Effects of baffle on the acoustic mode characteristics of liquid rocket engine combustion chambers

-

摘要:

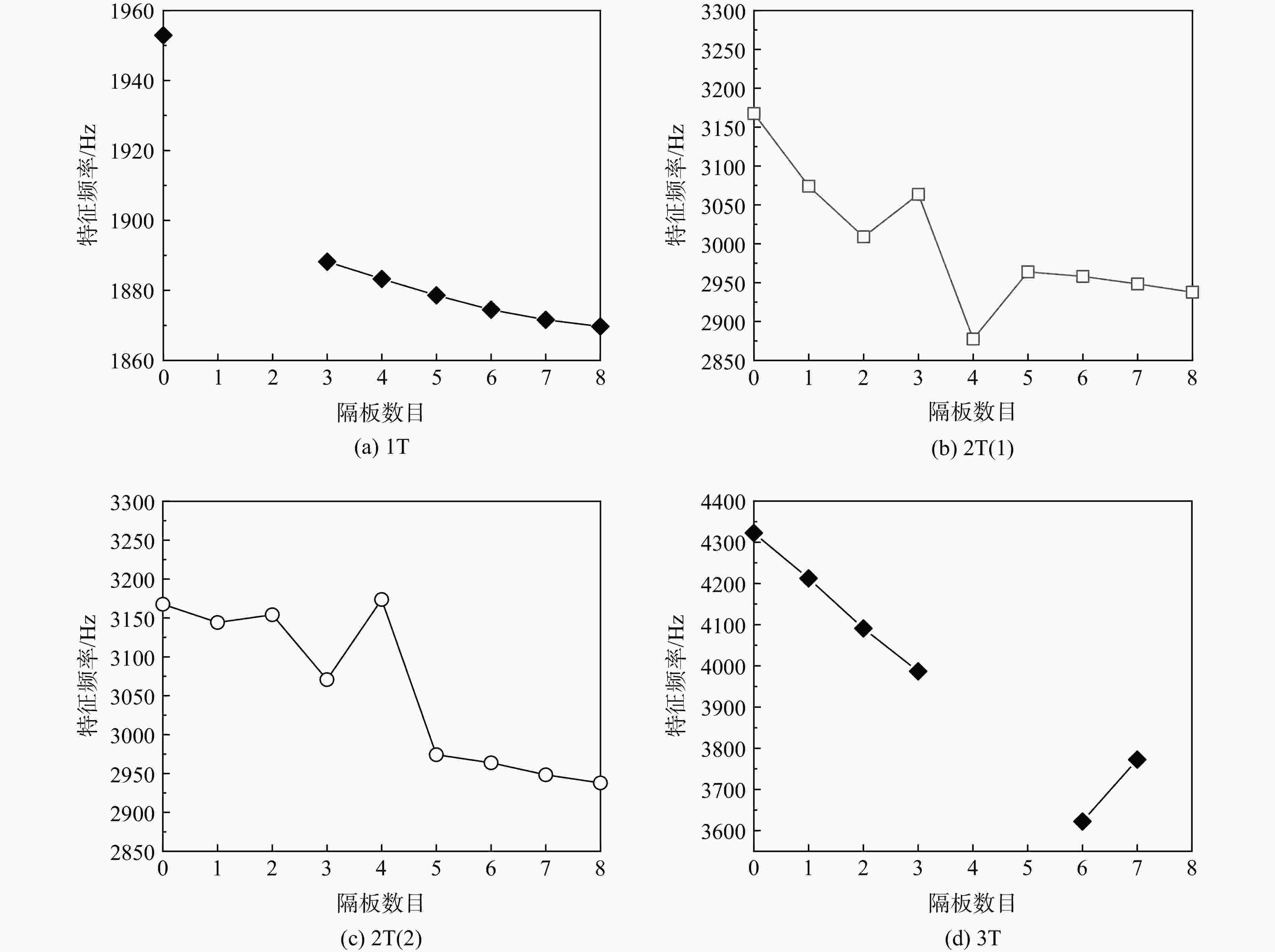

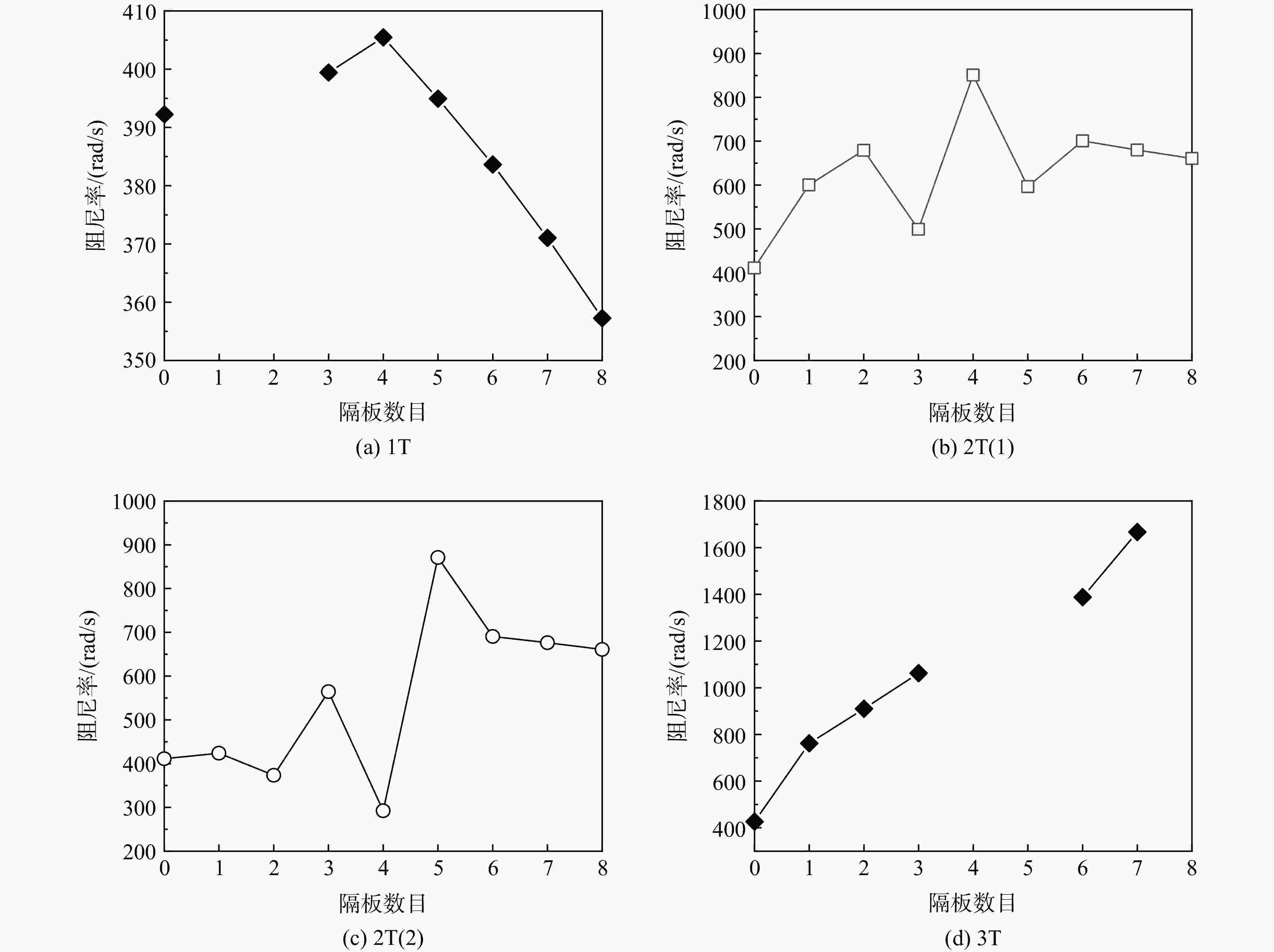

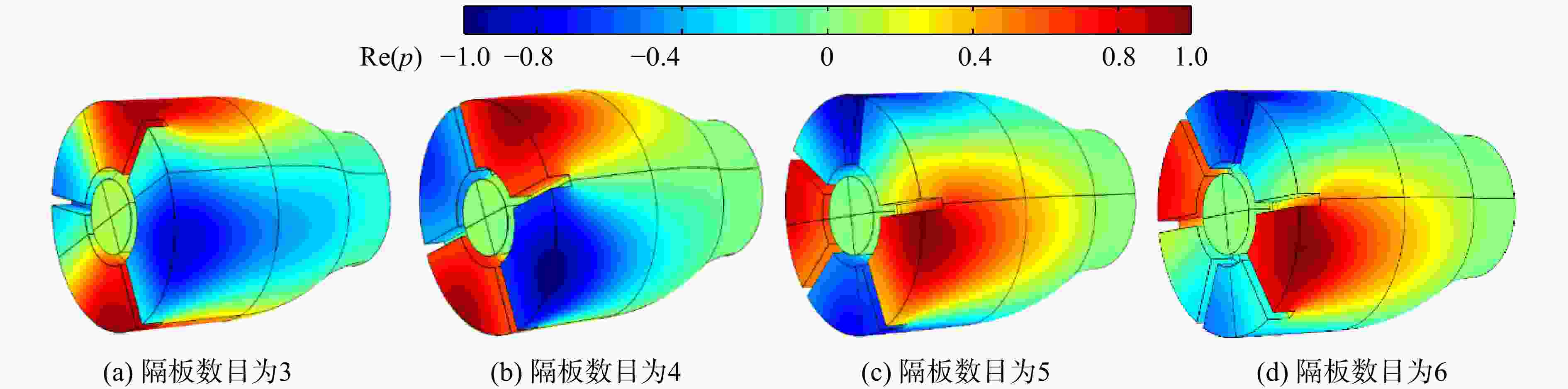

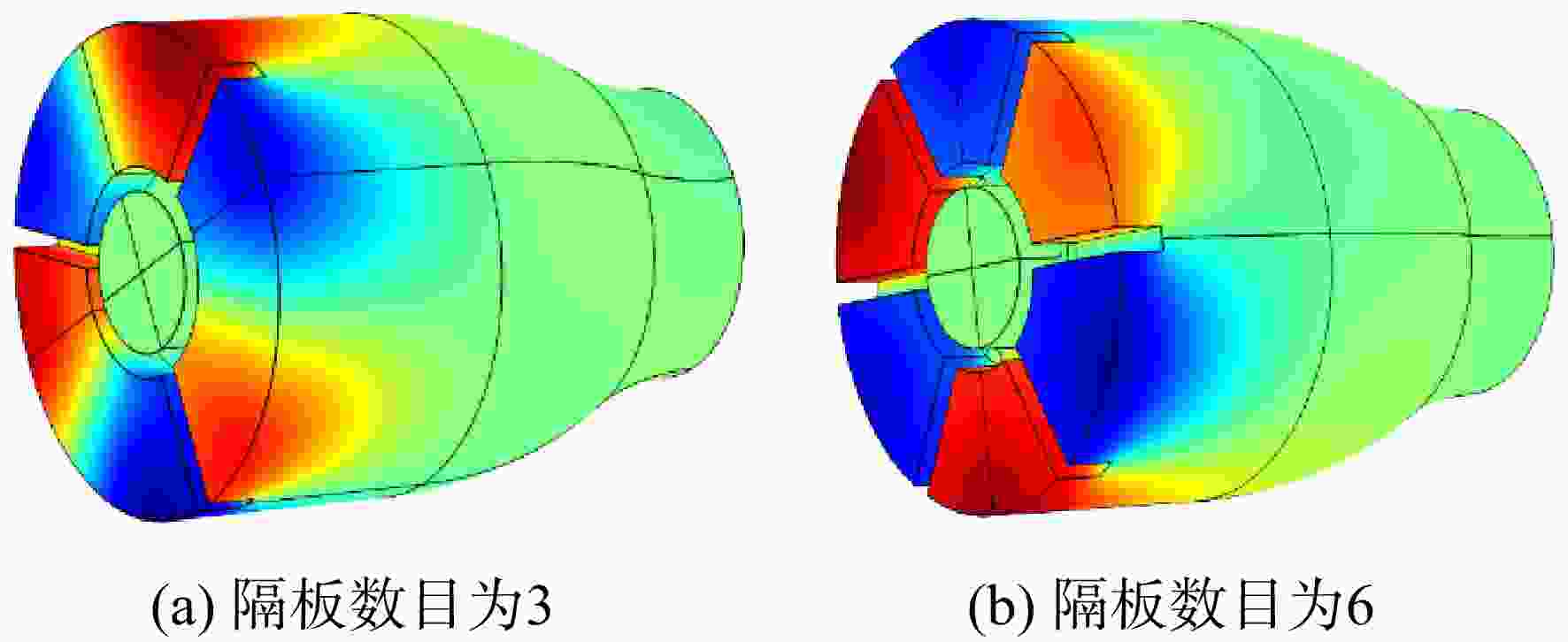

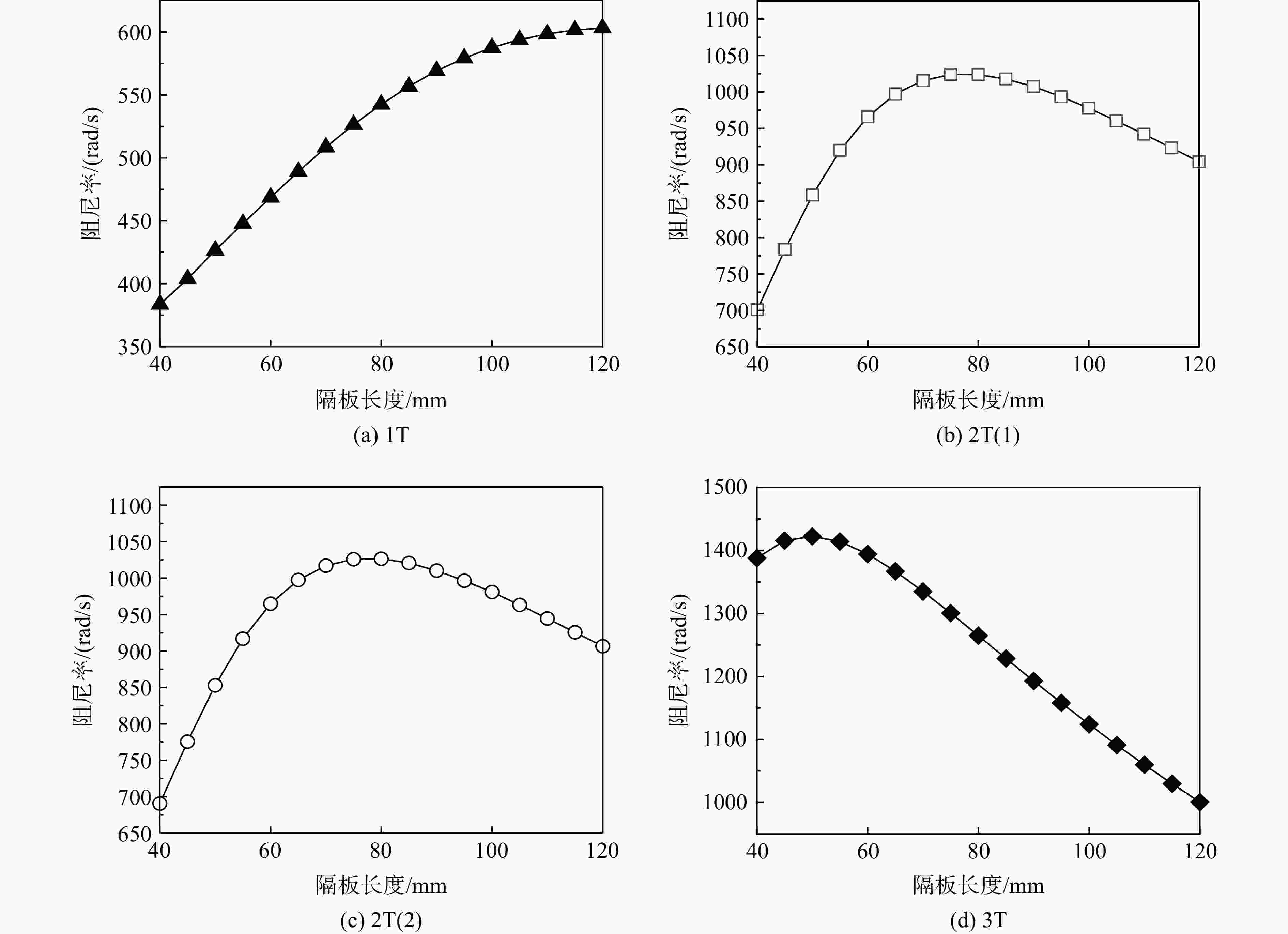

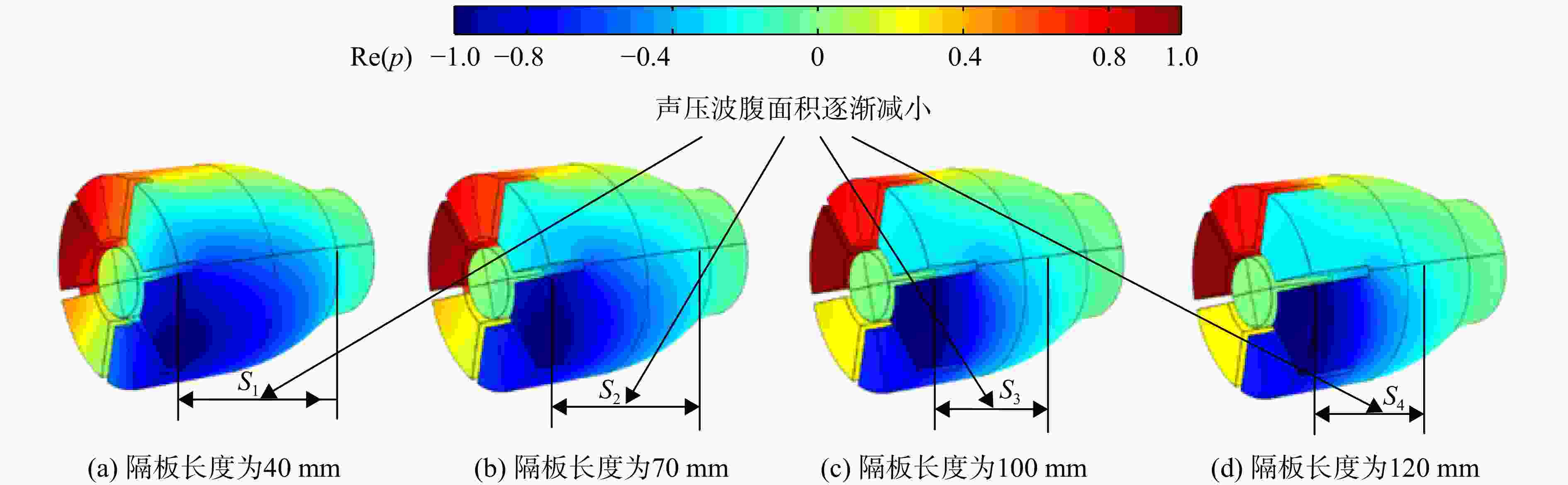

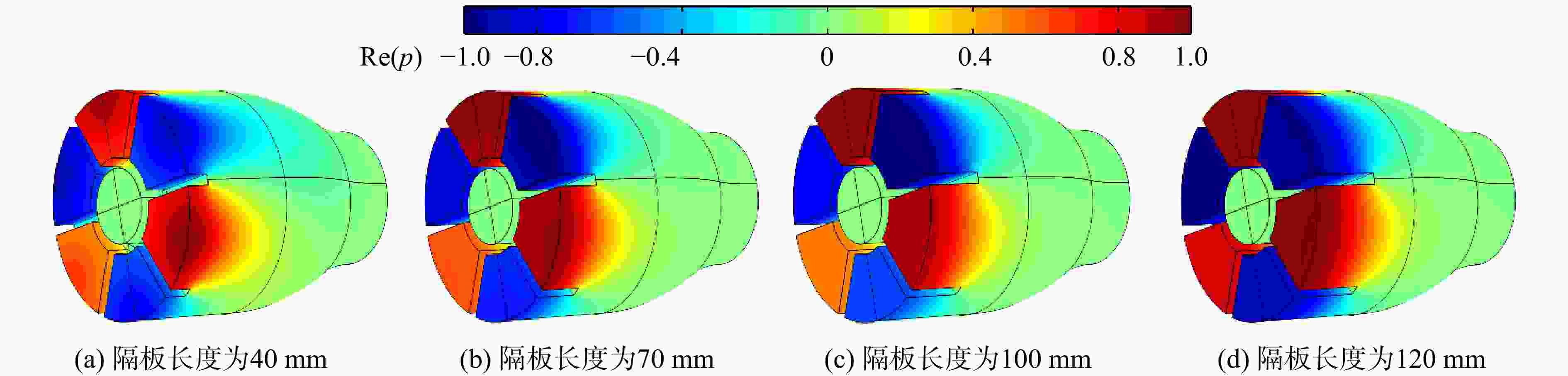

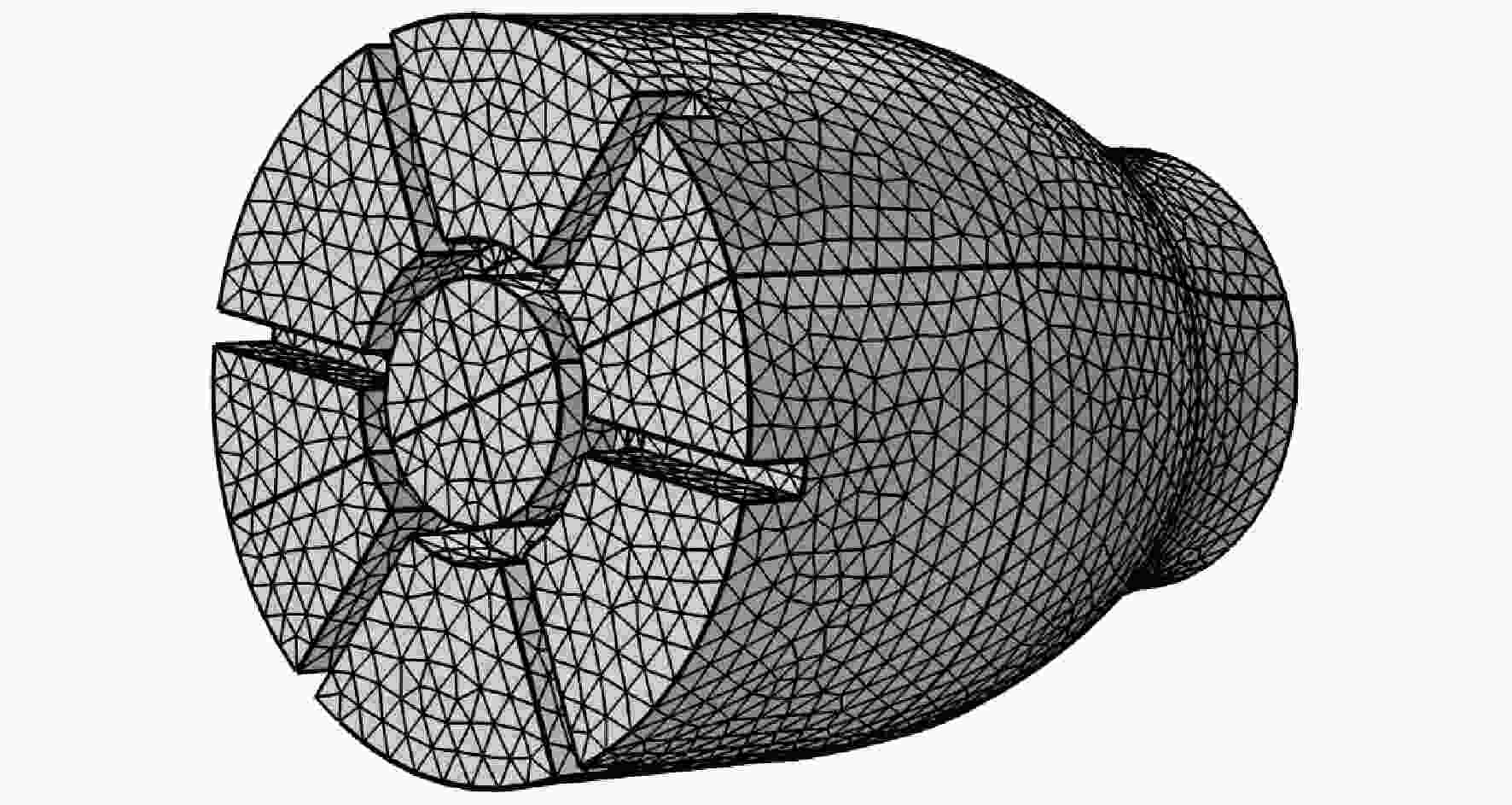

通过采用声学有限元法,求解带有平均流源项的亥姆霍兹方程,进而在考虑燃烧室高温、平均流场因素基础上分析了隔板结构参数对液体火箭发动机燃烧室声学模态特性影响规律。结果表明:增加隔板数目或长度,均会降低燃烧室1阶切向模态的特征频率;存在最佳隔板数目4,使燃烧室1阶切向模态阻尼率最大;而隔板长度越长,1阶切向模态声压波腹的分布面积越小,阻尼率越大;隔板型式对燃烧室1阶切向模态特性影响较小。

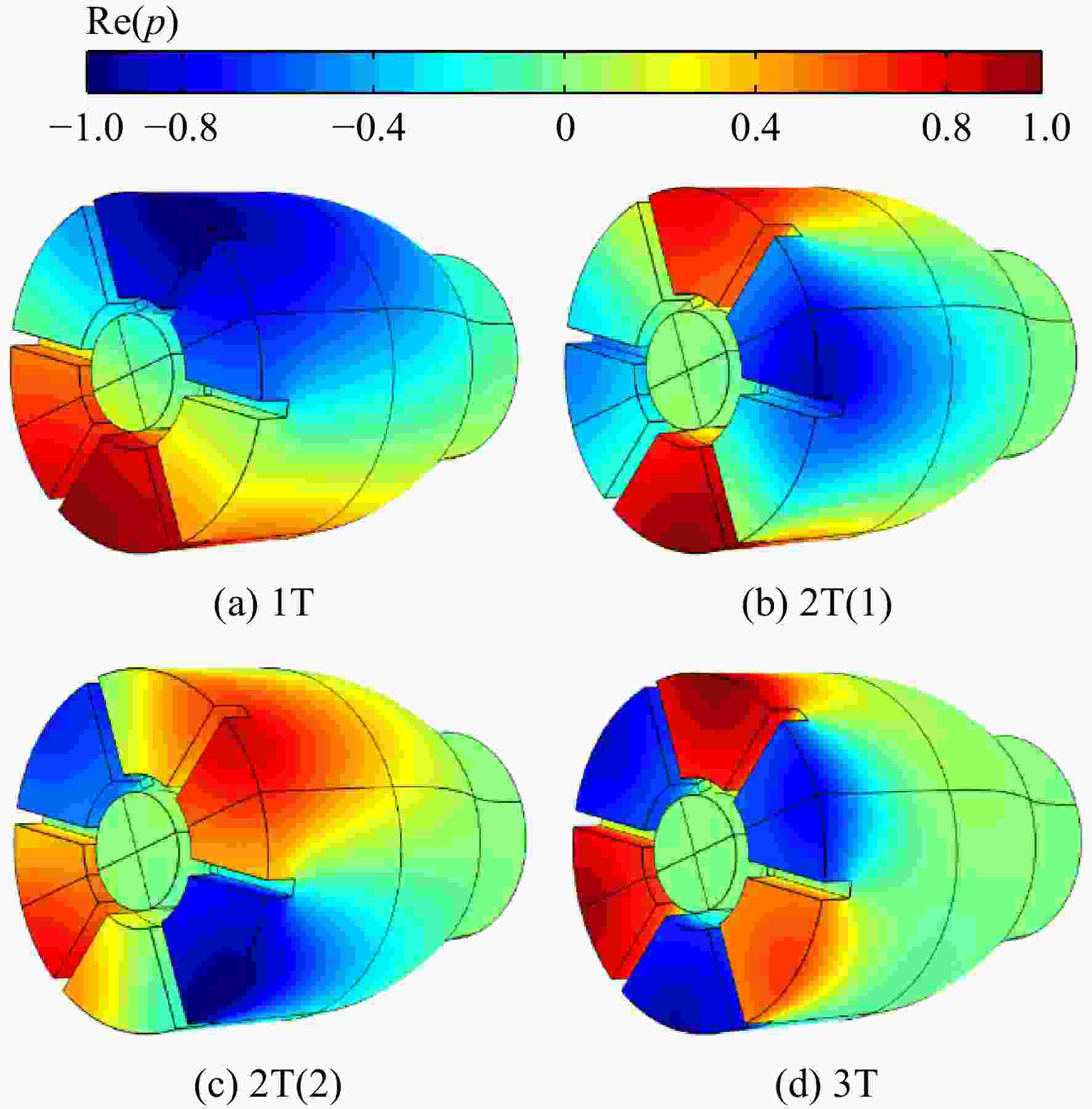

Abstract:The Helmholtz equation with the mean flow source term was solved by the acoustic finite element method. Then, on the basis of considering the high temperature and average flow field of the combustion chamber, the influence of baffle structure parameters on the acoustic mode characteristics of the liquid rocket engine combustion chamber was analyzed. The results showed that: increasing the number or length of baffle reduced the eigenfrequency of the first-order tangential mode of the combustion chamber; when the number of baffle was 4, the damping rate of the first-order tangential mode of the combustion chamber was greatest; the longer length of the baffle indicated the smaller distribution area of the first-order tangential mode acoustic pressure and the larger damping rate; the type of baffle had an insignificant effect on the first-order tangential mode characteristics of the combustion chamber.

-

Key words:

- baffle /

- liquid rocket engine /

- combustion chamber /

- acoustic mode characteristics /

- Helmholtz equation

-

表 1 RD-170发动机燃烧室几何结构参数[11]

Table 1. Geometrical parameters of the RD-170engine combustion chamber[11]

mm 参数 数值 燃烧室直径 380 燃烧室圆柱段长度 490 喉部直径 235.6 隔板高度 40 隔板厚度 18.7 隔板轮毂直径 143 喷嘴直径 17.5 表 2 RD-170发动机燃烧室平均流场参数[12]

Table 2. Average flow field parameters in the RD-170 engine combustion chamber[12]

参数 燃烧室 喷嘴 压力/MPa 24.55 27.0 温度/K 3676.1 687.7 比热比 1.2 1.33 摩尔质量/(g/mol) 24.21 31.91 密度/(kg/m3) 19.45 150.7 声速/(m/s) 1231.9 487.5 速度/(m/s) 326.9 93.4 表 3 RD-170发动机燃烧室主要声学模态的特征频率及阻尼率

Table 3. Eigenfrequencies and damping rates of the main acoustic modes of the RD-170 engine combustion chamber

模态 频率/Hz 阻尼率/(rad/s) 1L 1405.1 602.4 1T 1874.5 383.6 1L1T 2614.2 616.1 2T(1) 2958 700.8 2T(2) 2963.7 690.6 3T 3622.5 1387.8 表 4 不同隔板型式下燃烧室前3阶切向模态的特征频率

Table 4. Eigenfrequencies of the first three orders of tangential modes of the combustion chamber with different type of baffles

模态 隔板1 隔板2 隔板3 特征频率/Hz 特征频率/Hz 变化幅度/% 特征频率/Hz 变化幅度/% 1T 1874.5 1860.5 −0.8 1887.3 0.7 2T(1) 2958 3075.2 4.0 3118 5.4 2T(2) 2963.7 3083.7 4.0 3125 5.4 3T 3622.5 3613.5 −0.2 3845.1 6.1 表 5 不同隔板型式下燃烧室前3阶切向模态的阻尼率

Table 5. Damping rates of the first three orders of tangential modes of the combustion chamber with different type of baffles

模态 隔板1 隔板2 隔板3 阻尼率/(rad/s) 阻尼率/(rad/s) 变化幅度/% 阻尼率/(rad/s) 变化幅度/% 1T 383.6 403.6 5.2 400.0 4.3 2T(1) 700.8 909.6 30.8 760.6 8.5 2T(2) 690.6 918.7 33 753.1 9.1 3T 1387.8 1400.3 0.9 1186.4 −14.5 -

[1] YANG V, ANDERSON W E. 液体火箭发动机燃烧不稳定性[M]. 张宝炯, 洪鑫, 陈杰, 译. 北京: 科学出版社, 2001. [2] 王振国. 液体火箭发动机燃烧过程建模与数值仿真[M]. 北京: 国防工业出版社, 2012. [3] 付虓,郭志辉,杨甫江. 模型预混燃烧室线性稳定性分析[J]. 航空动力学报,2015,30(5): 1099-1105.FU Xiao,GUO Zhihui,YANG Fujiang. Linear stability analysis of modal premixed combustor[J]. Journal of Aerospace Power,2015,30(5): 1099-1105. (in Chinese) [4] 曹晨,谭永华,陈建华,等. 大直径液氧煤油发动机燃烧室结构和隔板型式对声学特性的影响[J]. 推进技术,2021,42(7): 1581-1592.CAO Chen,TAN Yonghua,CHEN Jianhua,et al. Effects of structural parameters and baffle patterns on acoustic characteristics of combustion chamber for large diameter LOX/kerosene engine[J]. Journal of Propulsion Technology,2021,42(7): 1581-1592. (in Chinese) [5] 刘旺,李敬轩,杨立军. 隔板喷嘴对燃烧室切向声学模态作用研究[J]. 推进技术,2019,40(6): 1348-1353.LIU Wang,LI Jingxuan,YANG Lijun. Effects of baffled injectors on transverse acoustic mode in a combustor[J]. Journal of Propulsion Technology,2019,40(6): 1348-1353. (in Chinese) [6] 曹晨,陈建华,赵剑,等. 大直径液氧煤油发动机燃烧室抗脉动隔板技术[J]. 推进技术,2019,40(2): 331-338.CAO Chen,CHEN Jianhua,ZHAO Jian,et al. Investigation on anti-pulsating baffle of large diameter LOX/kerosene rocket engine combustor[J]. Journal of Propulsion Technology,2019,40(2): 331-338. (in Chinese) [7] FARSHCHI M,MEHRJOU H,SALEHI M M. Acoustic characteristics of a rocket combustion chamber: radial baffle effects[J]. Applied Acoustics,2009,70(8): 1051-1060. doi: 10.1016/j.apacoust.2009.03.001 [8] MILANO D, QUINLAN J, KIRKPATRICK A, et al. Computation of acoustic oscillations and combustion stability in a rocket engine with combined hub/blade baffles[R]. AIAA 2009-4866, 2009. [9] 李丹琳,田原,孙纪国. 隔板对燃烧室声学特性的影响[J]. 航空动力学报,2012,27(3): 715-720.LI Danlin,TIAN Yuan,SUN Jiguo. Effects of baffle on combustion acoustic characteristics of liquid rocket engine[J]. Journal of Aerospace Power,2012,27(3): 715-720. (in Chinese) [10] 马列波,聂万胜. 隔板片数量对液体火箭发动机燃烧不稳定性的影响[J]. 导弹与航天运载技术,2020(6): 27-32.MA Liebo,NIE Wansheng. The influence of baffle number to the combustion instability of liquid rocket engine[J]. Missiles and Space Vehicles,2020(6): 27-32. (in Chinese) [11] DRANOVSKY M L, YANG V, CULICK F, et al. Combustion instabilities in liquid rocket engines testing and development practices in Russia[M]. Houston, US: American Institute of Aeronautics and Astronautics, 2007. [12] LIOI C,KU D,YANG V. Linear acoustic analysis of main combustion chamber of an oxidizer-rich staged combustion engine[J]. Journal of Propulsion and Power,2018,34(6): 1505-1518. doi: 10.2514/1.B36878 [13] 王昆,房爱兵,邢双喜,等. 基于火焰面波动机理的热释放模型理论推导及其模态分析[J]. 航空动力学报,2016,31(6): 1309-1317.WANG Kun,FANG Aibing,XING Shuangxi,et al. Heat release model related to flame variation mechanism and modal analysis[J]. Journal of Aerospace Power,2016,31(6): 1309-1317. (in Chinese) [14] HEILMANN G,HIRSCH C,SATTELMAYER T. Energetically consistent computation of combustor stability with a model consisting of a helmholtz-fem-domain and a low-order network[J]. Journal of Engineering for Gas Turbines Power,2021,143(5): 1-11. [15] SCHULZE M. Linear stability assessment of cryogenic rocket engines[D]. Munich, German: Technical University of Munich, 2016. [16] KIM S K,CHOI H S,KIM H J,et al. Finite element analysis for acoustic characteristics of combustion stabilization devices[J]. Aerospace Science and Technology,2015,42: 229-240. doi: 10.1016/j.ast.2015.01.024 [17] KIM H J,SEO S,LEE K J,et al. Stability rating tests for the length-optimization of baffles in a liquid propellant combustion chamber using a pulse Gun[J]. Aerospace Science and Technology,2008,12(3): 214-222. doi: 10.1016/j.ast.2007.06.003 [18] YOU Danning,KU D D,YANG V. Acoustic waves in baffled combustion chamber with radial and circumferential blades[J]. Journal of Propulsion and Power,2013,29(6): 1453-1467. doi: 10.2514/1.B34923 [19] 郭康康. 液氧/煤油火箭发动机高频燃烧不稳定性数值研究[D]. 北京: 航天工程大学, 2018.GUO Kangkang. Research on high frequency combustion instability in LOX/ kerosene rocket engine[D]. Beijing: Space Engineering University, 2018. (in Chinese) -

下载:

下载: