Influence of machining deviation of curvic couplings tooth surface on fitting state

-

摘要:

为了优化圆弧端齿装配工艺,对圆弧端齿齿面加工偏差对齿面配合状态的影响机理进行了研究。根据圆弧端齿加工原理,研究了关键成型参数对齿面偏差的影响规律,建立了圆弧端齿装配初始齿面间隙模型,研究了齿面偏差对端齿盘装配初始齿面间隙的影响规律。理论研究和试验研究表明:齿面偏差是导致装配初始齿面间隙的直接原因。通过优化安装相位能使装配初始齿面间隙的均值减小18%,方差减小25%。为圆弧端齿连接结构装配精度形成原理与装配工艺优化研究提供基础,对于提高圆弧端齿连接的航空发动机转子装配品质具有重要的意义。

Abstract:In order to optimize curvic couplings assembly process, the influence of machining deviation of curvic couplings tooth surface on fitting state was theoretically studied. Based on the curvic coupling machining theory, the effect of key machining parameters on surface deviation was investigated. An assembly initial tooth surface clearance model of the curvic couplings was built. The effect of surface deviation on assembly initial tooth surface clearance of the curvic couplings was analyzed. According to theoretical and experimental study, tooth surface deviation directly caused the assembly initial tooth surface clearance. By optimizing the installation phase, the mean and variance of assembly initial tooth surface clearance can be reduced by 18%, and the variance can be reduced by 25%. The work provides a foundation for the principle of the assembly accuracy formation and parameter optimization of curvic couplings, contributing to assembly quality improvement of aero-engine rotors connected by curvic couplings.

-

Key words:

- curvic coupling /

- assembly process /

- surface deviation /

- surface clearance /

- fitting status

-

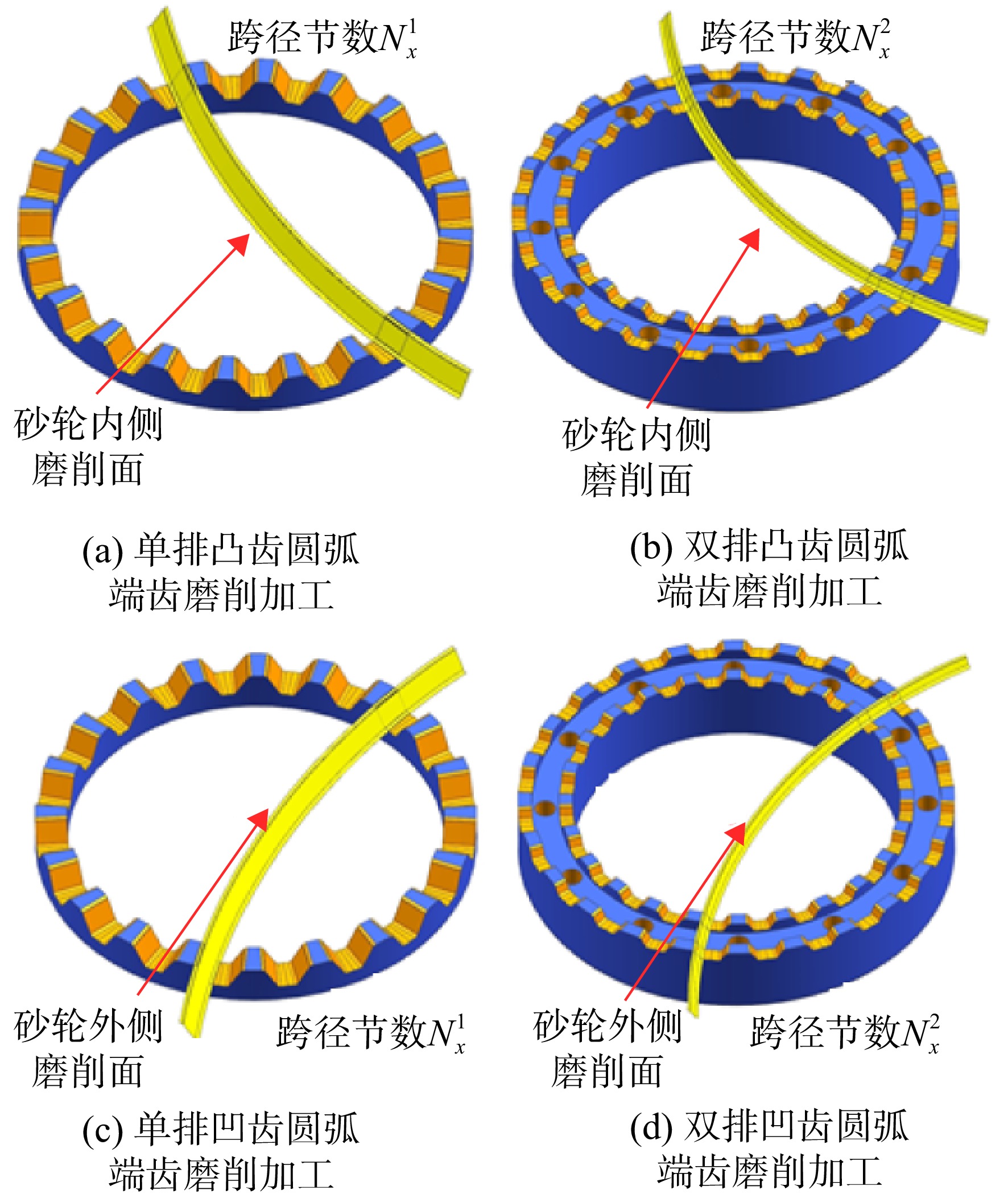

$Z$ 圆弧端齿齿数 ${N_x}$ 跨径节数 $S$ 磨削砂轮与端齿盘的中心距 $m$ 安装相位顺序 ${r'_{{\rm{gw}}}}$ 实际磨削砂轮半径 ${r_{{\rm{gw}}}}$ 理想磨削砂轮半径 ${h_{\rm{a}}}$ 圆弧端齿齿顶高 ${h_{\rm{b}}}$ 圆弧端齿齿根高 $R$ 圆弧端齿盘外半径 $r$ 圆弧端齿盘内半径 $\theta $ 理想圆弧端齿齿面压力角 $\theta '$ 实际圆弧端齿齿面压力角 $\eta _{{\rm{e}}{\text{-}}{\rm{cave}}}^i$ 圆弧端齿凹齿齿面偏差 $\eta _{{\rm{e}}{\text{-}}{\rm{vex}}}^i$ 圆弧端齿凸齿齿面偏差 ${P^i}$ 圆弧端齿实际节距 $P_{\rm{e}}^i$ 圆弧端齿节距偏差 $P_{{\rm{e}}{\text{-}}{\rm{vex}}}^i$ 凸齿圆弧端齿节距偏差 $P_{{\rm{e}}{\text{-}}{\rm{cave}}}^i$ 凹齿圆弧端齿节距偏差 ${P_{\rm{b}}}$ 标准圆弧端齿节距 $\eta _m^i$ 圆弧端齿齿面啮合偏差 $g_m^i$ 圆弧端齿初始齿面间隙 $N$ 圆弧端齿螺栓孔数 $k$ 安装角度 ${\varGamma }_{\text{b}}^i$ 理想齿面 ${\varGamma }_{\text{e}}^i$ 偏差齿面 表 1 优化装配与直接装配对比

Table 1. Comparison of optimized assembly and direct assembly

安装相位顺序编号 间隙均值/mm 间隙方差/mm2 1 0.01783 0.00012 12 0.01461 0.00009 -

[1] 于启军,肖雷. 圆弧端齿的加工[J]. 制造技术与机床,2014(5): 114-116.YU Qijun,XIAO Lei. Curvic coupling grinding[J]. Manufacturing Technology and Machine Tool,2014(5): 114-116. (in Chinese) [2] DAVIDSON J K,WILCOX L E. Minimizing assembly runout in turbo-machines made with curvic® couplings[J]. Journal of Engineering for Power,1976,98(1): 37-46. doi: 10.1115/1.3446108 [3] HUSSAIN T,YANG Z,POPOV A A,et al. Straight-build assembly optimization: a method to minimize stage-by-stage eccentricity error in the assembly of axisymmetric rigid components (two-dimensional case study)[J]. Journal of Manufacturing Science and Engineering,2011,133(3): 031014.1-031014.9. [4] 尹泽勇,欧园霞,李彦,等. 轴向预紧端齿连接转子的动力特性分析[J]. 航空动力学报,1994,9(2): 133-136. doi: 10.13224/j.cnki.jasp.1994.02.006YIN Zeyong,OU Yuanxia,LI Yan,et al. A dynamic characteristic analysis for axially prestressed rotor systems with curvic couplings[J]. Journal of Aerospace Power,1994,9(2): 133-136. (in Chinese) doi: 10.13224/j.cnki.jasp.1994.02.006 [5] 胡柏安,尹泽勇,徐友良. 两段预紧的端齿连接转子轴向预紧力的确定[J]. 机械强度,1999,21(4): 274-277, 284.HU Baian,YIN Zeyong,XU Youliang. Determination of axial preloads of rotor with curvic couplings pretightened into two segments[J]. Journal of Mechanical Strength,1999,21(4): 274-277, 284. (in Chinese) [6] 尹泽勇,欧园霞,胡柏安,等. 端齿连接及变轴力的影响[J]. 航空动力学报,1994,9(2): 129-132.YIN Zeyong,OU Yuanxia,HU Baian,et al. Influences of curvic coupling connection and variable axial forces[J]. Journal of Aerospace Power,1994,9(2): 129-132. (in Chinese) [7] 张森棠, 赵恒, 吴志新, 等. 基于加工精度指标标定的圆弧端齿数控加工方法: CN101733482A[P]. 2010-06-16. [8] 蔺志强,张森堂,吴志新,等. 圆弧端齿数控加工技术研究[J]. 装备制造,2009(12): 184, 186.LIN Zhiqiang,ZHANG Sentang,WU Zhixin,et al. Research on NC machining technology of circular arc end teeth[J]. China Equipment,2009(12): 184, 186. (in Chinese) [9] 刘恒,洪杰,邵伏永,等. 圆弧端齿结构设计和加工工艺研究进展与展望[J]. 推进技术,2018,39(4): 721-730.LIU Heng,HONG Jie,SHAO Fuyong,et al. Progress and prospect of structural design and processing technology of CURVIC coupling[J]. Journal of Propulsion Technology,2018,39(4): 721-730. (in Chinese) [10] LIU Heng,HONG Jie,RUAN Shilun,et al. A model accounting for stiffness weakening of curvic couplings under various loading conditions[J]. Mathematical Problems in Engineering,2020,2020: 1-17. [11] 刘恒,洪杰,李垒栋,等. 圆弧端齿联轴器定位机理研究[J]. 推进技术,2019,40(6): 1382-1388.LIU Heng,HONG Jie,LI Leidong,et al. Positioning mechanism of curvic coupling[J]. Journal of Propulsion Technology,2019,40(6): 1382-1388. (in Chinese) [12] 宋健. 机车牵引齿轮用端齿联轴器的参数计算与强度分析[D]. 辽宁 大连: 大连交通大学, 2015.SONG Jian. Parameter calculation and strength analysisof end-toothed coupling of locomotive traction gear[D]. Dalian Liaoning: Dalian Jiaotong University, 2015. (in Chinese) [13] 李业明. 大功率机车弹性联轴器及圆弧端齿联结技术研究[D]. 成都: 西南交通大学, 2009.LI Yeming. Study on the flexible coupling and arc tooth connection technology for the superpower locomotive[D]. Chengdu: Southwest Jiaotong University, 2009. (in Chinese) [14] 黄发. 圆弧端齿结构设计方法研究[D]. 南京: 南京航空航天大学, 2013.HUANG Fa. Design method of curvic couplings[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013. (in Chinese) [15] 李爱民. 圆弧端齿结构设计方法与微动疲劳寿命预测模型研究[D]. 南京: 南京航空航天大学, 2015.LI Aimin. Research on design method of curvic couplings and fretting fatigue life prediction model[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015. (in Chinese) [16] WANG Xiaoming,CAO Zifei,SUN Chuanzhi,et al. Positioning and orientation error measurement and assembly coaxiality optimization in rotors with curvic couplings[J]. Measurement,2021,186: 110167.1-110167.12. [17] Gleason Works. Curvic coupling design[M]. New York: Gleason Works, 1942. [18] 吴鸿雁,徐国胜,赵海龙,等. 端面弧齿联轴节加工参数误差对齿面误差的影响[J]. 机械传动,2017,41(11): 54-59.WU Hongyan,XU Guosheng,ZHAO Hailong,et al. Influence of the manufacturing parameter error on tooth surface error of curvic coupling[J]. Journal of Mechanical Transmission,2017,41(11): 54-59. (in Chinese) -

下载:

下载: