Damping characteristics and design method of tubular vortex reducer damper

-

摘要:

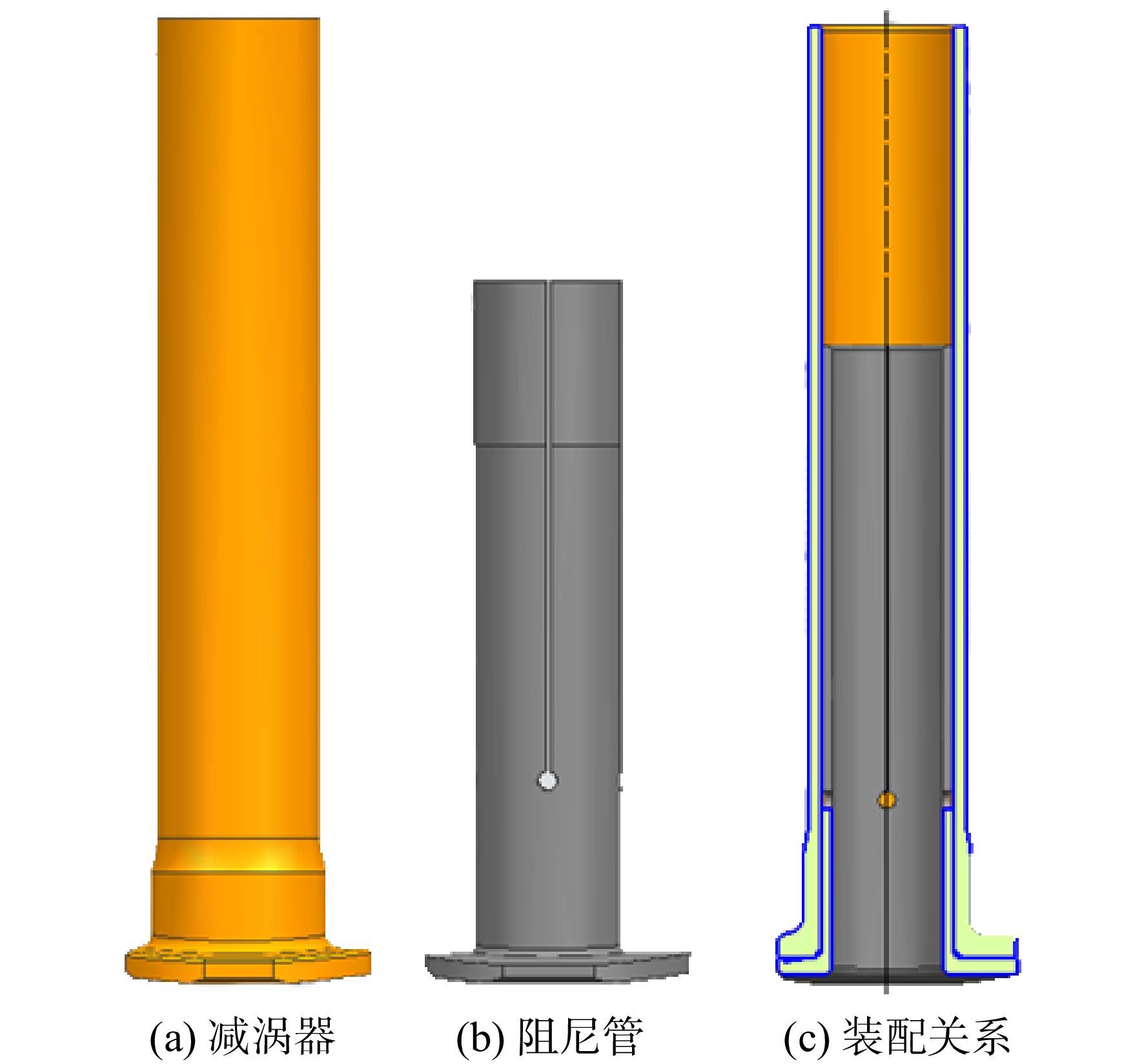

为了抑制管式减涡器工作中的振动,开展对应的阻尼结构设计与减振特性研究工作。针对管式减涡器,总结了阻尼结构的设计参数,在此基础上,归纳了管式减涡器阻尼结构的设计流程。使用该方法对某型发动机减涡器进行阻尼结构设计和减振特性计算,并进行试验验证。结果表明,该方法设计的阻尼器具有良好的阻尼减振效果,可以将关键点应力水平降低80%以上。并且试验得到的减振效果与达到最优减振效果的正压力区间都与计算结果接近,验证了该方法在预测减振特性时的准确性。

Abstract:In order to suppress the vibration of tubular vortex in operation, corresponding damping structure design and damping characteristics research were carried out. For the tubular vortex reducer, the design parameters of the damping structure were summarized. On this basis, the design process of the damping structure of the tubular vortex reducer was summarized. This method was used to design the damping structure and calculate the damping characteristics of an engine vortex reducer, and test verification was carried out. The results showed that the damper designed by this method has good damping effect and can reduce the stress level at key points by more than 80%. The test results and the normal pressure range to achieve the optimal damping effect were close to the calculation results, verifying the accuracy of the method in predicting the damping characteristics.

-

Key words:

- vortex reducer /

- damping structure /

- dry friction damping /

- design flow /

- vibration reduction test

-

表 1 不同管长阻尼管的设计开口宽度

Table 1. Design opening width of damping tube with different tube lengths

阻尼管管长/% 周向位移/mm 设计开口宽度/mm 40 0.25 0.5 60 0.41 0.8 80 0.56 1.0 表 2 阻尼管减振特性分析结果汇总

Table 2. Analysis results of damping characteristics of damping tube

阻尼管管长/% 最优减振效果/% 最优无量纲正压力 40 83.17 25 60 77.89 50 80 73.15 20 表 3 不同管长阻尼管过盈量设计值

Table 3. Design values of interference of damping tubes with different tube lengths

管长/% 设计过盈量/mm 接触压力/N 最优正压力/N 40 0.011 132.57 125 60 0.038 255.22 250 80 0.035 103.19 100 表 4 最优正压力结果对比

Table 4. Comparison of optimal normal pressure results

阻尼管管长/% 计算最优

无量纲正压力试验最优

正压力区间40 25 10~30 60 50 20~100 80 20 50~150 -

[1] 吴丽军,陈潇,邓双国,等. 减涡器流阻特性计算分析[J]. 燃气轮机技术,2014,27(3): 37-43.WU Lijun,CHEN Xiao,DENG Shuangguo,et al. Flow resistance characteristics of vortex reducer computation and analysis[J]. Gas Turbine Technology,2014,27(3): 37-43. (in Chinese) [2] HIDE R. On source-sink flows in a rotating fluid[J]. Journal of Fluid Mechanics,1968,32(4): 737-764. doi: 10.1017/S002211206800100X [3] FIROUZIAN M,OWEN J M,PINCOMBE J R,et al. Flow and heat transfer in a rotating cylindrical cavity with a radial inflow of fluid[J]. International Journal of Heat and Fluid Flow,1986,7(1): 21-27. doi: 10.1016/0142-727X(86)90037-8 [4] 罗翔,白阳,何建. 压气机盘腔径向引流减涡器研究综述[J]. 南京航空航天大学学报,2019,51(4): 427-437.LUO Xiang,BAI Yang,HE Jian. Review of vortex reducer in radial inflow of compressor disk cavity[J]. Journal of Nanjing University of Aeronautics and Astronautics,2019,51(4): 427-437. (in Chinese) [5] GÜNTHER A, UFFRECHT W, KAISER E, et al. Experimental analysis of varied vortex reducer configurations for the internal air system of jet engine gas turbines[R]. ASME Paper GT2008-50738, 2008. [6] LIANG Zhirong,LUO Xiang,FENG Ye,et al. Experimental investigation of pressure losses in a co-rotating cavity with radial inflow employing tubed vortex reducers with varied nozzles[J]. Experimental Thermal and Fluid Science,2015,66: 304-315. doi: 10.1016/j.expthermflusci.2015.03.008 [7] 赵义祯,魏嵩,毛军逵,等. 管式减涡器入口局部压降和流阻特性[J]. 航空动力学报,2021,36(1): 42-52. doi: 10.13224/j.cnki.jasp.2021.01.006ZHAO Yizhen,WEI Song,MAO Junkui,et al. Local pressure drop and flow resistance characteristic at entrance of tubed vortex reducer[J]. Journal of Aerospace Power,2021,36(1): 42-52. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.01.006 [8] FARTHING P R,OWEN J M. De-swirled radial inflow in a rotating cavity[J]. International Journal of Heat and Fluid Flow,1991,12(1): 63-70. doi: 10.1016/0142-727X(91)90009-K [9] 魏大盛,马梦弟,王延荣,等. 减涡器破裂转速预测方法及试验验证[J]. 航空动力学报,2022,37(4): 704-710.WEI Dasheng,MA Mengdi,WANG Yanrong,et al. Prediction method and experimental verification of the burst speed of the vortex reducer[J]. Journal of Aerospace Power,2022,37(4): 704-710. (in Chinese) [10] ALFORD J S. Protection of labyrinth seals from flexural vibration[J]. Journal of Engineering for Power,1964,86(2): 141-147. doi: 10.1115/1.3677564 [11] 孙世威. 旋转薄壁圆筒干摩擦减振设计研究[D]. 沈阳: 东北大学, 2013.SUN Shiwei. Rotating thin-walled cylinder dry friction damping design studies[D]. Shenyang: Northeastern University, 2013. (in Chinese) [12] 温伟,漆文凯. 基于整体叶盘环形摩擦阻尼器减振分析及设计[J]. 航空动力学报,2020,35(4): 777-782.WEN Wei,QI Wenkai. Vibration reduction analysis and design of friction ring damper in blisk[J]. Journal of Aerospace Power,2020,35(4): 777-782. (in Chinese) [13] 林茂山. 短柱壳—约束层阻尼系统建模与减振机理研究[D]. 沈阳: 东北大学, 2011.LIN Maoshan. The modeling and damping mechanism research on constrained layer damping short cylindrical shell system[D]. Shenyang: Northeastern University, 2011. (in Chinese) [14] 曾亮,李琳. 带有阻尼环(套筒)的篦齿封严装置动力响应特性实验[J]. 航空动力学报,2008,23(10): 1813-1818,1820.ZENG Liang,LI Lin. Experiments on dynamic response of labyrinth air seals with damping-ring/sleeves[J]. Journal of Aerospace Power,2008,23(10): 1813-1818,1820. (in Chinese) [15] DEN HARTOG J P. Forced vibrations with combined coulomb and viscous friction[J]. Journal of Fluids Engineering,1931,53(2): 107-115. doi: 10.1115/1.4022656 [16] DUAN Y, ZANG C, PETROV E. Analysis of forced response of high-mode vibrations of mistuned bladed discs using reduced-order modelling methodology[C]//26th International Conference on Noise and Vibration Engineering. Leuven, Belgium: KU Leuven, 2014: 2551-2564. [17] 漆文凯. 涡轮转子叶片叶根阻尼装置减振特性分析及实验研究[D]. 南京: 南京航空航天大学, 2005.QI Wenkai. Analysis and experimental study on vibration reduction characteristics of turbine rotor blade root damping device[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2005. (in Chinese) [18] 漆文凯,高德平. 摩擦阻尼减振设计中的局部滑动问题[J]. 航空学报,2006,27(5): 805-809.QI Wenkai,GAO Deping. Microslip study on friction damping and its application in design of vibration reduction[J]. Acta Aeronautica et Astronautica Sinica,2006,27(5): 805-809. (in Chinese) [19] 吴绵绵. 涡轮叶片摩擦阻尼减振设计方法研究[D]. 南京: 南京航空航天大学, 2010.WU Mianmian. A vibration-reduced design method for turbine blade with friction damper[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2010. (in Chinese) [20] 张云娟. 涡轮叶片干摩擦阻尼减振特性研究[D]. 南京: 南京航空航天大学, 2014.ZHANG Yunjuan. Research on dynamic characteristic of turbine blade with friction damper[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2014. (in Chinese) [21] 陈俊杰. 带冠叶盘干摩擦阻尼减振特性研究[D]. 南京: 南京航空航天大学, 2015.CHEN Junjie. Research on vibration characteristicof shrouded bladed disk with friction damper[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015. (in Chinese) -

下载:

下载: