Numerical simulation of effect of tip clearance and vibration damper on performance of multi-stage axial flow compressor

-

摘要:

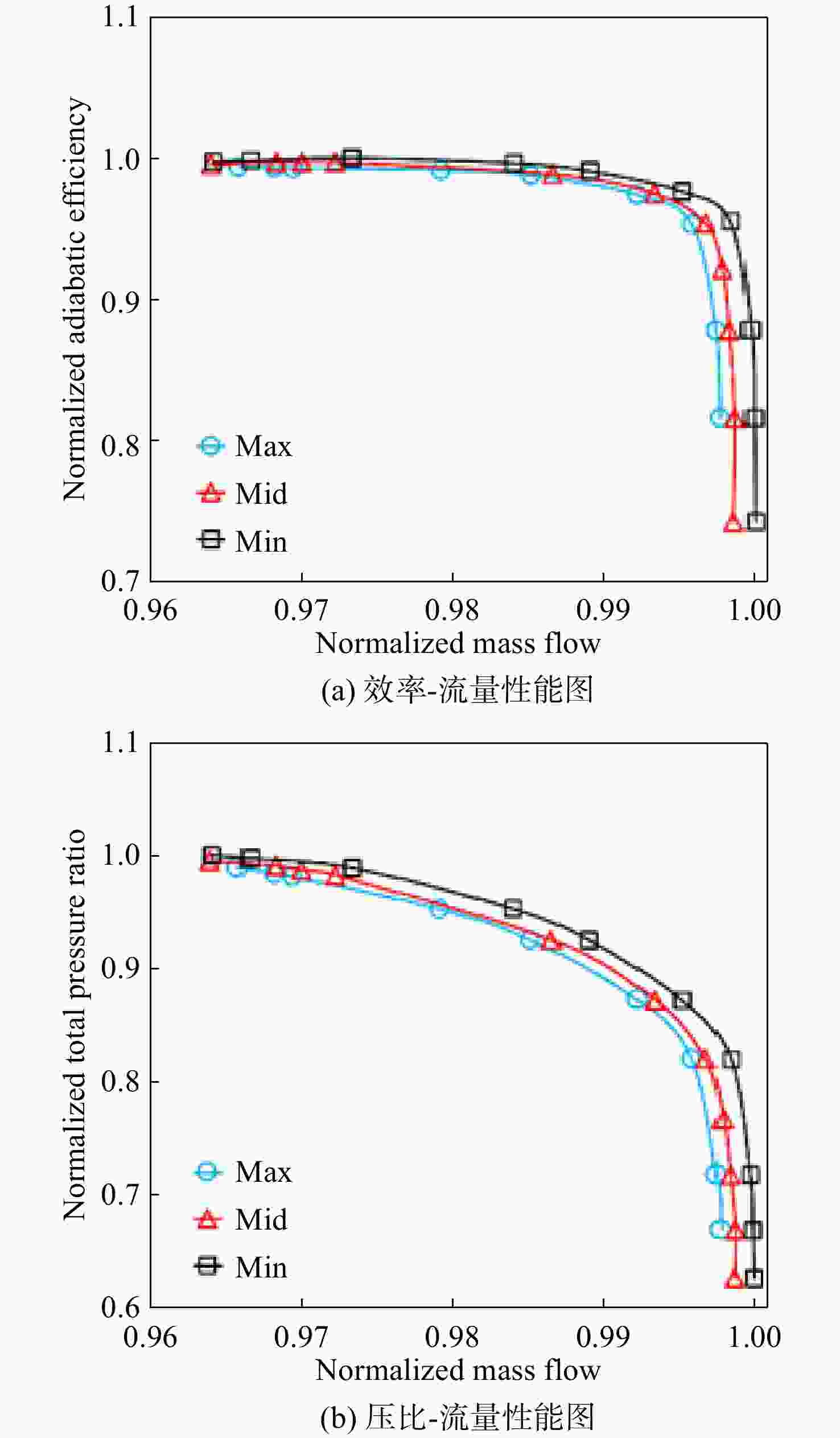

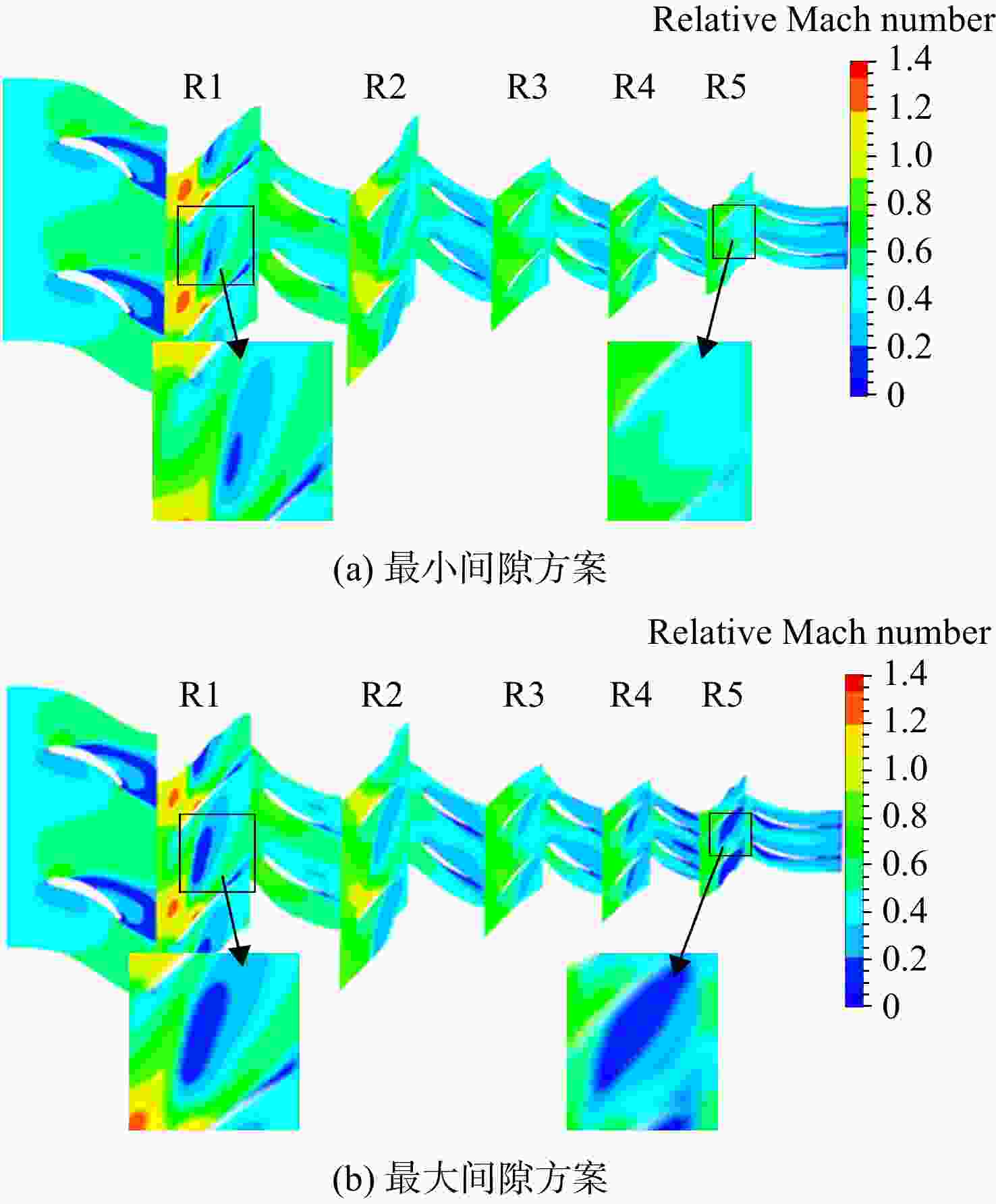

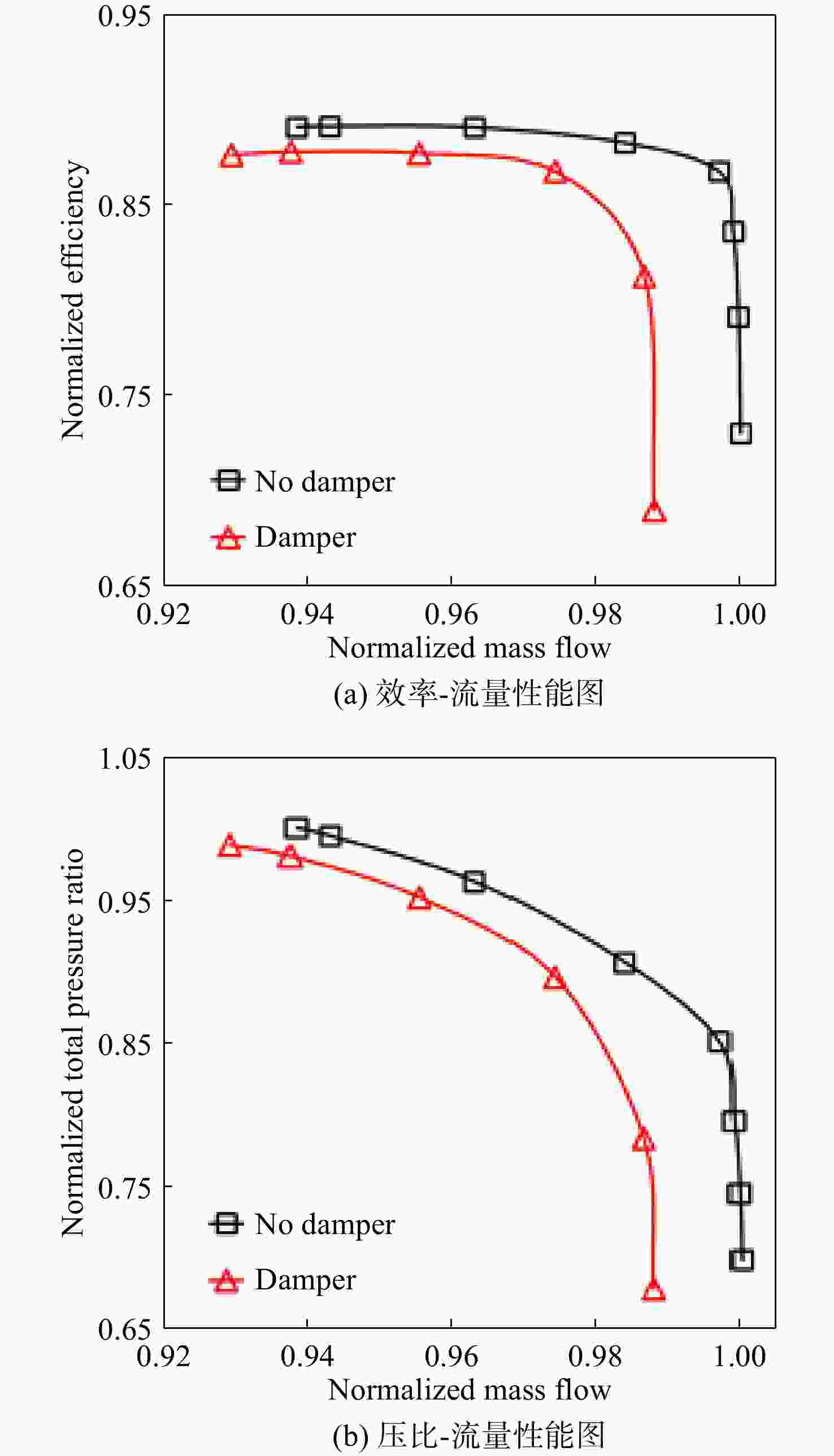

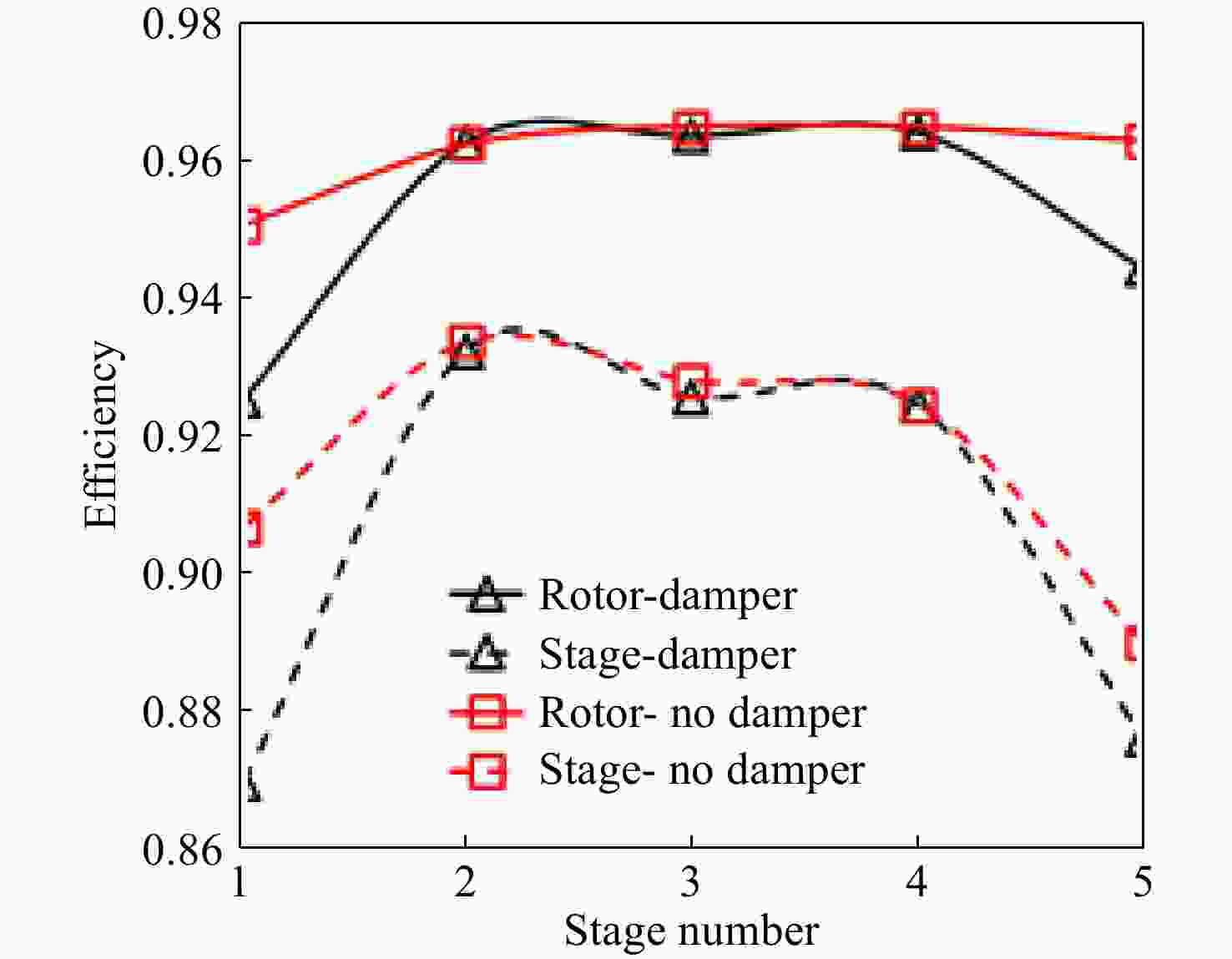

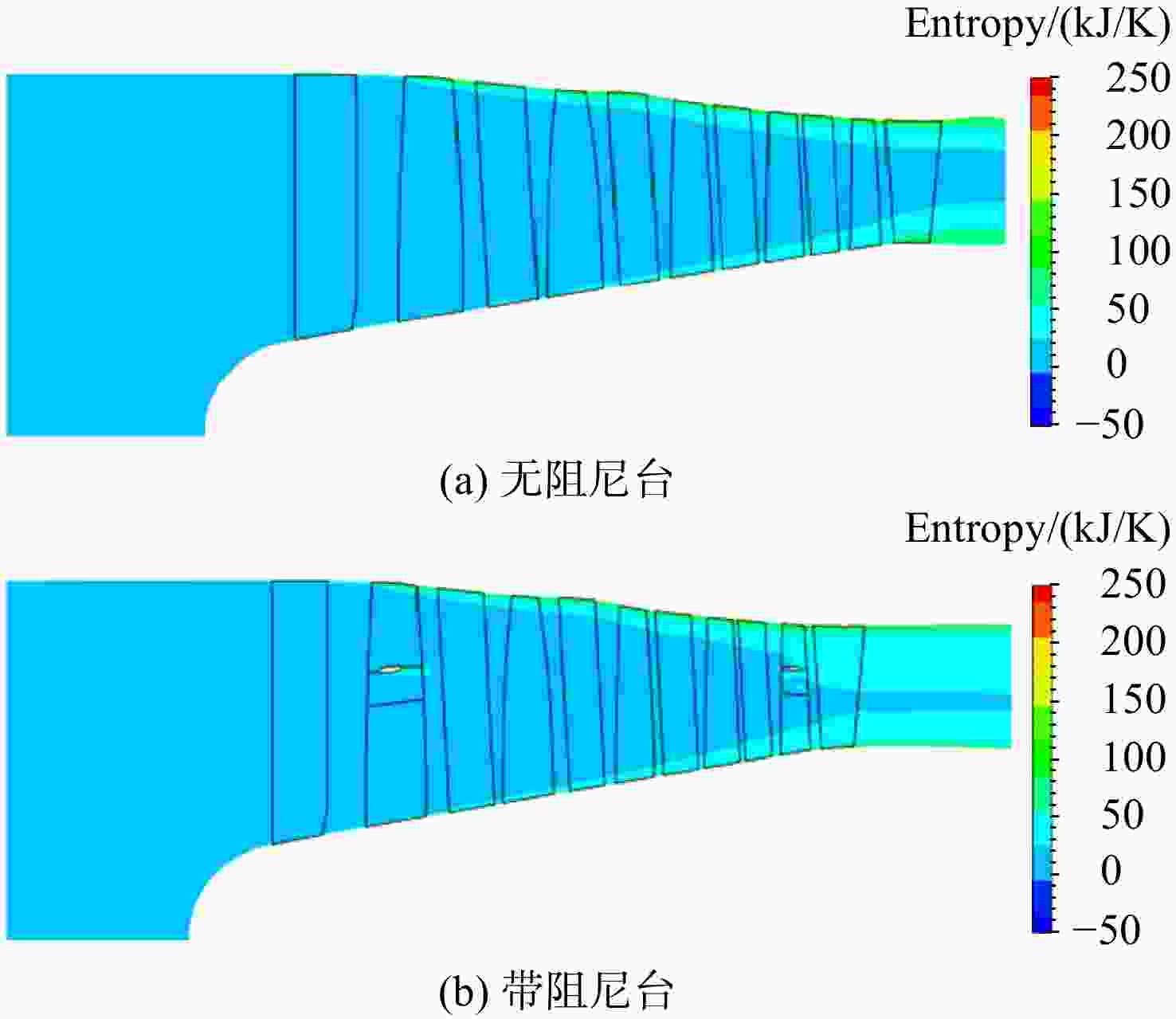

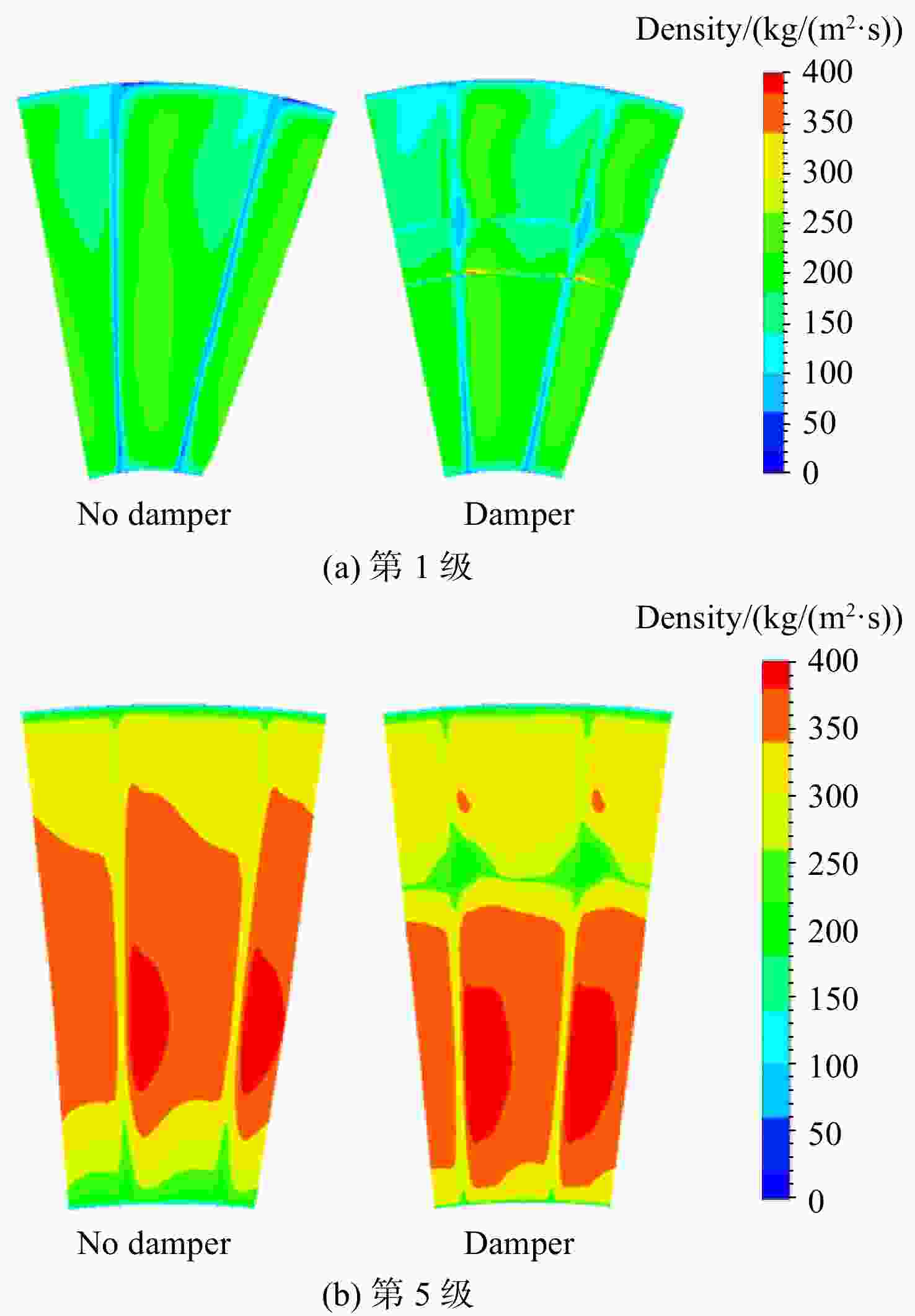

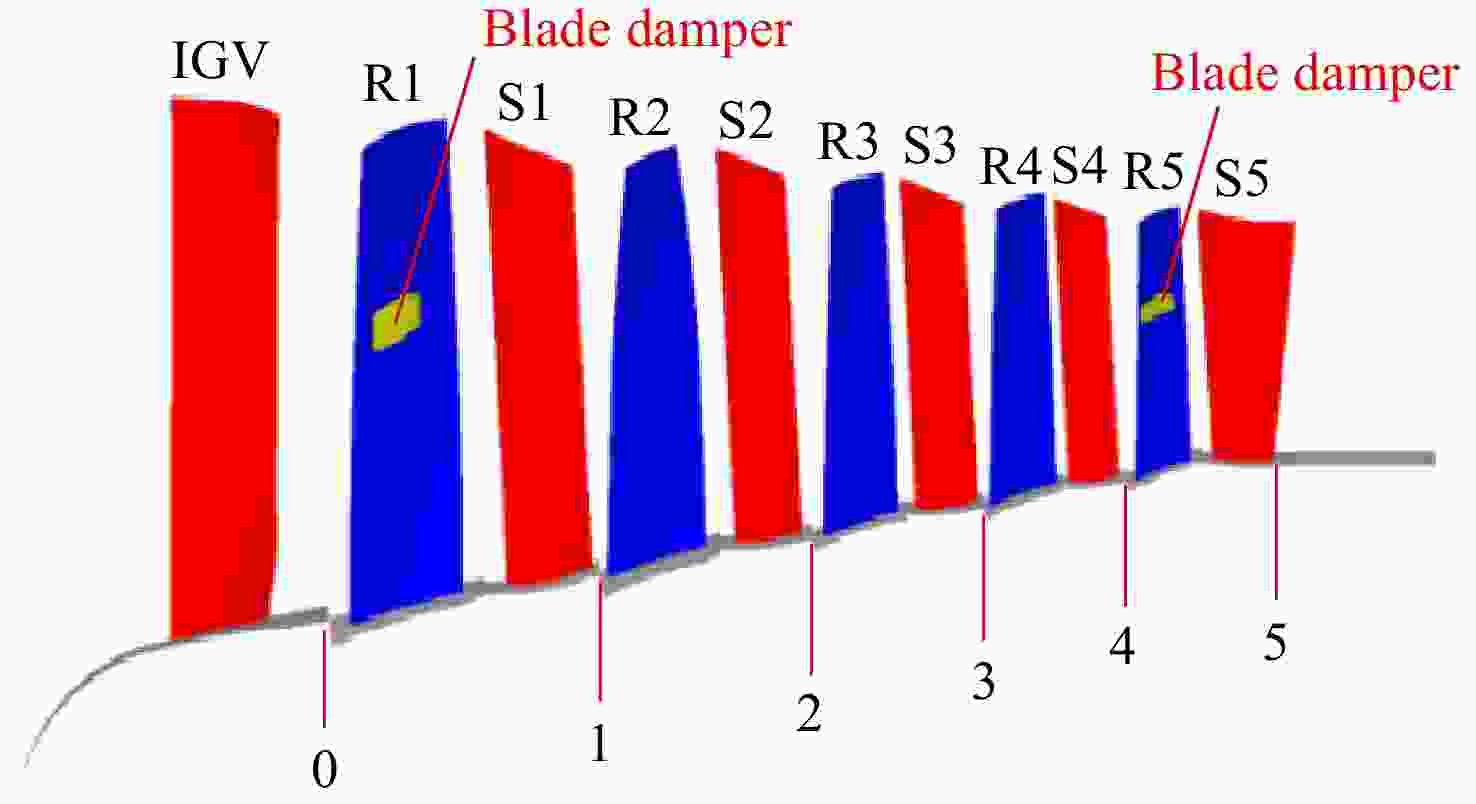

以某多级轴流压气机为研究对象,采用数值模拟的方法研究了叶顶间隙和减振阻尼台对压气机气动性能的影响。研究揭示了叶顶间隙变化对叶顶泄漏流动的影响规律,分析了各级转子叶顶间隙变化对多级轴流压气机性能影响的相对大小。研究发现针对所研究的多级轴流压气机,第5级转子叶顶间隙的变化对压气机性能的影响幅度最大,当叶顶间隙从0.390 mm增加到1.007 mm时,级效率下降了1.72%;而其他级的效率下降幅度较少,最大降幅不超过0.6%。此外,研究了第1级及第5级转子叶片阻尼台对多级压气机性能影响,分析了阻尼台对流场结构及流通能力的影响,揭示了阻尼台影响性能的机理。研究结果表明,当存在阻尼台时,多级轴流压气机的峰值效率、峰值压比以及堵塞质量流量都会下降,其中峰值效率下降了1.6%,峰值压比下降了1.2%,堵塞质量流量下降了1.2%;尤其是第1级和第5级效率明显下降,第1级级效率下降约5.2%,第5级级效率下降约1.6%。在阻尼台存在的地方总压损失大,密流值会降低,流通能力会下降。

Abstract:A multi-stage axial flow compressor was studied by numerical simulation to determine the effect of tip clearance and damper table on its aerodynamic performance. The influence principle of tip clearance change on tip leakage flow was revealed, and the relative magnitude of the influence of rotor tip clearance change on the performance of multi-stage axial compressor was analyzed. It was found that for the studied multi-stage axial flow compressors, the change of the tip clearance of the fifth stage rotor had the largest impact on the compressor performance. Stage efficiency decreased by 1.72% when the tip clearance increased from 0.390 mm to 1.007 mm. There was a maximum reduction of 0.6% in other stages. Furthermore, the first-stage and fifth-stage rotor blade damper tables were investigated for their effects on compressor performance. The influence of the damper table on the flow field structure and flow capacity was analyzed, and the mechanism of the damper table affecting the performance was revealed. The results showed that when there was the damping table, the peak efficiency, peak pressure ratio and choke flow rate of multi-stage axial flow compressor decreased; as the peak efficiency decreased by 1.6%, the peak pressure ratio decreased by 1.2%, and the choke flow decreased by 1.2%. Especially, the efficiency of the first and fifth staged decreased obviously, the efficiency of the first stage decreased by about 5.2%, and that of the fifth stage decreased by about 1.6%. As a result of the damping table, the pressure loss was caused, the density flow and flow capacity decreased.

-

表 1 压气机的相关设计参数

Table 1. Relevant design parameters of compressor

参数 数值 设计转速/(r/min) 8000 总压比 2.95 第1级压比 1.29 第2级压比 1.30 第3级压比 1.21 第4级压比 1.22 第5级压比 1.20 R1进口马赫数 1.20 R1轮毂比 0.30 表 2 不同方案下各级转子相对和绝对叶顶间隙数值

Table 2. Values of absolute and relative rotor tip clearances at all stages under different schemes

转子级数 叶顶间隙最小值 叶顶间隙最大值 叶顶间隙中间值 相对值/% 绝对值/mm 相对值/% 绝对值/mm 相对值/% 绝对值/mm 第1级 0.30 0.846 0. 45 1.292 0. 39 1.092 第2级 0.42 0.996 0.63 1.492 0.54 1.292 第3级 0.40 0.778 0.70 1.374 0.60 1.174 第4级 0.48 0.826 0.87 1.510 0.75 1.310 第5级 0.26 0.390 0.79 1.207 0.66 1.007 -

[1] DENTON J D. The 1993 IGTI scholar lecture: loss mechanisms in turbomachines[J]. Journal of Turbomachinery,1993,115(4): 621-656. doi: 10.1115/1.2929299 [2] INOUE M,KUROUMARU M. Structure of tip clearance flow in an isolated axial compressor rotor[J]. Journal of Turbomachinery,1989,111(3): 250-256. doi: 10.1115/1.3262263 [3] SUDER K L,CELESTINA M L. Experimental and computational investigation of the tip clearance flow in a transonic axial compressor rotor[J]. Journal of Turbomachinery,1996,118(2): 218-229. doi: 10.1115/1.2836629 [4] YAMADA K, KIKUTA H, FURUKAWA M, et al. Effects of tip clearance on the stall inception process in an axial compressor rotor[R]. ASME GT2013-95479, 2013. [5] TAN C S. Three-dimensional and tip clearance flows in compressor[R]. Brussels, Belgium: VKI Lecture Series 2006-06 on Advances in Axial Compressor Aerodynamics, 2006. [6] RIÉRA W,MARTY J,CASTILLON L,et al. Zonal detached-eddy simulation applied to the tip-clearance flow in an axial compressor[J]. Journal of Aircraft,2016,53(4): 2377-2391. [7] Chunill H. Effects of double-leakage tip clearance flow on the performance of a compressor stage with a large rotor tip gap[J]. Journal of Turbomachinery,2017,139(6): 1-9. [8] SOHAIL M U,HAMDANI H R,PERVEZ K H. CFD analysis of tip clearance effects on the performance of transonic axial compressor[J]. Fluid Dynamics,2020,55(1): 133-144. doi: 10.1134/S0015462820010127 [9] 宋兆泓. 航空发动机典型故障分析[M]. 北京: 北京航空航天大学出版社, 1993. [10] ZHANG C,MA M,LIU D,et al. Influence analysis of blade parameters on damper coefficient of turbine damper[J]. Journal of Huazhong University of Science and Technology,2017,45(11): 98-102. [11] KUMAR D, BARAD S, SURESH T N. Gas turbine blade damper: a design optimization study to mitigate high resonance blade vibration[R]. ASME GTINDIA2013-3748, 2013. [12] SHORR B, SEREBRIAKOV N, MEL'NIKOVA G, et al. Numerical and experimental estimation of the turbine blade damper efficiency[R]. ASME GT2018-76974, 2018. [13] YEN H Y, SHEN M. Development of a passive turbine blade damper using magneto mechanical coating[R]. ASME 2000-GT-0366, 2000. [14] SZWEDOWICZ J, SECALL-WIMMEL T H, DÜNCK-KERST P. Damping performance of axial turbine stages with loosely assembled friction bolts the non-linear dynamic assessment[R]. ASME GT2007-27506, 2007. [15] SZWEDOWICZ J, SECALL-WIMMEL T H, REGNERY D, et al. Scaling concept for axial turbine stages with loosely assembled friction bolts the linear dynamic assessment[R]. ASME GT2007-27502, 2007. [16] 段连丰,董宝常,王兆龙. 凸肩对单级压气机性能的影响[J]. 工程热物理学报,1982,3(2): 123-130.DUAN Lianfeng,DONG Baochang,WANG Zhaolong. Effect of part span shroud on performance of a single stage compressor[J]. Journal of Engineering Thermophysics,1982,3(2): 123-130. (in Chinese) [17] 李洪松,刘永葆,余又红,等. 凸肩对压气机叶片振动及气动特性影响研究[J]. 热力透平,2017,46(4): 263-304. doi: 10.13707/j.cnki.31-1922/th.2017.04.007LI Hongsong,LIU Yongbao,YU Youhong,et al. Research on effect of shroud on vibration and aerodynamic characteristics of compressor blade[J]. Thermal Turbine,2017,46(4): 263-304. (in Chinese) doi: 10.13707/j.cnki.31-1922/th.2017.04.007 [18] 贾朝波, 陈勇, 侯东旭, 等. 压气机转子带凸肩叶片掉块故障分析[J]. 2020, 46(4): 87-91.JIA Chaobo, CHEN Yong, HOU Dongxu, et al. Fracture failure analysis of a shrouded blade of compressor rotor[J]. 2020, 46(4): 87-91. (in Chinese) [19] 苏中亮,吴艳辉,楚武利,等. 减振阻尼台对风扇性能影响的数值仿真[J]. 计算机仿真,2010,27(7): 248-252. doi: 10.3969/j.issn.1006-9348.2010.07.061SU Zhongliang,WU Yanhui,CHU WuIi,et al. Numerical simulation of part span shroud effects on performance of a two-stage fan[J]. Computer Simulation,2010,27(7): 248-252. (in Chinese) doi: 10.3969/j.issn.1006-9348.2010.07.061 [20] 杨薇. 阻尼台对轴流跨声速压气机性能的数值研究[J]. 海军航空工程学院学报,2010,25(2): 125-128. doi: 10.3969/j.issn.1673-1522.2010.02.002YANG Wei. Numerical investigation of effect on flow field and performance of a single-stage transonic compressor with damped setting[J]. Journal of Naval Aeronautical and Astronautical University,2010,25(2): 125-128. (in Chinese) doi: 10.3969/j.issn.1673-1522.2010.02.002 -

下载:

下载: