Analysis on film flow characteristics of high lifting air static thrust bearings

-

摘要:

为明确空气静压轴承在高浮起量下的静/动态特性,采用瞬态模型分析支撑气膜湍流形成演变规律和能量耗散过程;结合双向流固热耦合的方法对流场特征区域的流态演变、温度分布、马赫数变化、涡量特征等进行描述;将理论分析与实验测试结果相结合,明确高浮起量下空气轴承气膜内部流场特征,以及系统的承载能力、刚度特性和微振动特性。研究表明:高浮起量下空气轴承气膜流场存在气动加热现象且伴随着负压产生;气膜内部的较大压降和流体的压缩性增强会导致空气轴承的静态特性变差;考虑流固热耦合效应能有效保证高浮起量下空气静压止推轴承静态特性的计算准确性,在1 MPa供气50 μm气膜时对承载力的计算误差仅为2.2%,对刚度的计算误差仅为2.7%。

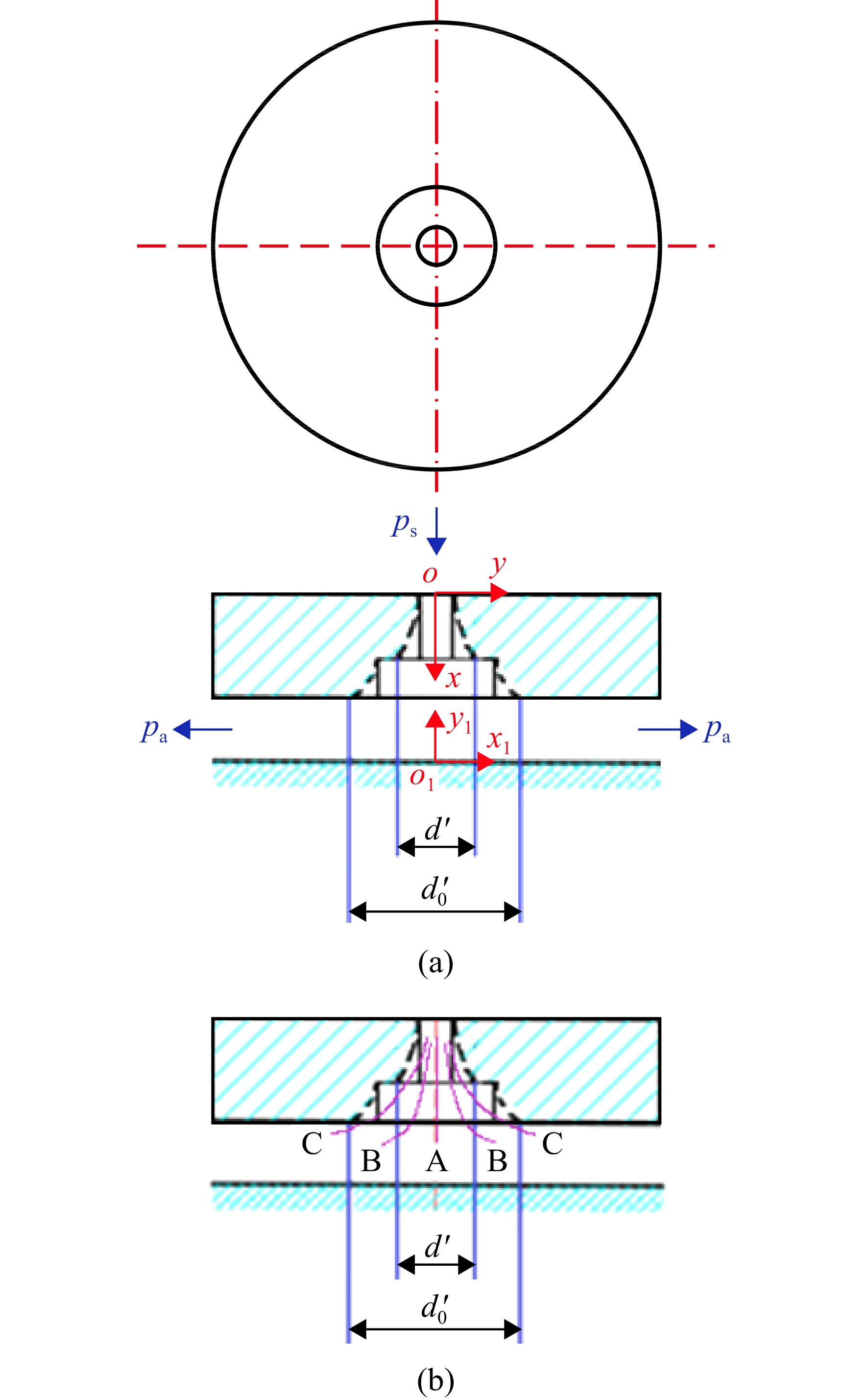

Abstract:In order to clarify the static/dynamic characteristics of aerostatic bearing under high lifting, the transient model was used to analyze the formation and evolution of supporting gas film turbulence and the energy dissipation process. Then, the flow state evolution, temperature distribution, Mach number variation and vorticity characteristics in the characteristic region of the flow field were described by the method of bidirectional fluid-solid thermal coupling. Furthermore, the theoretical analysis and experimental test results were combined to clarify the characteristics of the internal flow field of the air bearing film, the bearing capacity, stiffness characteristics and micro-vibration characteristics of the system under high lifting. The results showed that there was a phenomenon of aerodynamic heating in the film flow field of air bearing with negative pressure under high lifting. The large pressure drop inside the gas film and the enhanced compressibility of the fluid led to the bad static characteristics of the air bearing. Considering the fluid-solid thermal coupling effect, the calculation accuracy of static characteristics of aerostatic thrust bearings can be effectively guaranteed under high lifting. Especially, the calculation errors of bearing capacity and stiffness were only 2.2% and 2.7%, respectively, when air was supplied with 50 μm film at 1 MPa.

-

-

[1] 齐乃明,张文辉,高九州,等. 空间微重力环境地面模拟试验方法综述[J]. 航天控制,2011,29(3): 95-100. QI Naiming,ZHANG Wenhui,GAO Jiuzhou,et al. The primary discussion for the ground simulation system of spatial microgravity[J]. Aerospace Control,2011,29(3): 95-100. (in Chinese QI Naiming, ZHANG Wenhui, GAO Jiuzhou, et al . The primary discussion for the ground simulation system of spatial microgravity[J]. Aerospace Control,2011 ,29 (3 ):95 -100 . (in Chinese)[2] 李海旺,尹帅,闫晓军. 超微型高速空气轴承的动态特性[J]. 航空动力学报,2017,32(11): 2680-2686. LI Haiwang,YIN Shuai,YAN Xiaojun. Dynamic performance of super micro high speed air bearings[J]. Journal of Aerospace Power,2017,32(11): 2680-2686. (in Chinese LI Haiwang, YIN Shuai, YAN Xiaojun . Dynamic performance of super micro high speed air bearings[J]. Journal of Aerospace Power,2017 ,32 (11 ):2680 -2686 . (in Chinese)[3] BELFORTE G,COLOMBO F,RAPARELLI T,et al. Comparison between grooved and plane aerostatic thrust bearings: static performance[J]. Meccanica,2011,46(3): 547-555. doi: 10.1007/s11012-010-9307-y [4] 龙威,包钢. 小孔节流静压止推轴承超音速现象分析[J]. 液压气动与密封,2008,28(4): 64-68. LONG Wei,BAO Gang. Analysis of orifice compensated aerostatic bearing with supersonic flow[J]. Hydraulics Pneumatics & Seals,2008,28(4): 64-68. (in Chinese LONG Wei, BAO Gang . Analysis of orifice compensated aerostatic bearing with supersonic flow[J]. Hydraulics Pneumatics & Seals,2008 ,28 (4 ):64 -68 . (in Chinese)[5] 孙昂,马文琦,王祖温. 平面静压气浮轴承的超声速流场特性[J]. 机械工程学报,2010,46(9): 113-119. SUN Ang,MA Wenqi,WANG Zuwen. Characteristics of subsonic velocity field of externally pressurized gas thrust bearings[J]. Journal of Mechanical Engineering,2010,46(9): 113-119. (in Chinese doi: 10.3901/JME.2010.09.113 SUN Ang, MA Wenqi, WANG Zuwen . Characteristics of subsonic velocity field of externally pressurized gas thrust bearings[J]. Journal of Mechanical Engineering,2010 ,46 (9 ):113 -119 . (in Chinese) doi: 10.3901/JME.2010.09.113[6] 李运堂,蔺应晓,朱红霞,等. 基于大涡模拟静压气体推力轴承微幅自激振动特性分析[J]. 机械工程学报,2013,49(13): 56-62. LI Yuntang,LIN Yingxiao,ZHU Hongxia,et al. Analysis of the micro self-vibration of aerostatic thrust bearing based on large eddy simulation[J]. Journal of Mechanical Engineering,2013,49(13): 56-62. (in Chinese doi: 10.3901/JME.2013.13.056 LI Yuntang, LIN Yingxiao, ZHU Hongxia, et al . Analysis of the micro self-vibration of aerostatic thrust bearing based on large eddy simulation[J]. Journal of Mechanical Engineering,2013 ,49 (13 ):56 -62 . (in Chinese) doi: 10.3901/JME.2013.13.056[7] CHEN Xuedong,CHEN Han,ZHU Jincheng,et al. Vortex suppression and nano-vibration reduction of aerostatic bearings by arrayed microhole restrictors[J]. Journal of Vibration and Control,2017,23(5): 842-852. doi: 10.1177/1077546315586493 [8] 杜洪峰. 微重力实验中多孔质气体静压止推轴承跨缝特性研究[D]. 天津: 天津大学,2019. DU Hongfeng. Research on the characteristics of the porous aerostatic thrust bearing crossing the slot in the microgravity simulation experiments[D]. Tianjin: Tianjin University,2019. (in ChineseDU Hongfeng. Research on the characteristics of the porous aerostatic thrust bearing crossing the slot in the microgravity simulation experiments[D]. Tianjin: Tianjin University, 2019. (in Chinese) [9] LU Lihua,CHEN Wanqun,YU Nan,et al. Aerostatic thrust bearing performances analysis considering the fluid-structure coupling effect[J]. Proceedings of the Institution of Mechanical Engineers,Part J: Journal of Engineering Tribology,2016,230(12): 1588-1596. [10] ZHAO Xiaolong,ZHANG Junan,DONG Hao,et al. Numerical simulation and experimental study on the gas-solid coupling of the aerostatic thrust bearing with elastic equalizing pressure groove[J]. Shock and Vibration,2017,2017: 1-11. [11] 柴辉,龙威,杨绍华,等. 气固热耦合对微尺度气膜空气静压轴承承载特性的影响[J]. 昆明理工大学学报(自然科学版),2018,43(5): 52-59. CHAI Hui,LONG Wei,YANG Shaohua,et al. Effect of gas-solid thermal coupling on loading capacity of aerostatic bearing under micro-scale gas-film[J]. Journal of Kunming University of Science and Technology (Natural Science),2018,43(5): 52-59. (in Chinese CHAI Hui, LONG Wei, YANG Shaohua, et al . Effect of gas-solid thermal coupling on loading capacity of aerostatic bearing under micro-scale gas-film[J]. Journal of Kunming University of Science and Technology (Natural Science),2018 ,43 (5 ):52 -59 . (in Chinese)[12] SHI Jianghai,CAO Hongrui,JIN Xiaoliang. Investigation on the static and dynamic characteristics of 3-DOF aerostatic thrust bearings with orifice restrictor[J]. Tribology International,2019,138: 435-449. doi: 10.1016/j.triboint.2019.06.026 [13] MAAMARI N,KREBS A,WEIKERT S,et al. Stability and dynamics of an orifice based aerostatic bearing with a compliant back plate[J]. Tribology International,2019,138: 279-296. doi: 10.1016/j.triboint.2019.05.047 [14] 陈东菊,周帅,杨智,等. 稀薄效应对空气静压止推轴承性能影响[J]. 四川大学学报(工程科学版),2016,48(1): 194-199. CHEN Dongju,ZHOU Shuai,YANG Zhi,et al. Influence of flow factor in gas rarefied effects to aerostatic thrust bearing performance[J]. Journal of Sichuan University (Engineering Science Edition),2016,48(1): 194-199. (in Chinese CHEN Dongju, ZHOU Shuai, YANG Zhi, et al . Influence of flow factor in gas rarefied effects to aerostatic thrust bearing performance[J]. Journal of Sichuan University (Engineering Science Edition),2016 ,48 (1 ):194 -199 . (in Chinese)[15] FRANSSEN R H M,POTZE W,DE JONG P,et al. Large amplitude dynamic behavior of thrust air bearings: modeling and experiments[J]. Tribology International,2017,109: 460-466. doi: 10.1016/j.triboint.2016.12.024 [16] 魏先杰,龙威,任璞,等. 尺度效应下均压槽结构对空气静压轴承自激振动的影响[J]. 推进技术,2022,43(4): 297-306. WEI Xianjie,LONG Wei,REN Pu,et al. Effects of pressure groove structure on self-excited vibration of aerostatic bearing under scale effect[J]. Journal of Propulsion Technology,2022,43(4): 297-306. (in Chinese WEI Xianjie, LONG Wei, REN Pu, et al . Effects of pressure groove structure on self-excited vibration of aerostatic bearing under scale effect[J]. Journal of Propulsion Technology,2022 ,43 (4 ):297 -306 . (in Chinese)[17] COLOMBO F,MAFFIODO D,RAPARELLI T. Active gas thrust bearing with embedded digital valves and backpressure sensors[J]. Tribology Transactions,2017,60(5): 807-813. doi: 10.1080/10402004.2016.1213344 [18] YADAV S K,RAJPUT A K,RAM N,et al. A novel technique to compute static and dynamic performance characteristics of aerostatic thrust bearing[J]. Industrial Lubrication and Tribology,2018,70(1): 84-96. doi: 10.1108/ILT-04-2017-0090 [19] 王伟,王超,郑越青,等. 小孔节流气体静压推力轴承微振动机理研究[J]. 光学 精密工程,2020,28(8): 1761-1774. WANG Wei,WANG Chao,ZHENG Yueqing,et al. Study on nano-vibration mechanism of orifice throttle aerostatic thrust bearing[J]. Optics and Precision Engineering,2020,28(8): 1761-1774. (in Chinese WANG Wei, WANG Chao, ZHENG Yueqing, et al . Study on nano-vibration mechanism of orifice throttle aerostatic thrust bearing[J]. Optics and Precision Engineering,2020 ,28 (8 ):1761 -1774 . (in Chinese)[20] 王涛,陈国定,陈薄. 轴承腔气相介质流场的理论与试验[J]. 航空动力学报,2014,29(11): 2767-2773. WANG Tao,CHEN Guoding,CHEN Bo. Theory and experiment on air flow field in bearing chamber[J]. Journal of Aerospace Power,2014,29(11): 2767-2773. (in Chinese WANG Tao, CHEN Guoding, CHEN Bo . Theory and experiment on air flow field in bearing chamber[J]. Journal of Aerospace Power,2014 ,29 (11 ):2767 -2773 . (in Chinese) -

下载:

下载: