Prejudgment method of tenon structure in aero-engine preliminary design stage

-

摘要:

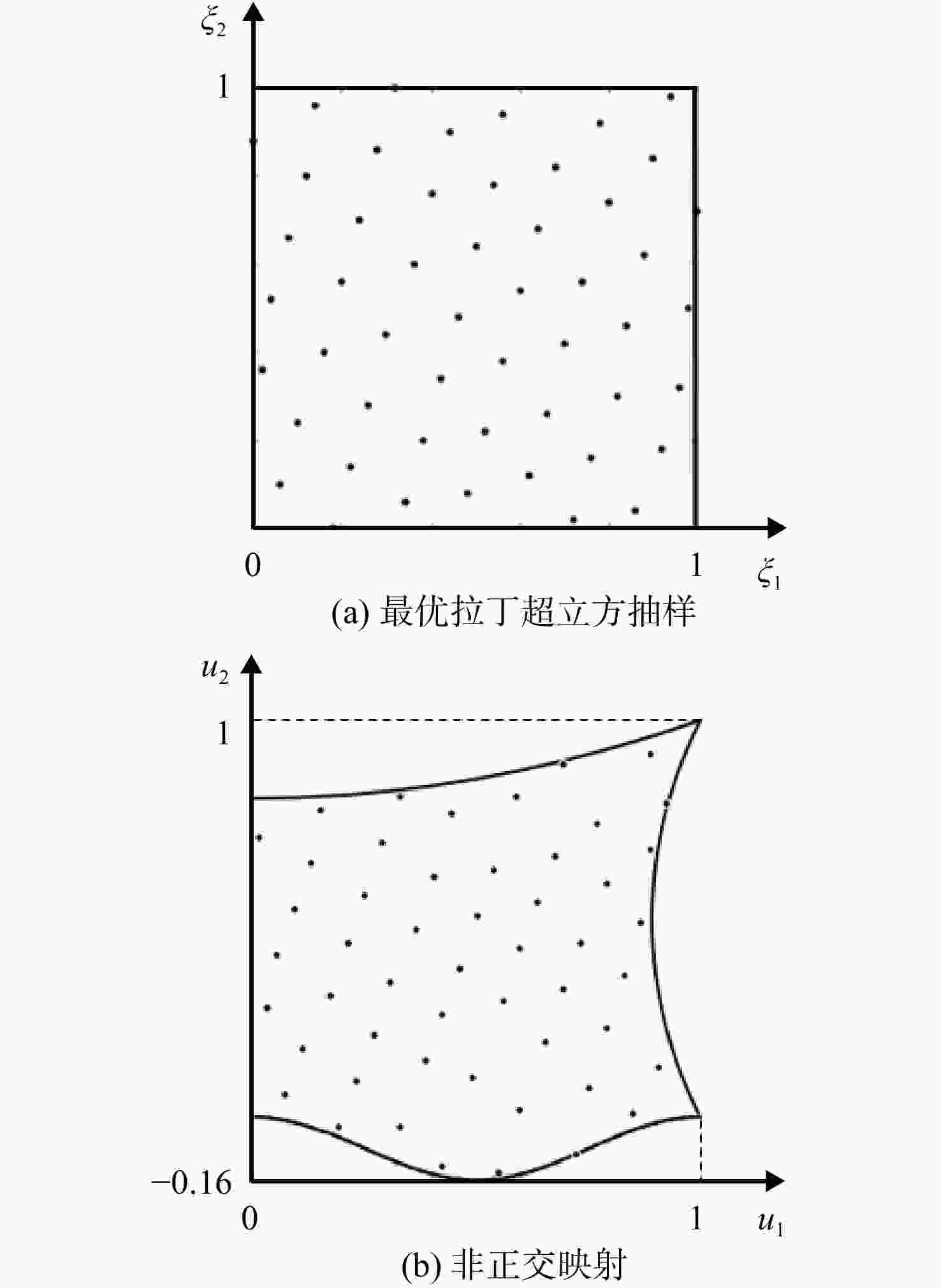

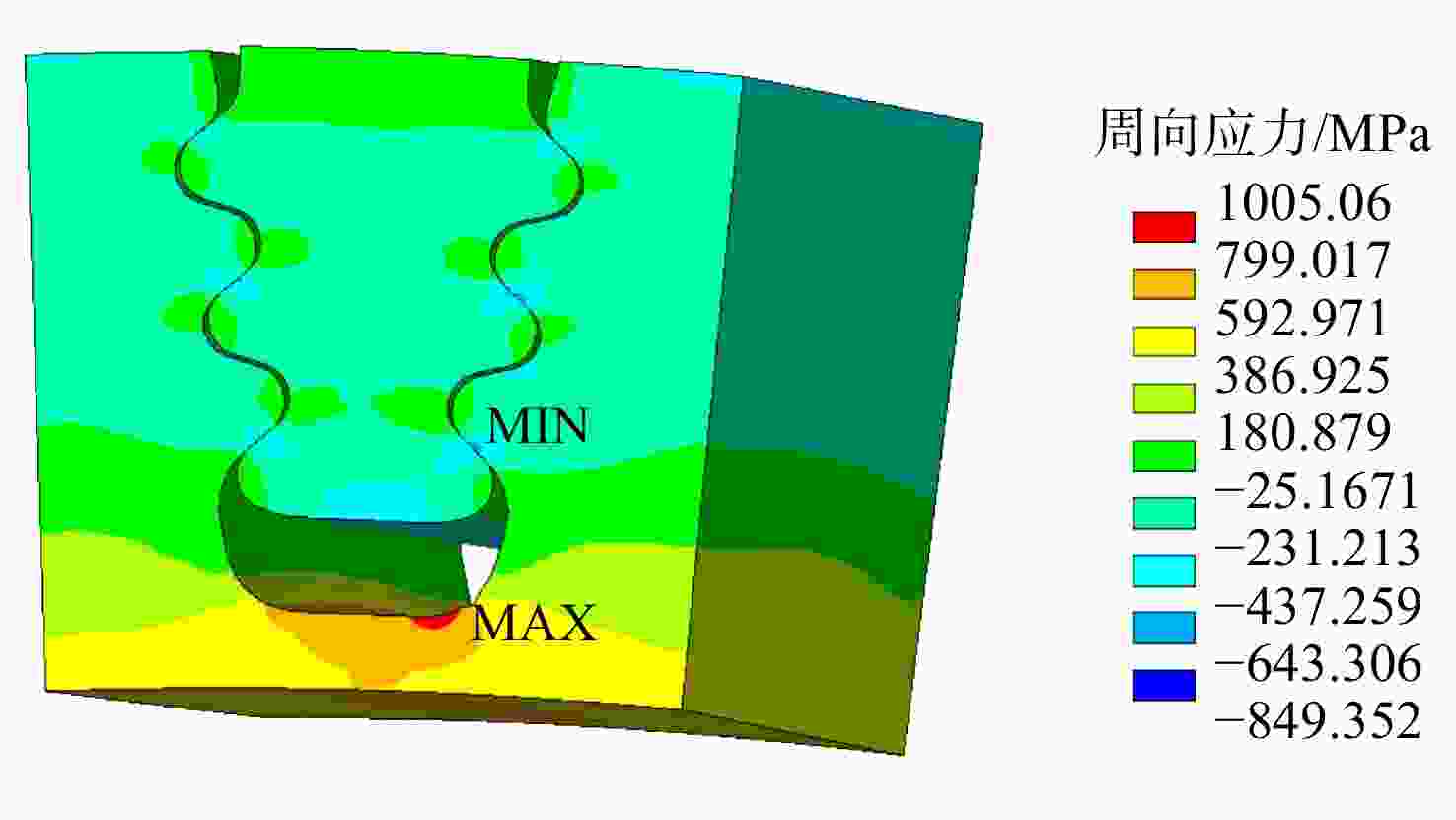

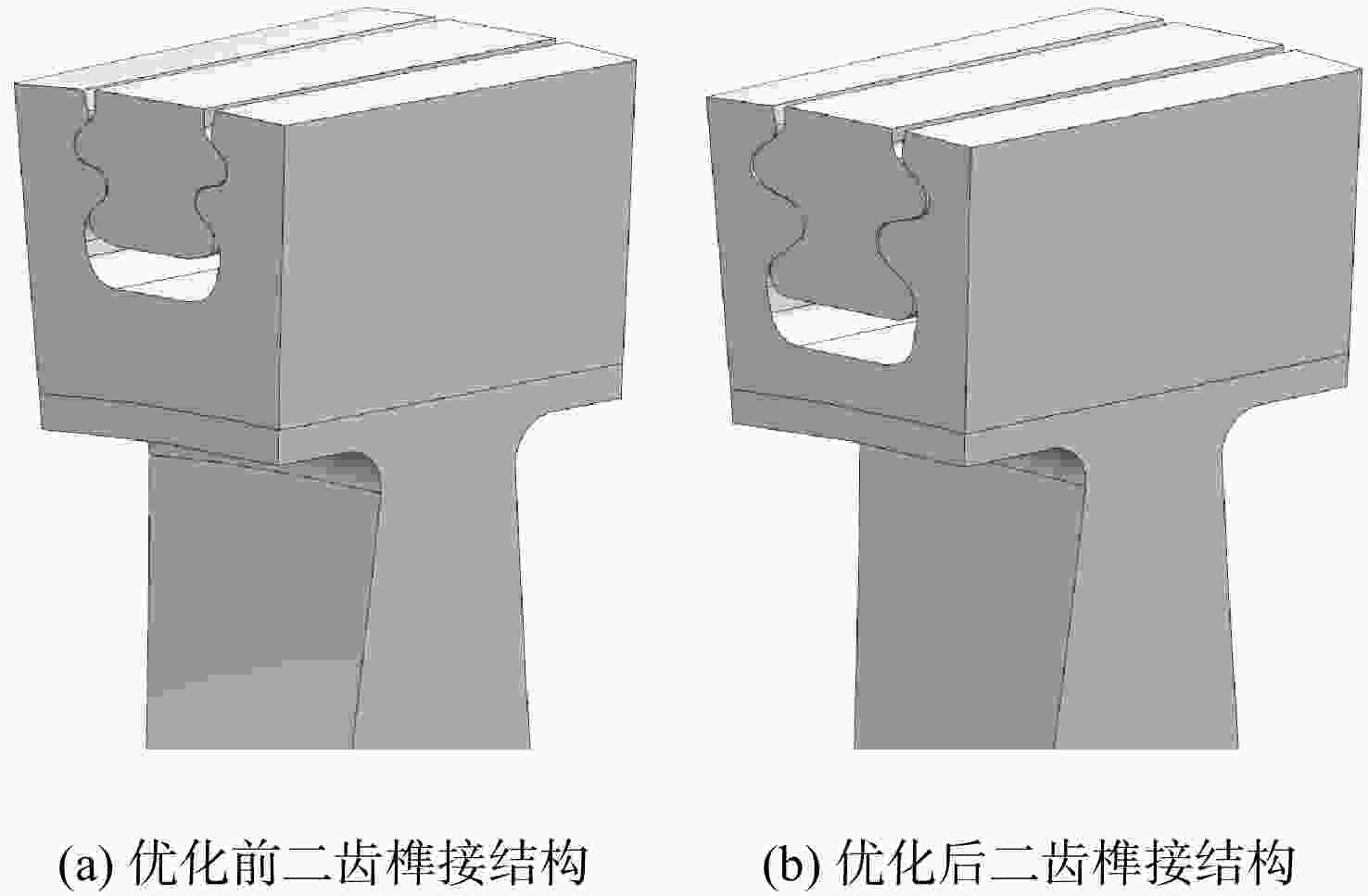

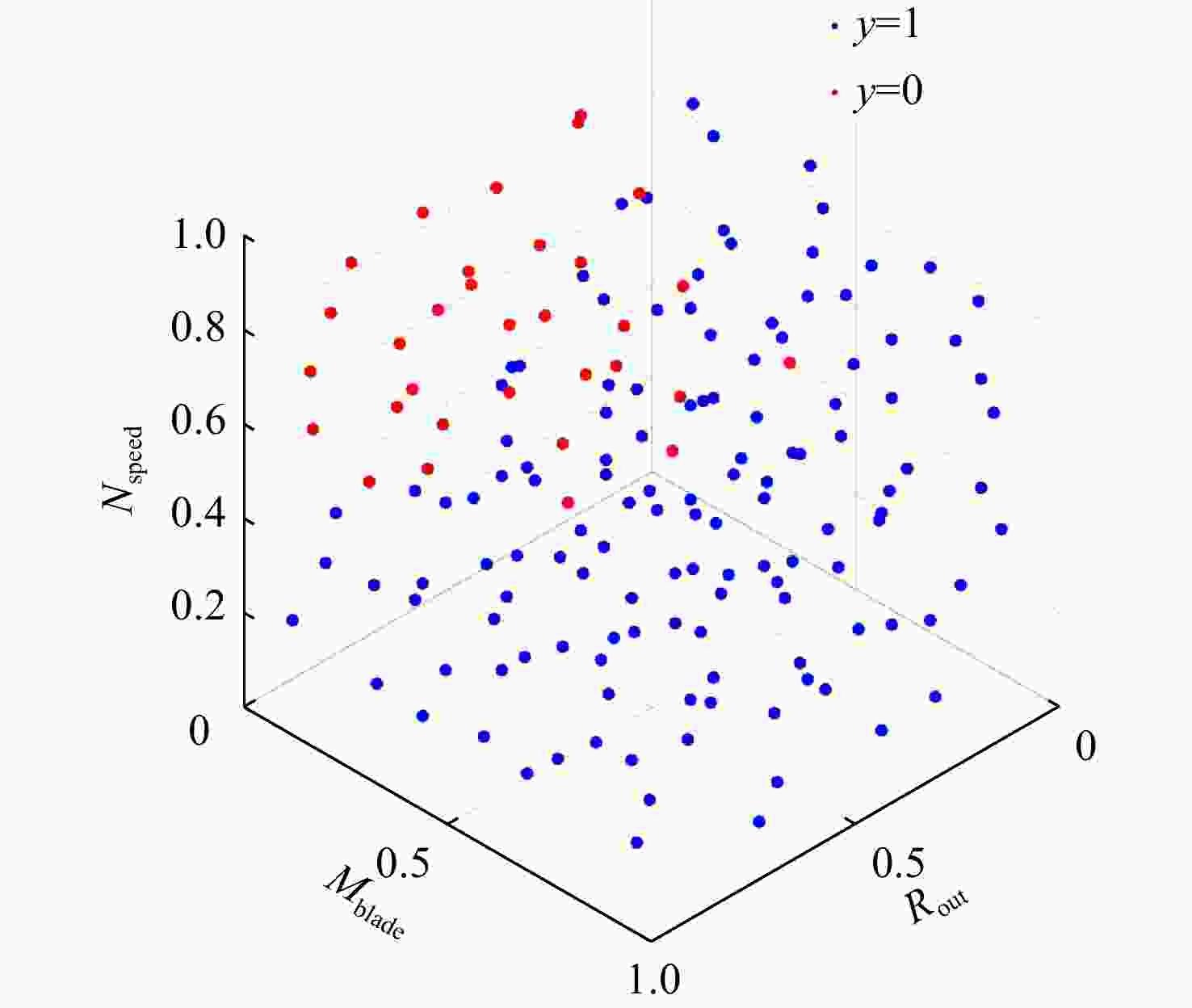

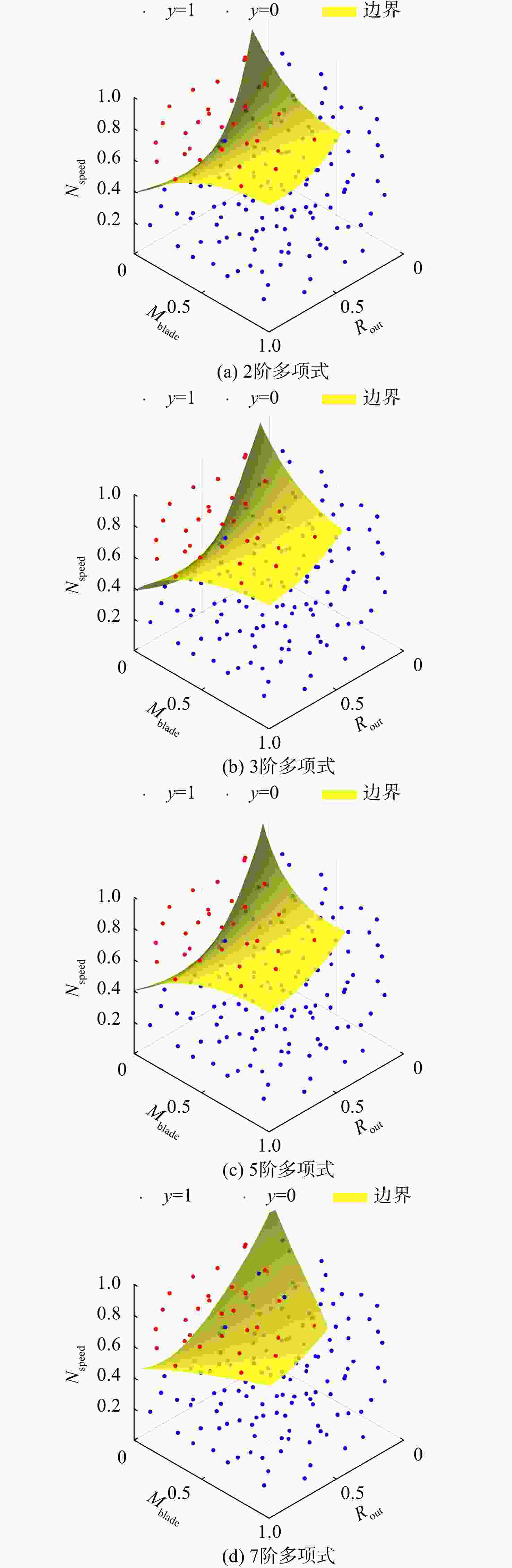

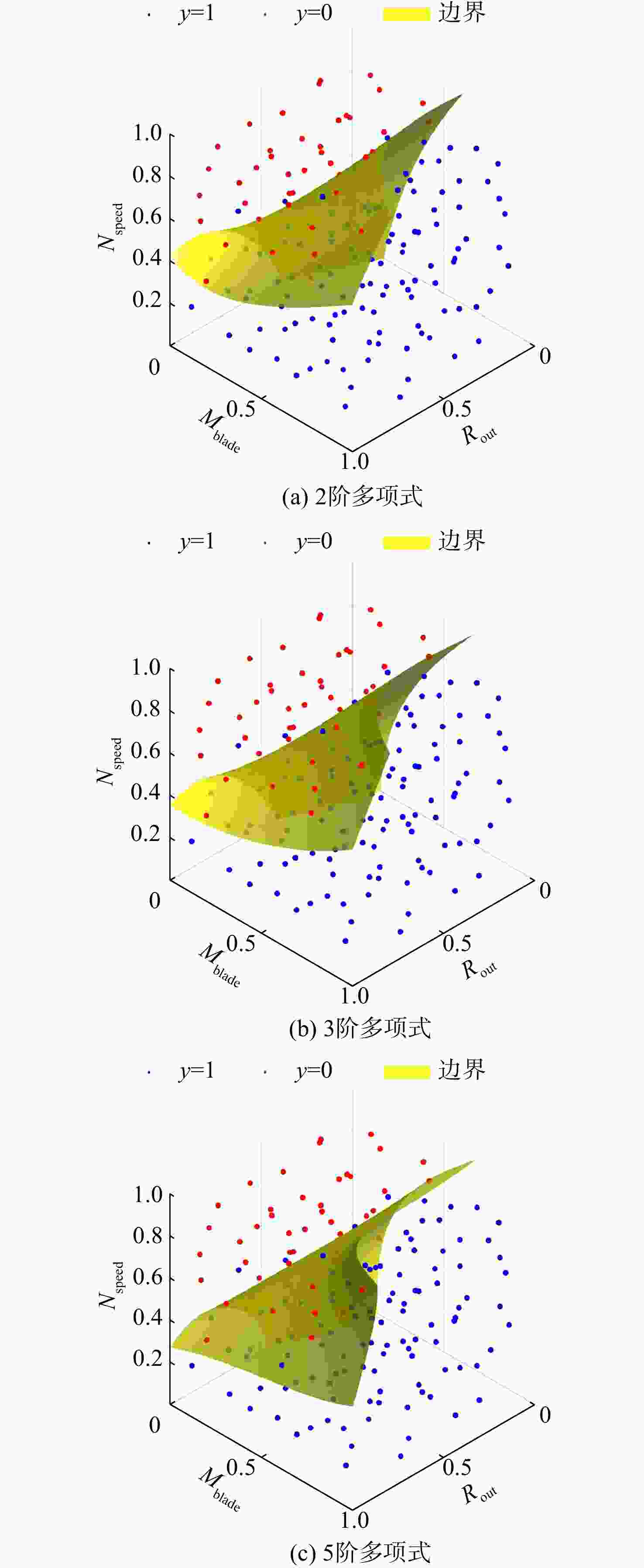

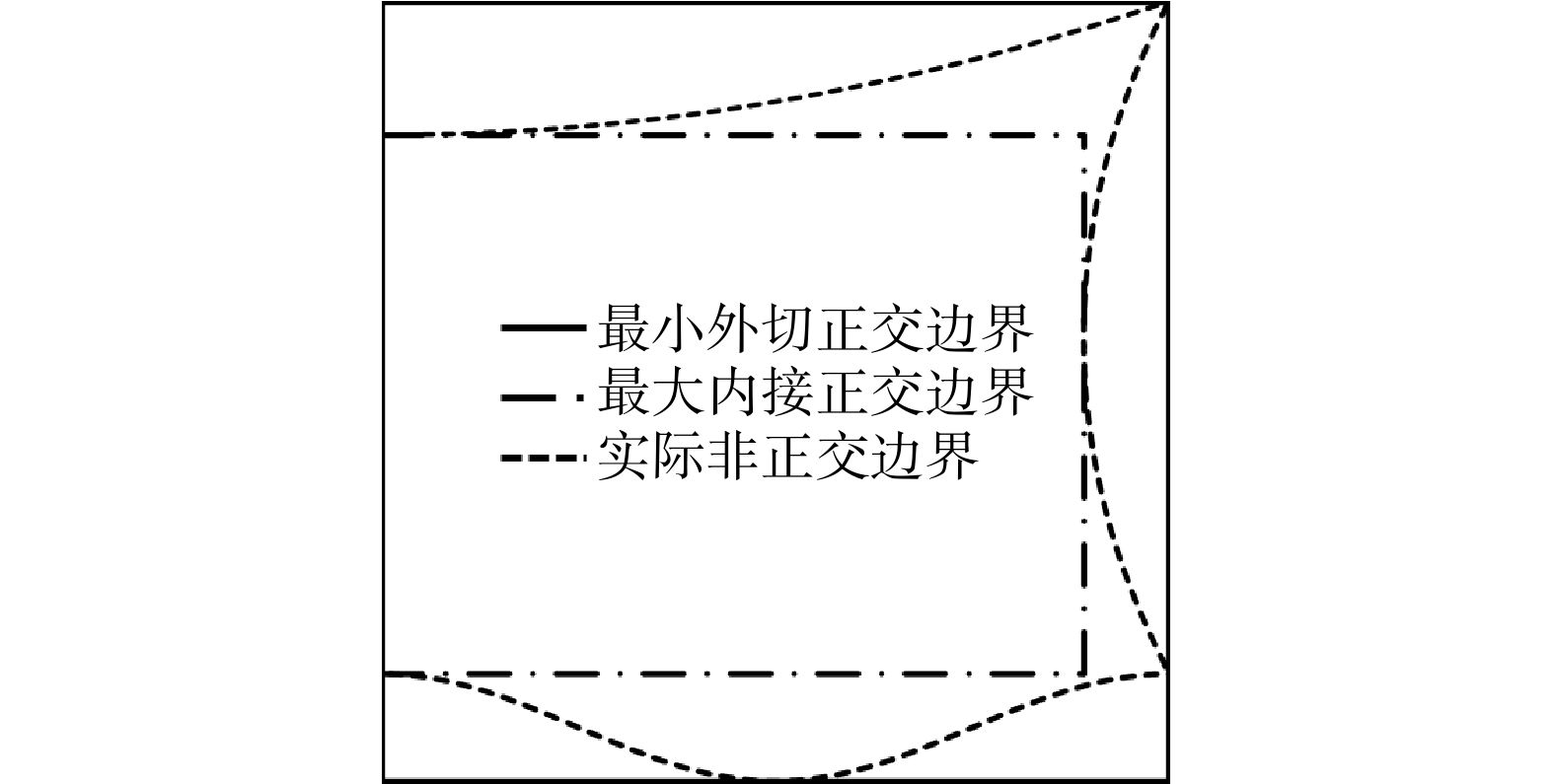

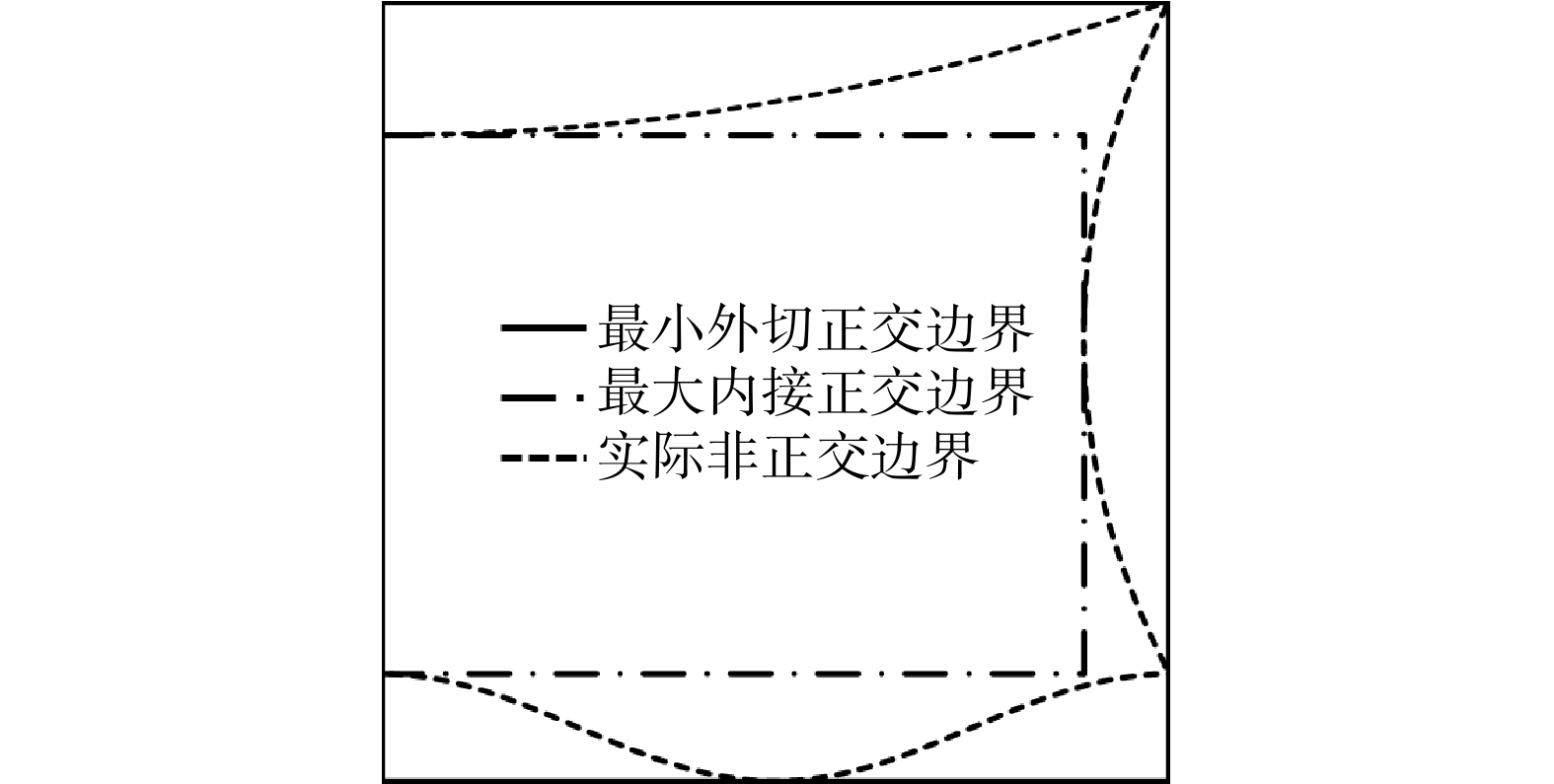

为适应自约束参数化建模方法所导致的非正交参数取值范围,提出了将传统正交设计空间的抽样点映射到非正交空间的映射方法。构建了基于机器学习逻辑回归的可行域边界识别方法,对样本空间响应是否满足相关准则进行判断。将此方法应用于某高压涡轮二齿和三齿榫接结构,发现某发动机初步设计方案会导致在详细设计阶段无法获得满足设计要求的榫接结构,需将榫接结构参数前置至初步设计阶段,与上级参数共同设计,防止其在详细设计阶段成为设计难点。通过边界识别方法发现,转速降低为15 575 r/min或轮盘外径降低为303 mm时可以设计出二齿榫接结构;转速降低为15 584 r/min或轮盘外径降低为301 mm时可以设计出三齿榫接结构。该方法可以作为发动机初步设计阶段各学科之间的一个迭代反馈信息,在发动机其他细节结构设计上具有推广性。

Abstract:In order to adapt to the range of non-orthogonal parameters caused by the self-constrained parametric modeling method, a mapping method was proposed to map the sampling points of the traditional orthogonal design space to the non-orthogonal space. A feasible domain boundary identification method based on machine learning logistic regression was constructed to judge the compliance of the sample space response with relevant criteria. This method was applied to a high pressure turbine two-/ three-tooth tenon structure, finding that an engine preliminary design scheme may fail to meet the design requirements in the detailed design phase of tenon structure, and tenon structure parameters may be advanced to the preliminary design stage, together with the superior parameter design, to prevent the design difficulties in the detailed design stage. Through the boundary identification method, it was found that when the speed was reduced to 15 575 r /min or the outer diameter of the wheel was reduced to 303 mm, the two-tooth tenon structure can be designed. When the speed was reduced to 15 584 r /min or the outer diameter of the wheel was reduced to 301 mm, the three-tooth tenon structure can be designed. This method can be used as an iterative feedback information among various disciplines in the initial engine design stage. The proposed method can be generalized to other details of the engine structure design.

-

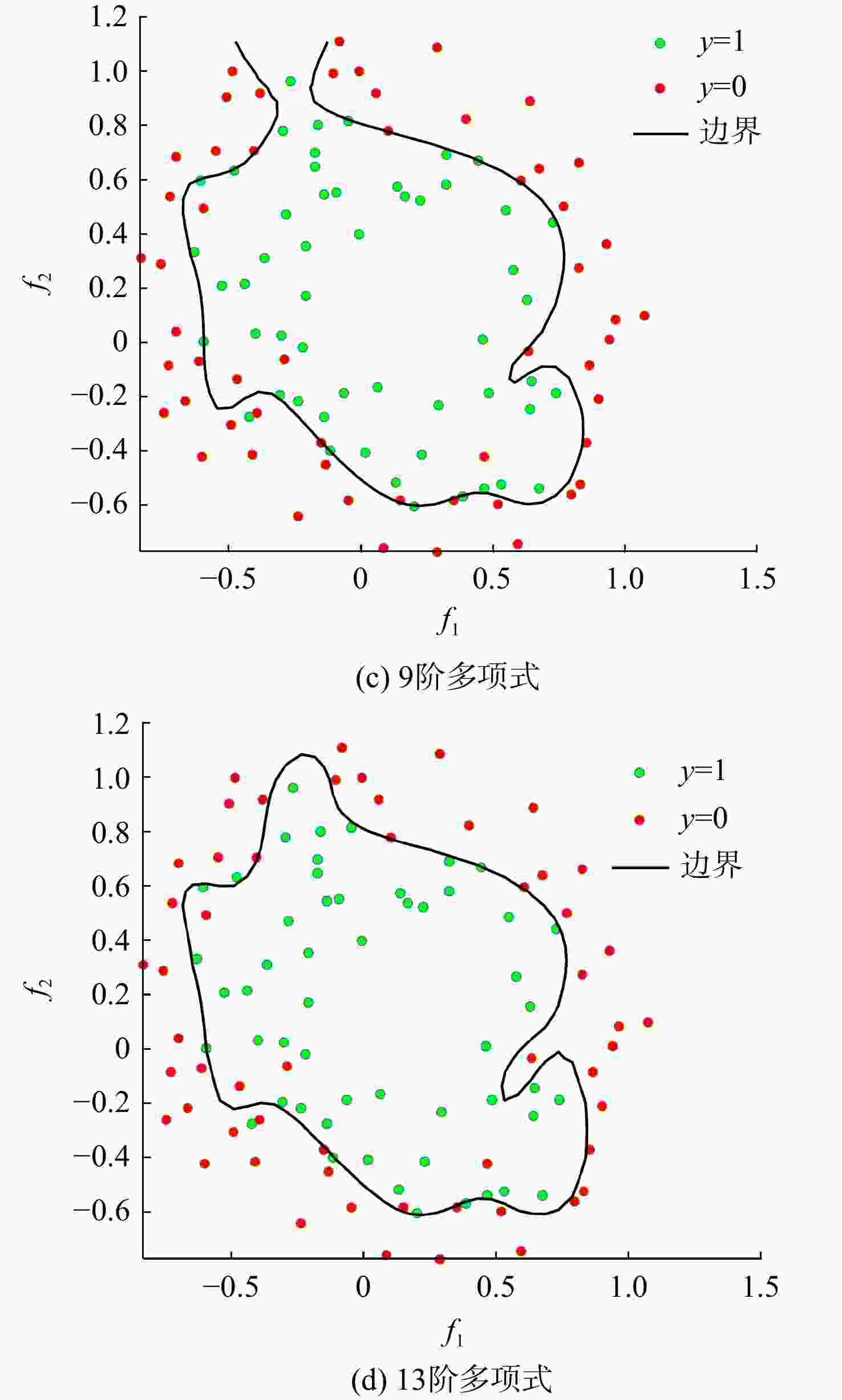

表 1 两因子不同阶次多项式逻辑回归拟合精度

Table 1. Two factors of different order polynomial logistic regression fitting accuracy

多项式阶次 多项式系数个数 回归拟合精度/% 2 6 86.11 3 10 86.11 4 15 85.19 5 21 88.89 6 28 88.89 7 36 90.74 8 45 91.67 9 55 91.67 10 66 91.67 11 78 92.59 12 91 90.74 13 105 91.67 表 2 高压涡轮榫接结构关键技术判别上级参数取值范围

Table 2. Value range of superior parameters for key technology discrimination of high pressure turbine tenon structure

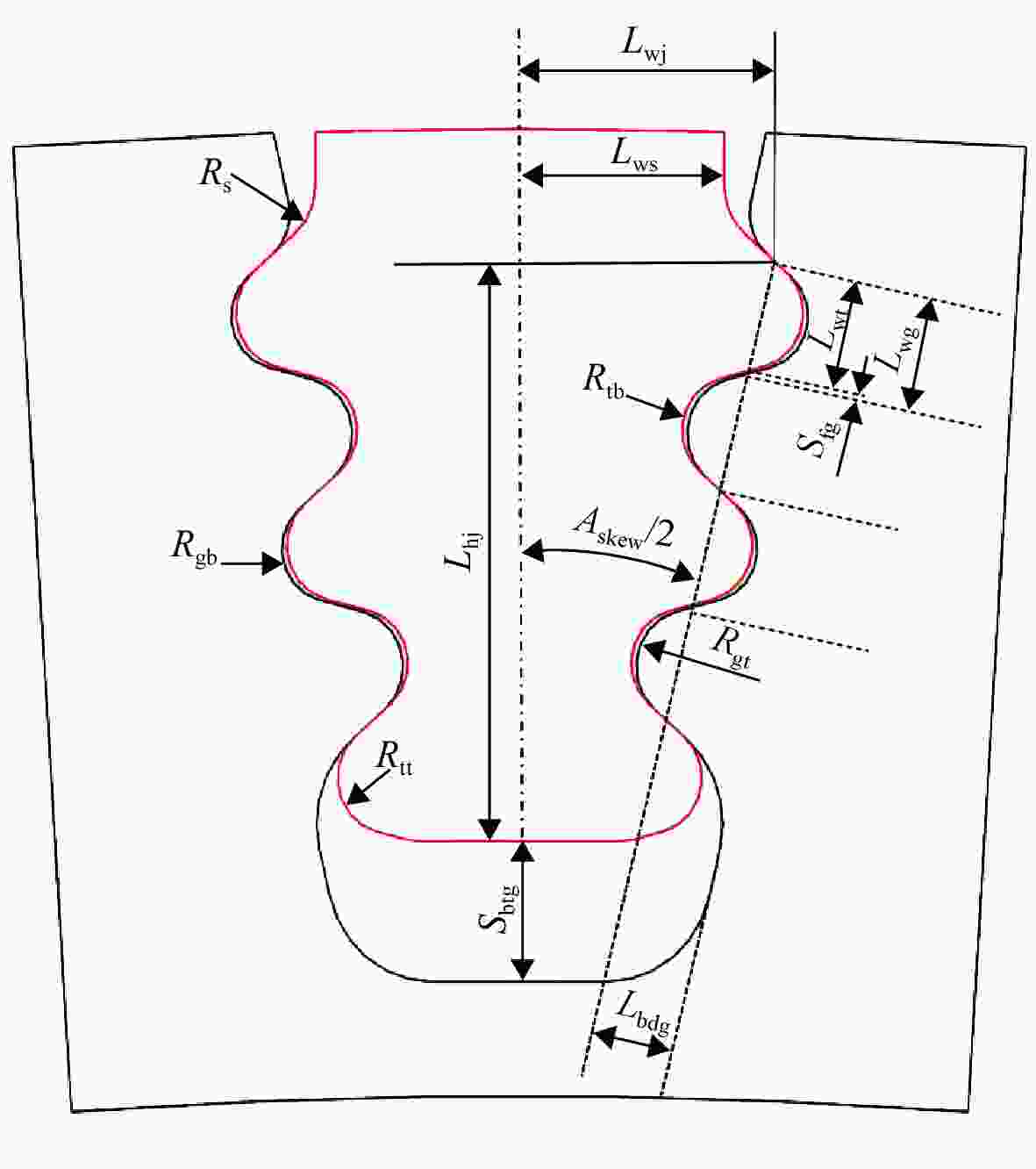

上级参数 下限值 上限值 轮盘外径/mm 280 320 叶片质量矩/(g·m) 35 80 转速/(rad/s) 1400 1700 表 3 高压涡轮榫接结构关键技术前置判别参数

Table 3. Prejudgment parameters of key technologies of high pressure turbine tenon structure

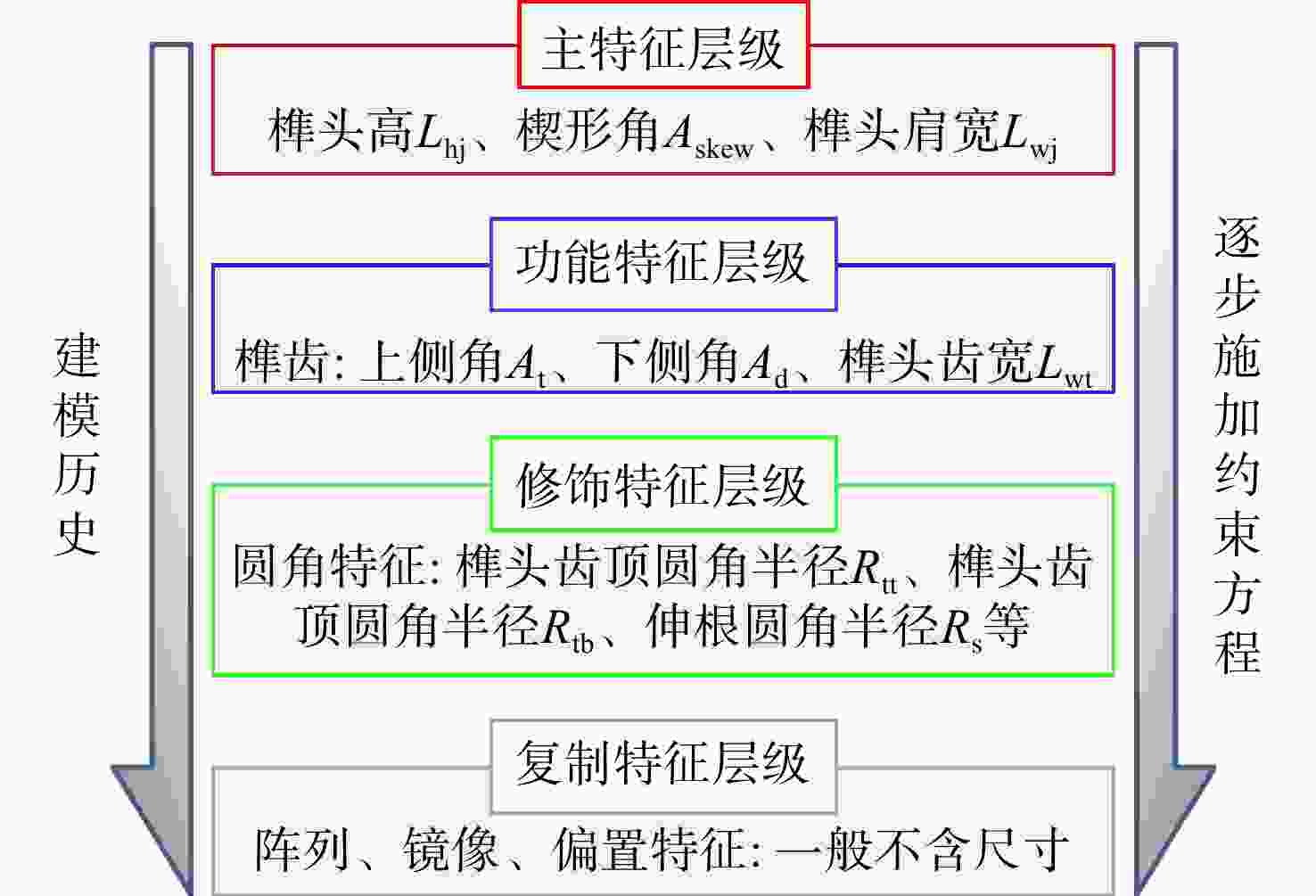

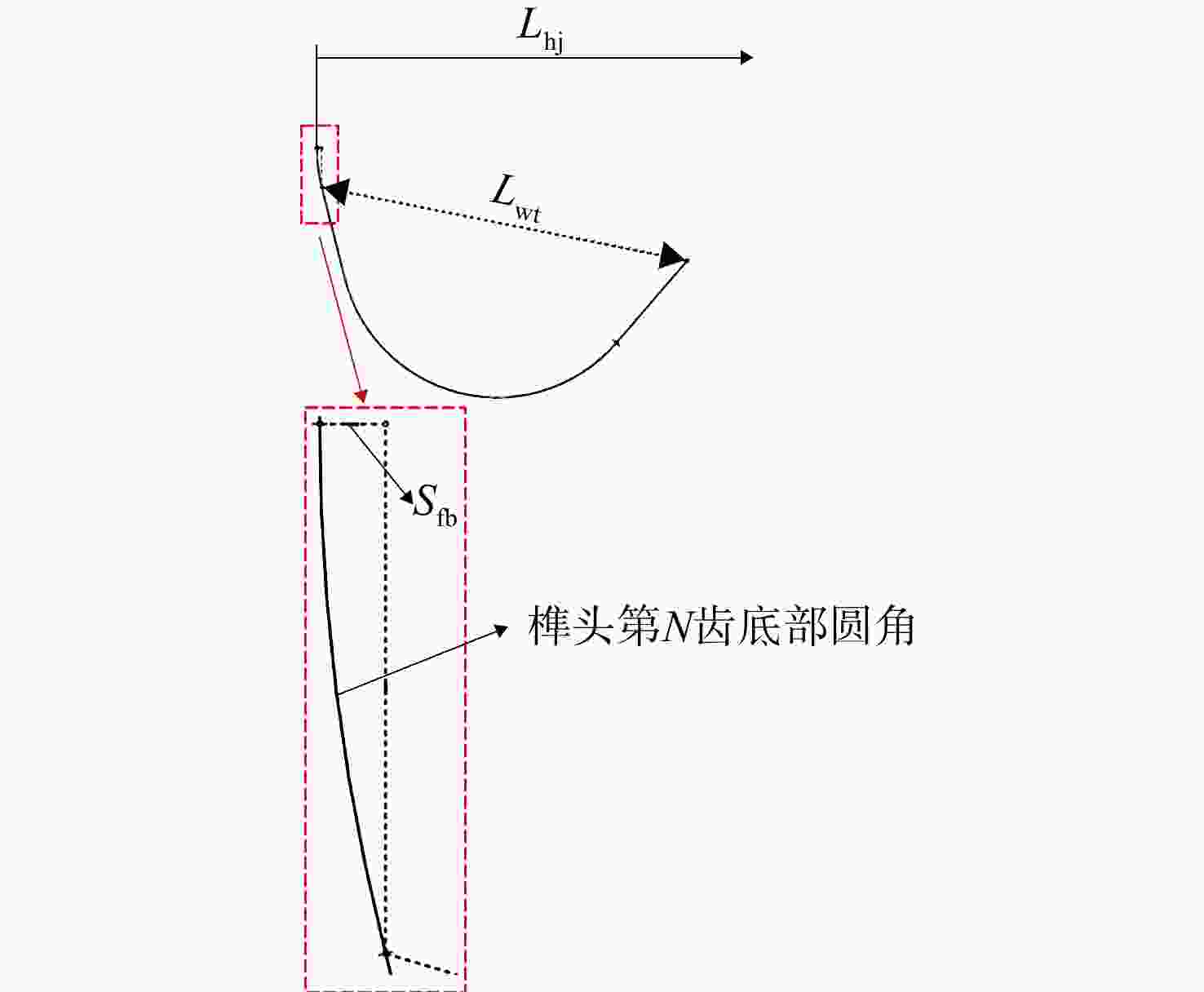

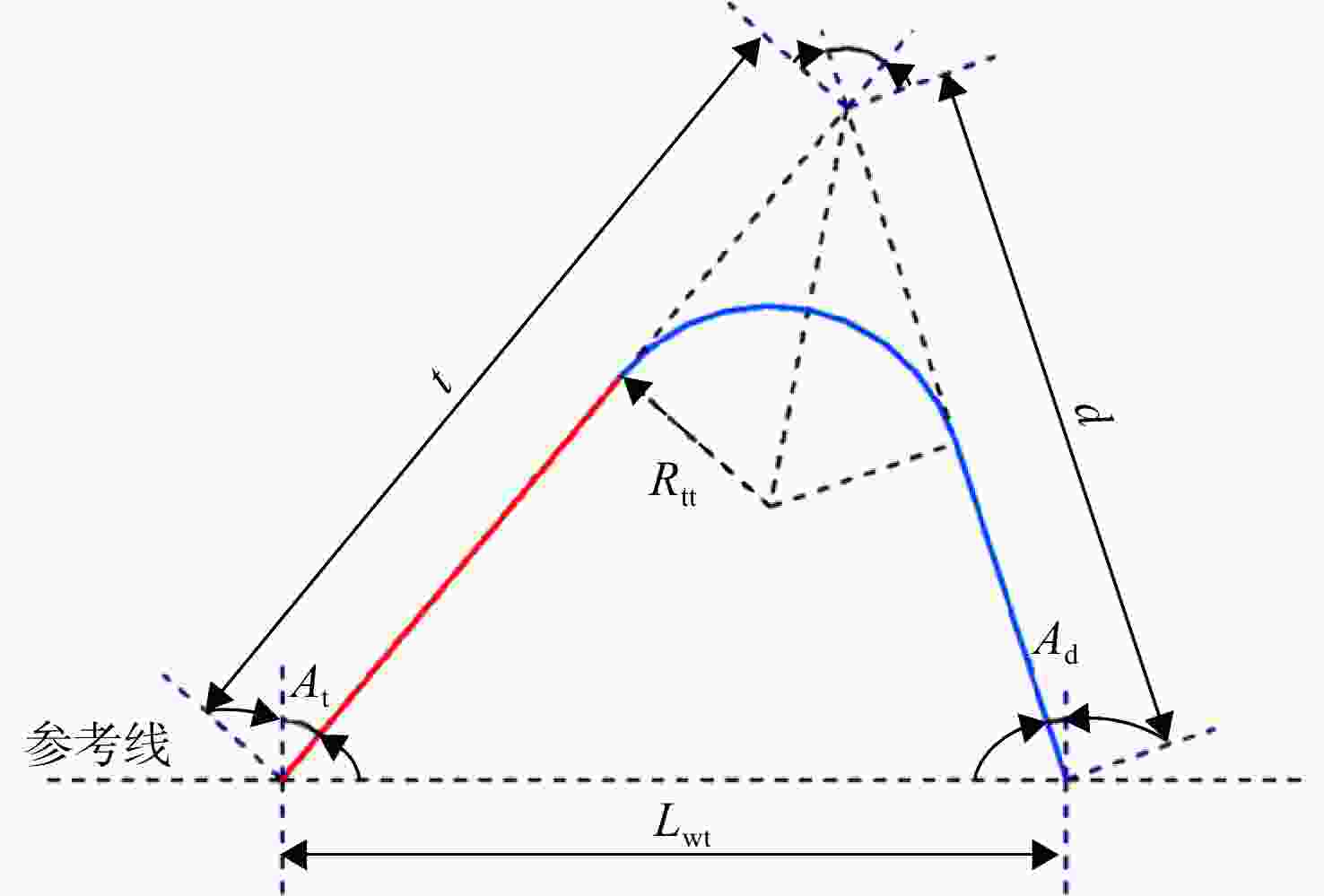

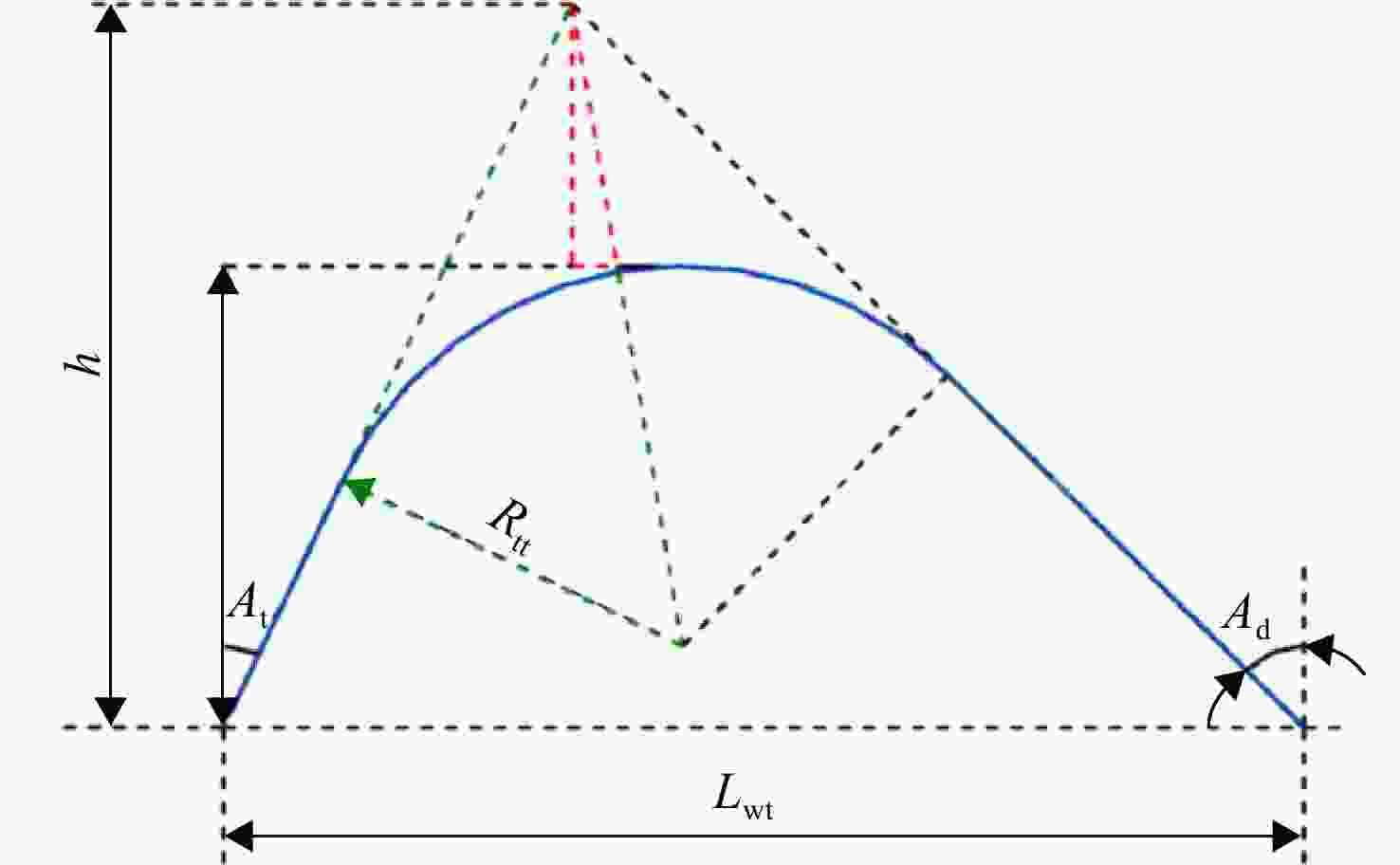

上级参数 下级参数 独立参数 半独立参数 非独立参数 轮盘外径 榫头高Lhj 榫头齿顶

圆角半径Rtt榫头齿宽Lwt 叶片质量矩 榫头颈宽Lwj 榫槽齿底

圆角半径Rgb榫头齿高Lht 转速 楔形角Askew 榫槽齿顶

圆角半径Rgt榫槽齿宽Lwg 上侧角At 榫头齿底

圆角半径Rtb下侧角Ad 伸根圆角半径Rs 榫头榫槽齿宽

间隙Sfg榫槽第N齿

齿深Lbdg榫头榫槽底部

间隙Sbtg榫槽第N齿

上圆弧半径Rbgb榫头底预留

圆角空间Sfb榫槽第N齿

下圆弧半径Rtgb伸根颈宽Lws 盘心等厚区

轴向厚度H1表 4 涡轮盘安全储备系数

Table 4. Safety reserve factor of turbine disc

参数 安全储备系数 弹性极限 破坏极限 子午面平均周向应力 1.33 1.57 子午面沿半径圆环最大平均径向应力 1.33 1.57 盘心最大周向应力 0.90 辐板最大单点径向应力 0.90 表 5 仿真成本

Table 5. Cost of simulation

分析类型 总时长/min 单步平均耗时/s 实际平均耗时/s 轴对称分析 1438 52.52 52.52 三维分析 7043 130.30 124.99 表 6 不同阶次逻辑回归拟合精度

Table 6. Fitting accuracy of different order logistic regression

多项式

阶次多项式

系数个数三齿拟合

精度/%二齿拟合

精度/%2 10 97.5155 94.4099 3 20 98.1366 96.2733 4 35 97.5155 93.7888 5 56 98.1366 93.1677 6 84 96.8944 93.7888 7 120 96.8944 95.6521 表 7 三齿榫接结构逻辑回归边界函数

Table 7. Logistic regression boundary function of three-tooth tenon structure

特征项 1 x z y x2 xz z2 特征项系数 3.8953 −10.2121 9.5142 30.1708 6.5452 −14.3047 −1.9825 特征项 xy yz y2 x3 x2z xz2 z3 特征项系数 7.9126 3.3575 2.2901 9.8839 −10.3288 −22.8682 −8.2799 特征项 x2y xyz yz2 xy2 y2z y3 特征项系数 4.0047 −10.6481 −4.7281 −5.8400 −8.3353 −1.5545 注:表中x 表示轮盘外径,y 表示叶片质量矩, z 表示轮盘转速,下同。 表 8 二齿榫接结构逻辑回归边界函数

Table 8. Logistic regression boundary function of two-tooth tenon structure

特征项 1 x z y x2 xz z2 特征项系数 −6.5744 12.8410 2.1666 40.9794 11.3447 −15.6261 −19.3266 特征项 xy yz y2 x3 x2z xz2 z3 特征项系数 −23.9871 −21.7655 8.1815 −11.6826 −6.5967 26.6870 6.0329 特征项 x2y xyz yz2 xy2 y2z y3 特征项系数 −7.8526 −6.2959 −0.3774 −1.8543 −0.3100 5.3692 表 9 三齿榫接结构关键设计判别结果

Table 9. Jugment results of key design of three-tooth tenon structure

上级参数 实际初值 归一化初值 $\theta ({\boldsymbol{X}})$ $g ( {\theta ({\boldsymbol{X}})} )$ 轮盘外径 308 mm 0.7000 −4.17 0.02 叶片质量矩 60 g·m 0.5556 轮盘转速 15800 r/min 0.8500 表 10 二齿榫接结构关键设计判别结果

Table 10. Jugment results of key design of two-tooth tenon structure

上级参数 实际初值 归一化初值 $\theta ({\boldsymbol{X}})$ $g ( {\theta ({\boldsymbol{X}})} )$ 轮盘外径 308 mm 0.7000 −1.25 0.22 叶片质量矩 60 g·m 0.5556 轮盘转速 15800 r/min 0.8500 -

[1] 尹泽勇,米栋,吴立强,等. 航空发动机多学科设计优化技术研究[J]. 中国工程科学,2007,9(6): 1-10. doi: 10.3969/j.issn.1009-1742.2007.06.001YIN Zeyong,MI Dong,WU Liqiang,et al. Research on multidisciplinary design optimization technology of aero engine[J]. Strategic Study of Chinese Academy of Engineering,2007,9(6): 1-10. (in Chinese) doi: 10.3969/j.issn.1009-1742.2007.06.001 [2] SAMPATH R, PLYBON R, MEYERS C, et al. High fidelity system simulation of aerospace vehicles using NPSS[R]. AIAA-2004-371, 2004. [3] 《航空发动机设计手册》总编委会. 航空发动机设计手册: 第5册 涡喷及涡扇发动机总体[M]. 北京: 航空工业出版社, 2001. [4] 黄鲁成,成雨,吴菲菲,等. 关于颠覆性技术识别框架的探索[J]. 科学学研究,2015,33(5): 654-664. doi: 10.3969/j.issn.1003-2053.2015.05.003HUANG Lucheng,CHENG Yu,WU Feifei,et al. Exploration of a framework for identifying disruptive technologies[J]. Research of Science of Science,2015,33(5): 654-664. (in Chinese) doi: 10.3969/j.issn.1003-2053.2015.05.003 [5] WIMMER M A,PEREIRA G V,RONZHYN A,et al. Transforming government by leveraging disruptive technologies: identification of research and training needs[J]. The Journal of Democracy and Open Government,2020,12(1): 87-114. doi: 10.29379/jedem.v12i1.594 [6] SHIBATA N,KAJIKAWA Y,TAKEDA Y,et al. Detecting emerging research fronts in regenerative medicine by the citation network analysis of scientific publications[J]. Technological Forecasting and Social Change,2011,78(2): 274-282. doi: 10.1016/j.techfore.2010.07.006 [7] MOMENI A,ROST K. Identification and monitoring of possible disruptive technologies by patent-development paths and topic modeling[J]. Technological Forecasting and Social Change,2016,104: 16-29. doi: 10.1016/j.techfore.2015.12.003 [8] BUCHANAN B, CORKEN R. A toolkit for the systematic analysis of patent data to assess a potentially disruptive technology[R]. London: Intellectual Property Office, 2010. [9] GIUNTA A, WOJTKIEWICZ S, ELDRED M. Overview of modern design of experiments methods for computational simulations[R]. AIAA 2003-649, 2003. [10] YETURU K. Machine learning algorithms, applications, and practices in data science[J]. Handbook of Statistics,2020,43: 81-206. [11] JURAFSKY D, MATIN J H. Speech and language processing[M]. 2nd ed. Upper Saddle River, US: Prentice Hall, 2008. [12] THOMPSON J F. A general three-dimensional elliptic grid generation system on a composite block structure[J]. Computer Methods in Applied Mechanics and Engineering,1987,64(1/2/3): 377-411. [13] 李卫平. 计算流体力学[M]. 武汉: 华中科技大学出版社, 2004. [14] GOLDMAN A,KAO Y C. Numerical solution to a two-dimensional conduction problem using rectangular and cylindrical body-fitted coordinate systems[J]. Journal of Heat Transfer,1981,103(4): 753-758. doi: 10.1115/1.3244537 [15] 程俊霞. 椭圆型网格生成方法及其应用[D]. 南京: 南京理工大学, 2002.CHENG Junxia. Elliptic mesh generation method and its application[D]. Nanjing: Nanjing University of Science and Technology, 2022. (in Chinese) [16] 华冬英, 李祥贵. 微分方程的数值解法与程序实现[M]. 北京: 电子工业出版社, 2016. [17] 周志华. 机器学习[M]. 北京: 清华大学出版社, 2016. [18] 胡文通. 细节结构在航空发动机初步设计阶段前置优化技术研究[D]. 北京: 北京航空航天大学, 2019.HU Wentong. Research on pre-optimization technology of detail structure in aeroengine preliminary design stage[D]. Beijing: Beihang University, 2019. (in Chinese) [19] 赵海. 涡轮榫头/榫槽结构设计方法研究[D]. 南京: 南京航空航天大学, 2005.ZHAO Hai. Study on design method of tenon/mortise structure for turbine[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2005. (in Chinese) [20] RR公司. Spey MK202发动机应力标准(EGD-3)[M]. 北京: 国际航空编辑部, 1979. [21] LU S,LI L. Twin-web structure optimization design for heavy duty turbine disk based for aero-engine[J]. Journal of Propulsion Technology,2011,32(5): 631-636. -

下载:

下载: