Contact load analysis of the duplex angular contact ball bearings with local defects

-

摘要:

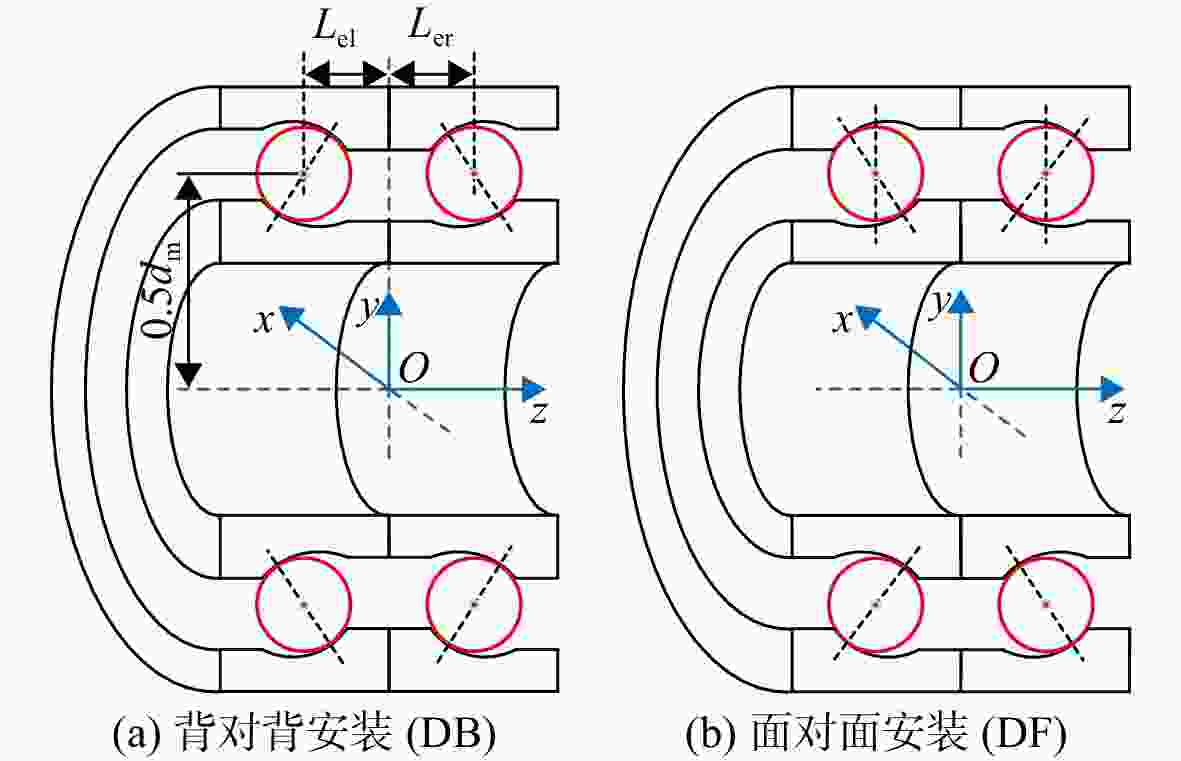

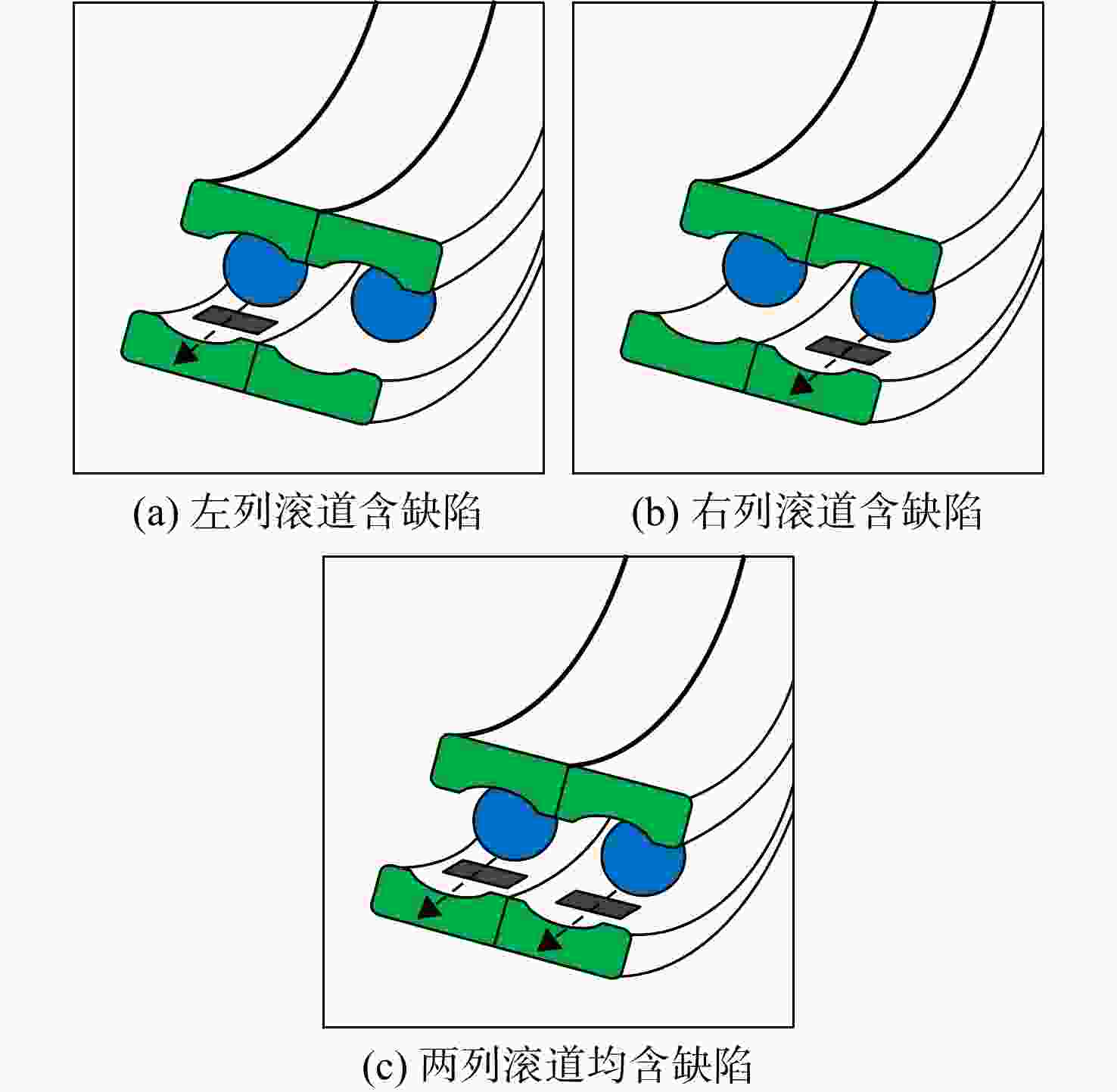

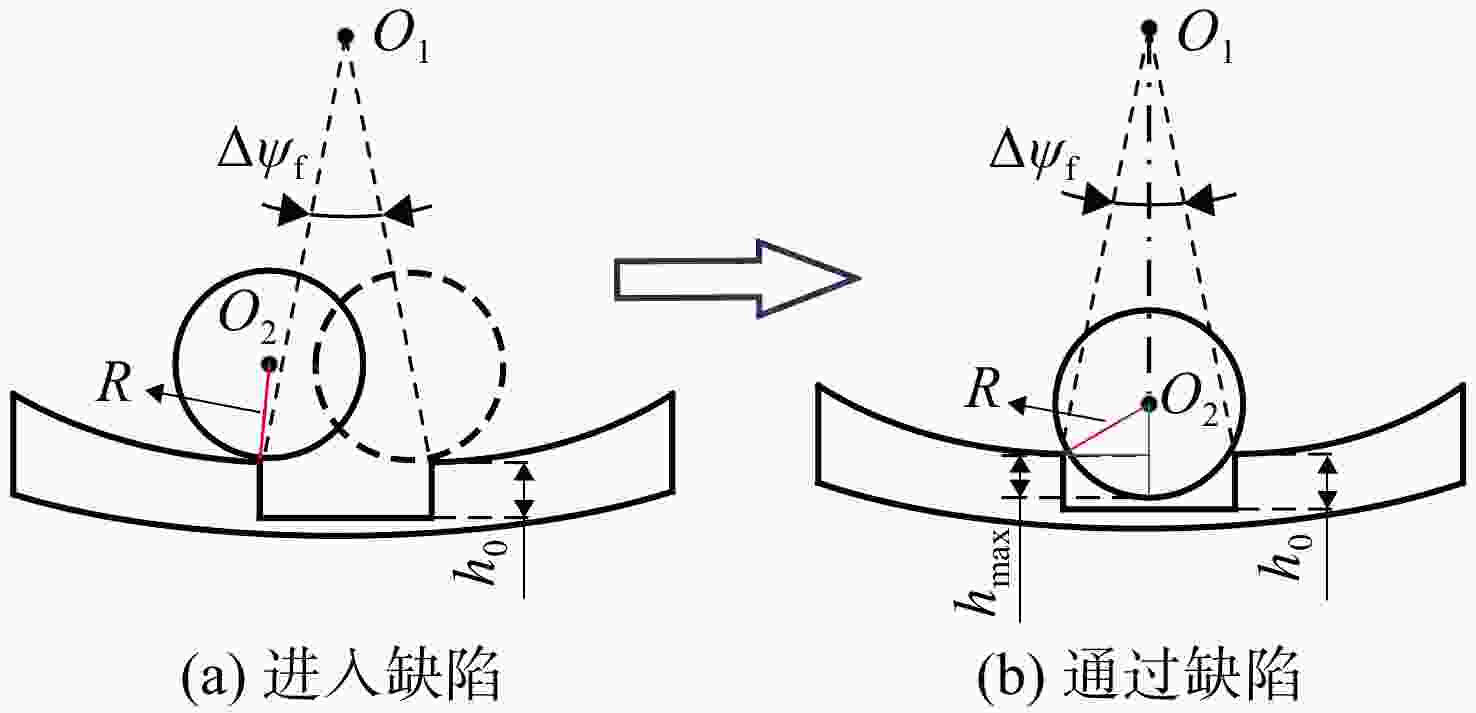

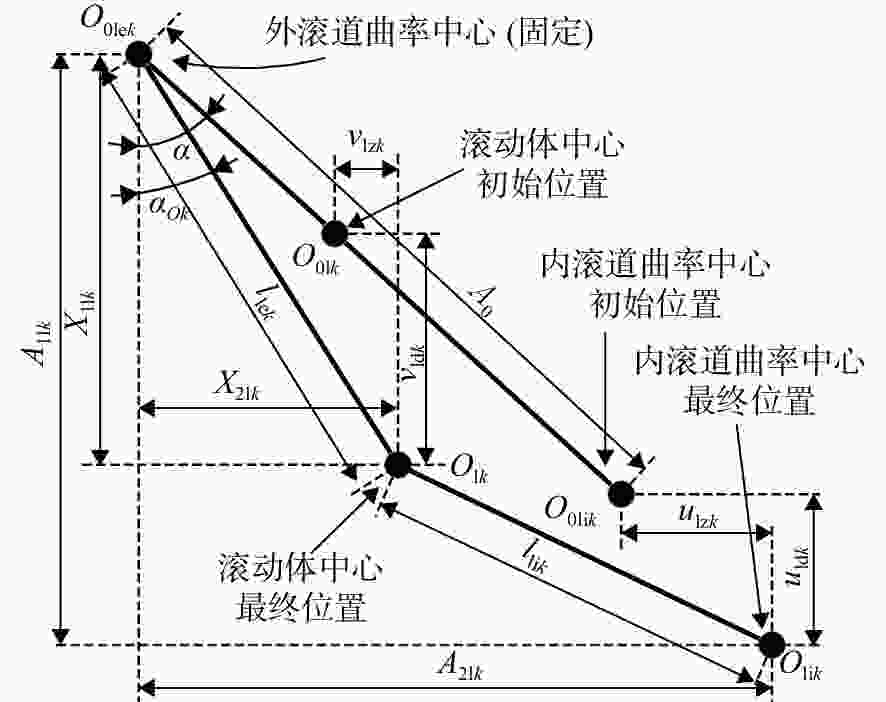

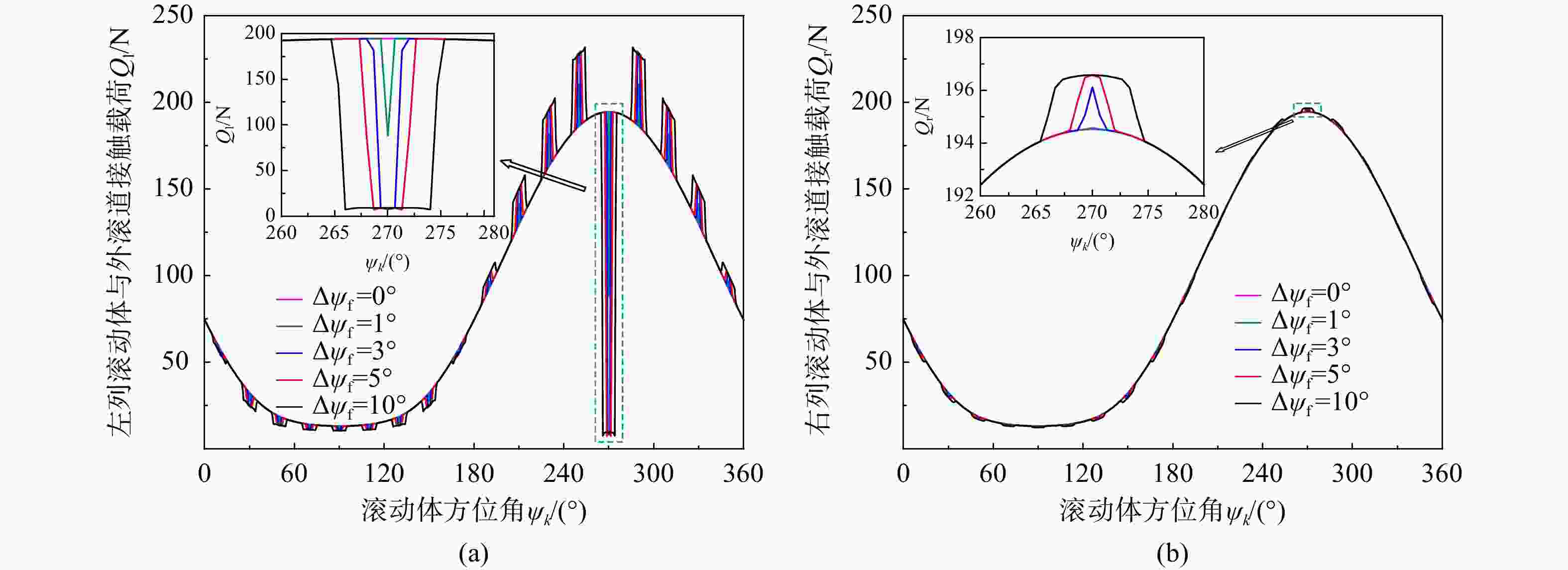

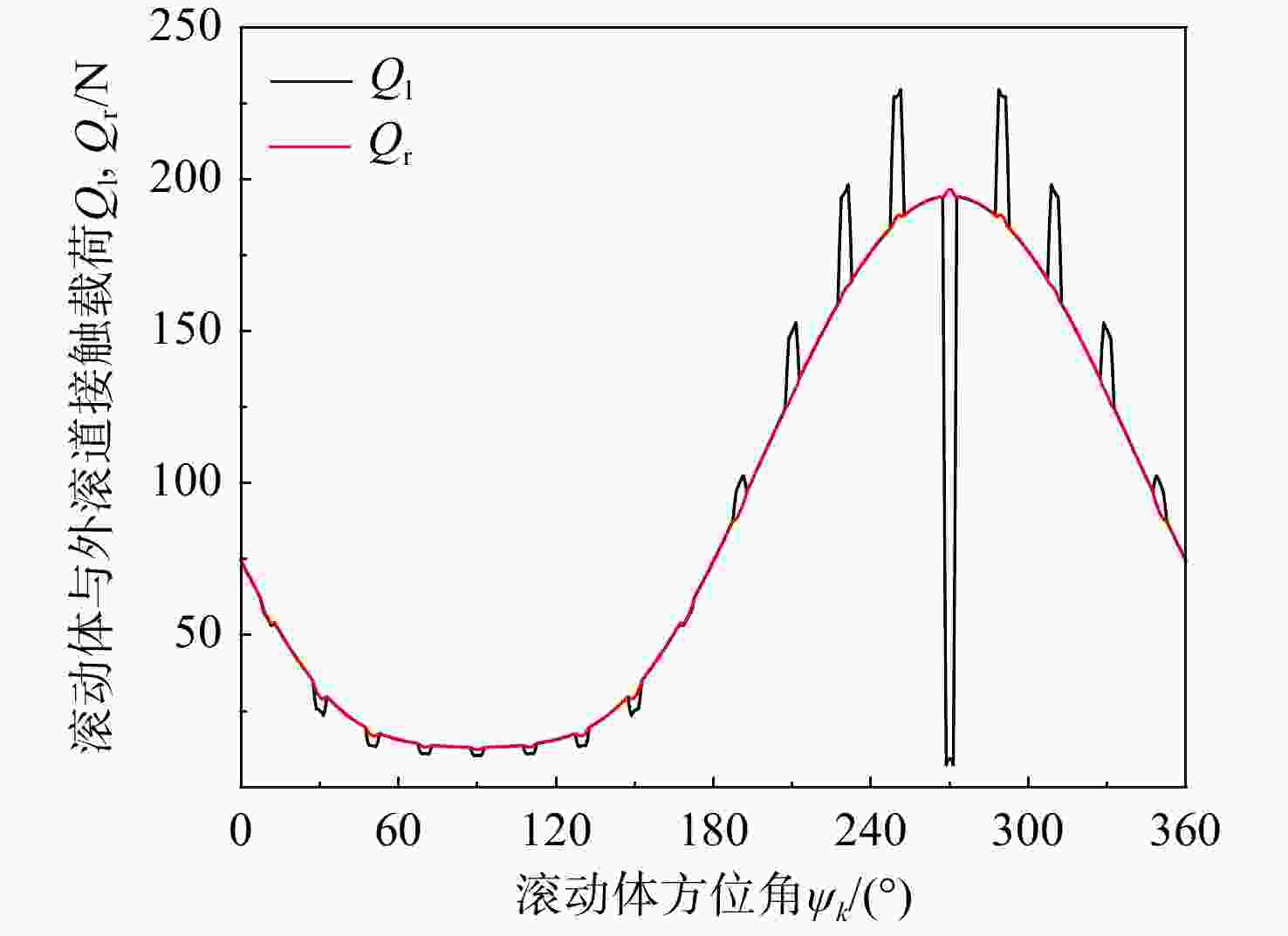

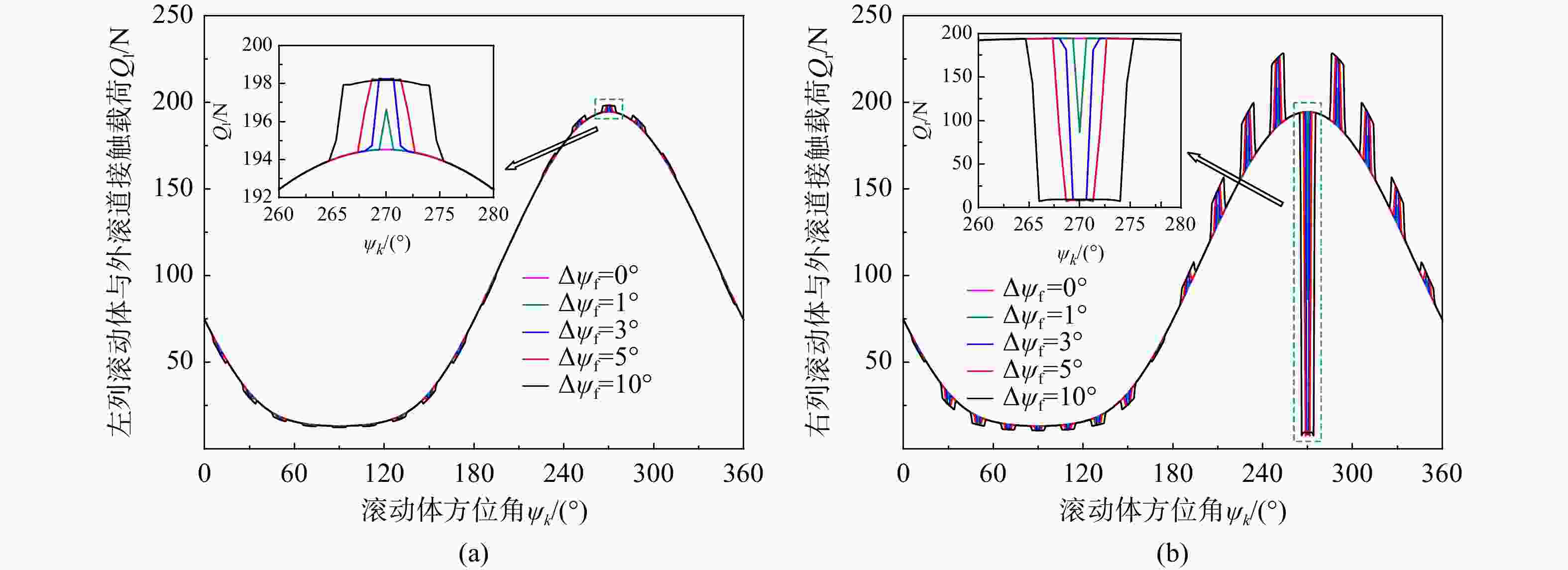

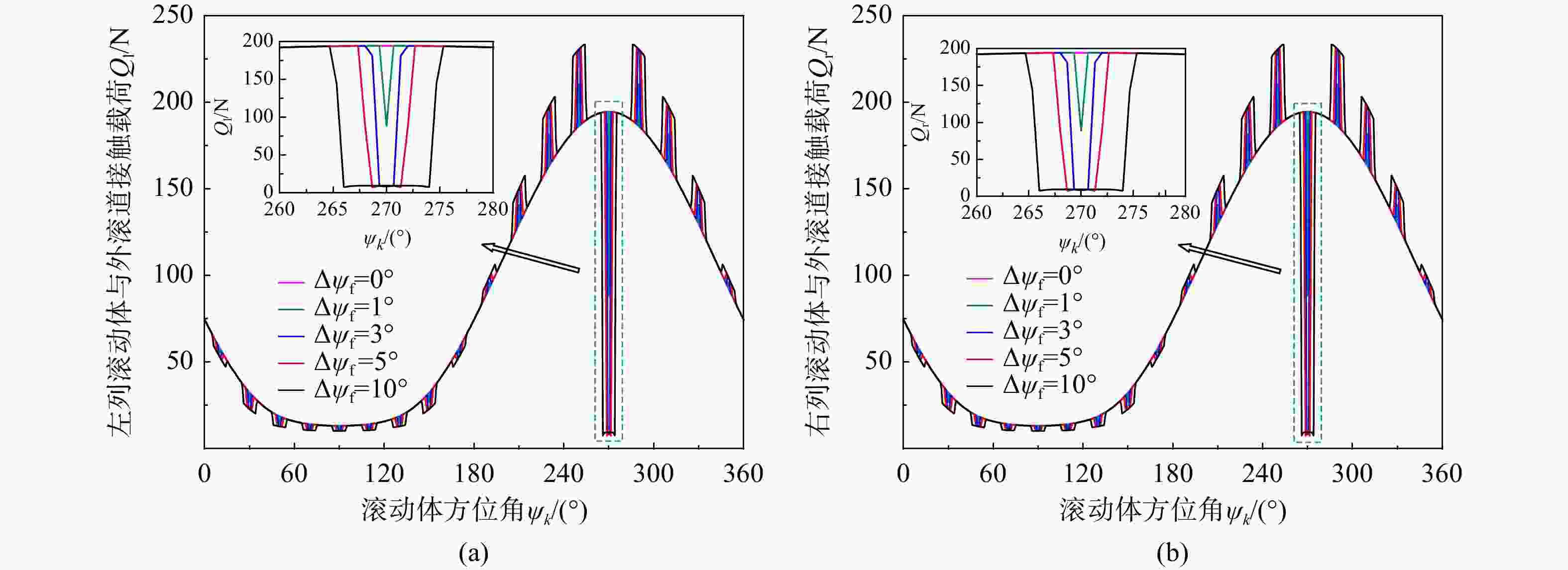

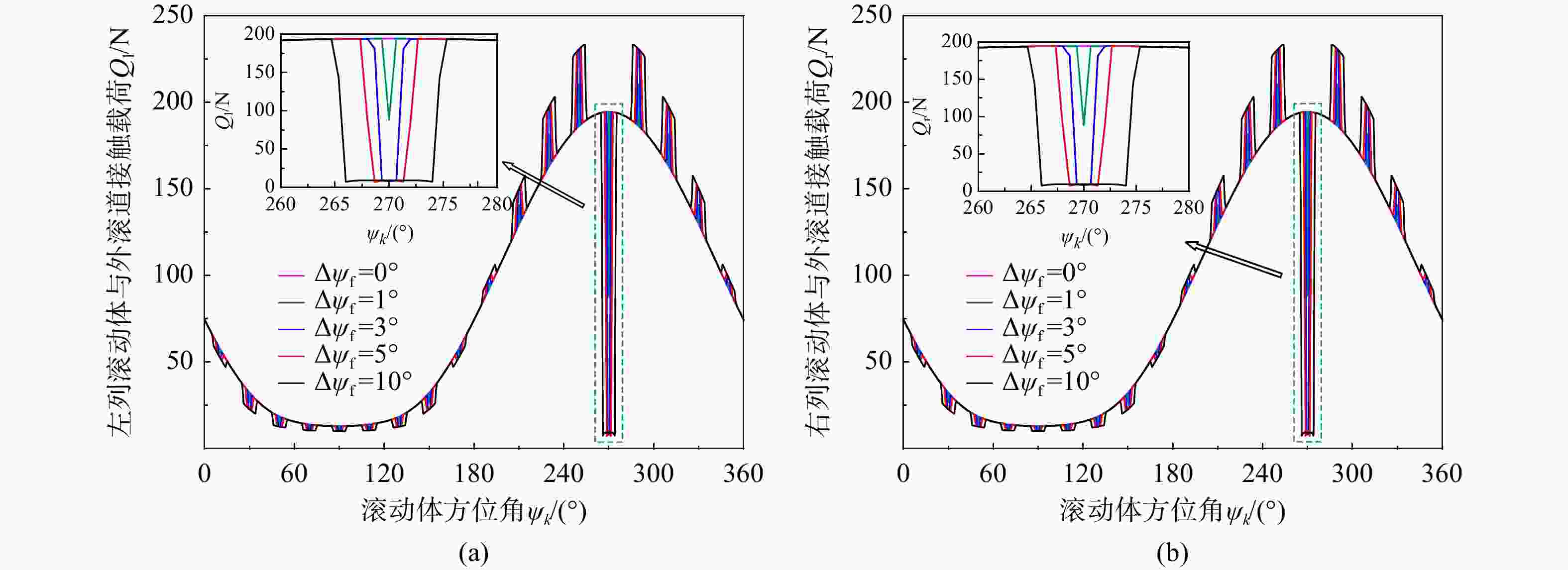

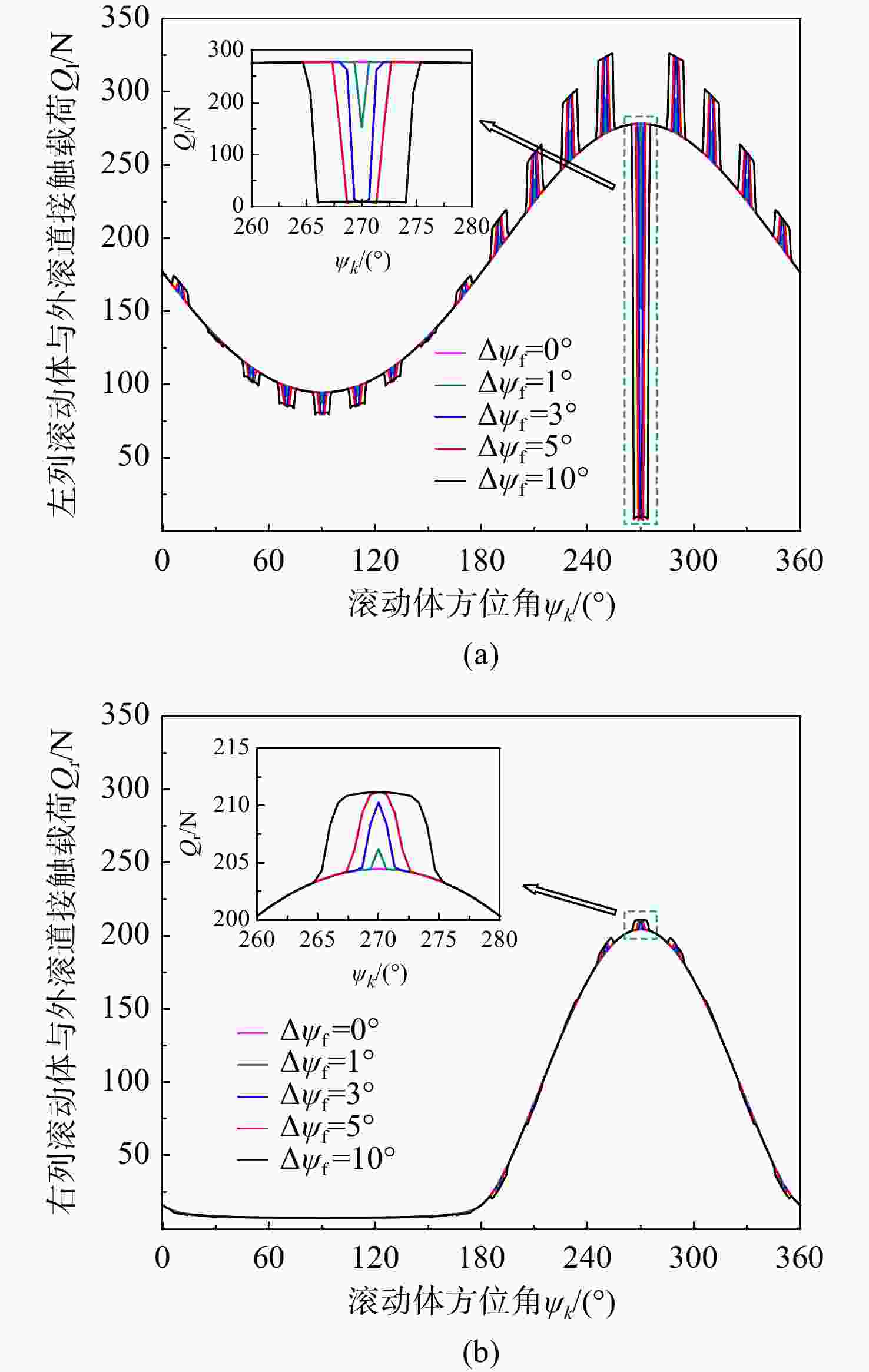

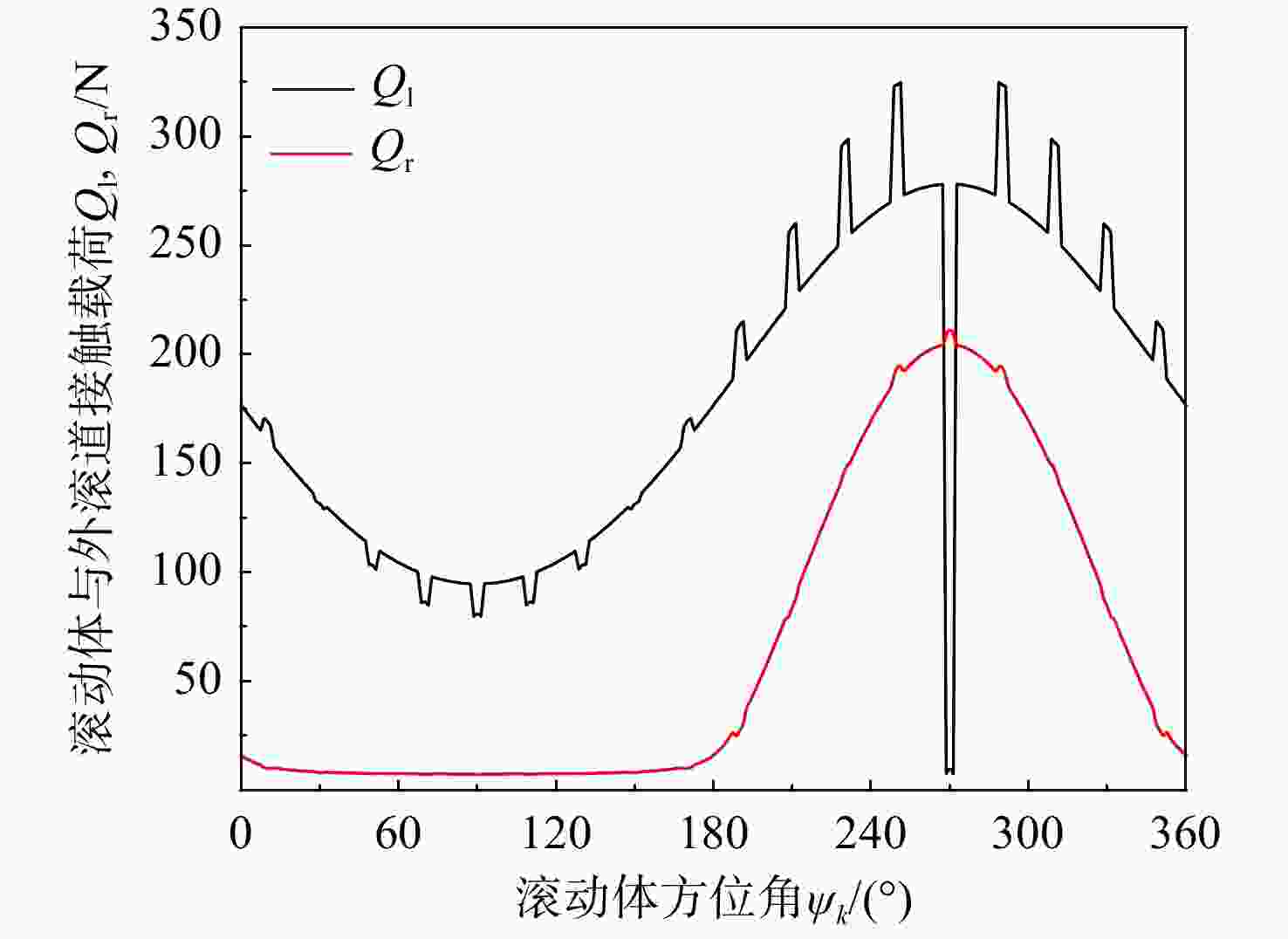

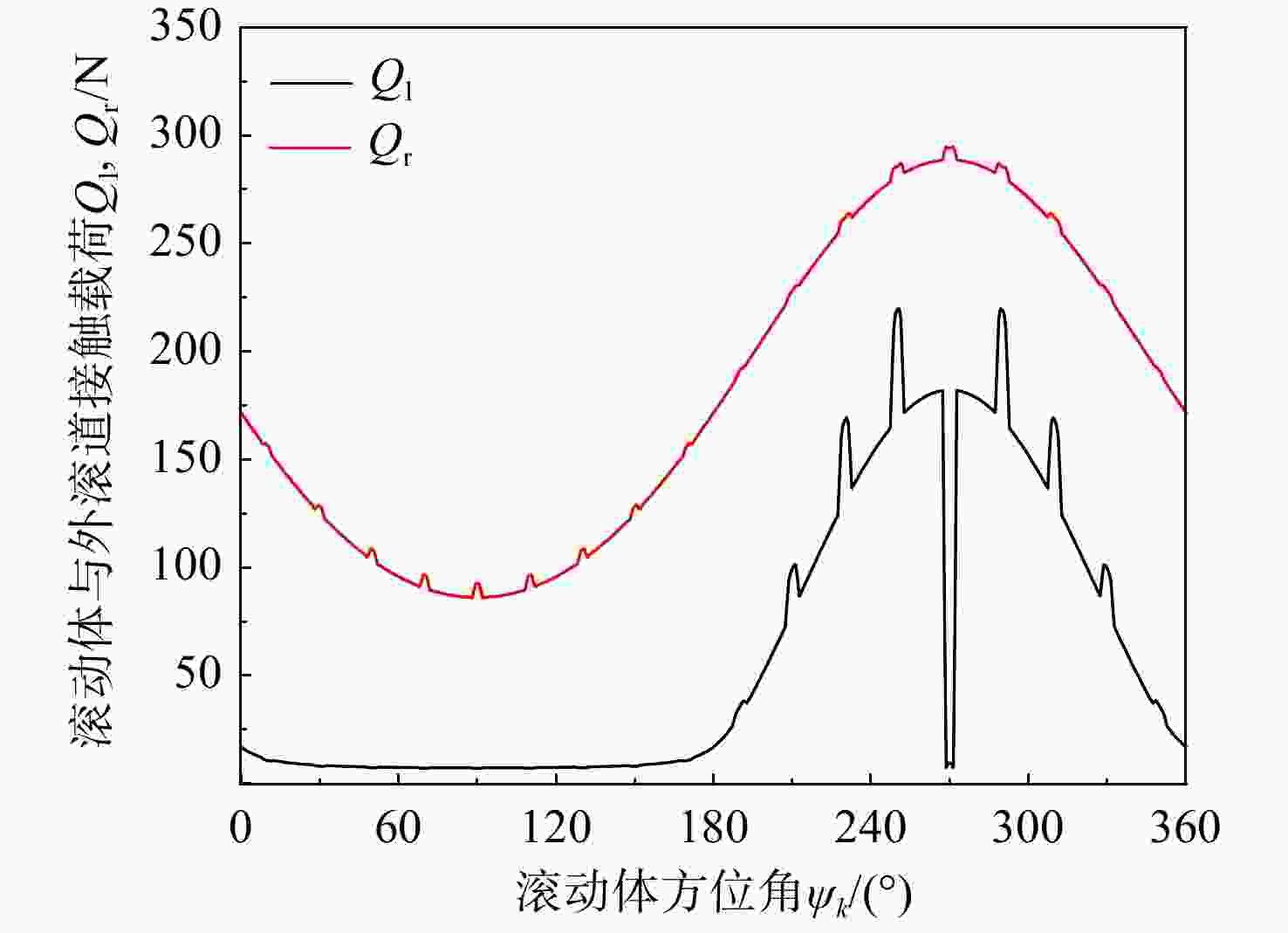

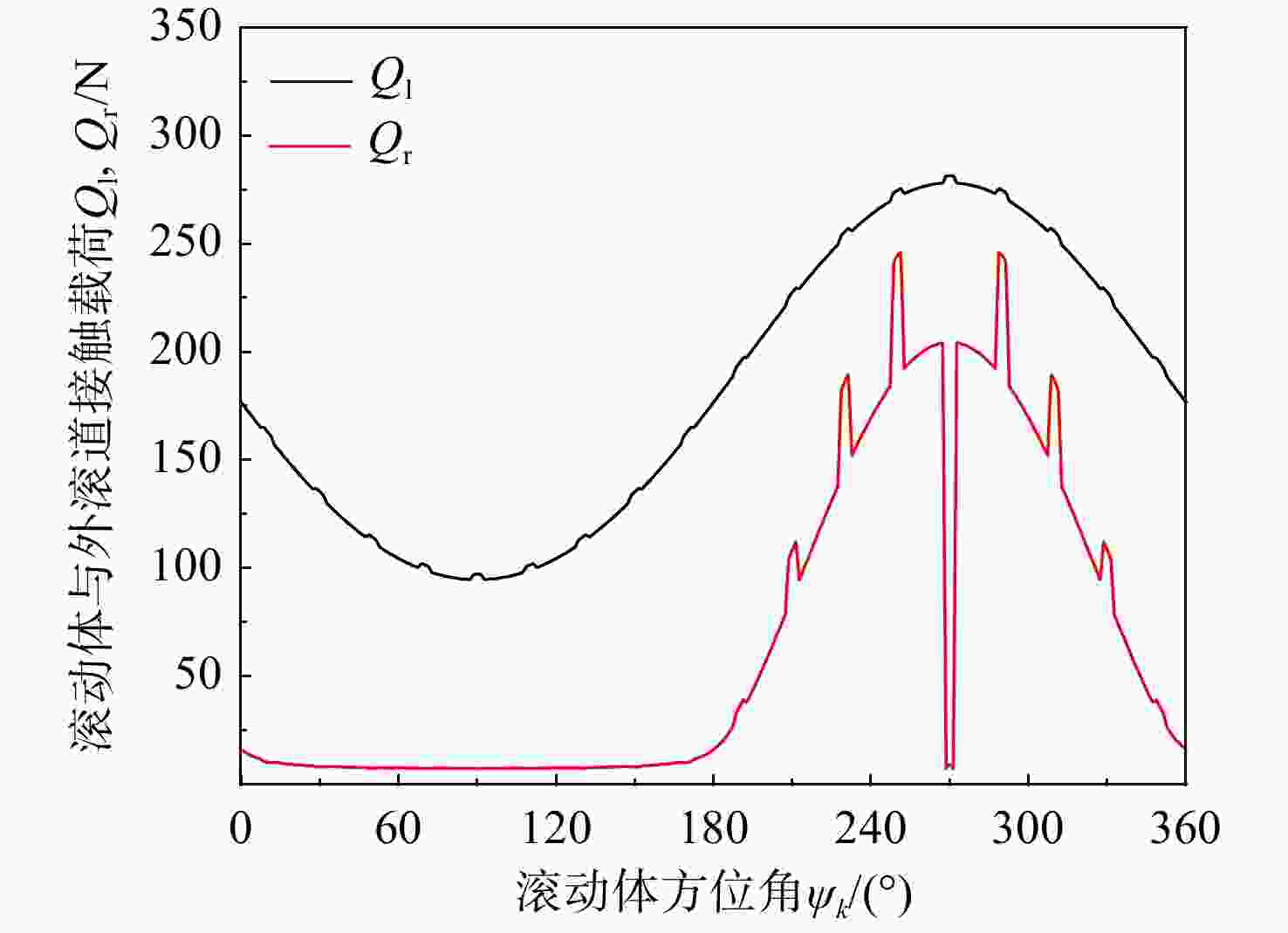

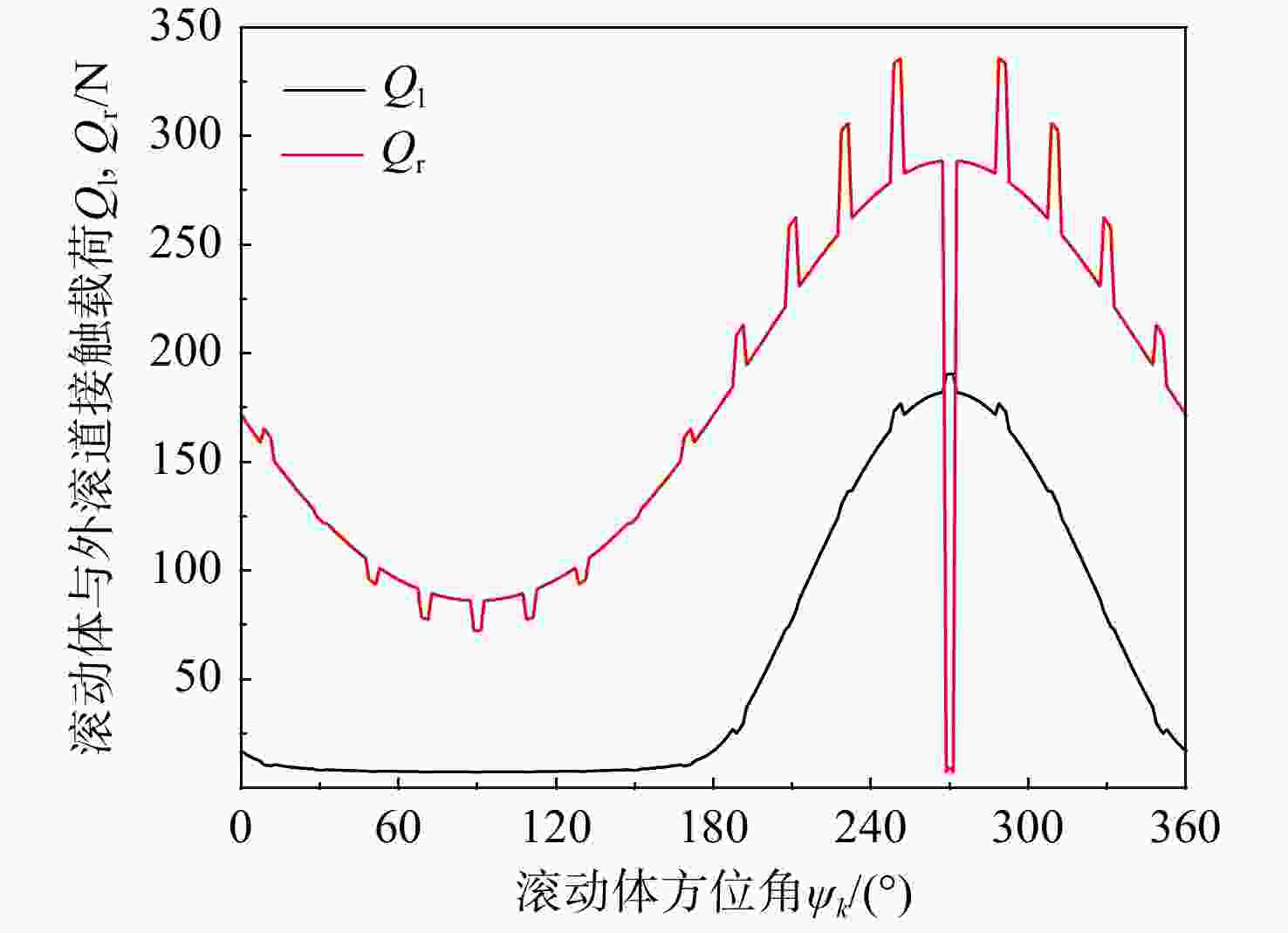

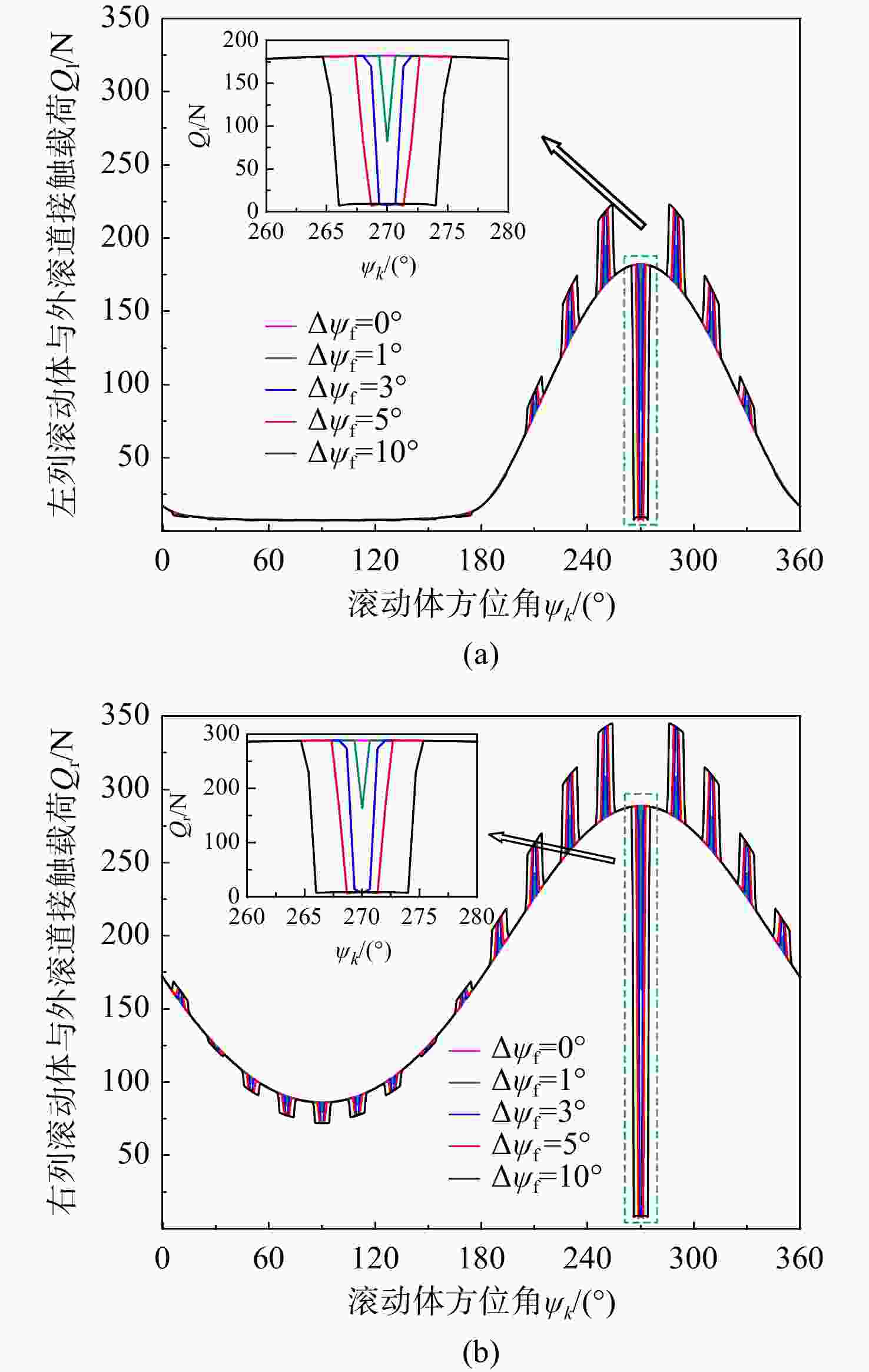

建立了外滚道含局部缺陷的成对角接触球轴承(DACBBs)准静态力学模型,并考虑了缺陷深度、周向宽度以及轴承的时变特性。在此基础上,对纯径向和联合载荷两种工况下局部缺陷的尺寸和位置对DACBBs内部接触载荷的影响进行了系统研究。结果表明:接触载荷对缺陷非常敏感,当左右列轴承分别或共同含局部缺陷时,轴承两列的载荷分布有较大差异。含缺陷的那列轴承载荷分布会产生局部突变现象,突变的幅值和宽度随缺陷尺寸的增大而增大,而不含缺陷的另一列轴承突变很小。另外,成对轴承应视为整体进行研究分析,不同安装方式下,缺陷产生的影响也有较大差异。当前研究对揭示DACBBs的失效机制、可靠性分析以及设计具有重要意义。

-

关键词:

- 成对角接触球轴承(DACBBs) /

- 局部缺陷 /

- 接触载荷分布 /

- 接触角分布 /

- 安装方式

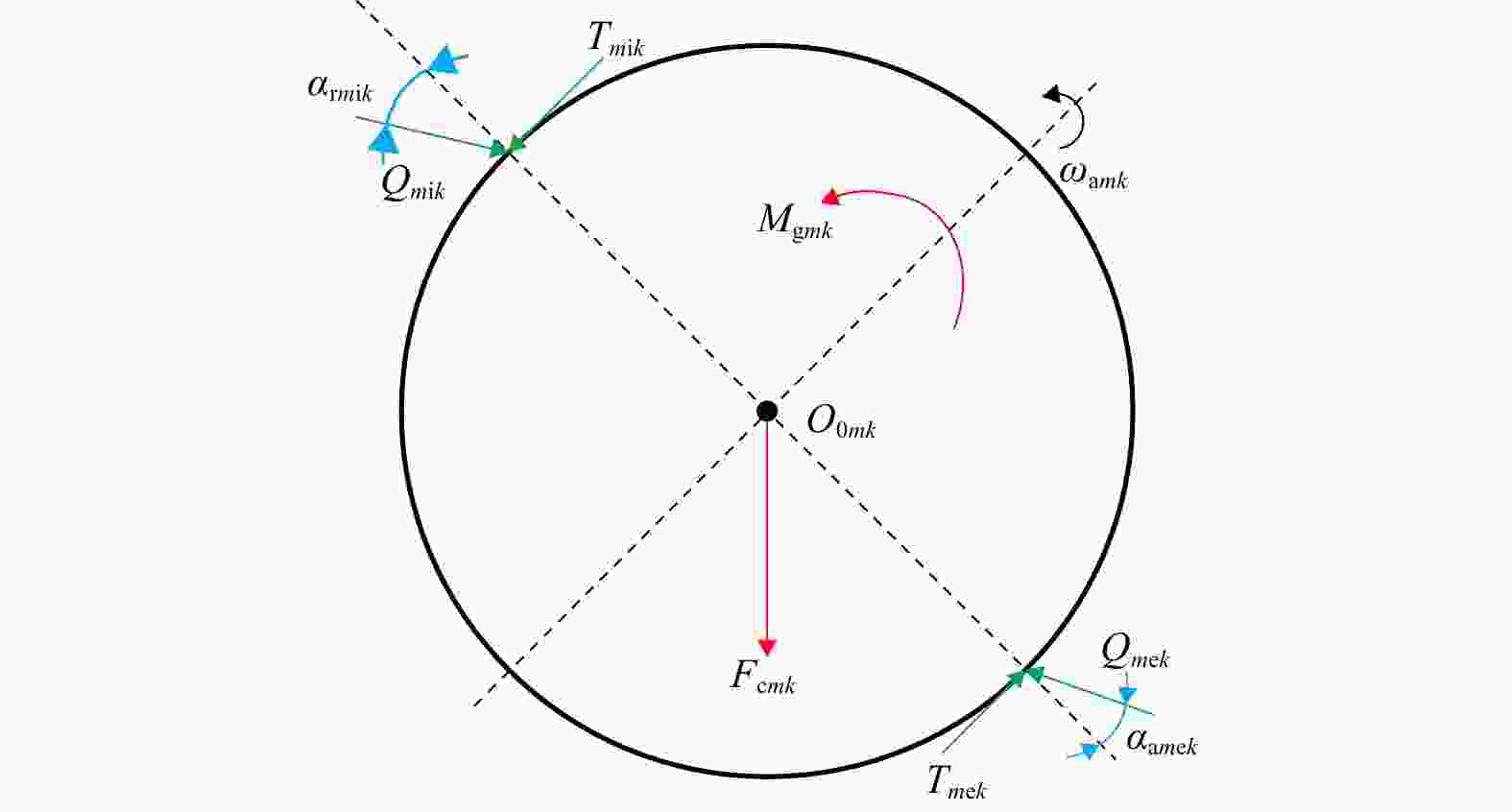

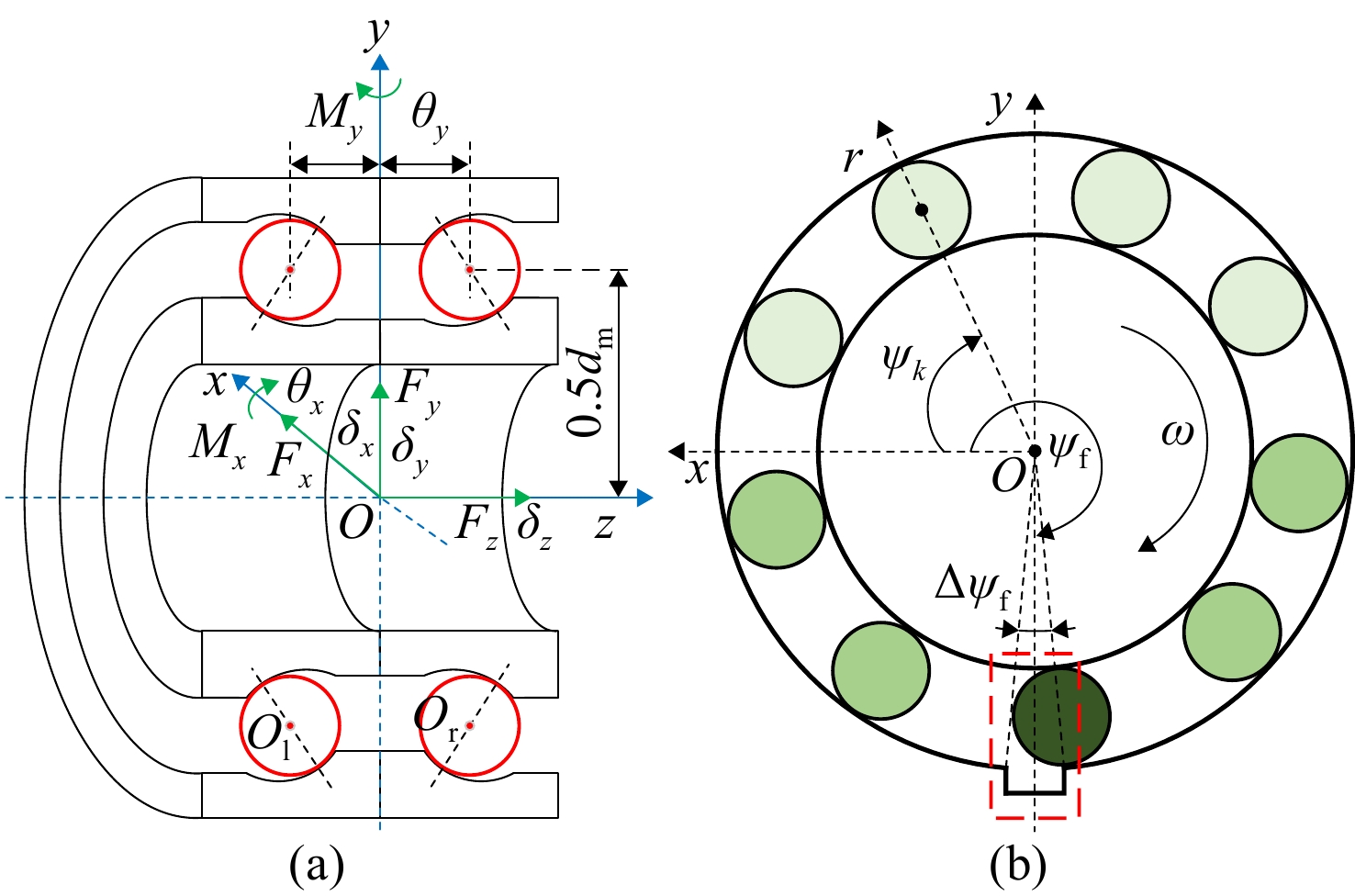

Abstract:A quasi-static mechanical model of the duplex angular contact ball bearings (DACBBs) with local defects on the outer raceway was established. The defect depth, circumferential extent and the time-varying characteristic of the bearing were considered. On this basis, the influences of the size and location of local defects on the internal contact load of DACBBs were systematically investigated under pure radial and combined loads. The results showed that the contact load was very sensitive to the local defect. When the left or the right row contained defect or both of them had defects, the load distribution of the two rows was quite different. The load distribution of the row with defect produced a local mutation, and the amplitude and width of the mutation increased with the increase in the defect size. However, the mutation of the other row without defects was very small. In addition, the DACBBs should be considered as a whole for research and analysis. Under different arrangements, the impact of defects was also quite different. The current study has important implications for revealing the failure mechanism, reliability analysis and design of DACBBs.

-

表 1 7010 AC/DB轴承参数

Table 1. Structural parameters of 7010 AC/DB

参数 数值 节圆直径${d_{\rm{m}}}$/mm 65 左列和右列之间距离${d_{\rm{c}}}$/mm 16 定位预紧${\delta _{\rm{p}}}$/μm 8 滚动体直径$ D $/mm 9 初始接触角$ \alpha $/(°) 25 每列滚动体个数$ Z $ 18 外滚道曲率半径系数${f_{\rm{e}}}$ 0.525 内滚道曲率半径系数${f_{\rm{i}}}$ 0.515 泊松比$ v $ 0.3 弹性模量E/105 MPa 2.06 局部缺陷深度$ {h_0} $/um 50 -

[1] LIU Jing,SHAO Yimin. Overview of dynamic modelling and analysis of rolling element bearings with localized and distributed faults[J]. Nonlinear Dynamics,2018,93(4): 1765-1798. doi: 10.1007/s11071-018-4314-y [2] CAO Hongrui,NIU Linkai,XI Songtao,et al. Mechanical model development of rolling bearing-rotor systems: a review[J]. Mechanical Systems and Signal Processing,2018,102: 37-58. doi: 10.1016/j.ymssp.2017.09.023 [3] TONG V C,HONG S W. Analysis of the stiffness and fatigue life of double-row angular contact ball bearings[J]. Journal of the Korean Society for Precision Engineering,2017,34(11): 813-821. doi: 10.7736/KSPE.2017.34.11.813 [4] GUNDUZ A,SINGH R. Stiffness matrix formulation for double row angular contact ball bearings: analytical development and validation[J]. Journal of Sound and Vibration,2013,332(22): 5898-5916. doi: 10.1016/j.jsv.2013.04.049 [5] JONES A B. A general theory for elastically constrained ball and radial roller bearings under arbitrary load and speed conditions[J]. Journal of Basic Engineering,1960,82(2): 309-320. doi: 10.1115/1.3662587 [6] HARRIS T A. Rolling bearing analysis: essential concepts of bearing technology[M]. New York: CRC, 2007. [7] CAO Yuzhong,ALTINTAS Y. A general method for the modeling of spindle-bearing systems[J]. Journal of Mechanical Design,2004,126(6): 1089-1104. doi: 10.1115/1.1802311 [8] ZHANG Xuening,HAN Qinkai,PENG Zhike,et al. A new nonlinear dynamic model of the rotor-bearing system considering preload and varying contact angle of the bearing[J]. Communications in Nonlinear Science and Numerical Simulation,2015,22(1/2/3): 821-841. [9] SHENG Xia,LI Beizhi,WU Zhouping,et al. Calculation of ball bearing speed-varying stiffness[J]. Mechanism and Machine Theory,2014,81: 166-180. doi: 10.1016/j.mechmachtheory.2014.07.003 [10] PETERSEN D,HOWARD C,PRIME Z. Varying stiffness and load distributions in defective ball bearings: Analytical formulation and application to defect size estimation[J]. Journal of Sound and Vibration,2015,337: 284-300. doi: 10.1016/j.jsv.2014.10.004 [11] 丁为民,潘帅航,张执南. 含缺陷滚动轴承内部载荷分布[J]. 机械设计与研究,2016,32(4): 79-84. doi: 10.13952/j.cnki.jofmdr.2016.0146DING Weimin,PAN Shuaihang,ZHANG Zhinan. Load distribution of rolling bearing with localized defect[J]. Machine Design and Research,2016,32(4): 79-84. (in Chinese) doi: 10.13952/j.cnki.jofmdr.2016.0146 [12] LI Xu,YU Kun,MA Hui,et al. Analysis of varying contact angles and load distributions in defective angular contact ball bearing[J]. Engineering Failure Analysis,2018,91: 449-464. doi: 10.1016/j.engfailanal.2018.04.050 [13] CHENG Hongchuan,ZHANG Yimin,LU Wenjia,et al. Research on time-varying stiffness of bearing based on local defect and varying compliance coupling[J]. Measurement,2019,143(5): 155-179. [14] GAO Shuai,CHATTERTON S,PENNACCHI P,et al. Behaviour of an angular contact ball bearing with three-dimensional cubic-like defect: a comprehensive non-linear dynamic model for predicting vibration response[J]. Mechanism and Machine Theory,2021,163(9): 104376.1-104376.24. [15] BERCEA I,NELIAS D,CAVALLARO G. A unified and simplified treatment of the non-linear equilibrium problem of double-row rolling bearings: Part 1 rolling bearing model[J]. Journal of Engineering Tribology,2003,217(3): 205-212. [16] XU Tengfei,YANG Lihua,WANG Kai. Characteristics of duplex angular contact ball bearing with combined external loads and angular misalignment[J]. Applied Sciences,2020,10(17): 5756.1-5756.25. [17] XU Tengfei,YANG Lihua,WU Wei,et al. Effect of angular misalignment of inner ring on the contact characteristics and stiffness coefficients of duplex angular contact ball bearings[J]. Mechanism and Machine Theory,2021,157(2): 104178.1-104178.22. [18] LIN Shengye,JIANG Shuyun. Study of the stiffness matrix of preloaded duplex angular contact ball bearings[J]. Journal of Tribology,2019,141(3): 032204.1-032204.13. [19] LIN Shengye,JIANG Shuyun. Dynamic characteristics of motorized spindle with tandem duplex angular contact ball bearings[J]. Journal of Vibration and Acoustics,2019,141(6): 061004.1-061004.12. [20] PETERSEN D,HOWARD C,SAWALHI N,et al. Analysis of bearing stiffness variations, contact forces and vibrations in radially loaded double row rolling element bearings with raceway defects[J]. Mechanical Systems and Signal Processing,2015,50: 139-160. [21] PARMAR V,SARAN V H,HARSHA S P. Effect of dynamic misalignment on the vibration response, trajectory followed and defect-depth achieved by the rolling-elements in a double-row spherical rolling-element bearing[J]. Mechanism and Machine Theory,2021,162(8): 104366.1-104366.22. [22] ZHANG Jinhua,FANG Bin,HONG Jun,et al. A general model for preload calculation and stiffness analysis for combined angular contact ball bearings[J]. Journal of Sound and Vibration,2017,411: 435-449. doi: 10.1016/j.jsv.2017.09.019 [23] ZHANG Jinhua,FANG Bin,HONG Jun,et al. Effect of preload on ball-raceway contact state and fatigue life of angular contact ball bearing[J]. Tribology International,2017,114: 365-372. doi: 10.1016/j.triboint.2017.04.029 [24] XU Tengfei,YANG Lihua,WU Wei,et al. The stiffness characteristics analysis of the duplex angular contact ball bearings based on a comprehensive multi-degree-of-freedom mathematical model[J]. Applied Mathematical Modelling,2022,106: 601-626. doi: 10.1016/j.apm.2022.02.017 -

下载:

下载: