Effects of measuring rakes on airflow measurements in flow pipe by area-integrated method

-

摘要:

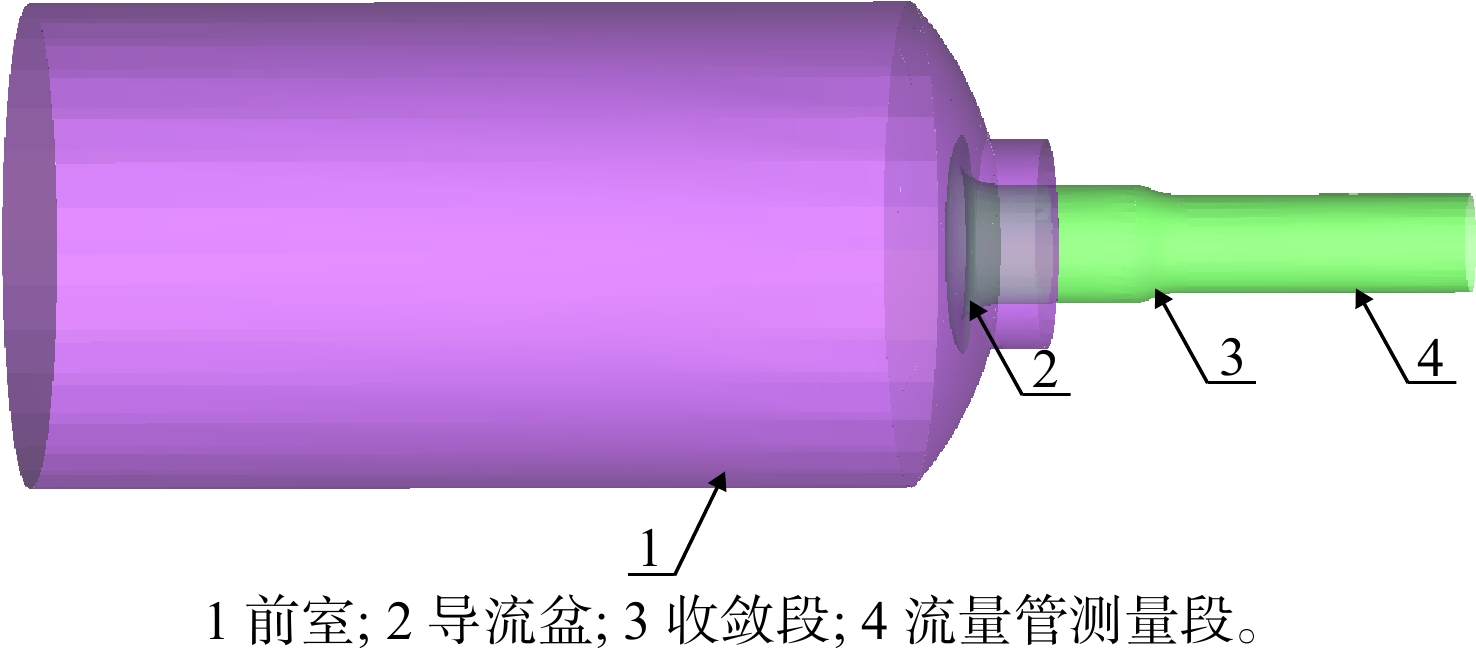

对采用面积积分法测量航空发动机空气流量的流量管三维流场进行数值模拟,分析不同雷诺数下测量耙测点径向分布、轴向位置、测量耙尺寸、总压耙及总温耙和静压测点的相对位置等对面积积分法流量测量的影响。结果表明:高精度的测量流量的面积积分法,理论上要求测试布局能全面准确反映整个测量截面上的流场信息,尤其是流量管环壁附面层内应尽可能多地布置测点。但太多的测点可能使测量耙数量过多、尺寸过大,这样会对流量管内流场产生较大干扰,反而降低流量测量精度。在现行的等环面测点布置方案基础上,适当减少主流区的测点,不会改变流量测量误差,这样能缩短测量耙的尺寸,降低测量耙的堵塞比,减少测量耙的气动力,并明显降低测试成本。但需要检查等环面截短方案及流向测量截面位置在流量管全工况范围内的适用性。测量截面越接近测量耙耙体,流量测量相对误差越大,测量耙的长度和高度对流量测量相对误差影响较小,测量耙宽度对流量测量误差影响较大。为减小流量管测量耙的堵塞比,建议总压耙布置在总温耙上游,静压和总压测量截面应布置在同一轴向位置。总温、总压测点的径向布局和测点数,总温、总压测量耙及静压测量截面的轴向位置关系,都会直接影响面积积分法测量流量的误差,在制定测量流量方案时,要格外重视各测量耙的测试布局。

Abstract:The three-dimensional flow field of an aeroengine flow pipe measured by area-integrated method was numerically simulated, and the effects of radial distribution, axial position, rake size, total pressure rake, total temperature rake and static pressure measurement position on the flow measurement by area-integrated method were analyzed under different Reynolds numbers. The results showed that, with the area-integrated method of high precision measurement flow, the measurement layout can completely and accurately reflect the flow field information on the whole measurement section, especially in the boundary layer of the flow pipe ring wall, and the measurement points should be arranged as much as possible. Too many measuring points may result in excessive number and oversize of measuring harrows, causing great interference to the flow field in the flow tube and reducing the flow measurement accuracy. On the basis of the equal torus measuring point layout scheme, the flow measurement error was not be changed if the measuring points in the main flow area were reduced appropriately, thus shortening the size of the measuring harrow, reducing the clogging ratio of the measuring harrow and the aerodynamic force of the measuring harrow, and significantly saving the test cost. However, it is necessary to check the applicability of the equal torus truncation scheme and the axial measurement section position in the whole working range of the flow pipe. The closer the measuring section to the rake body indicated the greater the relative error of flow measurement. The length and height of rake had little influence on the relative error of the flow measurement, but the width of the rake had great influence on the relative error of the flow measurement. In order to reduce the clogging ratio of the measuring rake of flow pipe, it is recommended that the total pressure rake should be arranged in the upstream of total temperature rake, and the measuring section of static pressure and total pressure should be arranged in the same axial position. The radial layout and number of total temperature or total pressure measuring points, the axial position of total temperature rake or total pressure rake and static pressure measuring section directly affected the error of measuring flow by area-integrated method. Special attention should be paid to the test layout of each rake when flow testing scheme was made.

-

Key words:

- area-integrated method /

- flow pipe /

- measuring rake /

- arrangement of measuring point /

- uncertainty

-

表 1 模拟测量耙的尺寸

Table 1. Simulating rake size

mm 尺寸 长 宽 高 倒角半径 Size1 50 10 20 4 Size2 80 10 20 4 Size3 80 15 20 4 Size4 80 20 20 4 Size5 80 10 10 4 Size6 80 10 30 4 表 2 流量测量相对误差

Table 2. Measuring errors of mass flow

测点布置方案 9-6点截短 11-8点截短 13-10点截短 方案一 −0.023 −0.026 −0.031 方案二 −0.137 −0.219 −0.147 -

[1] 侯敏杰. 高空模拟试验技术[M]. 北京: 航空工业出版社, 2014. [2] 杜鹤龄. 航空发动机高空模拟[M]. 北京: 国防工业出版社, 2002. [3] PATTERSON G, CROSS M. Ground test simulation fidelity of turbine engine airstarts[R] Washington: 29th Joint Propulsion Conference and Exhibit, 1993. [4] BEALE D. Experimental measurement of venturi dis-charge coefficient including sensitivity to geometric and flow quality variables [D]. Knoxville: University of Tennessee, 2002. [5] 中国航空综合技术研究所. 航空燃气涡轮发动机压气机气动性能试验方法: HB 7115-2020[S]. 北京: 航空工业出版社, 2020: 6-10. [6] ASME. Measurement of gas flow by bellmouth inlet flowmeters: MFC-26-2011[S]. New York: ASME International, 2018: 5-10. [7] CASTNER R. High altitude small engine test techniques at the NASA glenn propulsion systems lab[R]. Missouri: 22nd AIAA Aerodynamic Measurement Technology and Ground Testing Conference, 2002. [8] MA Hongwei, ZHANG Jun. Effects of measuring positions on the measured aerodynamic performance of a centrifugal compressor[J]. Journal of Thermal Science, 2010, 19(2): 110-114. [9] WOLTER J D, AREND D J, HIRT S M, et al. Development of a rotating rake array for boundary-layer-ingesting fan-stage measurements[R]. Atlanta: 53rd AIAA/SAE/ASEE Joint Propulsion Conference, 2017. [10] 庄欢,郭昕,马前容,等. 对带外涵的某型核心机空气流量确定的数值分析与试验研究[J]. 燃气涡轮试验与研究,2008,21(2): 11-14,52.ZHUANG Huan,GUO Xin,MA Qianrong,et al. Numerical and experimental study of the air flow determination of a core engine with by-pass duct[J]. Gas Turbine Experiment and Research,2008,21(2): 11-14,52. (in Chinese) [11] MA Hongwei,LI Shaohui,WEI Wei. Effects of probe support on the flow field of a low-speed axial compressor[J]. Journal of Thermal Science,2014,23(2): 120-126. doi: 10.1007/s11630-014-0685-7 [12] MA Hongwei, LI Shaohui, WEI Wei, Effects of probe support on the stall characteristics of a low-speed axial compressor[C]// Proceedings of 12th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows. Lerici: Journal of Thermal Science, 2015: 43-49. [13] 郭晨阳,田晓平. 不同类型测量耙对进气道流场影响的研究[J]. 中国科技信息,2019(12): 48-50.GUO Chenyang,TIAN Xiaoping. Study on the effect of different measuring harrows on inlet flow field[J]. China Science and Technology Information,2019(12): 48-50. (in Chinese) [14] HILDEBRANDT P, JOHANN E. Reducing static pressure measurement errors to increase accuracy of air mass flow measurement[R]. Albuquerque: 20th AIAA Advanced Measurement and Ground Testing Technology Conference, 1998. [15] BEALE D, HAND T, SEBOURN C. Development of a bellmouth airflow measurement technique for turbine engine ground test facilities[R]. Salt Lake City: 37th Joint Propulsion Conference and Exhibit, 2001. [16] 刘志友,马前容,师伟. 改善高空台试验中发动机性能参数不确定度的方法探讨[J]. 燃气涡轮试验与研究,2011,24(1): 1-7.LIU Zhiyou,MA Qianrong,SHI Wei. Methods of aero-engine performance paramance parameter uncertainty improvement in simulated altitude test[J]. Gas Turbine Experiment and Research,2011,24(1): 1-7. (in Chinese) [17] 史建邦,申世才,高扬,等. 航空发动机空气流量测量与计算方法研究[J]. 工程与试验,2011,51(4): 15-18,41.SHI Jianbang,SHEN Shicai,GAO Yang,et al. Research on the aero-engine airflow measurement and calculation method[J]. Engineering & Test,2011,51(4): 15-18,41. (in Chinese) [18] 钟华贵. 一种空气流量测量装置对比标定和不确定度评定方法[J]. 燃气涡轮试验与研究,2011,24(2): 1-4.ZHONG Huagui. An evaluation method on calibration and measurement uncertainty of an airflow rate easuring[J]. Gas Turbine Experiment and Research,2011,24(2): 1-4. (in Chinese) [19] 申世才,王小峰,高扬,等. 某型涡扇发动机进口空气流量测量参数敏感性分析[J]. 计算机测量与控制,2012,20(7): 1806-1808.SHEN Shicai,WANG Xiaofeng,GAO Yang,et al. Engine airflow measurement and calculation based on rake parameters[J]. Computer Measurement & Control,2012,20(7): 1806-1808. (in Chinese) [20] 李冰,郝晓乐,申世才. 航空发动机进口空气流量测量方案分析[J]. 燃气涡轮试验与研究,2013,26(4): 54-57.LI Bing,HAO Xiaole,SHEN Shicai. Measure method of aero-engine inlet airflow[J]. Gas Turbine Experiment and Research,2013,26(4): 54-57. (in Chinese) [21] 劳贤豪,朱银方. 发动机台架试验空气流量测量不确定度分析[J]. 航空精密制造技术,2022,58(2): 23-26.LAO Xianhao,ZHU Yinfang. Uncertainty analysis of gas flow measurement in gas turbine rig test[J]. Aviation Precision Manufacturing Technology,2022,58(2): 23-26. (in Chinese) -

下载:

下载: