Rapid identification and monitoring of digital twin wings damage patterns

-

摘要:

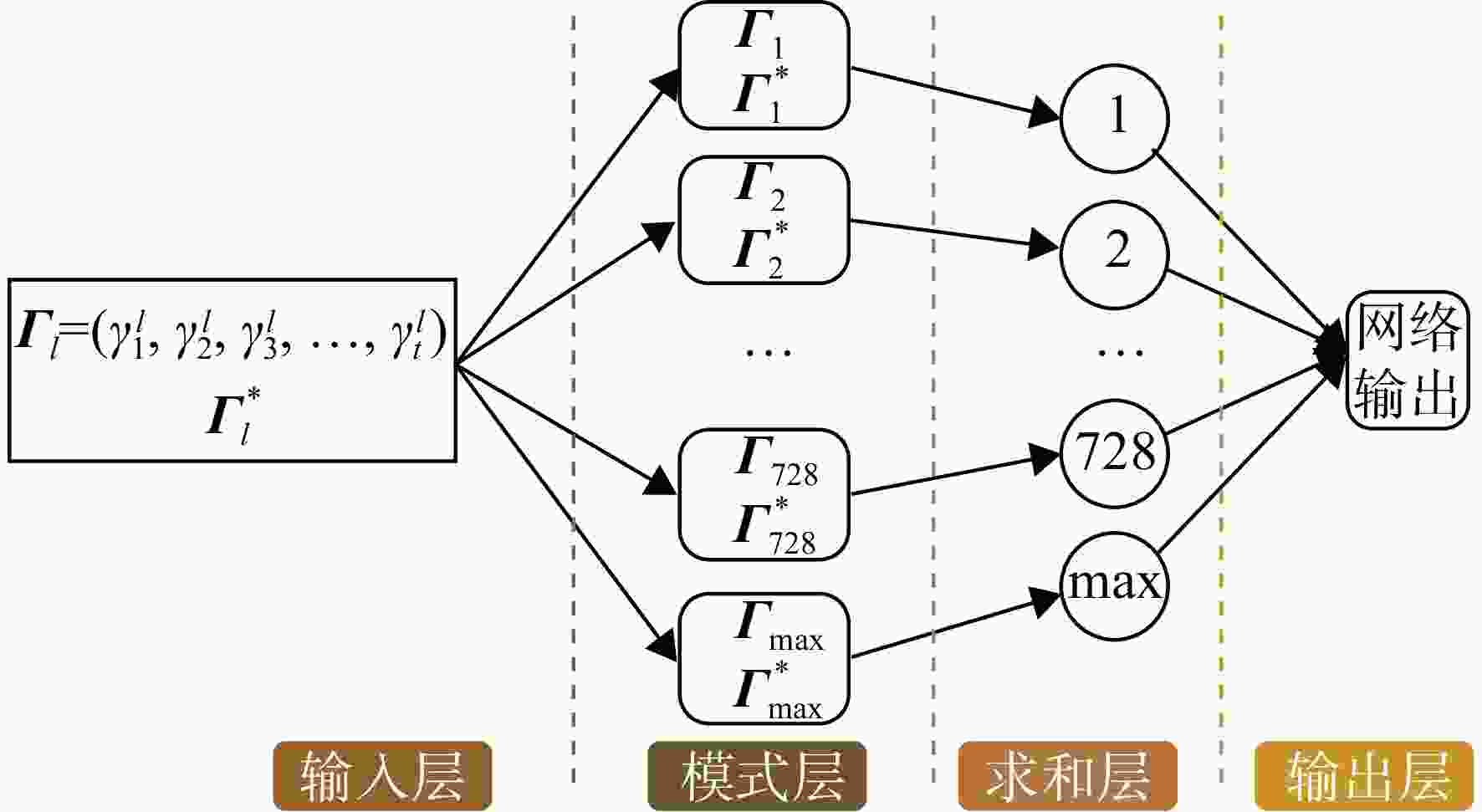

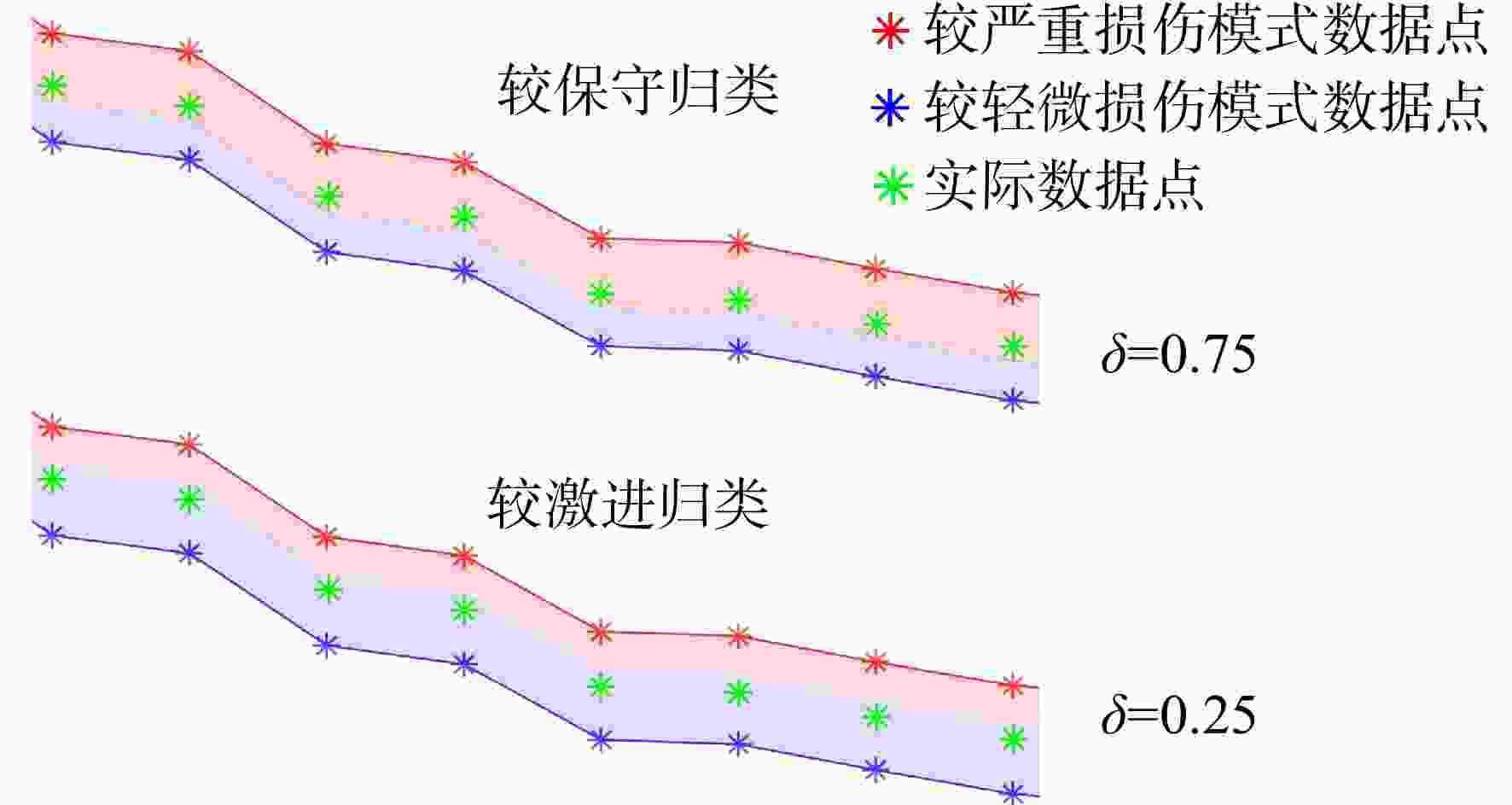

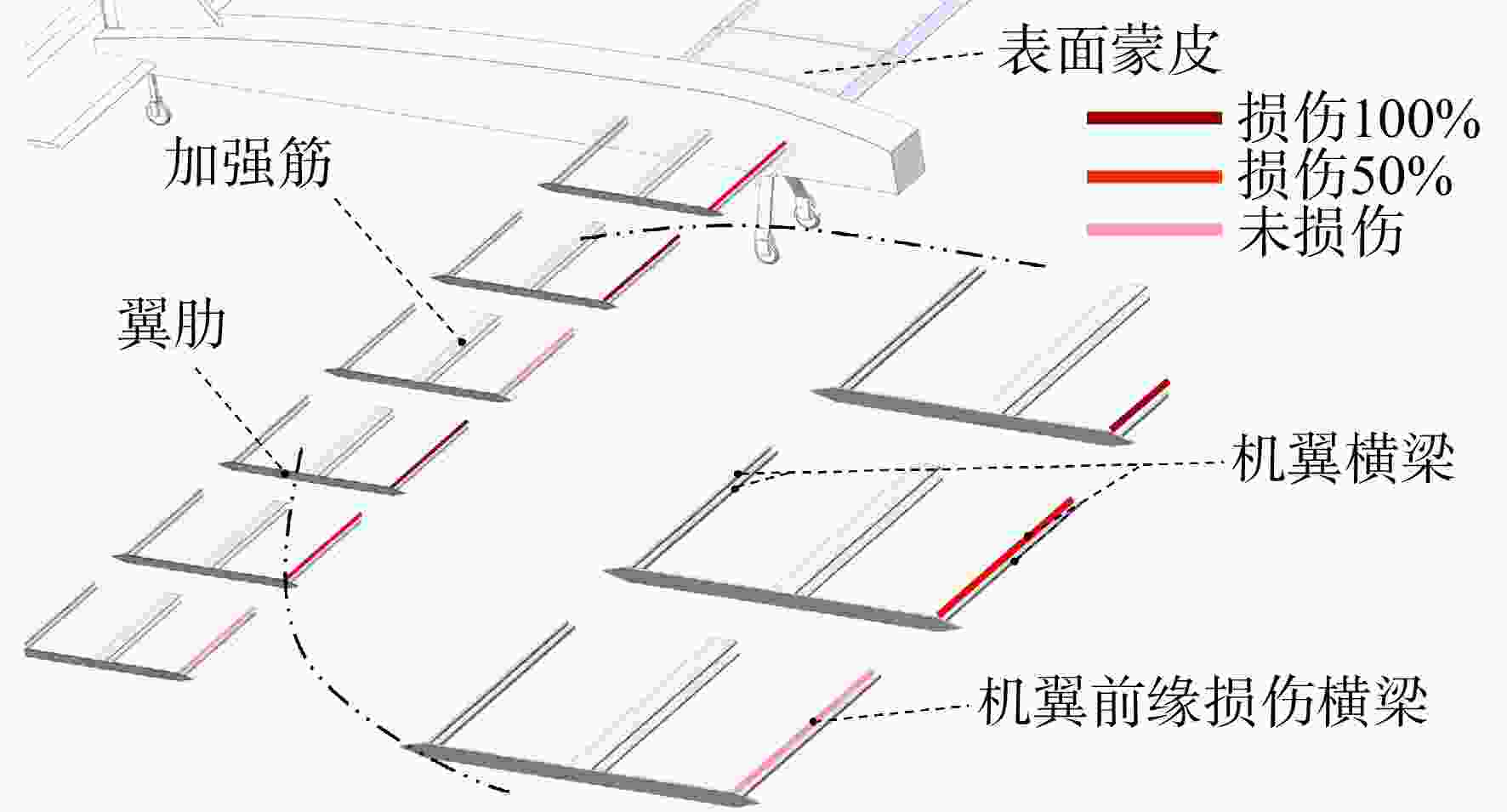

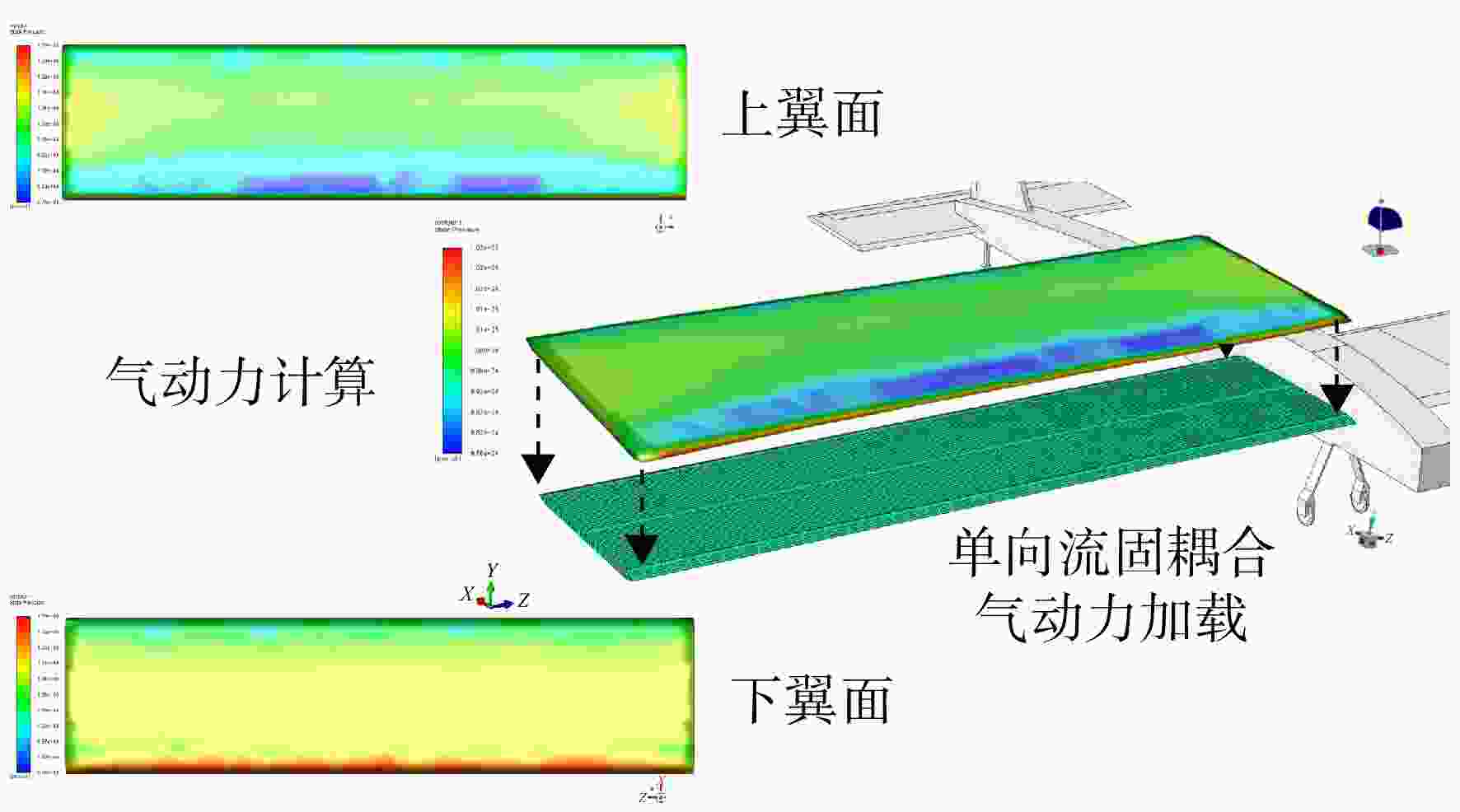

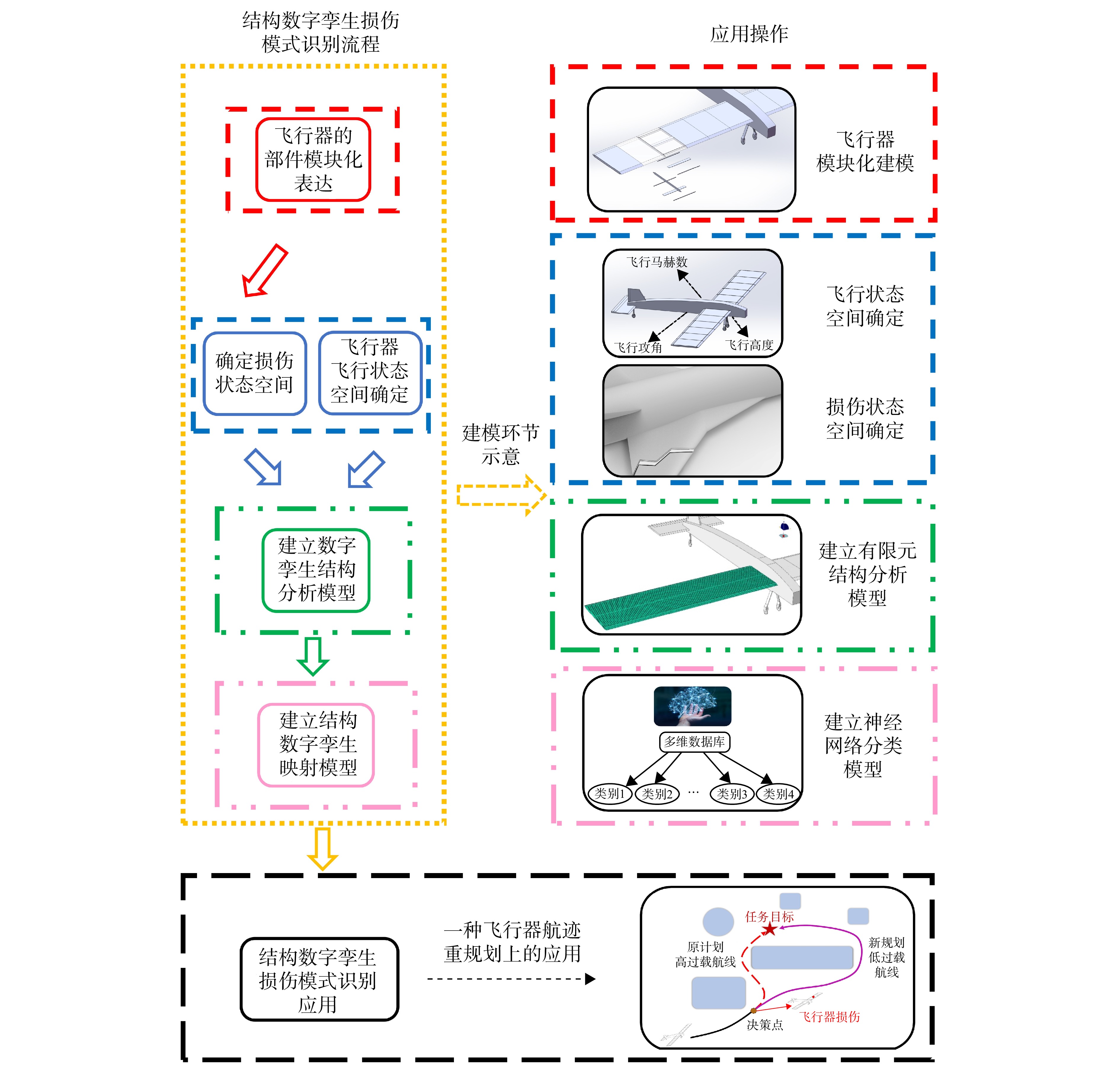

针对飞行器结构健康监测过程中存在的识别流程复杂、实时性较差问题,提出一种基于数字孪生技术的飞行器机翼损伤模式识别与监测方法。采用模块化技术构建飞行器机翼的数字孪生结构模型,基于概率神经网络建立了传感器数据在结构数字孪生模型中的映射方法,形成了通用的数字孪生飞行器结构损伤模式快速识别流程。以某无人机为例,基于此流程方法建立了其机翼的损伤模式快速识别模型并开展了对损伤的识别。结果表明:构建的飞行器结构数字孪生识别模型对损伤模式的识别准确率达到了96%以上,能够实现动态航迹规划任务。

Abstract:To address the problems of complex recognition and poor real-time performance in the process of structural health monitoring of aircraft, a digital twin technology-based damage pattern recognition and prediction method for aircraft wings was proposed. The digital twin structural model of the aircraft wing was constructed using modular technology, and the mapping method of sensor data in the structural digital twin model was established based on probabilistic neural network, forming a fast monitoring process of general digital twin aircraft structural damage pattern. Based on an unmanned aerial vehicle, a rapid damage pattern recognition model of its wings was developed. The results showed that the damage pattern identification accuracy of the digital twin recognition model for aircraft structures reached over 96%, which could complete the dynamic trajectory planning task.

-

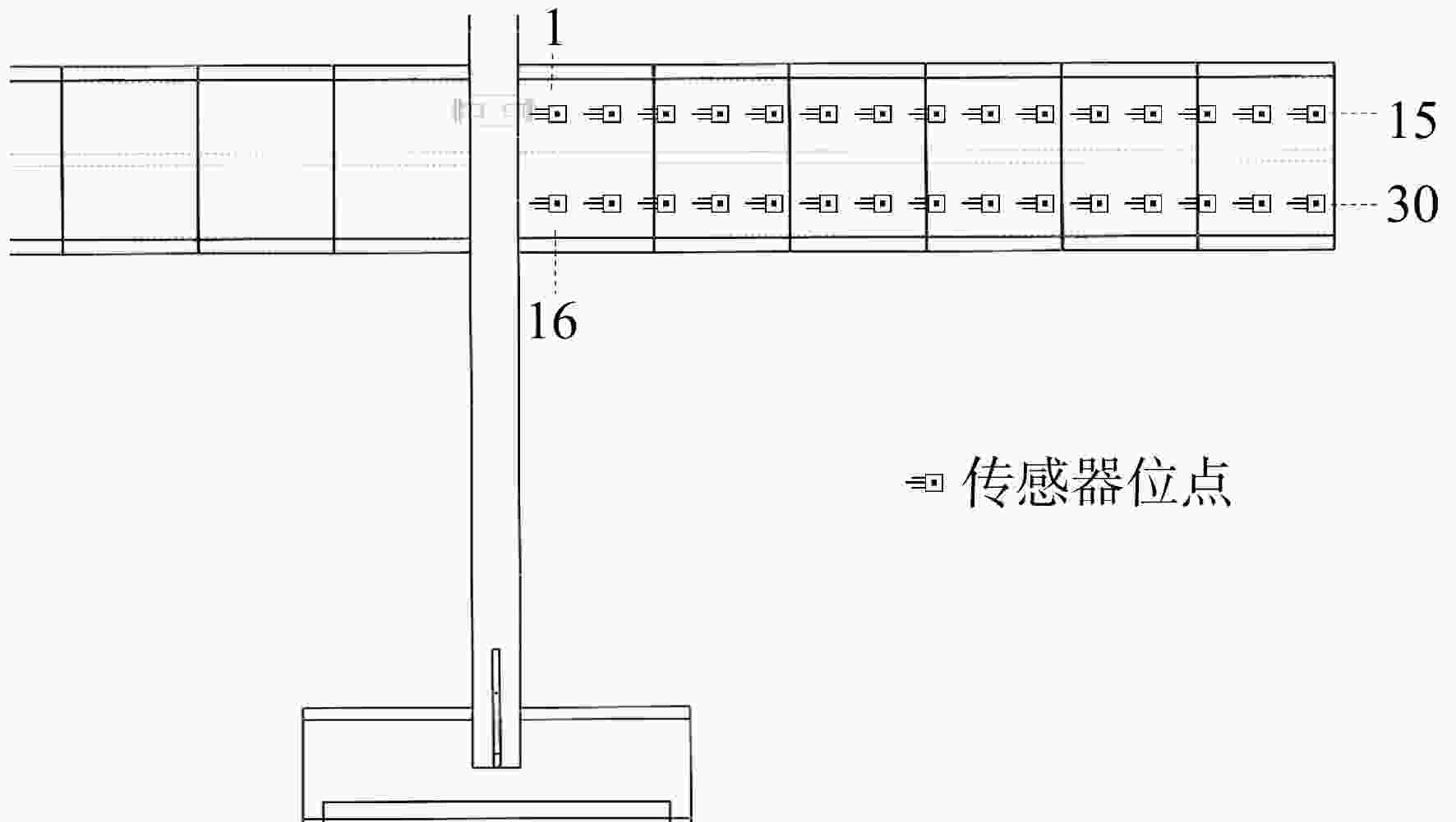

表 1 飞行器几何参数

Table 1. Geometry parameters of the aircraft

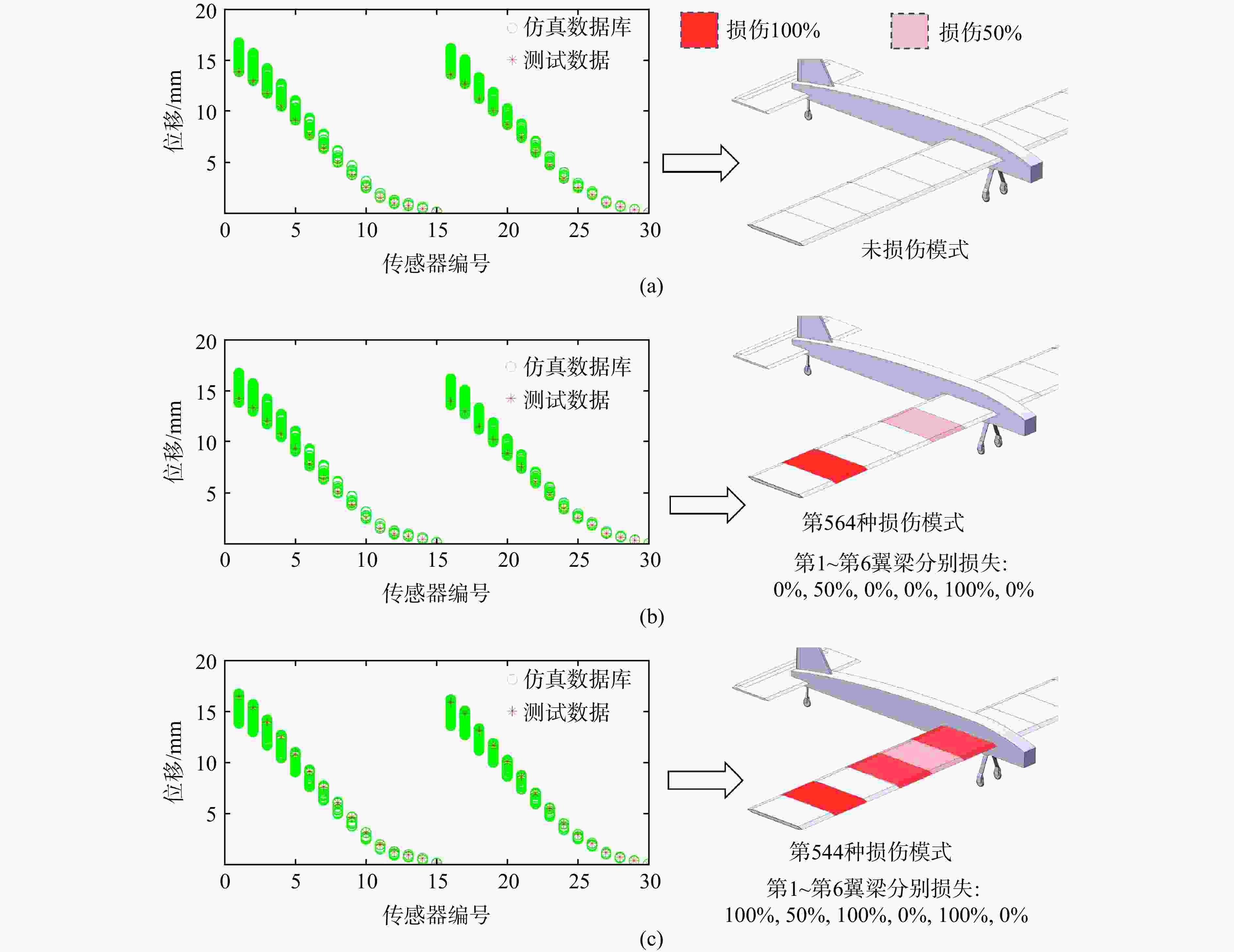

mm 类型 参数 数值 机身 长度 1400 厚度 70 机翼 单边翼展 1200 翼根弦长 300 翼梢弦长 300 翼面最大厚度 14 翼根最大翼厚长度 260 翼梢最大翼厚长度 260 单节隔框长度 200 表 2 识别结果示意

Table 2. Identification results illustrated

识别模型

偏移系数识别为较为严重

模式比例/%识别为较为完好

模式比例/%识别

准确率/%0.2 15.7530 84.2470 98.0782 0.5 43.3841 56.6159 97.8848 0.8 73.8063 26.1937 96.3594 表 3 识别结果差别分析

Table 3. Analysis of differences in identification results

识别不准确

数据编号识别损伤

模式实际损伤

模式损伤模式

差别1 第429种 第348种 第5翼梁实际损伤

50%,识别为0%2 第534种 第615种 第5翼梁实际损伤

50%,识别为损伤100%3 第555种 第393种 第5、第6翼梁实际

损伤50%、50%,识别

为损伤100%、0%表 4 识别模型抗干扰性能分析

Table 4. Analysis of the anti-interference performance of the recognition model

传感器精度/% 识别模型偏移系数 识别准确率/% 0.05 0.2 96.3539 0.5 95.5809 0.8 95.5008 0.2 0.2 90.7988 0.5 88.5217 0.8 87.2754 0.35 0.2 76.9342 0.5 75.5339 0.8 76.4658 -

[1] 武湛君,渠晓溪,高东岳,等. 航空航天复合材料结构健康监测技术研究进展[J]. 航空制造技术,2016,59(15): 92-102,109. WU Zhanjun,QU Xiaoxi,GAO Dongyue,et al. Research progress on structural health monitoring technology for aerospace composite structures[J]. Aeronautical Manufacturing Technology,2016,59(15): 92-102,109. (in Chinese WU Zhanjun, QU Xiaoxi, GAO Dongyue, et al . Research progress on structural health monitoring technology for aerospace composite structures[J]. Aeronautical Manufacturing Technology,2016 ,59 (15 ):92 -102, 109 . (in Chinese)[2] 林旭斌,张斌,葛悦涛. 国外智能化技术在高超声速飞行器领域的应用研究[J]. 飞航导弹,2020(12): 1-5,16. LIN Xubin,ZHANG Bin,GE Yuetao. Research on application of foreign intelligent technology in hypersonic vehicle field[J]. Aerodynamic Missile Journal,2020(12): 1-5,16. (in Chinese LIN Xubin, ZHANG Bin, GE Yuetao . Research on application of foreign intelligent technology in hypersonic vehicle field[J]. Aerodynamic Missile Journal,2020 (12 ):1 -5, 16 . (in Chinese)[3] 穆腾飞,李忠剑,戴喜妹. 飞机结构健康监测技术[J]. 民用飞机设计与研究,2020(3): 35-41. MU Tengfei,LI Zhongjian,DAI Ximei. Aircraft structural health monitoring technology[J]. Civil Aircraft Design & Research,2020(3): 35-41. (in Chinese MU Tengfei, LI Zhongjian, DAI Ximei . Aircraft structural health monitoring technology[J]. Civil Aircraft Design & Research,2020 (3 ):35 -41 . (in Chinese)[4] SU Zhongqing,YE Lin,LU Ye. Guided Lamb waves for identification of damage in composite structures: a review[J]. Journal of Sound and Vibration,2006,295(3/4/5): 753-780. [5] ROACH D. Real time crack detection using mountable comparative vacuum monitoring sensors[J]. Smart Structures and Systems,2009,5(4): 317-328. doi: 10.12989/sss.2009.5.4.317 [6] 孙洋,王彪,王巧云,等. 涂层式裂纹监测系统中基体裂纹穿越行为研究[J]. 力学学报,2015,47(5): 772-778. SUN Yang,WANG Biao,WANG Qiaoyun,et al. Study of the substrate crack penetration mechanisms in crack-detected coating system[J]. Chinese Journal of Theoretical and Applied Mechanics,2015,47(5): 772-778. (in Chinese SUN Yang, WANG Biao, WANG Qiaoyun, et al . Study of the substrate crack penetration mechanisms in crack-detected coating system[J]. Chinese Journal of Theoretical and Applied Mechanics,2015 ,47 (5 ):772 -778 . (in Chinese)[7] LIU Qijian,SUN Hu,WANG Tao,et al. On-site health monitoring of composite bolted joint using built-In distributed eddy current sensor network[J]. Materials,2019,12(17): 2785. doi: 10.3390/ma12172785 [8] MALKIN M,QING X P,LEONARD M,et al. Flight demonstration: health monitoring for bonded structural repairs[C]//Proceedings of the 3rd European Workshop Structural Health Monitoring. Granada,Spain: DEStech,2006: 167-175. [9] 卿新林,刘琦牮,张雨强,等. 飞行器复合材料全寿命结构健康监测技术[J]. 厦门大学学报(自然科学版),2021,60(3): 614-629. QING Xinlin,LIU Qijian,ZHANG Yuqiang,et al. Life-cycle health monitoring technology for aircraft composite structures[J]. Journal of Xiamen University (Natural Science),2021,60(3): 614-629. (in Chinese QING Xinlin, LIU Qijian, ZHANG Yuqiang, et al . Life-cycle health monitoring technology for aircraft composite structures[J]. Journal of Xiamen University (Natural Science),2021 ,60 (3 ):614 -629 . (in Chinese)[10] LIU Mengnan,FANG Shuiliang,DONG Huiyue,et al. Review of digital twin about concepts,technologies,and industrial applications[J]. Journal of Manufacturing Systems,2021,58: 346-361. doi: 10.1016/j.jmsy.2020.06.017 [11] AIAA Digital Engineering Integration Committee. Digital twin: definition & value [EB/OL]. [2022-10-11]. https://www.aia-aerospace.org/publications/digital-twin-definition-value-an-aiaa-and-aia-position-paper/. [12] 李鹏,潘凯,刘小川. 美国空军机体数字孪生计划的回顾与启示[J]. 航空科学技术,2020,31(9): 1-10. LI Peng,PAN Kai,LIU Xiaochuan. Retrospect and enlightenment of the AFRL airframe digital twin program[J]. Aeronautical Science & Technology,2020,31(9): 1-10. (in Chinese LI Peng, PAN Kai, LIU Xiaochuan . Retrospect and enlightenment of the AFRL airframe digital twin program[J]. Aeronautical Science & Technology,2020 ,31 (9 ):1 -10 . (in Chinese)[13] 陶飞,刘蔚然,张萌,等. 数字孪生五维模型及十大领域应用[J]. 计算机集成制造系统,2019,25(1): 1-18. TAO Fei,LIU Weiran,ZHANG Meng,et al. Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems,2019,25(1): 1-18. (in Chinese TAO Fei, LIU Weiran, ZHANG Meng, et al . Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems,2019 ,25 (1 ):1 -18 . (in Chinese)[14] 董雷霆,周轩,赵福斌,等. 飞机结构数字孪生关键建模仿真技术[J]. 航空学报,2021,42(3): 023981. DONG Leiting,ZHOU Xuan,ZHAO Fubin,et al. Key technologies for modeling and simulation of airframe digital twin[J]. Acta Aeronautica et Astronautica Sinica,2021,42(3): 023981. (in Chinese DONG Leiting, ZHOU Xuan, ZHAO Fubin, et al . Key technologies for modeling and simulation of airframe digital twin[J]. Acta Aeronautica et Astronautica Sinica,2021 ,42 (3 ):023981 . (in Chinese)[15] YE Yumei,YANG Qiang,YANG Fan,et al. Digital twin for the structural health management of reusable spacecraft: a case study[J]. Engineering Fracture Mechanics,2020,234: 107076. doi: 10.1016/j.engfracmech.2020.107076 [16] KAPTEYN M G,KNEZEVIC D J,WILLCOX K. Toward predictive digital twins via component-based reduced-order models and interpretable machine learning[R]. AIAA2020-0418,2020. [17] SINGH V,WILLCOX K E. Methodology for path planning with dynamic data-driven flight capability estimation[J]. AIAA Journal,2017,55(8): 2727-2738. doi: 10.2514/1.J055551 [18] MOHMMED A O,AL-KAYIEM H H,A B O,et al. One-way coupled fluid-structure interaction of gas-liquid slug flow in a horizontal pipe: experiments and simulations[J]. Journal of Fluids and Structures,2020,97: 103083. doi: 10.1016/j.jfluidstructs.2020.103083 [19] 郝春生,李汇军,张思聪,等. 微型标定风洞风机设计及流固耦合仿真分析[J]. 机械制造与自动化,2020,49(6): 85-89. HAO Chunsheng,LI Huijun,ZHANG Sicong,et al. Design and fluid-solid coupling simulation analysis of miniature calibration wind tunnel[J]. Machine Building & Automation,2020,49(6): 85-89. (in Chinese HAO Chunsheng, LI Huijun, ZHANG Sicong, et al . Design and fluid-solid coupling simulation analysis of miniature calibration wind tunnel[J]. Machine Building & Automation,2020 ,49 (6 ):85 -89 . (in Chinese)[20] 经海翔,黄友锐,徐善永,等. 基于数字孪生和概率神经网络的矿用通风机预测性故障诊断研究[J]. 工矿自动化,2021,47(11): 53-60. JING Haixiang,HUANG Yourui,XU Shanyong,et al. Research on the predictive fault diagnosis of mine ventilator based on digital twin and probabilistic neural network[J]. Industry and Mine Automation,2021,47(11): 53-60. (in Chinese JING Haixiang, HUANG Yourui, XU Shanyong, et al . Research on the predictive fault diagnosis of mine ventilator based on digital twin and probabilistic neural network[J]. Industry and Mine Automation,2021 ,47 (11 ):53 -60 . (in Chinese)[21] 杨辰. 结构健康监测的传感器优化布置研究进展与展望[J]. 振动与冲击,2020,39(17): 82-93. YANG Chen. Advances and prospects for optimal sensor placement of structural health monitoring[J]. Journal of Vibration and Shock,2020,39(17): 82-93. (in Chinese YANG Chen . Advances and prospects for optimal sensor placement of structural health monitoring[J]. Journal of Vibration and Shock,2020 ,39 (17 ):82 -93 . (in Chinese)[22] LIU Wei,GAO Weicheng,SUN Yi,et al. Optimal sensor placement for spatial lattice structure based on genetic algorithms[J]. Journal of Sound and Vibration,2008,317(1/2): 175-189. -

下载:

下载: