Drag and heat flux reduction performance of supersonic vehicle with combination model of aerospike/aerodisk and double jet

-

摘要:

为降低超声速飞行器的气动力和热载荷,研究一种减阻杆/盘与双喷流组合构型,并采用数值方法分析了几何参数和喷流参数对流场特征以及减阻和防热性能的影响。结果表明:减阻杆长径比对构型的减阻效率影响较小,但对防热效率影响较大;增加减阻盘直径比,构型的减阻效率先增大后减小,防热效率先减小后增大,但当逆向喷流总压较高时,减阻盘直径比对减阻和防热效率的影响均较小;提高逆向喷流总压比,构型的减阻和防热效率一直处于较高水平,且其变化幅度均不明显;提高侧向喷流总压比,构型的减阻和防热效率均增大,减阻效率变化率增大,防热效率变化率减小;侧向喷流出口位置远离钝体头部,减阻效率增大,防热效率减小;适当选取减阻杆/盘与双喷流参数,可达到57.1%的减阻效率,同时防热效率达到100.4%。

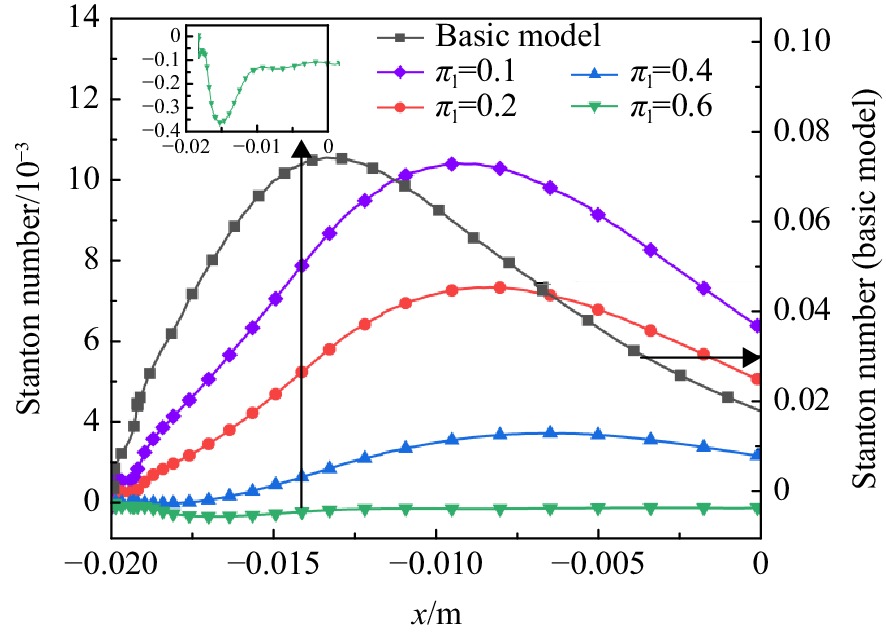

Abstract:In order to reduce aerodynamic and thermal loads of the supersonic vehicle, a combination model of aerospike/aerodisk and double jet was studied, and the effects of geometrical parameters and jet parameters on flow field characteristics, drag and heat flux reduction were analyzed numerically. The results showed that: the length-to-diameter ratio of the aerospike had little effect on the drag reduction efficiency of the configuration, but had a great effect on the heat flux reduction efficiency. When the diameter ratio of the aerodisk increased, the drag reduction efficiency of the configuration increased first and then decreased, and the heat flux reduction efficiency decreased first and then increased. However, when the total pressure of the opposing jet was high, the diameter ratio of aerodisk had little effect on the drag and heat flux reduction efficiency. When the total pressure ratio of the opposing jet increased, the drag and heat flux reduction efficiency of the configuration was kept at a high level, and the variation range was not obvious. When the total pressure ratio of the lateral jet increased, both the drag and heat flux reduction efficiency of the configuration increased, and the change rate of the drag reduction efficiency increased, while the change rate of the heat flux reduction efficiency decreased. The location of the lateral jet was far away from the blunt body, which increased the drag reduction efficiency and decreased the heat flux reduction efficiency. The drag reduction efficiency of 57.1% and heat flux reduction efficiency of 100.4% can be achieved by properly selecting the aerospike/aerodisk and double jet parameters.

-

Key words:

- supersonic flow /

- aerodisk /

- jet /

- drag reduction /

- heat flux reduction

-

表 1 边界条件

Table 1. Boundary conditions

参数 数值 自由来流 总压/MPa 1.37 总温/K 397 马赫数 3.98 侧向喷流 马赫数 1.00 总温/K 300 表 2 三种网格划分细节

Table 2. Details of the three sets of grids

网格尺寸 第一层边界层高度/10−6 m 网格总数 y+ 粗网格 5.0 299591 0.91 中等网格 1.0 333454 0.18 细网格 0.5 380544 0.07 -

[1] 岳连捷,张旭,张启帆,等. 高马赫数超燃冲压发动机技术研究进展[J]. 力学学报,2022,54(2): 263-288.YUE Lianjie,ZHANG Xu,ZHANG Qifan,et al. Research progress on high-Mach-number scramjet engine technologies[J]. Chinese Journal of Theoretical and Applied Mechanics,2022,54(2): 263-288. (in Chinese) [2] 徐世南,吴催生. 高超声速飞行器热防护结构研究进展[J]. 飞航导弹,2019(4): 48-55. doi: 10.16338/j.issn.1009-1319.20180344XU Shinan,WU Cuisheng. Research progress on thermal protection structure of hypersonic vehicle[J]. Aerodynamic Missile Journal,2019(4): 48-55. (in Chinese) doi: 10.16338/j.issn.1009-1319.20180344 [3] SUN Xiwan,HUANG Wei,OU Min,et al. A survey on numerical simulations of drag and heat reduction mechanism in supersonic/hypersonic flows[J]. Chinese Journal of Aeronautics,2019,32(4): 771-784. doi: 10.1016/j.cja.2018.12.024 [4] HUANG Wei,CHEN Zheng,YAN Li,et al. Drag and heat flux reduction mechanism induced by the spike and its combinations in supersonic flows: a review[J]. Progress in Aerospace Sciences,2019,105: 31-39. doi: 10.1016/j.paerosci.2018.12.001 [5] WANG Zhenguo,SUN Xiwan,HUANG Wei,et al. Experimental investigation on drag and heat flux reduction in supersonic/hypersonic flows: a survey[J]. Acta Astronautica,2016,129: 95-110. doi: 10.1016/j.actaastro.2016.09.004 [6] LU Haibo,LIU Weiqiang. Investigation of thermal protection system by forward-facing cavity and opposing jet combinatorial configuration[J]. Chinese Journal of Aeronautics,2013,26(2): 287-293. doi: 10.1016/j.cja.2013.02.005 [7] HUANG Wei,YAN Li,LIU Jun,et al. Drag and heat reduction mechanism in the combinational opposing jet and acoustic cavity concept for hypersonic vehicles[J]. Aerospace Science and Technology,2015,42: 407-414. doi: 10.1016/j.ast.2015.01.029 [8] HUANG Wei,JIANG Yanping,YAN Li,et al. Heat flux reduction mechanism induced by a combinational opposing jet and cavity concept in supersonic flows[J]. Acta Astronautica,2016,121: 164-171. doi: 10.1016/j.actaastro.2016.01.008 [9] SUN Xiwan,GUO Zhenyun,HUANG Wei,et al. Drag and heat reduction mechanism induced by a combinational novel cavity and counterflowing jet concept in hypersonic flows[J]. Acta Astronautica,2016,126: 109-119. doi: 10.1016/j.actaastro.2016.04.022 [10] SUN Xiwan,GUO Zhenyun,HUANG Wei,et al. A study of performance parameters on drag and heat flux reduction efficiency of combinational novel cavity and opposing jet concept in hypersonic flows[J]. Acta Astronautica,2017,131: 204-225. doi: 10.1016/j.actaastro.2016.11.044 [11] JIANG Zonglin,LIU Yunfeng,HAN Guilai,et al. Experimental demonstration of a new concept of drag reduction and thermal protection for hypersonic vehicles[J]. Acta Mechanica Sinica,2009,25(3): 417-419. doi: 10.1007/s10409-009-0252-8 [12] LIU Yunfeng,JIANG Zonglin. Concept of non-ablative thermal protection system for hypersonic vehicles[J]. AIAA Journal,2013,51(3): 584-590. doi: 10.2514/1.J051875 [13] BARZEGAR G M,IMANI M,GANJI D D. Heat reduction using conterflowing jet for a nose cone with aerodisk in hypersonic flow[J]. Aerospace Science and Technology,2014,39: 652-665. doi: 10.1016/j.ast.2014.07.005 [14] HUANG Jie,YAO Weixing. Multi-objective design optimization of hypersonic spiked blunt body with opposing jet[J]. Journal of Spacecraft and Rockets,2019,56(5): 1553-1563. doi: 10.2514/1.A34459 [15] HUANG Wei,LIU Jun,XIA Zhixun. Drag reduction mechanism induced by a combinational opposing jet and spike concept in supersonic flows[J]. Acta Astronautica,2015,115: 24-31. doi: 10.1016/j.actaastro.2015.04.025 [16] EGHLIMA Z,MANSOUR K,FARDIPOUR K. Heat transfer reduction using combination of spike and counterflow jet on blunt body at high Mach number flow[J]. Acta Astronautica,2018,143: 92-104. doi: 10.1016/j.actaastro.2017.11.012 [17] QU Feng,SUN Di,BAI Junqiang,et al. Numerical investigation of blunt body’s heating load reduction with combination of spike and opposing jet[J]. International Journal of Heat and Mass Transfer,2018,127: 7-15. doi: 10.1016/j.ijheatmasstransfer.2018.06.154 [18] MORADI R,MOSAVAT M,BARZEGAR GERDROODBARY M,et al. The influence of coolant jet direction on heat reduction on the nose cone with Aerodome at supersonic flow[J]. Acta Astronautica,2018,151: 487-493. doi: 10.1016/j.actaastro.2018.06.026 [19] OU Min,YAN Li,HUANG Wei,et al. Detailed parametric investigations on drag and heat flux reduction induced by a combinational spike and opposing jet concept in hypersonic flows[J]. International Journal of Heat and Mass Transfer,2018,126: 10-31. doi: 10.1016/j.ijheatmasstransfer.2018.05.013 [20] OU Min,YAN Li,HUANG Wei,et al. Design exploration of combinational spike and opposing jet concept in hypersonic flows based on CFD calculation and surrogate model[J]. Acta Astronautica,2019,155: 287-301. doi: 10.1016/j.actaastro.2018.12.012 [21] HUANG Jie,YAO Weixing. A novel non-ablative thermal protection system with combined spike and opposing jet concept[J]. Acta Astronautica,2019,159: 41-48. doi: 10.1016/j.actaastro.2019.02.005 [22] MENG Yushan,YAN Li,HUANG Wei,et al. Fluid-thermal coupled investigation on the combinational spike and opposing/lateral jet in hypersonic flows[J]. Acta Astronautica,2021,185: 264-282. doi: 10.1016/j.actaastro.2021.05.022 [23] ZHU Liang,LI Yingkun,GONG Lunkun,et al. Coupled investigation on drag reduction and thermal protection mechanism induced by a novel combinational spike and multi-jet strategy in hypersonic flows[J]. International Journal of Heat and Mass Transfer,2019,131: 944-964. doi: 10.1016/j.ijheatmasstransfer.2018.11.119 [24] 黄杰,姚卫星. 高超声速飞行器激波控制减阻技术[J]. 宇航学报,2020,41(10): 1280-1287. doi: 10.3873/j.issn.1000-1328.2020.10.005HUANG Jie,YAO Weixing. Drag reduction of hypersonic vehicles by shock control[J]. Journal of Astronautics,2020,41(10): 1280-1287. (in Chinese) doi: 10.3873/j.issn.1000-1328.2020.10.005 [25] KALIMUTHU R, RATHAKRISHNAN E. Aerospike for drag reduction in hypersonic flow[R]. Hartford, CT, US: 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, 2008. [26] HAYASHI K,ASO S,TANI Y. Experimental study on thermal protection system by opposing jet in supersonic flow[J]. Journal of Spacecraft and Rockets,2006,43(1): 233-236. doi: 10.2514/1.15332 [27] HUANG Wei,LI Langquan,CHEN Xiaoqian et al. Parametric effect on the flow and mixing properties of transverse gaseous injection flow fields with streamwise slot: a numerical study[J]. International Journal of Hydrogen Energy,2017,42(2): 1252-1263. doi: 10.1016/j.ijhydene.2016.09.028 [28] MOTOYAMA N, MIHARA K, MIYAJIMA R et al. Thermal protection and drag reduction with use of spike in hypersonic flow[R]. Kyoto: 10th AIAA/NAL-NASDA-ISAS International Space Planes and Hypersonic Systems and Technologies Conference, 2001. [29] HAYASHI K, ASO S. Effect of pressure ratio on aerodynamic heating reduction due to opposing jet[R]. Orlando, US: 33rd AIAA Fluid Dynamics Conference and Exhibit, 2003. [30] NAKAMURA T, KANEKO M, MENSHOV I, et al. Numerical simulation on aerodynamic interaction between a side jet and flow around a blunt body in hypersonic flow[R]. Reno, Nevada, US : 41st Aerospace Sciences Meeting and Exhibit, 2003. -

下载:

下载: