Calculation method of meshing impact excitation of loaded gear pair

-

摘要:

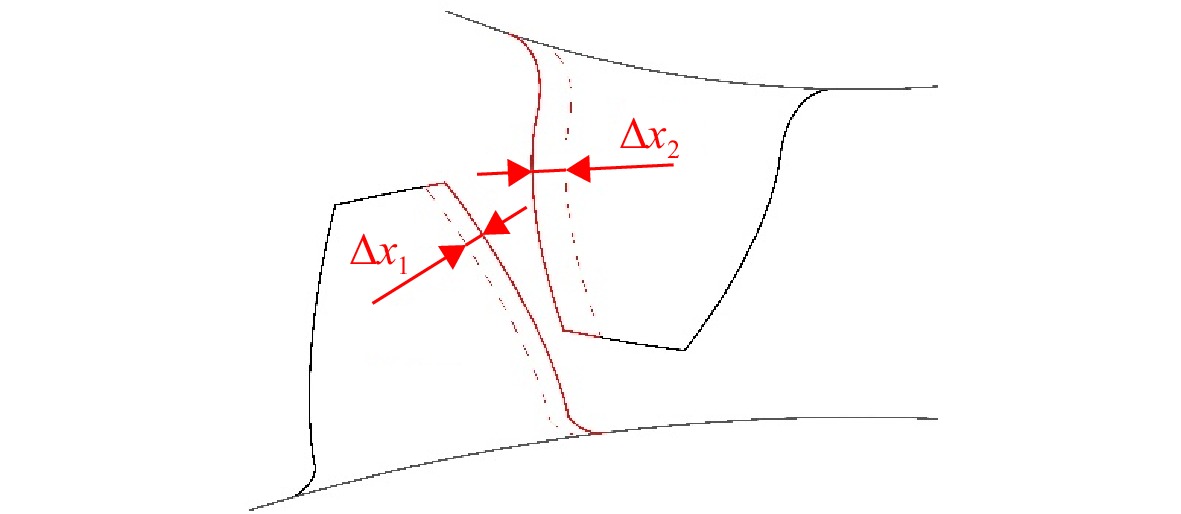

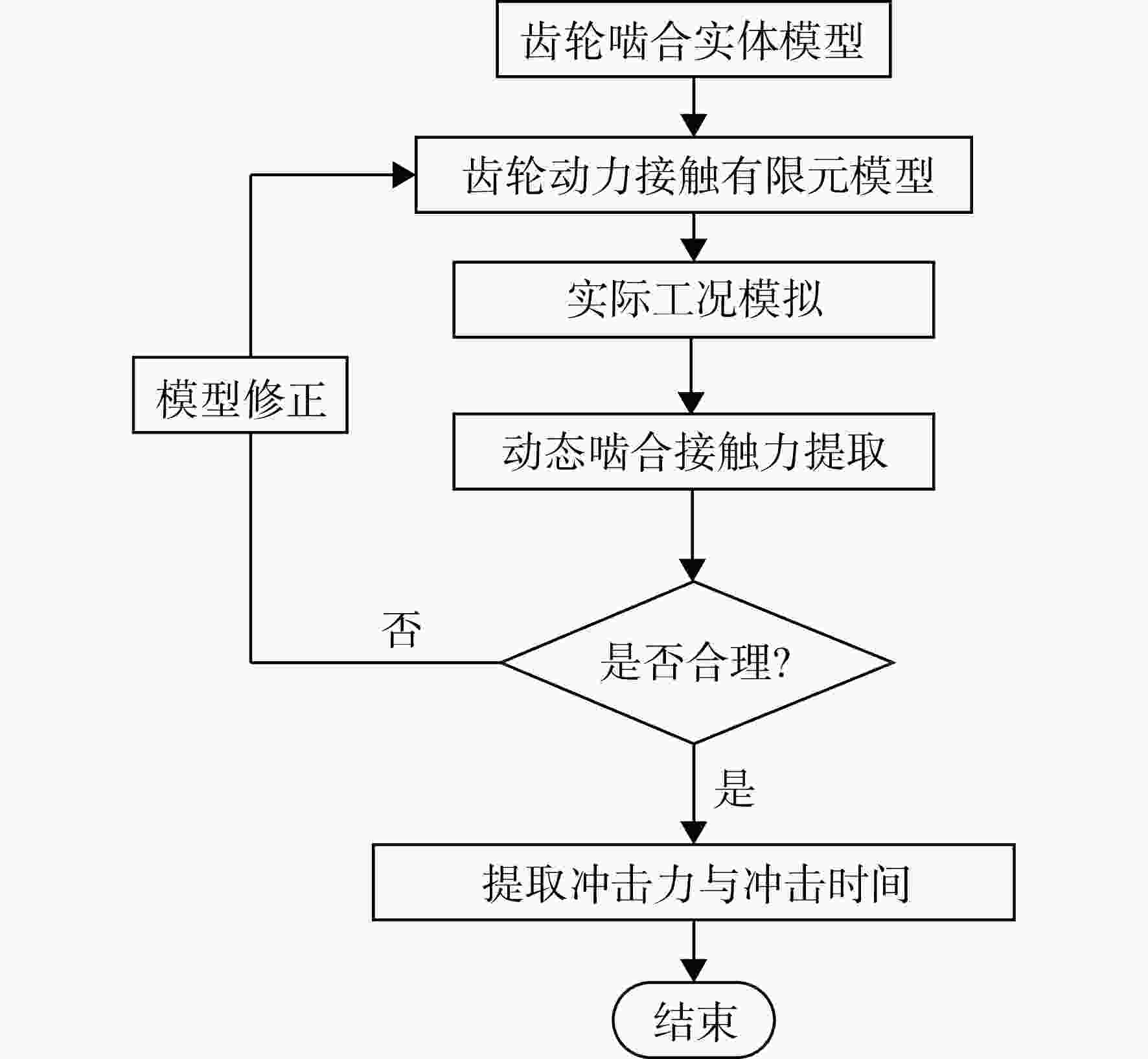

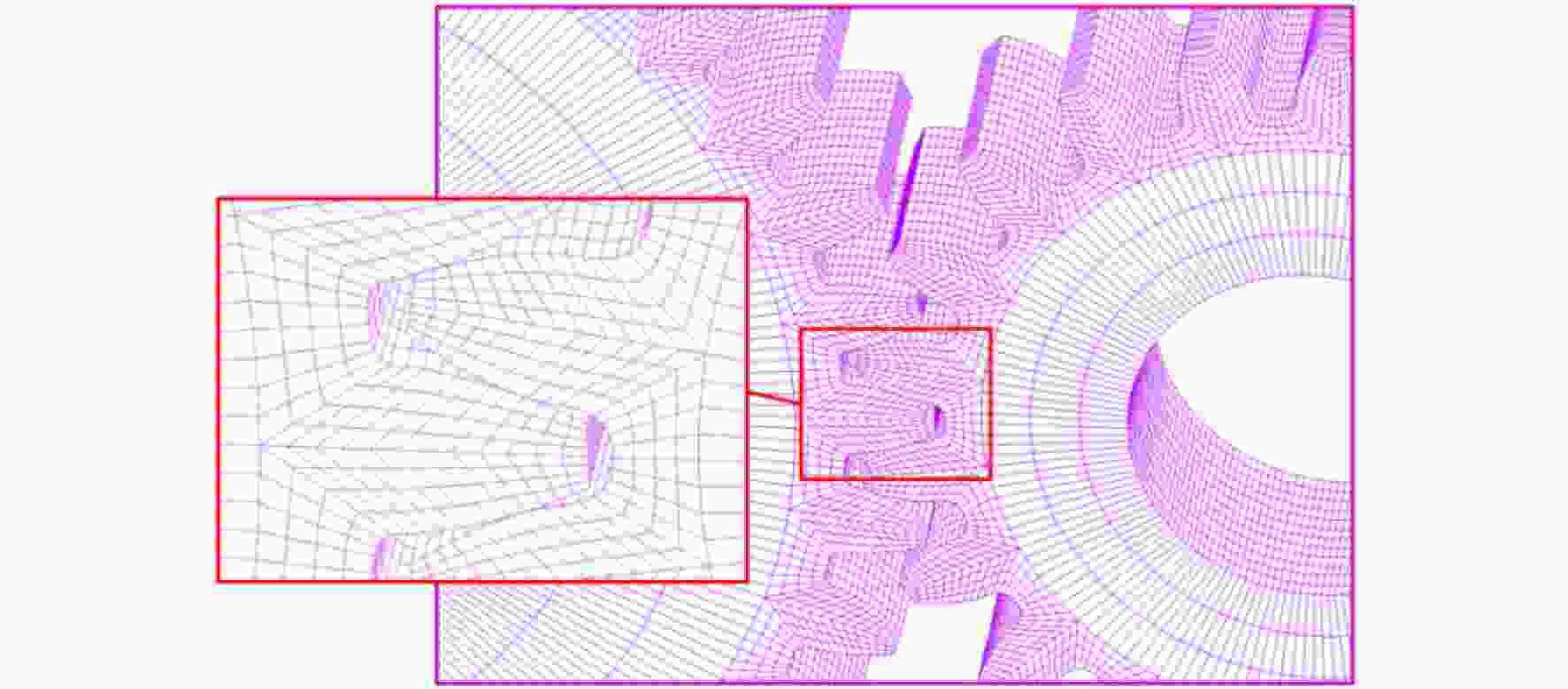

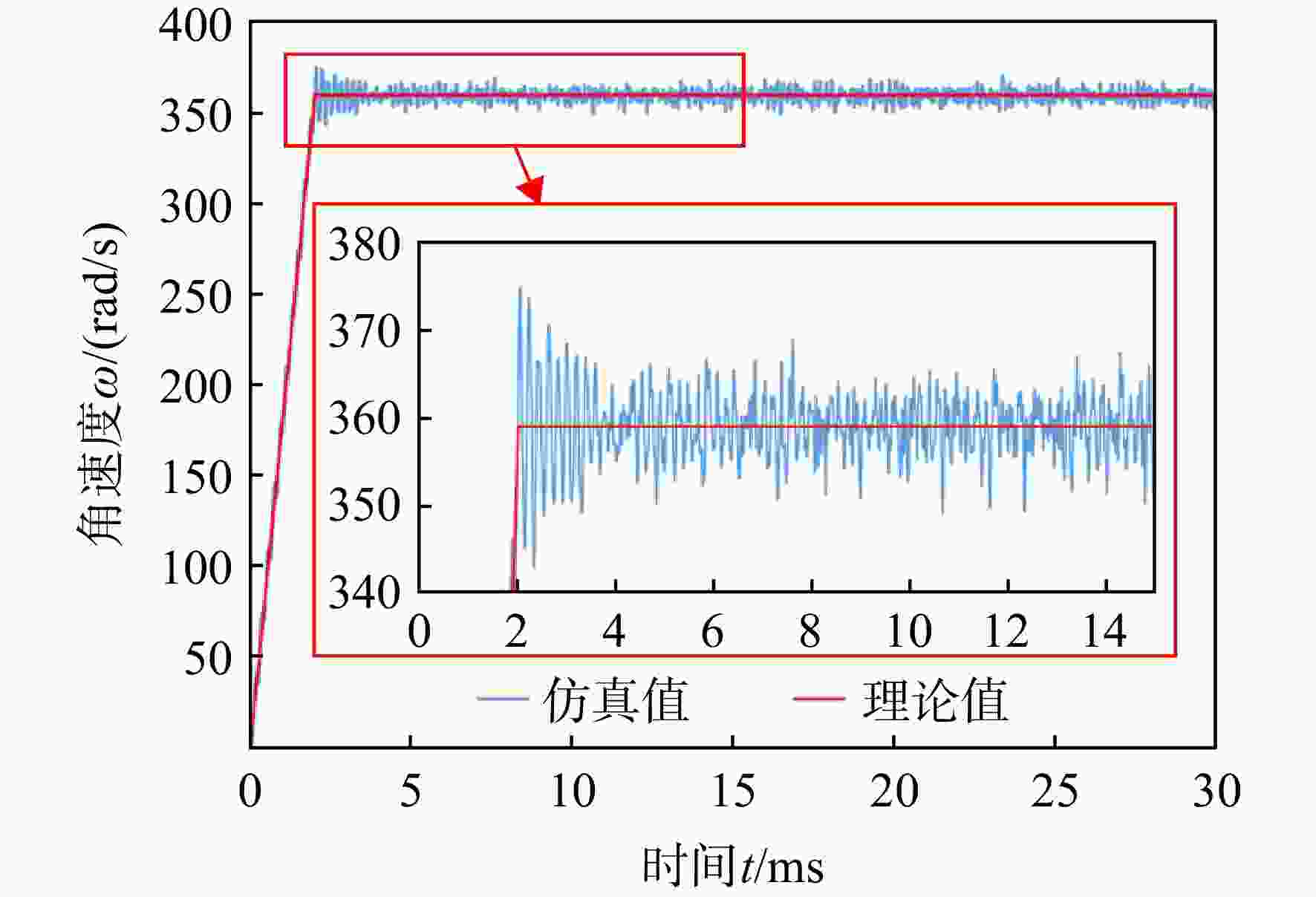

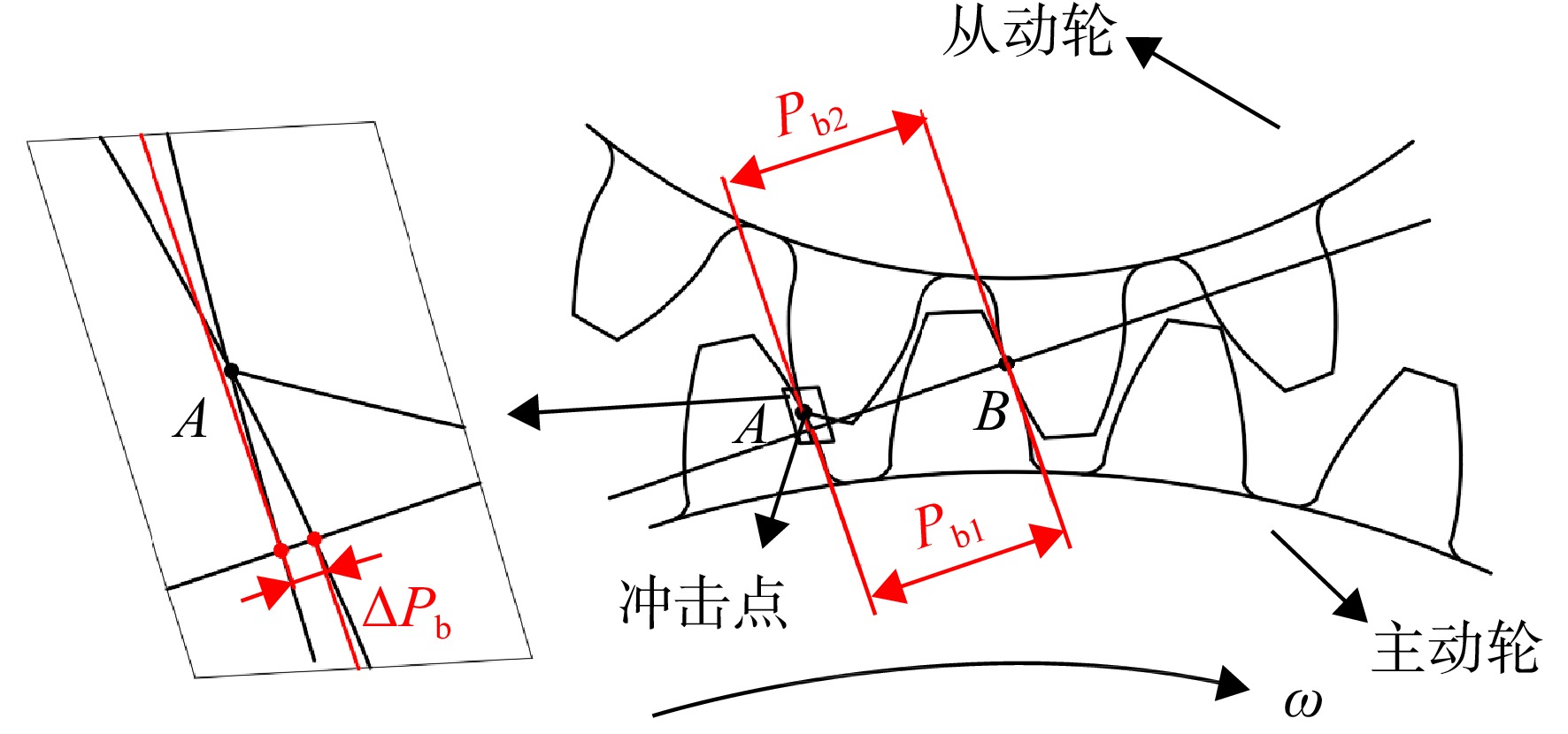

针对目前理论不能准确计算受载齿轮啮入冲击时间的问题,提出一种基于圆柱碰撞理论与接触动力学理论的受载齿轮副啮入冲击激励计算方法,准确计算受载齿轮啮入冲击时间与冲击力。建立受载变形下的渐开线齿轮啮入冲击数学模型,应用反转法计算出线外啮合点的精确位置,基于圆柱碰撞理论求得齿对啮入冲击力。同时在所建立的啮入冲击数学模型上,准确计算冲击时间,并与现有计算方法进行对比分析。而后根据齿轮运行真实工况,对航空机匣齿轮副进行动态接触有限元分析,提取冲击时间与冲击力,并与理论进行对比。结果表明:计算模型的啮入冲击时间误差在15%以内,最大啮入冲击力误差小于10%,故该冲击激励计算方法能对冲击时间与最大啮入冲击力进行准确快速求解。

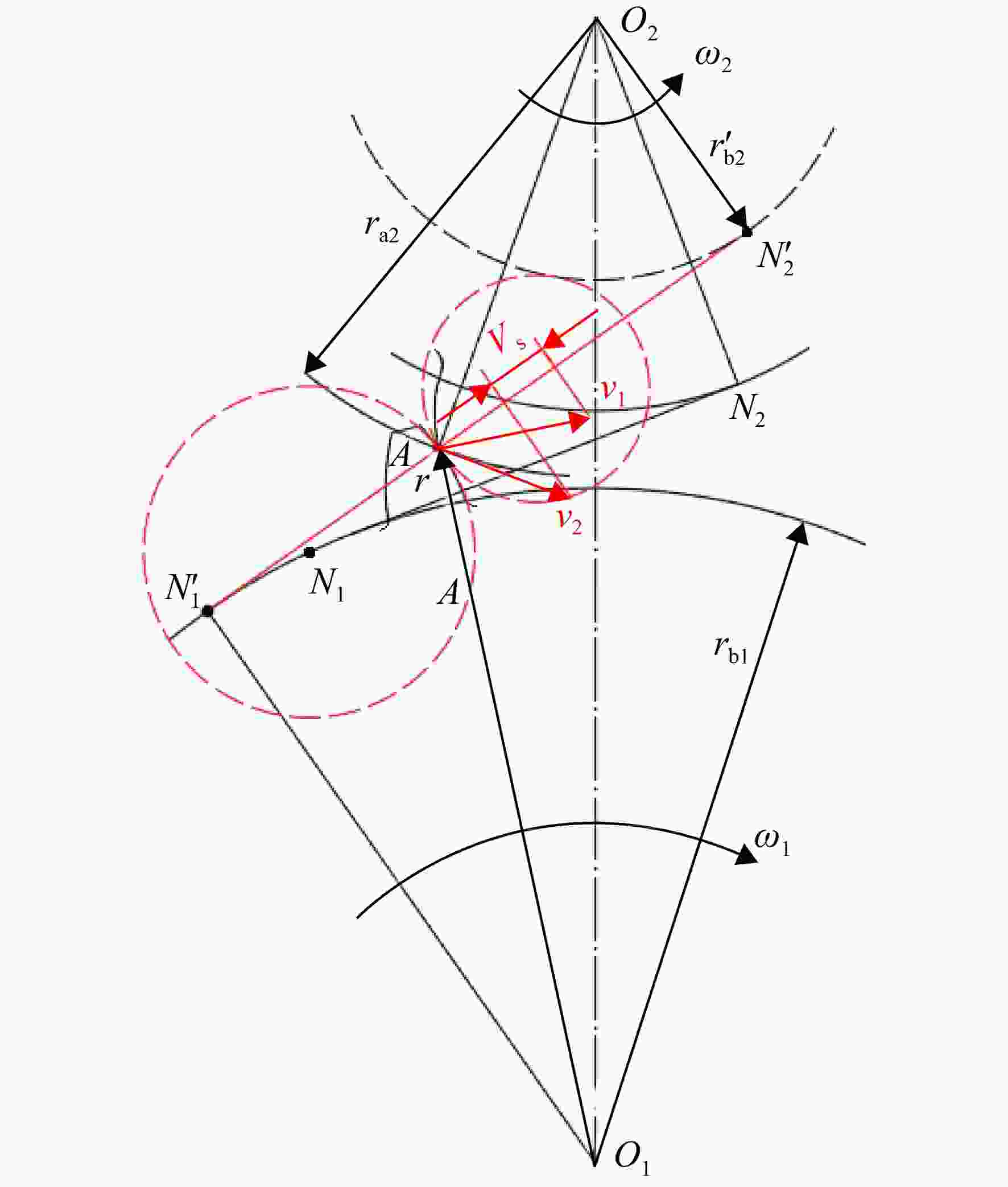

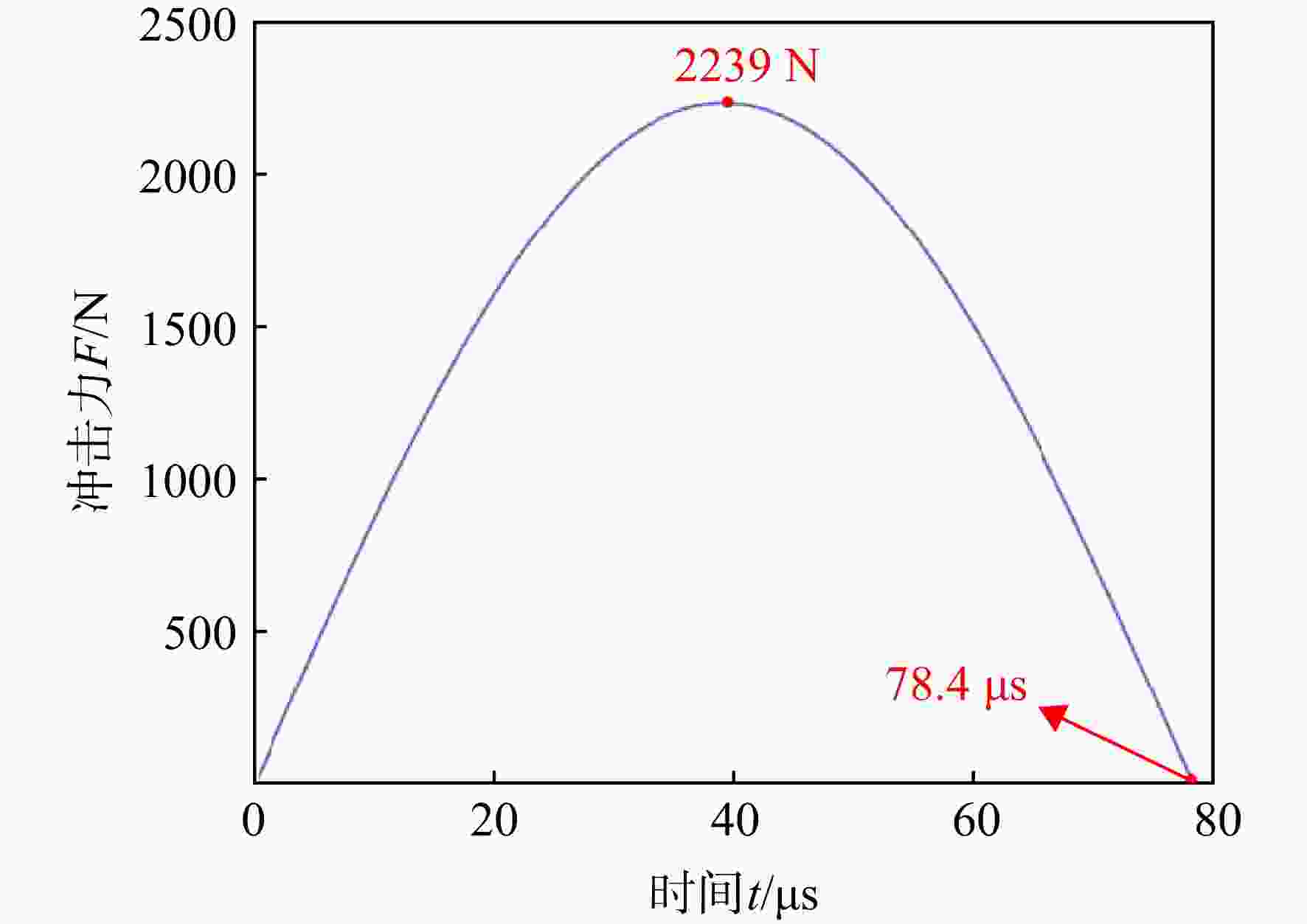

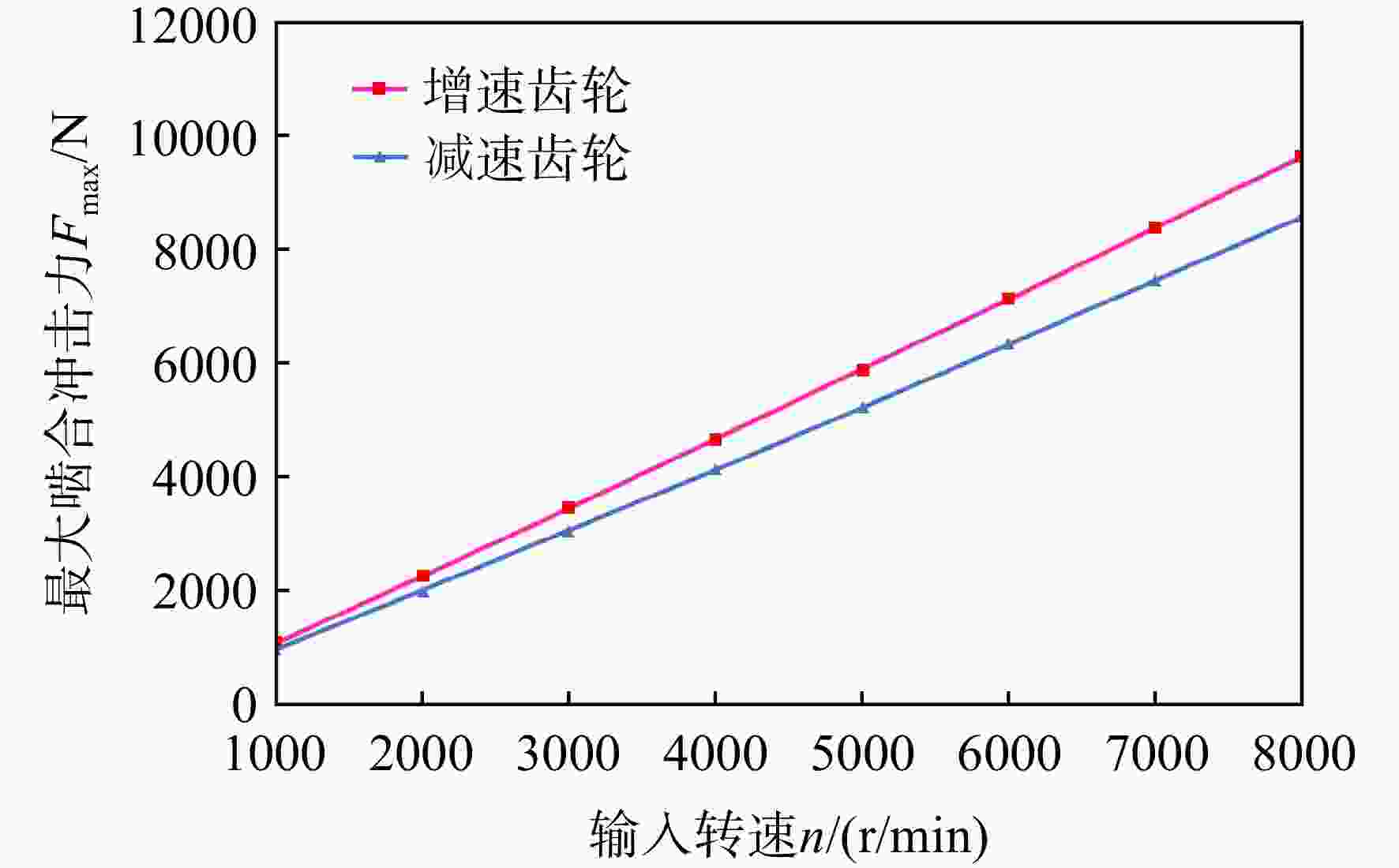

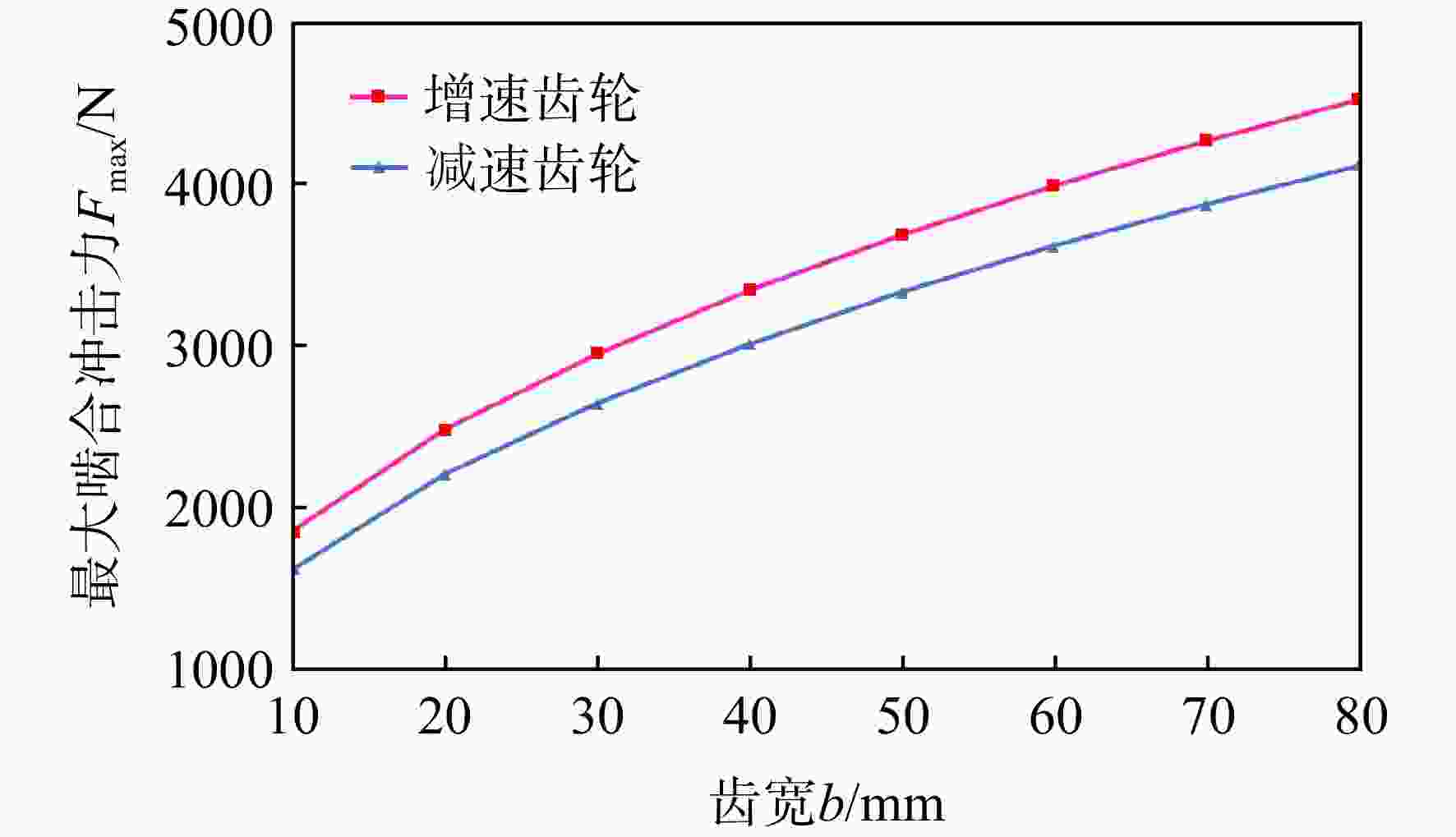

Abstract:In view of the problem that the current theory can not accurately calculate the meshing impact time of loaded gear, a calculation method of meshing impact excitation of loaded gear pair based on cylindrical collision theory and contact dynamics theory was proposed to accurately calculate the meshing impact time and impact force of loaded gear. The mathematical model of meshing impact of involute gear under load and deformation was established. The exact position of the outer meshing point of the line was calculated by the inversion method, and the meshing impact force of the tooth pair was obtained based on the cylindrical collision theory. At the same time, on the basis of the established mathematical model of meshing impact, the impact time was accurately calculated and compared with the existing calculation methods. Then, according to the actual working condition of the gear, the dynamic contact finite element analysis of the gear pair of the aircraft gearbox was carried out, while the impact time and impact force were extracted, and compared with the theory. The results showed that the error of the meshing impact time of the calculation model was within 15%, and the error of the maximum meshing impact force was less than 10%. Therefore, the impact excitation calculation method can accurately and quickly solve the impact time and the maximum meshing impact force.

-

Key words:

- impact time /

- meshing impact /

- off line contact /

- cylindrical collision /

- dynamic contact

-

表 1 两冲击时间计算方法对比

Table 1. Comparison of two impact time calculation methods

转速/(r/min) ts/μs tc/μs ta/μs 1000(n1) 36.3 215 1666.7 10000(n2) 33.2 7.34 166.7 100000(n3) 2500 0.245 16.7 表 2 齿轮副几何参数

Table 2. Geometric parameters of gear pair

参数 主动轮 从动轮 齿数Z 36 21 模数m/mm 3 压力角α/(°) 20 齿宽b/mm 16 中心距a/mm 85.5 齿顶高系数ha 1 顶隙系数c 0.25 -

[1] GAO Qiang,TANABE M,NISHIHARA K. Contact-impact analysis of geared rotor systems[J]. Journal of Sound and Vibration,2009,319(1/2): 463-475. [2] WANG Peiyu,FAN S C,HUANG Zigui. Spiral bevel gear dynamic contact and tooth impact analysis[J]. Journal of Mechanical Design,2011,133(8): 084501.1-084501.6. [3] XIANG Dong,SHEN Yinhua,WEI Yaozhong. A contact force model considering meshing and collision states for dynamic analysis in helical gear system[J]. Chinese Journal of Mechanical Engineering,2019,32(1): 1-12. doi: 10.1186/s10033-018-0313-7 [4] ZIEGLER P,EBERHARD P. Simulative and experimental investigation of impacts on gear wheels[J]. Computer Methods in Applied Mechanics and Engineering,2008,197(51/52): 4653-4662. [5] WU Yongjun,WANG Jianjun,HAN Qinkai. Contact finite element method for dynamic meshing characteristics analysis of continuous engaged gear drives[J]. Journal of Mechanical Science and Technology,2012,26(6): 1671-1685. doi: 10.1007/s12206-012-0416-5 [6] 唐进元,周炜,陈思雨. 齿轮传动啮合接触冲击分析[J]. 机械工程学报,2011,47(7): 22-30. doi: 10.3901/JME.2011.07.022TANG Jinyuan,ZHOU Wei,CHEN Siyu. Contact-impact analysis of gear transmission system[J]. Journal of Mechanical Engineering,2011,47(7): 22-30. (in Chinese) doi: 10.3901/JME.2011.07.022 [7] CHEN S Y, TANG J Y, LIU X. The dynamic transmission error and the tooth meshing force based on ANSYS/LS-DYNA[C]//Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Las Vegas, US, 2009: 547-552. [8] 符双学,周长江. 基于精确建模的齿轮传动线外啮合冲击研究[J]. 中国工程机械学报,2016,14(3): 221-226. doi: 10.15999/j.cnki.311926.2016.03.007FU Shuangxue,ZHOU Changjiang. Corner contact impact on gear transmission based on accurate modeling[J]. Chinese Journal of Construction Machinery,2016,14(3): 221-226. (in Chinese) doi: 10.15999/j.cnki.311926.2016.03.007 [9] DING Han,RONG Shifeng,RONG Kaibin,et al. Semi-FEM dynamic meshing impact forecasting model for spiral bevel and hypoid gear transmission[J]. Applied Mathematical Modelling,2022,104: 279-305. doi: 10.1016/j.apm.2021.11.014 [10] GUO Fang,FANG Zongde. A new algorithm to solve meshing-in impact considering the measured pitch error and to investigate its influence on the dynamic characteristics of a gear system[J]. International Journal of Precision Engineering and Manufacturing,2019,20(3): 395-406. doi: 10.1007/s12541-019-00047-7 [11] HU Shengyang,FANG Zongde,LIU Chao,et al. Measurements and theoretical analysis of a helical gear meshing impact signal[J]. Proceedings of the Institution of Mechanical Engineers: Part K Journal of Multi-Body Dynamics,2019,233(4): 827-839. doi: 10.1177/1464419319853435 [12] MU Yanming,FANG Zongde,LI Wenli. Impact analysis and vibration reduction design of spiral bevel gears[J]. Proceedings of the Institution of Mechanical Engineers: Part K Journal of Multi-Body Dynamics,2019,233(3): 668-676. doi: 10.1177/1464419319827398 [13] 武宝林,杨素君,姚俊红. 齿轮传动中啮合冲击的理论分析[J]. 机械科学与技术,2003,22(1): 55-57. doi: 10.3321/j.issn:1003-8728.2003.01.018WU Baolin,YANG Sujun,YAO Junhong. Theoretical analysis on meshing impact of involute gears[J]. Mechanical Science and Technology,2003,22(1): 55-57. (in Chinese) doi: 10.3321/j.issn:1003-8728.2003.01.018 [14] HE Zeyin,ZHANG Tao,LIN Tengjiao. Novel mathematical modelling method for meshing impact of helical gear[J]. Mechanism and Machine Theory,2020,152: 103949.1-103949.12. [15] LI Yang,WU Baolin,ZHU Linlin. Analysis and calculation of double circular arc gear meshing impact model[J]. The Open Mechanical Engineering Journal,2015,9(1): 160-167. doi: 10.2174/1874155X01509010160 [16] ZHOU Changjiang,CHEN Siyu. Modeling and calculation of impact friction caused by corner contact in gear transmission[J]. Chinese Journal of Mechanical Engineering,2014,27(5): 958-964. doi: 10.3901/CJME.2014.0616.110 [17] 唐进元,刘欣,戴进. 基于ANSYS/LS-DYNA的齿轮传动线外啮合冲击研究[J]. 振动与冲击,2007,26(9): 40-44, 50, 169. doi: 10.3969/j.issn.1000-3835.2007.09.010TANG Jinyuan,LIU Xin,DAI Jin. Study on corner contact shock of gear transmission by ansys/ls-dyna software[J]. Journal of Vibration and Shock,2007,26(9): 40-44, 50, 169. (in Chinese) doi: 10.3969/j.issn.1000-3835.2007.09.010 [18] 郭芳,方宗德,张西金. 考虑实测基节误差的修形齿轮啮入冲击计算[J]. 振动与冲击,2018,37(22): 30-35, 42. doi: 10.13465/j.cnki.jvs.2018.22.005GUO Fang,FANG Zongde,ZHANG Xijin. Calculation on the meshing-in impact of a modified gear considering the measured pitch error[J]. Journal of Vibration and Shock,2018,37(22): 30-35, 42. (in Chinese) doi: 10.13465/j.cnki.jvs.2018.22.005 [19] 张金梅,刘更,周建星,等. 考虑啮入冲击作用下减速器的振动噪声分析[J]. 振动与冲击,2013,32(13): 118-122, 141. doi: 10.3969/j.issn.1000-3835.2013.13.022ZHANG Jinmei,LIU Geng,ZHOU Jianxing,et al. Vibration and noise radiation analysis for a gear reducer considering meshing impact[J]. Journal of Vibration and Shock,2013,32(13): 118-122, 141. (in Chinese) doi: 10.3969/j.issn.1000-3835.2013.13.022 [20] 李应刚,陈天宁,王小鹏,等. 圆柱碰撞冲击噪声理论分析与数值仿真[J]. 振动与冲击,2014,33(15): 162-166, 173. doi: 10.13465/j.cnki.jvs.2014.15.028LI Yinggang,CHEN Tianning,WANG Xiaopeng,et al. Theoretical analysis and numerical simulation for impact noise due to collision of two cylinders[J]. Journal of Vibration and Shock,2014,33(15): 162-166, 173. (in Chinese) doi: 10.13465/j.cnki.jvs.2014.15.028 -

下载:

下载: