Experiment on high-speed sand continuous erosion characteristics of CCF300/QY9511 composite laminates

-

摘要:

针对CCF300/QY9511碳纤维/双马树脂复合材料层合板开展了连续冲蚀试验,研究了不同冲蚀条件下的质量冲蚀率和损伤规律。结果表明:随着冲蚀角度和供砂率的增加,质量冲蚀率先增加后减少,并在60°左右出现峰值冲蚀率;冲蚀率随冲蚀速度的增加而增加;复合材料表面铺设平纹布可增强复合材料抗低速冲蚀的能力,但增强效果在高速冲蚀时不明显;复合材料主要冲蚀机制为微裂纹的产生、纤维的断裂、纤维-基体脱黏以及基体变形。该研究明晰了双马树脂基复合材料层合板材料的去除机理及损伤变化规律,为后续航空复合材料结构抗冲蚀研究奠定了基础。

Abstract:Continuous erosion test was carried out for the CCF300/QY9511 carbon fiber/ bismaleimide resin composite laminate, and the mass erosion rate and damage law under different erosion conditions were studied. It was found that the mass erosion first increased and then decreased with the increase of the erosion angle. The peak erosion rate appeared around the erosion angle of 60°. The erosion rate increased with the increase of the erosion rate, while it first increased and then decreased with the increase of the sand supply rate. Laying plain weave cloth on the surface of the composite laminates could enhance the ability of the composite material to resist low-speed erosion. However, the improvement effect under high-speed erosion was not obvious. The main erosion mechanisms of composite materials accounted for the generation of micro-cracks, fiber breakage, fiber-matrix debonding, and matrix deformation. The research clarified the removal mechanism and damage change law of composite laminates, laying a foundation for subsequent research on erosion resistance of composite materials.

-

Key words:

- composite laminates /

- bismaleimide resin /

- sand erosion /

- damage mechanism /

- continuous erosion

-

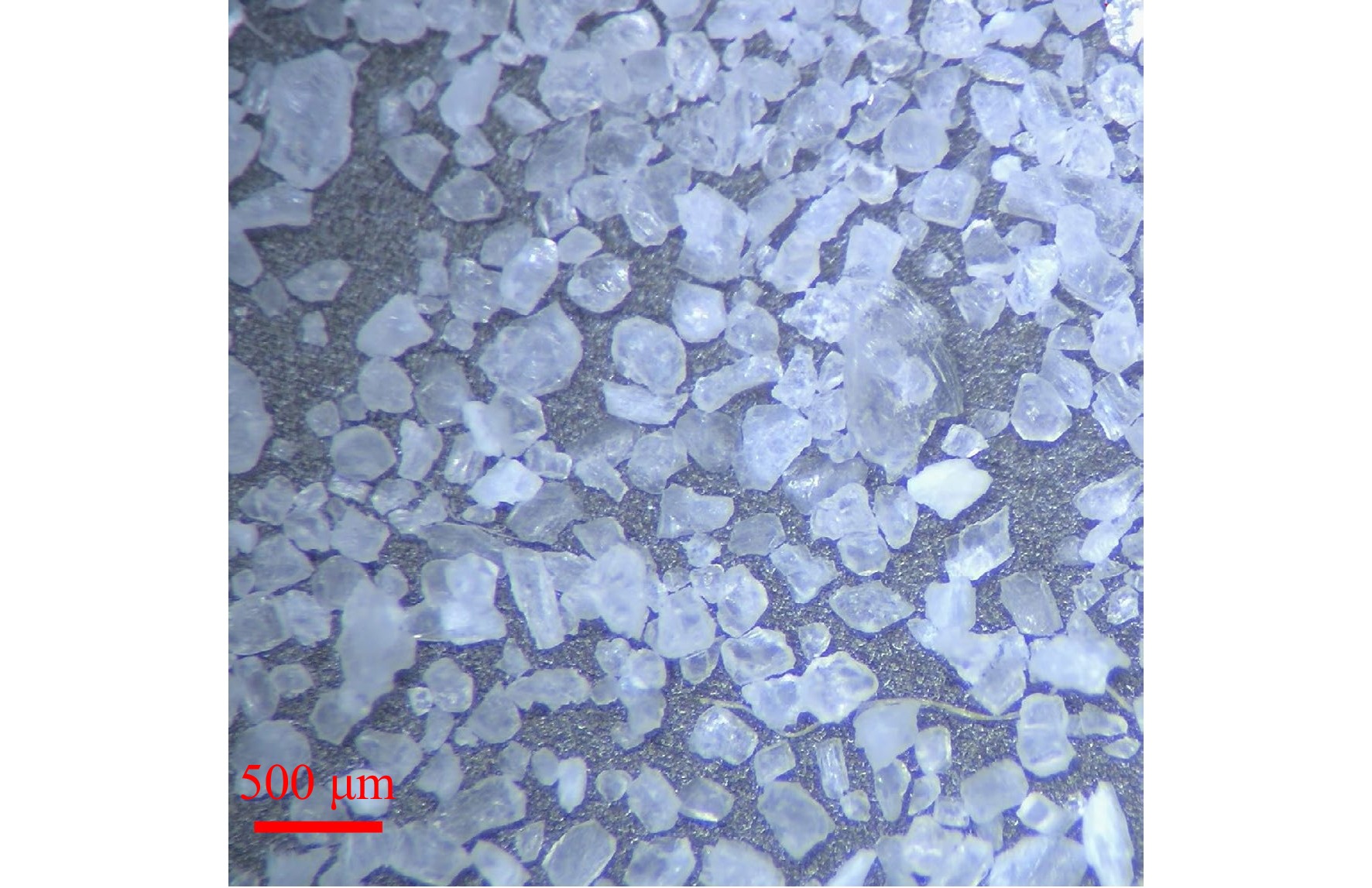

表 1 试验用砂粒的粒径占比

Table 1. Proportion of the particle size of the sand used in the test

粒径范围/μm 质量占比/% 0~75 3~7 0~125 18~22 0~200 46~50 0~400 82~86 0~600 93~97 0~900 98~99 0~1000 100 表 2 供气压力与砂粒速度关系

Table 2. Relationship between air pressure and sand velocity

供气压力

p/MPa砂粒速度范围

v/(m/s)砂粒平均速度

$\bar{V} $/(m/s)0.10 70~110 91.3 0.15 70~160 112.4 0.20 70~170 124.3 0.25 90~210 154.4 0.30 120~230 174.8 0.35 170~300 237.6 0.45 230~370 299.0 0.55 260~400 320.1 0.65 280~420 342.8 表 3 不同冲蚀速度下连续砂冲蚀试验结果

Table 3. Continuous sand erosion test results at different erosion rates

冲蚀角度/(°) 冲蚀速度/(m/s) 冲蚀时间/s 供砂率/(g/s) 冲蚀前质量/g 冲蚀后质量/g 质量冲蚀率/% 平均冲蚀率/% 30 100 20 0.246 3.8255 3.8118 0.278 0.266 3.8172 3.8036 0.276 3.8091 3.7971 0.244 160 20 0.246 3.8978 3.8750 0.463 0.538 3.9219 3.8929 0.589 3.8822 3.8546 0.561 220 20 0.246 3.8256 3.7606 1.321 1.634 3.7800 3.6951 1.726 3.9955 3.9042 1.856 60 100 20 0.246 3.9443 3.9019 0.862 0.796 3.9597 3.9238 0.730 3.9537 3.9146 0.795 160 20 0.246 3.9119 3.8511 1.236 1.099 3.9397 3.8909 0.992 3.9364 3.8838 1.069 220 20 0.246 3.9841 3.8308 3.116 3.846 3.8173 3.5978 4.461 4.0099 3.8151 3.959 90 100 20 0.246 3.9452 3.9117 0.559 0.572 3.9130 3.8855 0.559 3.9578 3.9284 0.598 160 20 0.246 3.9574 3.9056 1.053 1.056 3.9270 3.8730 1.098 3.9096 3.8595 1.018 220 20 0.246 3.8374 3.6884 3.028 3.318 3.9485 3.7751 3.524 3.8342 3.6669 3.400 表 4 表面铺设平纹布复合材料连续冲砂试验结果

Table 4. Test results of continuous sand erosion of plain weave on the composites surface

冲蚀角度/

(°)冲蚀速度/

(m/s)常规材料

冲蚀率/%表面平纹布材料

冲蚀率/%45 100 0.541 0.444 160 0.756 1.211 220 3.001 3.325 60 100 0.796 0.639 160 1.056 1.68 220 3.846 4.278 90 100 0.559 0.491 160 1.099 1.43 220 3.318 3.886 表 5 不同冲蚀角度下的复合材料损伤区域尺寸

Table 5. Damage morphology size under different erosion angles

冲蚀角度/(°) 损伤面积/mm2 椭圆长轴/mm 椭圆短轴/mm 30 304.31 27.1 14.34 45 247.09 20.87 15.10 60 193.01 16.50 15.02 75 174.27 15.62 15.04 90 169.32 15.07 14.91 -

[1] 白旭鹏. 直升机桨叶冲蚀磨损特性研究[D]. 长春: 吉林大学,2021. BAI Xupeng. Research on erosion and wear characteristics of helicopter blades[D]. Changchun: Jilin University,2021. (in ChineseBAI Xupeng. Research on erosion and wear characteristics of helicopter blades[D]. Changchun: Jilin University, 2021. (in Chinese) [2] ZAHAVI J,SCHMITT G F. Solid particle erosion of reinforced composite materials[J]. Wear,1981,71(2): 179-190. doi: 10.1016/0043-1648(81)90337-9 [3] 刘奇. 复合材料叶片抗冲蚀性能研究及SPH仿真分析[D]. 南京: 南京航空航天大学,2013. LIU Qi. Research on SPH simulation analysis and resistance test about erosion of composite blade[D]. Nanjing: Nanjing University of Aeronautics and Astronautics,2013. (in ChineseLIU Qi. Research on SPH simulation analysis and resistance test about erosion of composite blade[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013. (in Chinese) [4] KAUNDAL R. Role of process variables on solid particle erosion of polymer composites: a critical review[J]. Silicon,2017,9(2): 223-238. doi: 10.1007/s12633-014-9191-5 [5] SHARMA A,CHOUDHARY M,AGARWAL P,et al. Review on erosion wear characteristic of natural fiber reinforced polymer composite[J]. Materials Today: Proceedings,2021,44: 4795-4800. doi: 10.1016/j.matpr.2020.11.395 [6] SURESH A,HARSHA A P,GHOSH M K. Solid particle erosion of unidirectional fibre reinforced thermoplastic composites[J]. Wear,2009,267(9/10): 1516-1524. [7] BARKOULA N M,KARGER-KOCSIS J. Effects of fibre content and relative fibre-orientation on the solid particle erosion of GF/PP composites[J]. Wear,2002,252(1/2): 80-87. [8] 姜秉元. 玻璃纤维/环氧树脂复合材料的粒子冲击磨损研究[J]. 复合材料学报,1993,10(4): 85-89. JIANG Bingyuan. Study of solid particle erosion in glass fiber/epoxy composite materials[J]. Acta Materiae Compositae Sinica,1993,10(4): 85-89. (in Chinese doi: 10.13801/j.cnki.fhclxb.1993.04.013JIANG Bingyuan. Study of solid particle erosion in glass fiber/epoxy composite materials[J]. Acta Materiae Compositae Sinica, 1993, 10(4): 85-89. (in Chinese) doi: 10.13801/j.cnki.fhclxb.1993.04.013 [9] 王彦平,龚卓,王起才. 环氧树脂及其复合材料的固体颗粒冲蚀磨损[J]. 建筑材料学报,2015,18(4): 652-657. WANG Yanping,GONG Zhuo,WANG Qicai. Solid particle erosive wear of epoxy and its composites[J]. Journal of Building Materials,2015,18(4): 652-657. (in Chinese doi: 10.3969/j.issn.1007-9629.2015.04.020WANG Yanping, GONG Zhuo, WANG Qicai. Solid particle erosive wear of epoxy and its composites[J]. Journal of Building Materials, 2015, 18(4): 652-657. (in Chinese) doi: 10.3969/j.issn.1007-9629.2015.04.020 [10] POOL K V,DHARAN C K H,FINNIE I. Erosive wear of composite materials[J]. Wear,1986,107(1): 1-12. doi: 10.1016/0043-1648(86)90043-8 [11] BALLOUT Y A,HOVIS S K,TALIA J E. Erosion in glass-fiber reinforced epoxy composite[J]. Scripta Metallurgica et Materialia,1990,24(1): 195-200. doi: 10.1016/0956-716X(90)90591-4 [12] 于晶晶,吴杨敏,赵文杰,等. 纤维增强环氧树脂复合材料抗固体颗粒流冲蚀磨损研究进展[J]. 表面技术,2017,46(11): 29-36. YU Jingjing,WU Yangmin,ZHAO Wenjie,et al. Erosive wear resistance of fiber-reinforced epoxy resin to solid particle flow[J]. Surface Technology,2017,46(11): 29-36. (in Chinese doi: 10.16490/j.cnki.issn.1001-3660.2017.11.005YU Jingjing, WU Yangmin, ZHAO Wenjie, et al. Erosive wear resistance of fiber-reinforced epoxy resin to solid particle flow[J]. Surface Technology, 2017, 46(11): 29-36. (in Chinese) doi: 10.16490/j.cnki.issn.1001-3660.2017.11.005 [13] ZHANG Na,YANG Fan,SHEN Changyu,et al. Particle erosion on carbon nanofiber paper coated carbon fiber/epoxy composites[J]. Composites Part B: Engineering,2013,54: 209-214. doi: 10.1016/j.compositesb.2013.05.003 [14] NAYAK S,MOHANTY J. Erosion wear behavior of benzoyl chloride modified areca sheath fiber reinforced polymer composites[J]. Composites Communications,2020,18: 19-25. doi: 10.1016/j.coco.2020.01.006 [15] ÖZEN İ,GEDIKLI H,ÖZTÜRK B. Improvement of solid particle erosion resistance of helicopter rotor blade with hybrid composite shield[J]. Engineering Failure Analysis,2021,121: 105175.1-105175.20. [16] 马忠云,方梅,吕广超,等. 热塑性聚氨酯无纺布对玻纤增强环氧复合材料耐冲蚀磨损性能的影响[J]. 材料保护,2020,53(3): 78-83. MA Zhongyun,FANG Mei,LYU Guangchao,et al. Influence of thermoplastic polyurethanes non-woven fabric on the erosion wear resistance of glass fiber/epoxy composites[J]. Materials Protection,2020,53(3): 78-83. (in Chinese doi: 10.16577/j.cnki.42-1215/tb.2020.03.014MA Zhongyun, FANG Mei, LYU Guangchao, et al. Influence of thermoplastic polyurethanes non-woven fabric on the erosion wear resistance of glass fiber/epoxy composites[J]. Materials Protection, 2020, 53(3): 78-83. (in Chinese) doi: 10.16577/j.cnki.42-1215/tb.2020.03.014 [17] YAN Cheng,CHEN Wei,ZHAO Zhenhua,et al. A probability prediction model of erosion rate for Ti-6Al-4V on high-speed sand erosion[J]. Powder Technology,2020,364: 373-381. doi: 10.1016/j.powtec.2020.01.058 [18] 陈伟,李舟,赵振华,等. TiN/Ti强韧涂层在砂尘高速冲蚀下的失效机理[J]. 航空动力学报,2019,34(9): 1866-1872. CHEN Wei,LI Zhou,ZHAO Zhenhua,et al. Failure mechanism of TiN/Ti strength and tough coating under high-speed sand-dust erosion[J]. Journal of Aerospace Power,2019,34(9): 1866-1872. (in Chinese doi: 10.13224/j.cnki.jasp.2019.09.002CHEN Wei, LI Zhou, ZHAO Zhenhua, et al. Failure mechanism of TiN/Ti strength and tough coating under high-speed sand-dust erosion[J]. Journal of Aerospace Power, 2019, 34(9): 1866-1872. (in Chinese) doi: 10.13224/j.cnki.jasp.2019.09.002 [19] OKA Y I,OKAMURA K,YOSHIDA T. Practical estimation of erosion damage caused by solid particle impact[J]. Wear,2005,259(1/2/3/4/5/6): 95-101. -

下载:

下载: