Reliability analysis of crack growth in turbine disk mortise based on Wiener process

-

摘要:

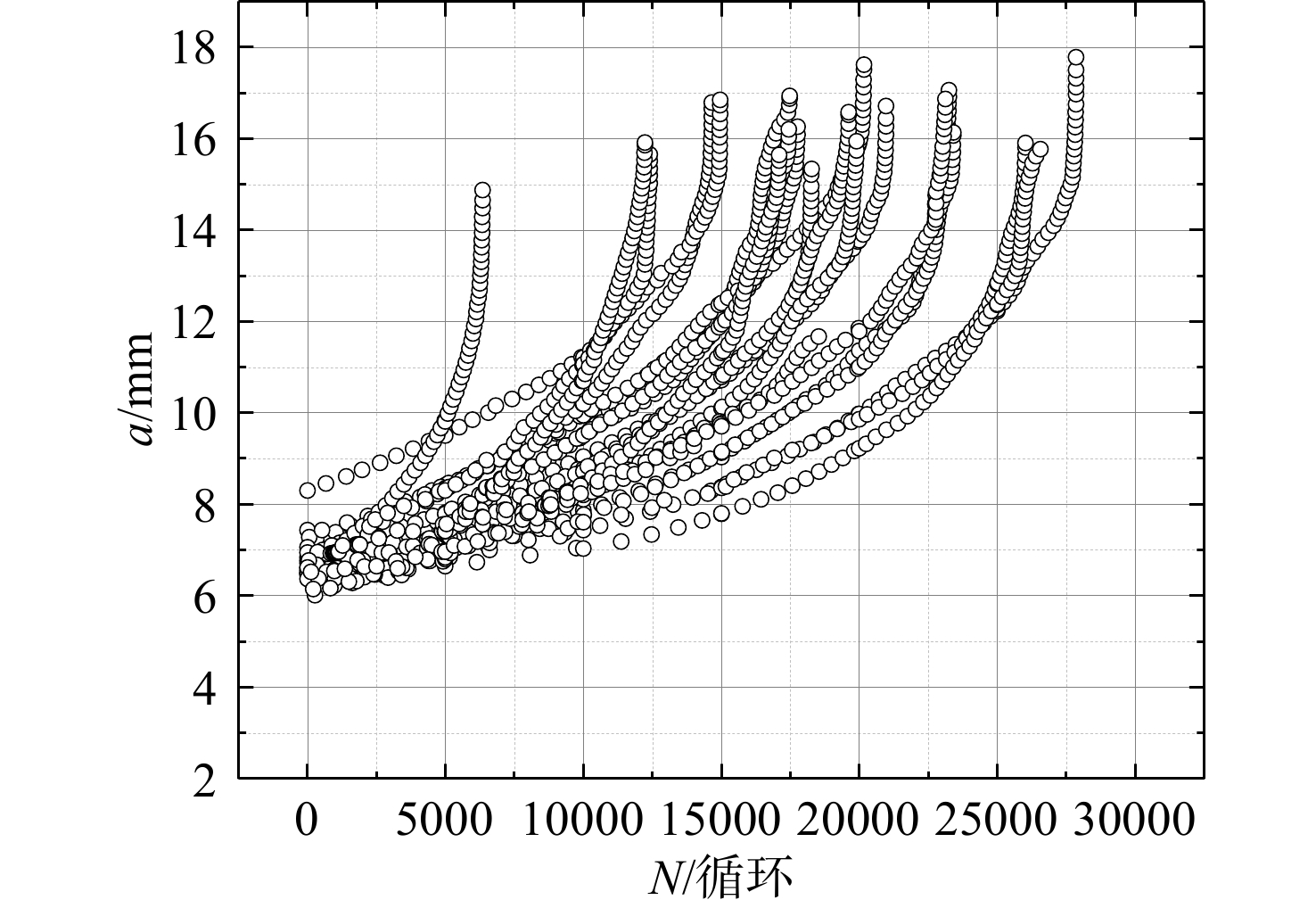

建立了考虑裂纹扩展退化过程的时变模型,并应用于涡轮盘榫槽裂纹扩展的概率寿命分析。首先,引入双时间尺度函数的Wiener过程,建立了GH4720Li高温合金的裂纹扩展时变模型,并通过紧凑拉伸试件的裂纹扩展试验进行验证。接着,以涡轮盘榫槽齿根关键部位为对象,建立了榫槽齿根角裂纹的权函数应力强度因子求解方法,并与真实涡轮盘榫槽裂纹扩展有限元分析结果进行对比。最后,结合权函数与裂纹扩展时变模型,建立了涡轮盘榫槽疲劳裂纹扩展可靠性分析方法。分析结果表明,涡轮盘榫槽结构裂纹扩展退化的寿命呈现较大的分散性,均值为14177循环,标准差为1090.09循环,99.87%可靠度下的裂纹扩展寿命预测为10312循环。

Abstract:A time-varying model considering crack growth degradation process was established and applied to the probabilistic life analysis of crack growth in the turbine disk mortise. Firstly, a time-varying crack growth model of GH4720Li superalloy was established by introducing the Wiener stochastic process with double time scale functions. And it was verified by crack growth test of compact tensile specimens. Then, taking the root of the turbine disk’s mortise tooth as the key object, the weight function method for solving the stress intensity factor of the crack in the root of the turbine disk’s mortise tooth was established and compared with the finite element analysis results of the crack growth in the turbine disk mortise. Finally, combining the weight function and the time-varying crack growth model, the reliability analysis method for fatigue crack growth degradation of the turbine disk mortise was established. Analysis results showed that the crack growth degradation life of the turbine disk’s mortise presented a large dispersion, with an average value of 14177 cycles and a standard deviation of 1090.09 cycles. The prediction of crack growth life was 10312 cycles when the reliability was 99.87%.

-

表 1 参考载荷及应力强度因子

Table 1. Reference loadings and stress intensity factors

载荷 示意图 应力分布 参考应力强度因子 均布

$ \sigma \left( x \right) = {\sigma _0} $ $K_{0\;A/B}^{} = {\sigma _0}\sqrt {\dfrac{ { {\text{π} }b} }{Q} } F_{0\;A/B}^{}$ 线性

$\sigma \left( x \right) = {\sigma _0}\left( {1 - \dfrac{x}{a} } \right)$ $K_{1A/B}^{} = {\sigma _0}\sqrt {\dfrac{ { {\text{π} }b} }{Q} } F_{1A/B}^{}$ 2次

$\sigma \left( x \right) = {\sigma _0}{\left( {1 - \dfrac{x}{a} } \right)^2}$ $K_{2A/B}^{} = {\sigma _0}\sqrt {\dfrac{ { {\text{π} }b} }{Q} } F_{2A/B}^{}$ 表 2 参考载荷下拟合参数

$ p_k^{ij} $ Table 2. Fitting parameter

$ p_k^{ij} $ under reference loadings载荷 $ p_k^{ij} $ 点A 点B αi0 αi1 αi2 αi3 αi4 βi0 βi1 βi2 βi3 βi4 均布

i=0p1ij 1.995 −1.603 18.444 −25.500 18.013 2.387 −1.542 20.039 −26.521 22.052 p2ij −1.088 1.830 −18.775 29.690 −21.158 −1.624 1.590 −19.949 27.390 −22.745 p3ij 0.300 −0.674 6.408 −10.756 7.669 0.459 −0.529 6.562 −9.234 7.673 p4ij −0.030 0.079 −0.715 1.237 −0.880 −0.046 0.057 −0.704 1.008 −0.839 线性

i=1p1ij 0.494 −0.797 11.320 −16.511 11.841 1.990 −0.780 11.741 −14.271 13.364 p2ij −0.185 0.765 −10.810 18.061 −13.243 −1.353 0.695 −11.065 13.685 −13.129 p3ij 0.042 −0.256 3.522 −6.278 4.645 0.386 −0.210 3.506 −4.389 4.288 p4ij −0.004 0.029 −0.379 0.700 −0.520 −0.039 0.021 −0.367 0.463 −0.459 2次

i=2p1ij 0.268 −0.645 8.770 −13.295 9.453 1.749 −0.578 8.682 −10.353 10.179 p2ij −0.083 0.625 −8.421 14.500 −10.524 −1.192 0.519 −8.202 9.950 −10.021 p3ij 0.016 −0.209 2.749 −5.027 3.679 0.342 −0.158 2.602 −3.194 3.277 p4ij −0.001 0.023 −0.296 0.559 −0.410 −0.034 0.016 −0.272 0.337 −0.351 表 3 不同可靠度下裂纹扩展寿命

Table 3. Crack growth life at different reliabilities

可靠度/% 寿命/循环 50.00 14205 99.00 11465 99.87 10312 99.99 8301 -

[1] 沈锡钢. 大涵道比涡扇发动机总体性能与循环参数设计[J]. 航空科学技术,2011(4): 4-7. doi: 10.3969/j.issn.1007-5453.2011.04.002SHEN Xigang. Design of performance and cycle parameters of high bypass ratio turbofan[J]. Aeronautical Science and Technology,2011(4): 4-7. (in Chinese) doi: 10.3969/j.issn.1007-5453.2011.04.002 [2] 陈光. 航空发动机结构设计分析[M]. 北京:北京航空航天大学出版社,2014. [3] LIN Y K,YANG J N. A stochastic theory of fatigue crack propagation[J]. AIAA Journal,1985,23(1): 117-124. doi: 10.2514/3.8879 [4] LONG X Y,LIU K,JIANG C,et al. Uncertainty propagation method for probabilistic fatigue crack growth life prediction[J]. Theoretical and Applied Fracture Mechanics,2019,103: 102268.1-102268.13. [5] 熊峻江,刘文挺,高镇同. 疲劳裂纹扩展速率试验数据的可靠性分析模型[J]. 强度与环境,1997(4): 6-10.XIONG Junjiang,LIU Wenting,GAO Zhentong. Reliability analysis models of fatigue crack growth rate data[J]. Structure and Environment Engineering,1997(4): 6-10. (in Chinese) [6] GIANNELLA V. Stochastic approach to fatigue crack-growth simulation for a railway axle under input data variability[J]. International Journal of Fatigue,2021,144: 106044.1-106044.15. [7] LUO J,BOWEN P. A probabilistic methodology for fatigue life prediction[J]. Acta Material,2003,51(12): 3537-3550. doi: 10.1016/S1359-6454(03)00172-1 [8] YANG J N,HSI W H,MANNING S D,et al. Stochastic crack propagation in fastener holes[J]. Journal of Aircraft,1985,22(9): 810-817. doi: 10.2514/3.45206 [9] YE Z,WANG Y,TSUI K,et al. Degradation data analysis using Wiener processes with measurement errors[J]. IEEE Transactions on Reliability,2013,62(4): 772-780. doi: 10.1109/TR.2013.2284733 [10] 厉海涛,金光,周经伦,等. 动量轮维纳过程退化建模与寿命预测[J]. 航空动力学报,2011,26(3): 622-627. doi: 10.13224/j.cnki.jasp.2011.03.022LI Haitao,JIN Guang,ZHOU Jinglun,et al. Momentum wheel Wiener process degradation modeling and life prediction[J]. Journal of Aerospace Power,2011,26(3): 622-627. (in Chinese) doi: 10.13224/j.cnki.jasp.2011.03.022 [11] 朱磊,左洪福,蔡景. 基于Wiener过程的民用航空发动机性能可靠性预测[J]. 航空动力学报,2013,28(5): 1006-1012.ZHU Lei,ZUO Hongfu,CAI Jing. Performance reliability prediction for civil aviation aircraft engine based on Wiener process[J]. Journal of Aerospace Power,2013,28(5): 1006-1012. (in Chinese) [12] WHITMORE G A,SCHENKELBERG F. Modelling accelerated degradation data using Wiener diffusion with a timescale transformation[J]. Lifetime Data Analysis,1997,3(1): 27-45. doi: 10.1023/A:1009664101413 [13] ANNOR-NYARKO M,XIA Hong. Numerical fracture analysis of a reactor pressure vessel based on abaqus-FRANC3D co-simulation method[J]. Procedia Structural Integrity,2022,37: 225-232. doi: 10.1016/j.prostr.2022.01.078 [14] RICE J. Some remarks on elastic crack-tip stress field[J]. International Journal of Solids and Structures,1972,8(6): 751-758. doi: 10.1016/0020-7683(72)90040-6 [15] BUECKNER H F. A novel principle for the computation of stress intensity factors[J]. Journal of Applied Mathematics and Mechanics,1970,50(10): 529-546. [16] MOFTAKHAR A A,GLINKA G. Calculation of stress intensity factors by efficient integration of weight functions[J]. Engineering Fracture Mechanics,1992,43(5): 749-756. doi: 10.1016/0013-7944(92)90005-Y [17] GLINKA G,SHEN G. Universal features of weight functions for cracks in mode I[J]. Engineering Fracture Mechanics,1991,40(6): 1135-1146. doi: 10.1016/0013-7944(91)90177-3 [18] 万志鹏,王涛,李钊,等. 晶界一次γ′相对GH4720Li合金晶粒长大行为的影响[J]. 材料热处理学报,2020,41(8): 173-181.WAN Zhipeng,WANG Tao,LI Zhao,et al. Influence of grain boundary primary γ′ precipitates on grain growth behavior of GH4720Li superalloy[J]. Transctions of Materials and Heat Treatment,2020,41(8): 173-181. (in Chinese) [19] 王桂荣,赵晴,许良. TC4-DT钛合金小裂纹扩展行为研究[J]. 科技通报,2018,34(6): 95-100. doi: 10.13774/j.cnki.kjtb.2018.06.020WANG Guirong,ZHAO Qing,XU Liang. Study on fatigue small crack growth behavior of TC4-DT tianium alloy[J]. Bulletin of Science and Technology,2018,34(6): 95-100. (in Chinese) doi: 10.13774/j.cnki.kjtb.2018.06.020 [20] 杨杭. 基于统计可靠性的广布疲劳损伤可检裂纹评估[D]. 天津:中国民航大学,2016.YANG Hang. Research on widespread fatigue damage detectable crack based on reliability[D]. Tianjin:Civil Aviation University of China,2016.(in Chinese) [21] 刘凯,崔荣洪,侯波,等. PVD薄膜传感器裂纹检测概率测定与分析[J]. 材料工程,2019,47(9): 160-166.LIU Kai,CUI Ronghong,HOU Bo,et al. Estimation and analysis of probability of PVD film sensor crack detection[J]. Journal of Materials Engineering,2019,47(9): 160-166. (in Chinese) [22] LEE D,YOON S,PARK J,et al. Demonstration of model-assisted probability of detection framework for ultrasonic inspection of cracks in compressor blades[J]. NDT and E International,2022,128: 102618.1-102618.11. -

下载:

下载: