Experiment on film cooling characteristics of dustpan shaped holes at different positions of turbine blade

-

摘要:

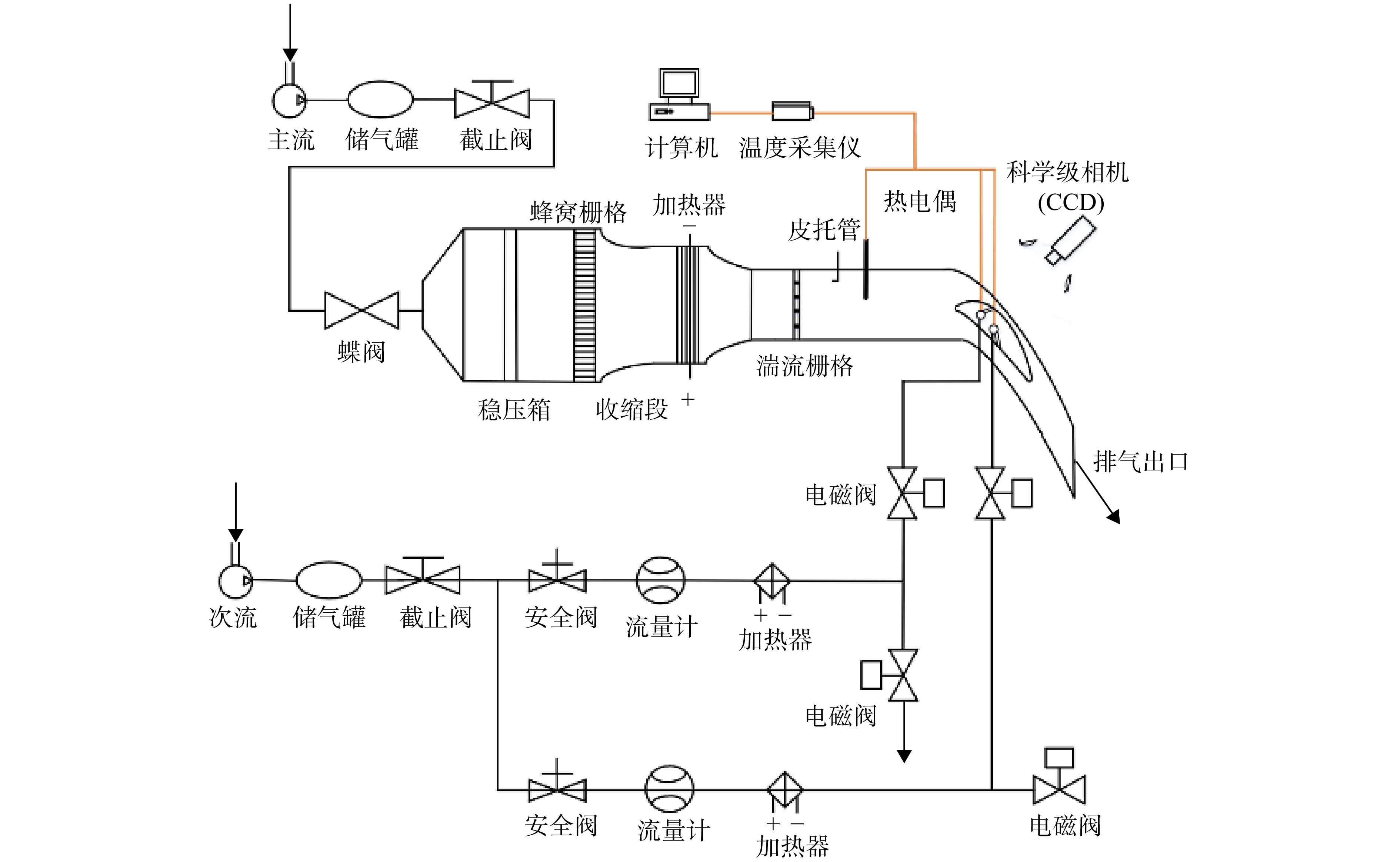

采用压敏漆(PSP)技术实验研究了簸箕形孔在涡轮工作叶片吸力面和压力面不同位置的气膜冷却效率分布特性,分析了吹风比(吹风比为0.5、1.0、2.0)和湍流度(湍流度为 0.62%、16.0%对气膜冷却效率的影响规律。实验结果表明:吸力面和压力面上的簸箕形孔最佳吹风比分别在

M =1.0和M =2.0附近,吸力面上的簸箕形孔在低湍流度和中等吹风比(吹风比为1.0)下具有较高的气膜冷效,压力面上的簸箕形孔在高吹风比和高湍流度下具有更大的气膜覆盖面积和气膜冷效;吸力面的气膜覆盖面积和展向平均气膜冷效整体显著高于压力面,压力面曲率较大处的簸箕形孔气膜冷效最差。湍流度对气膜冷效的影响程度与吹风比相当;湍流度增强使得压力面气膜冷效降低,但提高了吸力面在高吹风比下的气膜冷效,同时降低了吸力面气膜冷效对吹风比变化的敏感性。-

关键词:

- 涡轮工作叶片 /

- 簸箕形气膜孔 /

- 气膜冷却效率 /

- 压敏漆(PSP)技术 /

- 湍流度

Abstract:The distribution characteristics of film cooling effectiveness of dustpan shaped holes at different positions of suction surface and pressure surface of turbine blade were studied by pressure sensitive paint (PSP) measurement technique. The effects of blowing ratio (blowing ratio of 0.5, 1.0, 2.0) and turbulence intensity (turbulence intensity of 0.62%, 16.0%) on film cooling effectiveness were analysed. The experimental results showed that the optimum blowing ratios of the dustpan shaped holes on the suction surface and pressure surface were around blowing ratio of 1.0 and 2.0, respectively. The dustpan shaped holes on the suction surface had higher film cooling effectiveness under low turbulence and medium blowing ratio (blowing ratio of 1.0). The dustpan shaped holes on the pressure surface had larger film coverage area and film cooling effectiveness under high blowing ratio and high turbulence. The film coverage area and spanwise averaged film cooling effectiveness on the suction surface were significantly higher than those on the pressure surface. And the film cooling performance of dustpan shaped holes at the position with large curvature was the worst on the pressure surface. The influence of turbulence on film cooling effectiveness was similar to that of blowing ratio. The enhancement of turbulence reduced the film cooling effectiveness on the pressure surface, but improved the film cooling performance on the suction surface under high blowing ratio, and reduced the sensitivity of the film cooling performance to the change of blowing ratio on the suction surface.

-

表 1 实验工况参数

Table 1. Experiment conditions

参数 数值 $ Re $/106 1.71 $ {T}_{\mathrm{u}}/{\text{%}} $ 0.62 (无湍流格栅),16 $ M $ 0.5,1.0,2.0 表 2 气膜冷效不确定度

Table 2. Film-cooling effectiveness uncertainty

$ \eta $ $ (\Delta \eta /\eta ) /{\text{%}} $ 0.5 1.41 0.4 2.12 0.3 3.29 0.2 5.66 0.1 12.7 -

[1] ZHANG Jingzhou,ZHANG Shengchang,WANG Chunhua,et al. Recent advances in film cooling enhancement: a review[J]. Chinese Journal of Aeronautics,2020,33(4): 1119-1136. doi: 10.1016/j.cja.2019.12.023 [2] DENG Hefang,TENG Jinfang,ZHU Mingmin,et al. Overall cooling performance evaluation for film cooling with different winglet pairs vortex generators[J]. Applied Thermal Engineering,2022,201: 117731.1-117731.13. [3] MENG Long,LI Haiwang,XIE Gang,et al. Film cooling performance of blade pressure side with three-row film holes under rotating condition[J]. International Journal of Heat and Mass Transfer,2022,188: 122593.1-122593.11. [4] PAITICH L C,RICHER P,JODOIN B,et al. An experimental study of the directional effects of effusion cooling on the cooling film effectiveness in Gas Turbine Combustors [R]. Tennessee,USA: AIAA Scitech 2021 Forum,2021. [5] GANZERT W,HILDEBRANDT T,FOTTNER L. Systematic experimental and numerical investigations on the aerothermodynamics of a film cooled turbine cascade with variation of the cooling hole shape: Part Ⅰ experimental Approach[R]. Munich,Germany: ASME Turbo Expo 2000: Power for Land,Sea,and Air,2000. [6] SAUMWEBER C,SCHULZ A. Free-stream effects on the cooling performance of cylindrical and fan-shaped cooling holes[R]. Copenhagen,Denmark: ASME Turbo Expo: Power for Land,Sea,and Air,2012. [7] ZHANG L Z,MOON H K. Turbine blade film cooling study: the effects of film hole location on the pressure side[R]. Montreal,Canada: ASME Turbo Expo: Power for Land,Sea,and Air,2007. [8] 刘聪,朱惠人,付仲议,等. 涡轮导叶吸力面簸箕型孔气膜冷却特性实验研究[J]. 推进技术,2016,37(6): 1142-1150. LIU Cong,ZHU Huiren,FU Zhongyi,et al. Experimental study of film cooling characteristics for dust-pan shaped holes on suction side in turbine guide vane[J]. Journal of Propulsion Technology,2016,37(6): 1142-1150. (in ChineseLIU Cong, ZHU Huiren, FU Zhongyi, et al. Experimental study of film cooling characteristics for dust-pan shaped holes on suction side in turbine guide vane[J]. Journal of Propulsion Technology, 2016, 37(6): 1142-1150. (in Chinese) [9] 姚春意,朱惠人,刘存良,等. 涡轮导叶压力面气膜孔排位置对气膜冷却特性的影响[J]. 推进技术,2020,41(7): 1560-1570. YAO Chunyi,ZHU Huiren,LIU Cunliang,et al. Effects of film hole row location on film cooling characteristic for pressure side of a turbine vane[J]. Journal of Propulsion Technology,2020,41(7): 1560-1570. (in Chinese doi: 10.13675/j.cnki.tjjs.190485YAO Chunyi, ZHU Huiren, LIU Cunliang, et al. Effects of film hole row location on film cooling characteristic for pressure side of a turbine vane[J]. Journal of Propulsion Technology, 2020, 41(7): 1560-1570. (in Chinese) doi: 10.13675/j.cnki.tjjs.190485 [10] 朱惠人,马兰,许都纯,等. 孔位对涡轮叶片表面气膜冷却换热系数的影响[J]. 推进技术,2005,26(4): 302-306. ZHU Huiren,MA Lan,XU Duchun,et al. Influences of position of hole-rows on film cooling heat transfer of turbine blade surface[J]. Journal of Propulsion Technology,2005,26(4): 302-306. (in Chinese doi: 10.13675/j.cnki.tjjs.2005.04.004ZHU Huiren, MA Lan, XU Duchun, et al. Influences of position of hole-rows on film cooling heat transfer of turbine blade surface[J]. Journal of Propulsion Technology, 2005, 26(4): 302-306. (in Chinese) doi: 10.13675/j.cnki.tjjs.2005.04.004 [11] MOORE J D,YOON C,BOGARD D G. Surface curvature effects on film cooling performance for shaped holes on a model turbine blade[J]. Journal of Turbomachinery,2020,142(11): 111008.1-111008.17. [12] WINKA J R,ANDERSON J B,BOGARD D G,et al. Convex curvature effects on film cooling adiabatic effectiveness[R]. San Antonio,Texas,USA: Turbine Technical Conference and Exposition,2013. [13] ZHANG L J,JAISWAL R S. Turbine nozzle endwall film cooling study using pressure sensitive paint[R]. New Orleans,US: ASME Turbo Expo: Power for Land,Sea,and Air,2001. [14] ZHANG Luzeng,MOON H K. Turbine nozzle endwall inlet film cooling: the effect of a back-facing step[R]. Anaheim,US: ASME International Mechanical Engineering Congress and Exposition,2004. [15] WRIGHT L M,GAO Z H,VARVEL T A,et al. Assessment of steady state PSP,TSP,and IR measurement techniques for flat plate film cooling[R]. San Francisco,US: ASME 2005 Summer Heat Transfer Conference collocated with the ASME 2005 Pacific Rim Technical Conference and Exhibition on Integration and Packaging of MEMS,NEMS,and Electronic Systems,2005. [16] NARZARY D P,LIU Kuochun,RALLABANDI A P,et al. Influence of coolant density on turbine blade film-cooling using pressure sensitive paint technique[J]. Journal of Turbomachinery,2012,134(3): 031006.1-031006.10. [17] KLINE S J,MCCLINTOCK F A. Description of uncertainties in single-sample experiments[J]. Mechanical Engineering,1953,75(7): 3-9. [18] SAUMWEBER C,SCHULZ A. Effect of geometry variations on the cooling performance of fan-shaped cooling holes[J]. Journal of Turbomachinery,2012,134(6): 905-919. [19] HAVEN B A,YAMAGATA D K,KUROSAKA M,et al. Anti-kidney pair of vortices in shaped holes and their influence on film cooling effectiveness[R]. Orlando,US: ASME International Gas Turbine and Aeroengine Congress and Exhibition,1997. [20] BOGARD D G,SCHMIDT D L,TABBITA M. Characterization and laboratory simulation of turbine airfoil surface roughness and associated heat transfer[R]. New York: ASME International Gas Turbine and Aeroengine Congress and Exhibition,1996. -

下载:

下载: