Dynamic accuracy’s evolutionary regularity of angular contact ball bearing based on design parameters

-

摘要:

为了确定成品轴承精度是否满足设计要求,合套和拆套是必然工序,不仅耗费工时,还可能引起滚动体和套圈划伤,致使产品精度下降,甚至丧失。根据角接触球轴承工作状态运动学和几何学关系,建立依据零件精度要素的接触角、径向跳动和轴向跳动的解析模型,提出动态精度计算方法,研究不同加工阶段轴承精度变化趋势,系统分析沟曲率半径、沟底直径、球直径及与之相关的精度要素与动态精度的关系。计算结果表明:沟底直径对接触角影响显著,为了满足设计要求,加工后可分组选配;误差幅值增大,径向和轴向跳动增大,几乎呈线性关系;球数对旋转精度影响不大,但会影响运行的稳定性。成品轴承动态精度检测数据与计算结果一致,说明模型准确合理,故通过零件设计参数检测即可得出动态精度是否满足运行要求,无需合套和拆套工序,有利于提升产品合格率和生产效率。

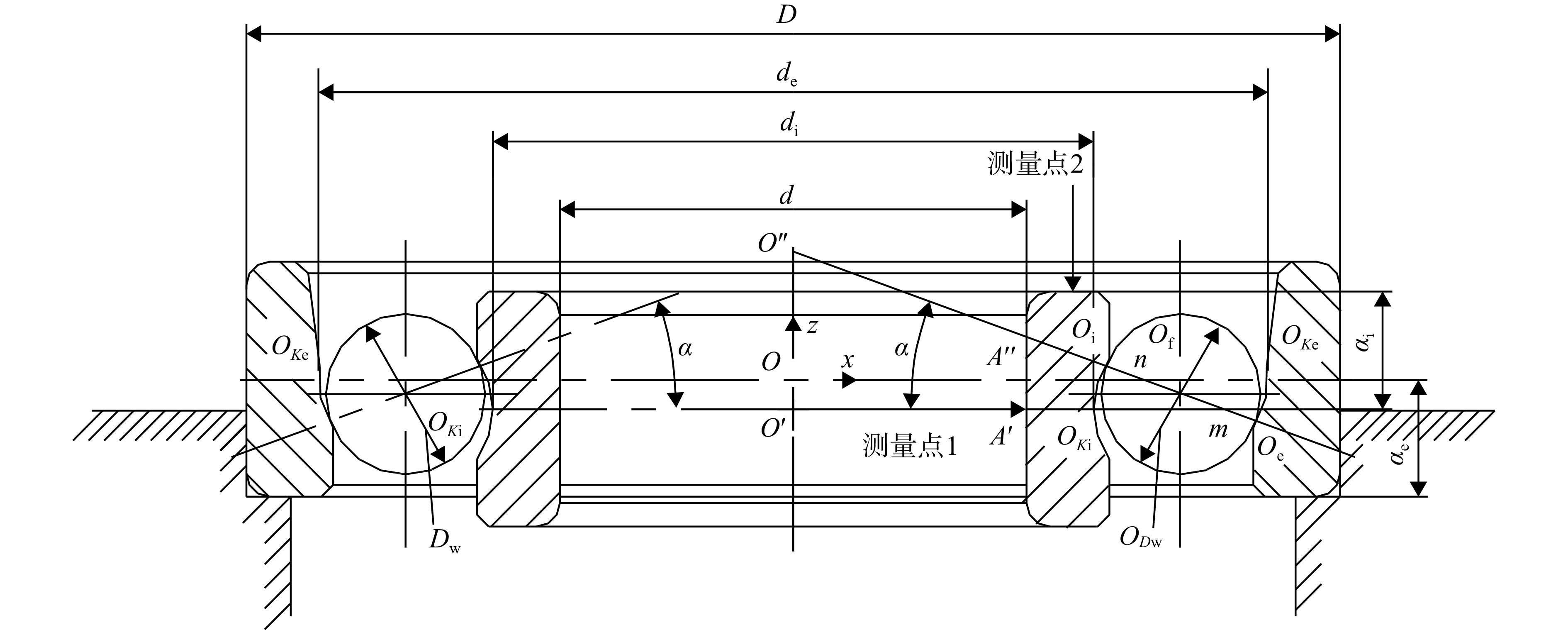

Abstract:Discussions were performed to determine whether the accuracy of finished bearing could meet the design requirements, as the assembly and disassembly as inevitable processes not only consume working hours, but also may cause scratches on the rolling element and ring, resulting in the decline or even loss of product accuracy. According to the kinematic and geometric relationship of the angular contact ball bearing at condition in motion, based on the accuracy elements of parts, the analytical models of contact angle, radial runout and axial runout of inner ring of assembled bearing were established, the calculation method of dynamic accuracy was proposed, the variation trends of bearing accuracy in different processing stages were studied, and the relationship between groove curvature radius, groove bottom diameter, ball diameter and related accuracy elements and dynamic accuracy was systematically analyzed. The calculation results showed that the groove bottom diameter had a significant influence on the contact angle. In order to meet the design requirements, selection in groups was required after machining; When the error amplitude increased, the radial and axial runout increased almost linearly; The number of balls had little effect on the rotation accuracy, but it affected the stability of operation. The dynamic accuracy test data of the finished bearing were consistent with the calculation results, which indicated that the model was accurate and reasonable. Therefore, whether the dynamic accuracy meets the operation requirements can be obtained through the test of the parts’ design parameters. There is no need for the sleeve assembly and disassembly, which is conducive to improving the qualification rate and production efficiency.

-

Key words:

- angular contact ball bearing /

- dynamic accuracy /

- error amplitude /

- radial runout /

- axial runout

-

表 1 不同加工阶段参数测量均值

Table 1. Mean value of parameter measurement in different processing stages

mm 检测参数 粗加工 精加工 超精加工 ri 3.4481 3.4943 3.4999 re 3.2833 3.2916 3.3102 di 53.7223 53.7123 53.6212 de 66.2943 66.2994 66.3673 ai 8.0234 8.002 8.002 ae 8.1337 8.122 8.122 d 44.9546 44.9997 44.9997 Dw 6 6 6.35 表 2 不同球数的动态精度

Table 2. Dynamic accuracy of different ball numbers

N Δα/(°) Kia/mm Sia/mm 20 0.17 0.0012 0.0043 18 0.17 0.0012 0.0044 16 0.171 0.0013 0.0043 14 0.171 0.0012 0.0043 12 0.172 0.0012 0.0044 10 0.172 0.0013 0.0044 8 0.172 0.0014 0.0045 表 3 不同球数的动态精度方差

Table 3. Dynamic precision variance of different ball numbers

N F2(α) F2(Kia)/10−7 F2(Sia)/10−7 22 0.00298 1.9285 3.3147 20 0.00306 1.9289 3.3150 18 0.00312 1.9291 3.3155 16 0.00314 1.9294 3.3157 14 0.00317 1.9298 3.3159 12 0.00322 1.9303 3.3163 10 0.00328 1.9307 3.3167 8 0.00333 1.9311 3.3170 -

[1] 刘鲁,赵聪,冯小川,等. 角接触球轴承在高速大载荷工况下滑油中断耐受能力分析[J]. 航空动力学报,2021,36(11): 2430-2436. LIU Lu,ZHAO Cong,FENG Xiaochuan,et al. Analysis of oil-off tolerance of angular contact ball bearing under condition of high speed and heavy load[J]. Journal of Aerospace Power,2021,36(11): 2430-2436. (in Chinese doi: 10.13224/j.cnki.jasp.20200526 LIU Lu, ZHAO Cong, FENG Xiaochuan, et al . Analysis of oil-off tolerance of angular contact ball bearing under condition of high speed and heavy load[J]. Journal of Aerospace Power,2021 ,36 (11 ):2430 -2436 . (in Chinese) doi: 10.13224/j.cnki.jasp.20200526[2] 杜建建,潘贤德,刘天一. 航空发动机角接触球轴承轴向力间接测量方法[J]. 航空学报,2022,43(9): 184-191. DU Jianjian,PAN Xiande,LIU Tianyi. Indirect measurement method for axial load of aero-engine angular contact ball bearing[J]. Acta Aeronautica et Astronautica Sinica,2022,43(9): 184-191 (in Chinese doi: 10.7527/j.issn.1000-6893.2022.9.hkxb202209011 DU Jianjian, PAN Xiande, LIU Tianyi . Indirect measurement method for axial load of aero-engine angular contact ball bearing[J]. Acta Aeronautica et Astronautica Sinica,2022 ,43 (9 ):184 -191 (in Chinese) doi: 10.7527/j.issn.1000-6893.2022.9.hkxb202209011[3] WANG Liqin,CUI Li,ZHENG Dezhi,et al. Nonlinear dynamics behaviors of a rotor roller bearing system with radial clearances and waviness considered[J]. Chinese Journal of Aeronautics,2008,21(1): 86-96. doi: 10.1016/S1000-9361(08)60012-6 [4] NOGUCHI S,HIRUMA K,KAWA H,et al. The Influence of location of balls and ball diameter difference in rolling bearings on the nonrepetitive runout (NRRO) of retainer revolution[J]. Precision Engineering,2005,29(1): 11-18. doi: 10.1016/j.precisioneng.2004.03.003 [5] NOGUCHI S,ONO K. Reduction of NRRO in ball bearings for HDD spindle motors[J]. Precision Engineering,2004,28(4): 409-418. doi: 10.1016/j.precisioneng.2004.01.005 [6] NOGUCHI S,HIRUMA K. Theoretical analysis of the NRRO of the components of retainer rotation in consideration of diameter difference and disposition of balls in a ball bearing[J]. Japanese Journal of Tribology,2003,48: 166-176. [7] NOGUCHI S,HIRUMA K. Theoretical analysis of the NRRO of the components of retainer rotation in consideration of diameter difference and disposition of balls in a ball bearing[J]. Japanese Journal of Tribology,2003,48(2): 167-176. [8] OKAMOTO J,OHMORI T,KITAHARA T. Study on run-out of ball bearings-relation between unroundness of race and locus of shaft in rotation[J]. Japanese Journal of Tribology,2001,46(7): 578-584. [9] TADA S. Three-dimensional analysis of non-repeatable runout (NRRO) in ball bearings[J]. Koyo Engineering Journal,2002,161: 31-37. [10] 余永健,李济顺,陈国定,等. 基于内圈滚道廓形的圆柱滚子轴承旋转精度[J]. 航空动力学报,2017,32(1): 155-161. YU Yongjian,LI Jishun,CHEN Guoding,et al. Rotational accuracy of the cylindrical roller bearing based on inner raceway profile[J]. Journal of Aerospace Power,2017,32(1): 155-161. (in Chinese doi: 10.13224/j.cnki.jasp.2017.01.021 YU Yongjian, LI Jishun, CHEN Guoding, et al . Rotational accuracy of the cylindrical roller bearing based on inner raceway profile[J]. Journal of Aerospace Power,2017 ,32 (1 ):155 -161 . (in Chinese) doi: 10.13224/j.cnki.jasp.2017.01.021[11] 余永健,陈国定,李济顺,等. 滚子几何误差对圆柱滚子轴承旋转精度的影响[J]. 西北工业大学学报,2019,37(4): 774-784. YU Yongjian,CHEN Guoding,LI Jishun,et al. Influence of geometric error of rollers on rotational accuracy of cylindrical roller bearings[J]. Journal of Northwestern Polytechnical University,2019,37(4): 774-784. (in Chinese doi: 10.3969/j.issn.1000-2758.2019.04.018 YU Yongjian, CHEN Guoding, LI Jishun, et al . Influence of geometric error of rollers on rotational accuracy of cylindrical roller bearings[J]. Journal of Northwestern Polytechnical University,2019 ,37 (4 ):774 -784 . (in Chinese) doi: 10.3969/j.issn.1000-2758.2019.04.018[12] LIU Yong,LI Ji,SHI Wen,et al. An algorithm to prediction the radial runout of cylindrical roller bearings[J]. Applied Mechanics and Materials,2011,80/81: 551-555. doi: 10.4028/www.scientific.net/AMM.80-81.551 [13] 陈月,邱明,杜辉,等. 机器人用四点接触球轴承旋转精度影响因素[J]. 中国机械工程,2020,31(14): 1678-1685,1692. CHEN Yue,QIU Ming,DU Hui,et al. Factors influencing rotation accuracy of four-point contact ball bearings for robots[J]. China Mechanical Engineering,2020,31(14): 1678-1685,1692. (in Chinese doi: 10.3969/j.issn.1004-132X.2020.14.006 CHEN Yue, QIU Ming, DU Hui, et al . Factors influencing rotation accuracy of four-point contact ball bearings for robots[J]. China Mechanical Engineering,2020 ,31 (14 ):1678 -1685, 1692 . (in Chinese) doi: 10.3969/j.issn.1004-132X.2020.14.006[14] 留剑,洪军,杨朝晖,等. 高速精密角接触球轴承旋转精度创成机理研究[J]. 西安交通大学学报,2011,45(11): 72-78. LIU Jian,HONG Jun,YANG Zhaohui,et al. Running accuracy of high speed precision angular contact ball bearings[J]. Journal of Xi’an Jiaotong University,2011,45(11): 72-78. (in Chinese LIU Jian, HONG Jun, YANG Zhaohui, et al . Running accuracy of high speed precision angular contact ball bearings[J]. Journal of Xi’an Jiaotong University,2011 ,45 (11 ):72 -78 . (in Chinese)[15] 袁幸,朱永生,洪军,等. 精密球轴承不可重复跳动影响主轴动特性的预测[J]. 吉林大学学报(工学版),2012,42(2): 382-387. YUAN Xing,ZHU Yongsheng,HONG Jun,et al. Prediction model of spindle dynamic characteristics affected by non-repetitive Run-out of precision ball bearing and its application[J]. Journal of Jilin University (Engineering and Technology Edition),2012,42(2): 382-387. (in Chinese doi: 10.13229/j.cnki.jdxbgxb2012.02.031 YUAN Xing, ZHU Yongsheng, HONG Jun, et al . Prediction model of spindle dynamic characteristics affected by non-repetitive Run-out of precision ball bearing and its application[J]. Journal of Jilin University (Engineering and Technology Edition),2012 ,42 (2 ):382 -387 . (in Chinese) doi: 10.13229/j.cnki.jdxbgxb2012.02.031[16] 国家质量监督检验检疫总局,中国国家标准化管理委员会. 滚动轴承 测量和检验的原则及方法: GB/T 307.2-2005[S]. 北京: 中国标准出版社,2005: 28. [17] BIAN Wei,WANG Zhenhua,YUAN Juntang,et al. Thermo-mechanical analysis of angular contact ball bearing[J]. Journal of Mechanical Science and Technology,2016,30(1): 297-306. doi: 10.1007/s12206-015-1233-4 [18] 国家质量监督检验检疫总局,中国国家标准化管理委员会. 滚动轴承 球 第2部分: 陶瓷球: GB/T 308.2-2010[S]. 北京: 中国标准出版社,2011: 10. -

下载:

下载: