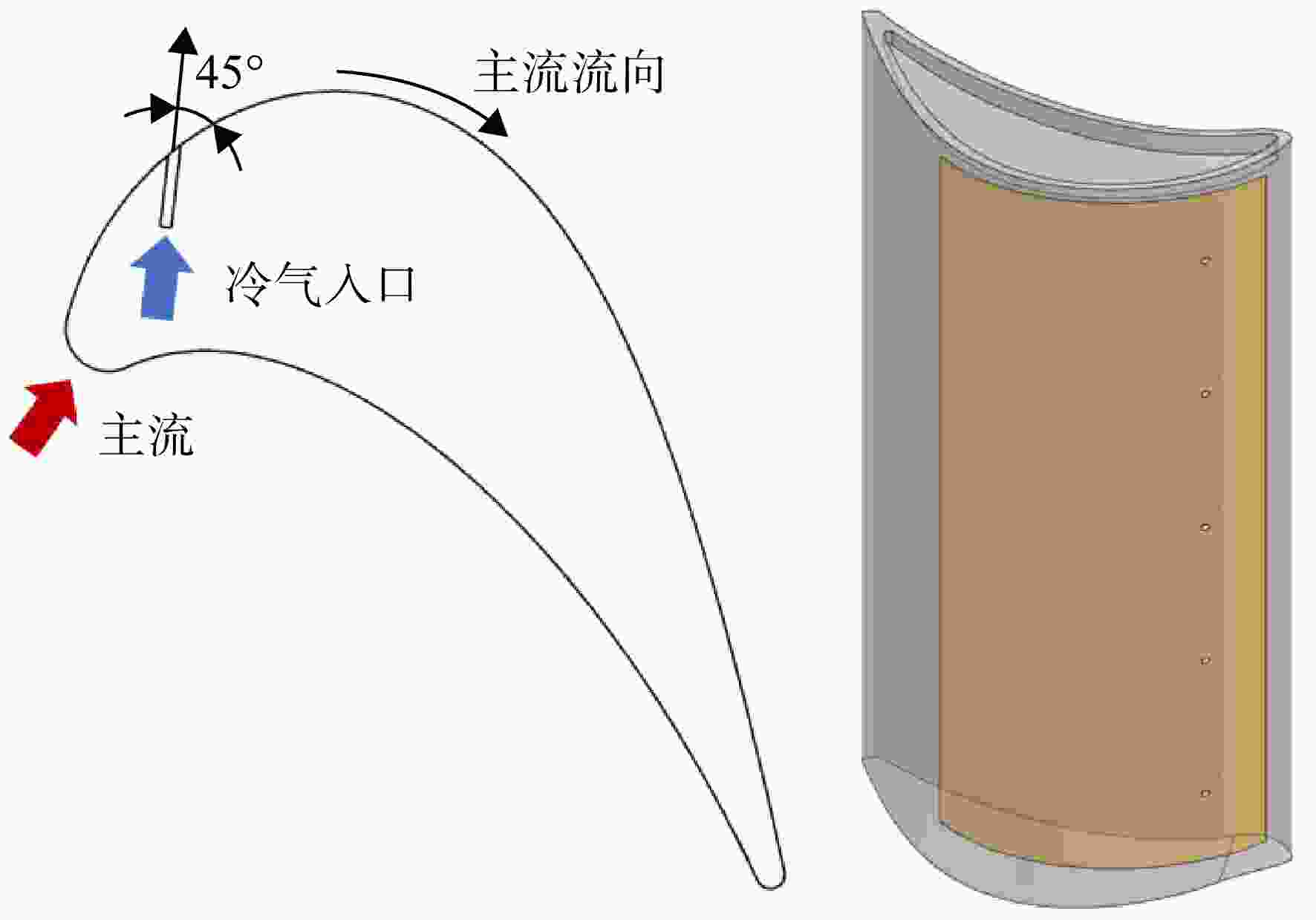

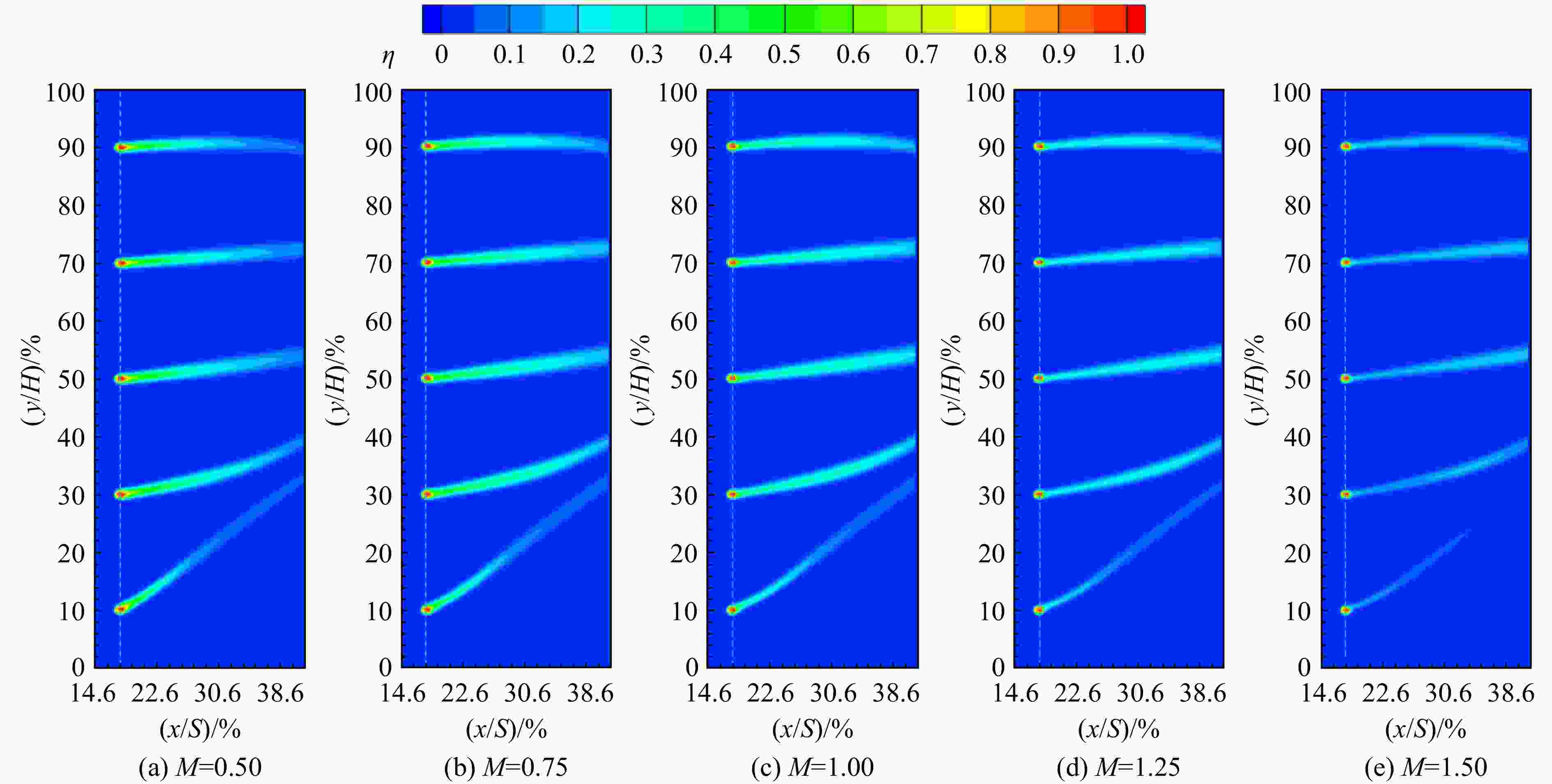

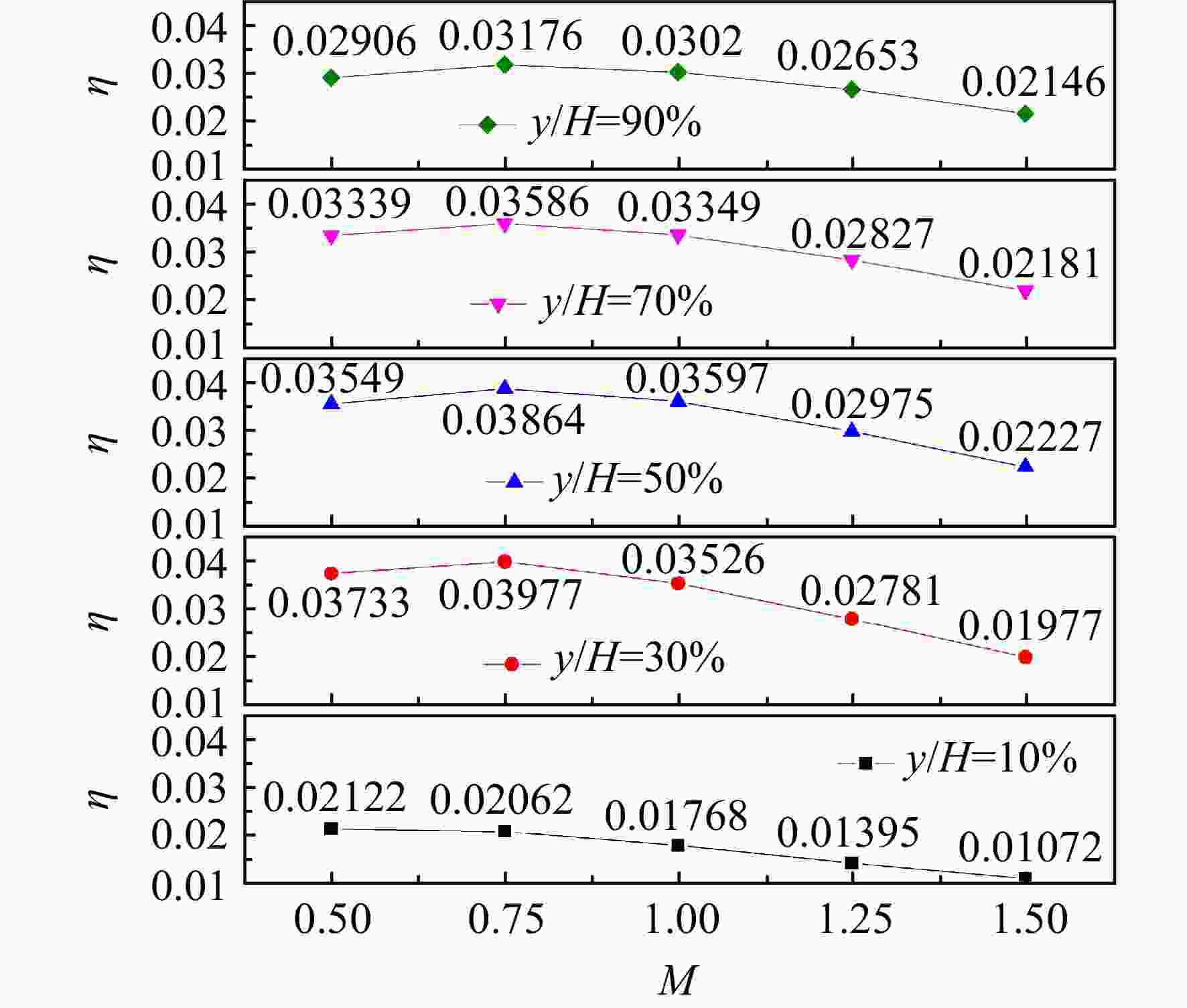

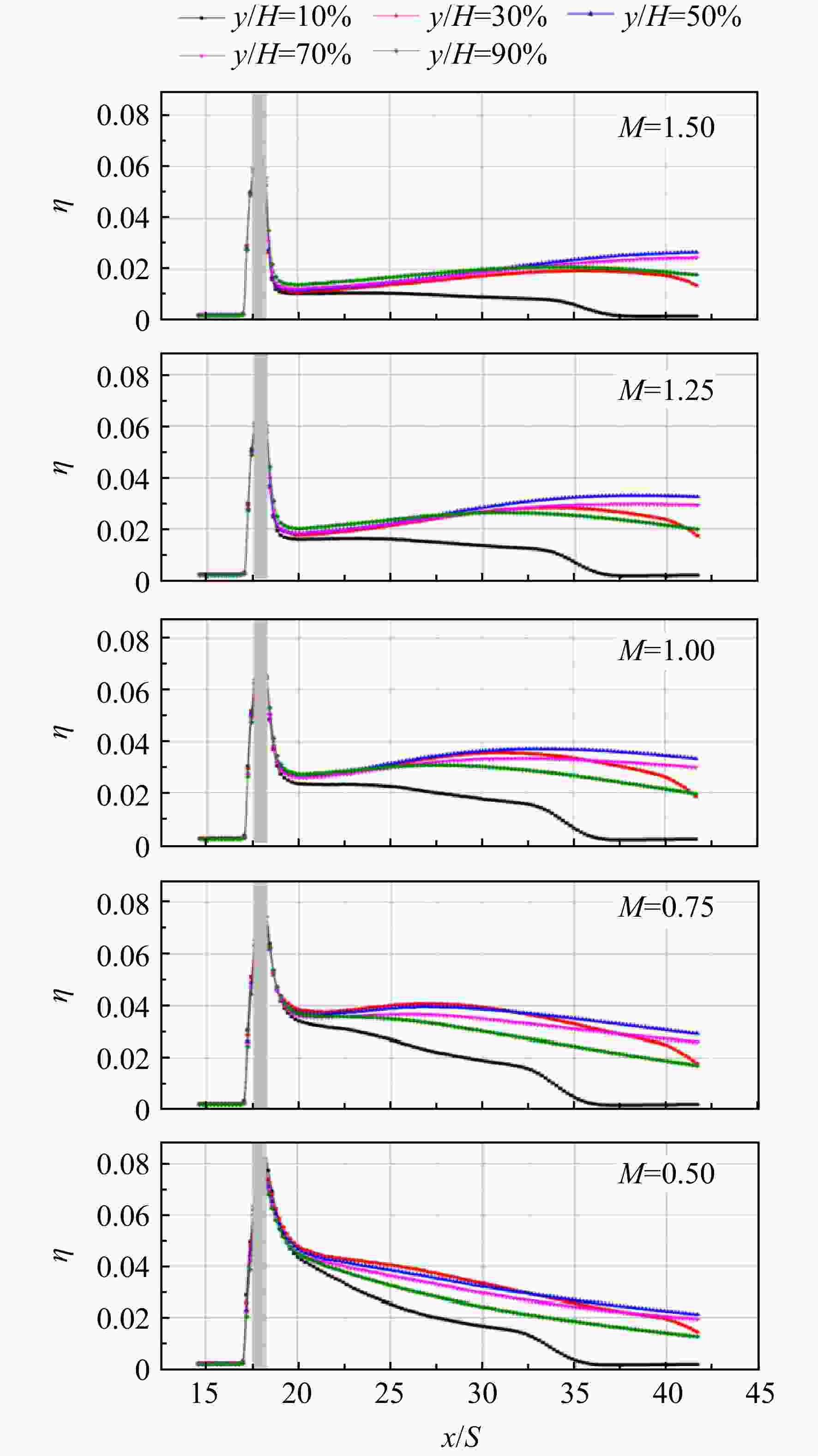

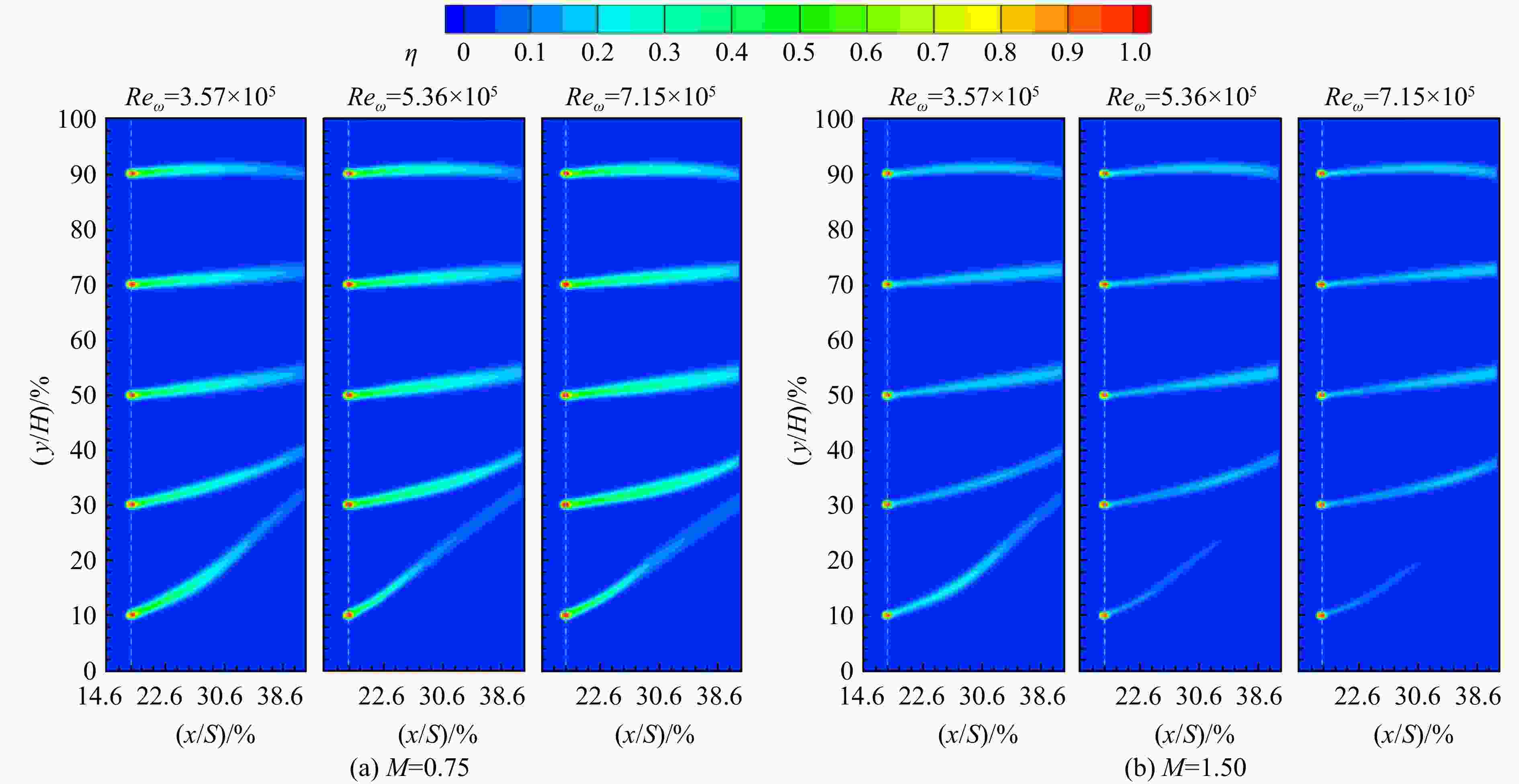

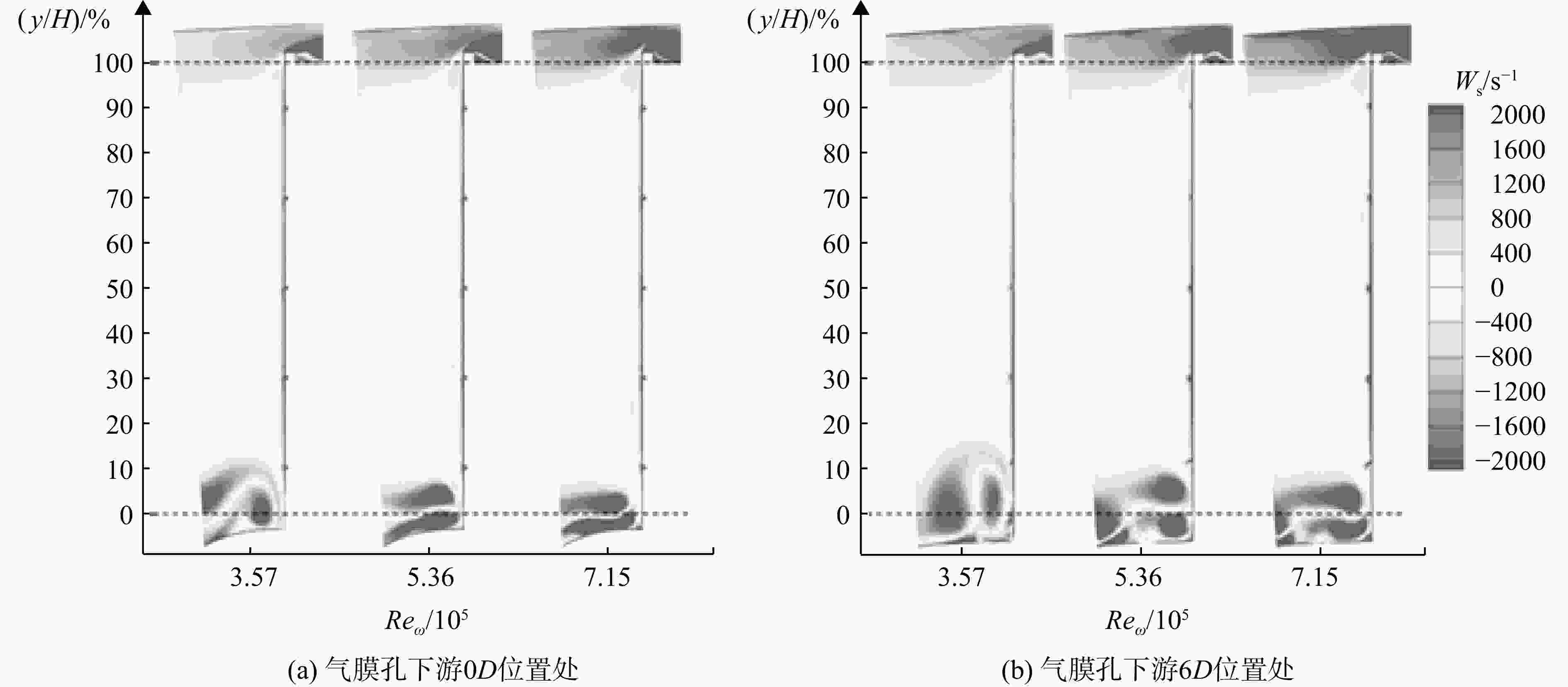

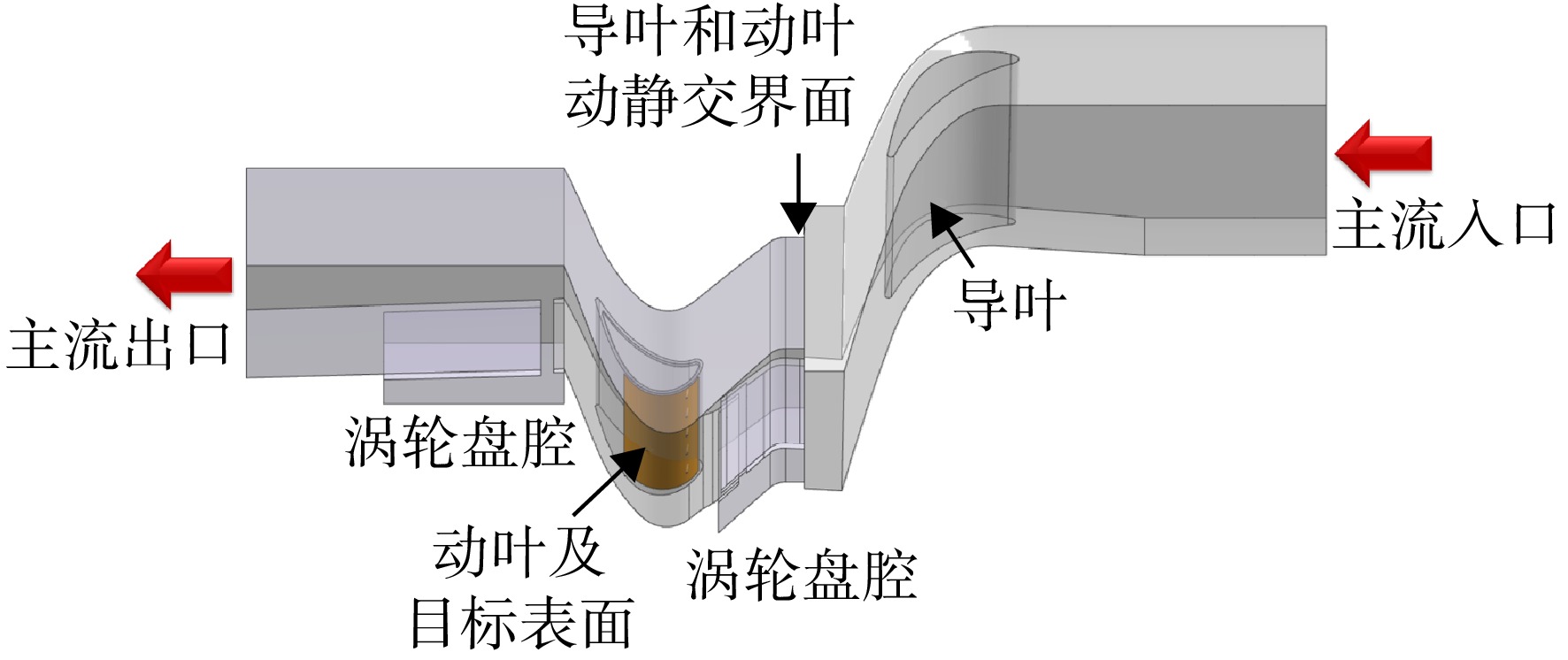

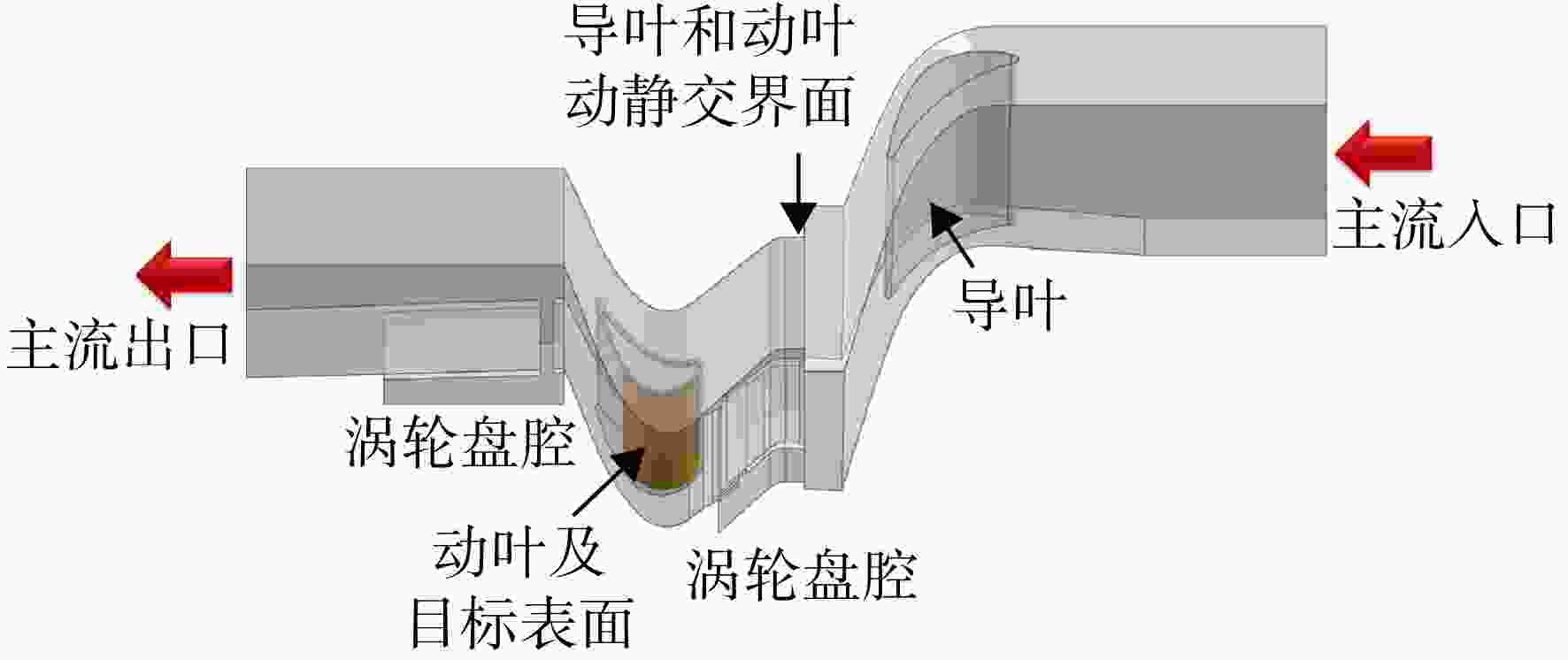

数值仿真研究了不同吹风比和旋转雷诺数条件下涡轮叶片吸力面不同叶高位置处气膜冷却效率分布的差异。研究涉及5个直径为0.8 mm的圆柱孔,气膜孔处于涡轮叶片吸力面17.8%流向位置处,并分别处于10%、30%、50%、70%和90%叶高位置处。研究在400、600 r/min和800 r/min转速下进行,分别对应旋转雷诺数357 000、536 000和715 000。研究涉及5个吹风比:0.50、0.75、1.00、1.25和1.50。研究结果表明:靠近叶根处的气膜受叶根通道涡影响明显向叶顶方向偏转。不同叶高位置处的气膜冷却效率分布存在明显差异。旋转给冷却射流带来附加离心力和哥氏力的作用,使得吹风比和旋转雷诺数的增加对不同叶高位置的气膜尾迹偏转产生不同影响。旋转雷诺数对不同叶高位置的气膜冷却影响存在差异。

Abstract:Simulations were carried out to investigate the difference of film cooling effectiveness distribution at different blade heights under different blowing ratios and rotational Reynolds numbers. Five cylindrical holes with a diameter of 0.8 mm were located at 17.8% streamwise location and at 10%, 30%, 50%, 70% and 90% blade height, respectively. The study was conducted under three rotational speeds of 400 , 600 r/min and 800 r/min, correspondingly to rotational Reynolds numbers of 357 000, 536 000 and 715 000, respectively. Five blowing ratios of 0.50, 0.75, 1.00, 1.25 and 1.50 were involved. Results showed that film trajectories in the near hub region were deflected a lot toward the tip under the effect of passage vortex. The distribution of film cooling effectiveness at different blade heights was different. Under the effect of centrifugal force and Coriolis force caused by rotation, the increase of blow ratio and rotating Reynolds number yielded different effects on film deflection at different blade heights. The effect of rotational Reynolds number on film cooling at different blade heights was different.

-

Key words:

- film cooling /

- rotor blade /

- suction surface /

- different blade heights /

- blowing ratio /

- rotational Reynolds number

-

表 1 主流和冷却射流工况设置

Table 1. Working condition setting of mainstream and coolant

转速/(r/min) (y/H)/% 主流流速/(m/s) 冷气质量流量/10−3 (g/s) M=0.50 M=0.75 M=1.00 M=1.25 M=1.50 400 10 7.30 1.400 2.101 2.801 3.501 4.201 30 8.68 1.664 2.496 3.329 4.161 4.993 50 7.84 1.504 2.256 3.009 3.761 4.513 70 6.88 1.319 1.978 2.637 3.297 3.956 90 5.79 1.110 1.665 2.219 2.774 3.329 600 10 13.00 2.494 3.740 4.987 6.234 7.481 30 14.02 2.688 4.032 5.376 6.720 8.064 50 12.55 2.406 3.609 4.812 6.014 7.217 70 10.82 2.075 3.113 4.151 5.188 6.226 90 9.00 1.727 2.590 3.454 4.317 5.180 800 10 18.63 3.573 5.360 7.146 8.933 10.719 30 19.45 3.729 5.594 7.458 9.323 11.188 50 17.31 3.319 4.979 6.639 8.298 9.958 70 14.82 2.841 4.262 5.683 7.104 8.524 90 12.20 2.340 3.510 4.680 5.850 7.020 -

[1] GOLDSTEIN R J,ECKERT E R G,RAMSEY J W. Film cooling with injection through holes: adiabatic wall temperatures downstream of a circular hole[J]. Journal of Engineering for Power,1968,90(4): 384-393. doi: 10.1115/1.3609223 [2] BERNSDORF S,ROSE M G,ABHARI R S. Modeling of film cooling: Part Ⅰ experimental study of flow structure[J]. Journal of Turbomachinery,2006,128(1): 141-149. doi: 10.1115/1.2098768 [3] BURDET A,ABHARI R S,ROSE M G. Modeling of film cooling: Part Ⅱ model for use in three-dimensional computational fluid dynamicscs[J]. Journal of Turbomachinery,2007,129(2): 221-231. doi: 10.1115/1.2437219 [4] YU Feiyan, YAVUZKURT S. Simulations of film cooling flow structure and heat transfer in the near field of cooling jets with a modified DES model[R]. ASME Paper GT2019-3683, 2019. [5] ZAMIRI A,CHUNG J T. Large eddy simulation of compound angle effects on cooling effectiveness and flow structure of fan-shaped holes[J]. International Journal of Heat and Mass Transfer,2021,178: 121599.1-121599.18. [6] ZHOU Zhiyu,LI Haiwang,XIE Gang,et al. The cooling performance of three-row compound angle holes on the suction surface of a rotating turbine blade[J]. Propulsion and Power Research,2021,10(1): 23-36. doi: 10.1016/j.jppr.2020.09.001 [7] HAVEN B A,KUROSAKA M. Kidney and anti-kidney vortices in crossflow jets[J]. Journal of Fluid Mechanics,1997,352: 27-64. doi: 10.1017/S0022112097007271 [8] JONES F B, FOX D W, OLIVER T, et al. Parametric optimization of film cooling hole geometry[R]. ASME Paper GT2021-59326, 2021. [9] SCHWARZ S G,GOLDSTEIN R J. The two-dimensional behavior of film cooling jets on concave surfaces[J]. Journal of Turbomachinery,1989,111(2): 124-130. doi: 10.1115/1.3262246 [10] SCHWARZ S G,GOLDSTEIN R J,ECKERT E R G. The influence of curvature on film cooling performance[J]. Journal of Turbomachinery,1991,113(3): 472-478. doi: 10.1115/1.2927898 [11] GAO Zhihong,NARZARY D P,HAN J C. Film cooling on a gas turbine blade pressure side or suction side with axial shaped holes[J]. International Journal of Heat and Mass Transfer,2008,51(9/10): 2139-2152. [12] ZHOU Zhiyu,LI Haiwang,WANG Haichao,et al. Film cooling of cylindrical holes on turbine blade suction side near leading edge[J]. International Journal of Heat and Mass Transfer,2019,141: 669-679. doi: 10.1016/j.ijheatmasstransfer.2019.07.028 [13] ZENG Lingyu,CHEN Pingting,LI Xueying,et al. Influence of simplifications of blade in gas turbine on film cooling performance[J]. Applied Thermal Engineering,2018,128: 877-886. doi: 10.1016/j.applthermaleng.2017.09.008 [14] DRING R P,BLAIR M F,JOSLYN H D. An experimental investigation of film cooling on a turbine rotor blade[J]. Journal of Engineering for Power,1980,102(1): 81-87. doi: 10.1115/1.3230238 [15] TAO Zhi,YANG Xiaojun,DING Shuiting,et al. Experimental study of rotation effect on film cooling over the flat wall with a single hole[J]. Experimental Thermal and Fluid Science,2008,32(5): 1081-1089. doi: 10.1016/j.expthermflusci.2007.12.003 [16] TAO Zhi,ZHAO Zhenming,DING Shuiting,et al. Suitability of three different two-equation turbulence models in predicting film cooling performance over a rotating blade[J]. International Journal of Heat and Mass Transfer,2009,52(5/6): 1268-1275. [17] TAO Zhi,LI Guoqing,DENG Hongwu,et al. Film cooling performance in a low-speed 1.5-stage turbine: effects of blowing ratio and rotation[J]. Journal of Enhanced Heat Transfer,2011,18(5): 419-432. doi: 10.1615/JEnhHeatTransf.2011003253 [18] 周志宇. 旋转状态下高压涡轮动叶吸力面气膜孔排布优化研究[D]. 北京: 北京航空航天大学, 2021.ZHOU Zhiyu. Optimization study of film hole arrangement on the suction surface of a rotating turbine blade[D]. Beijing: Beihang University, 2021. (in Chinese) [19] XIE Gang,TAO Zhi,ZHOU Zhiyu,et al. Effect of leading edge diameter ratio and mainstream Reynolds number on film cooling performance of rotating blade leading edge[J]. Applied Thermal Engineering,2021,186: 116047.1-116047.16. -

下载:

下载: