Force on the pintle of pintle variable thrust solid rocket motor

-

摘要:

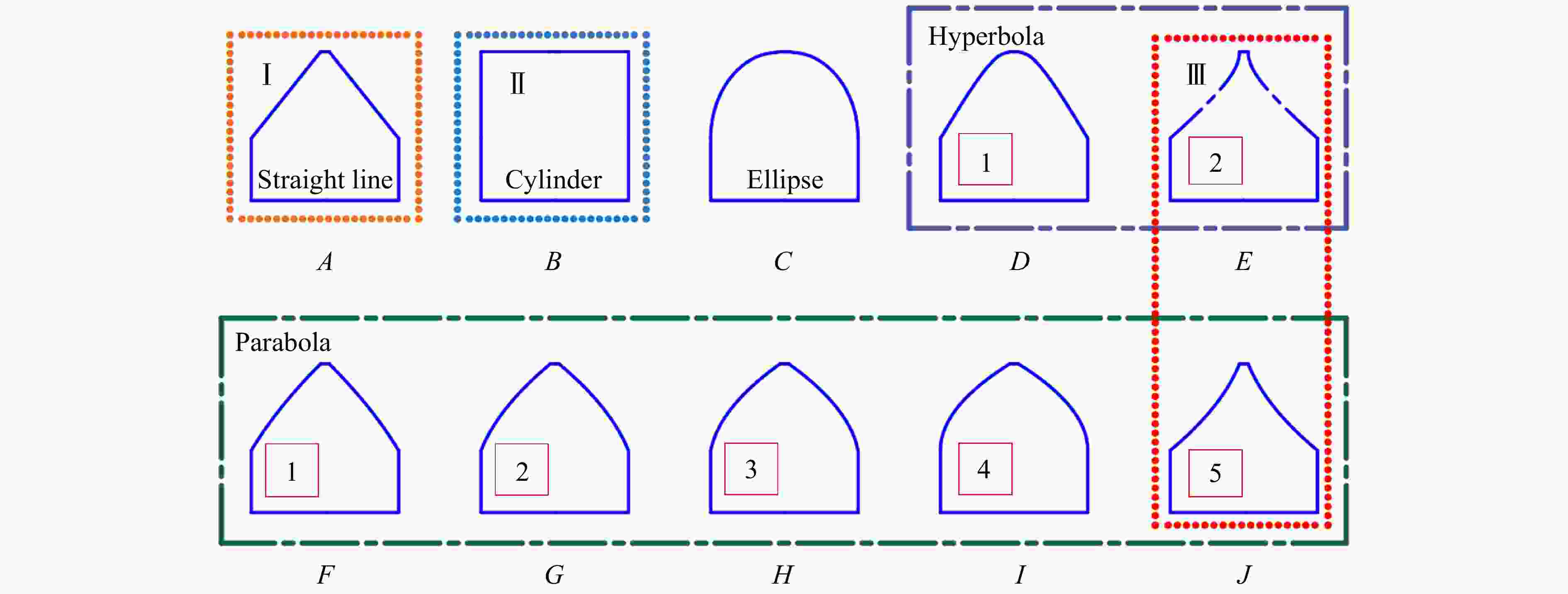

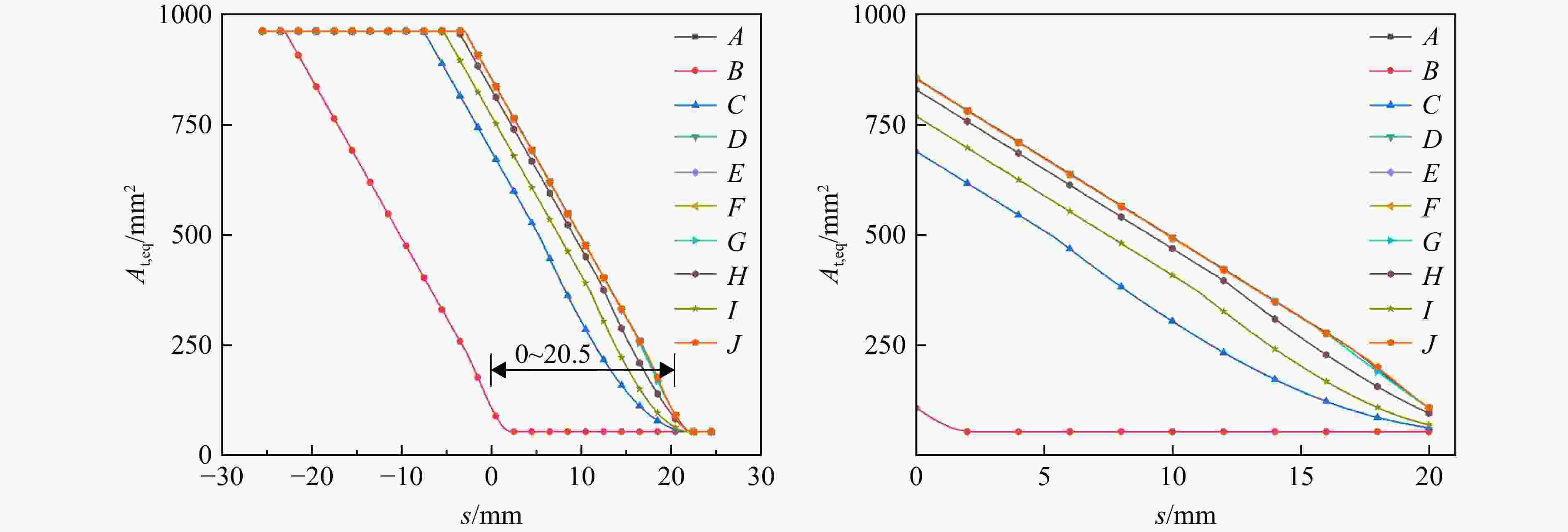

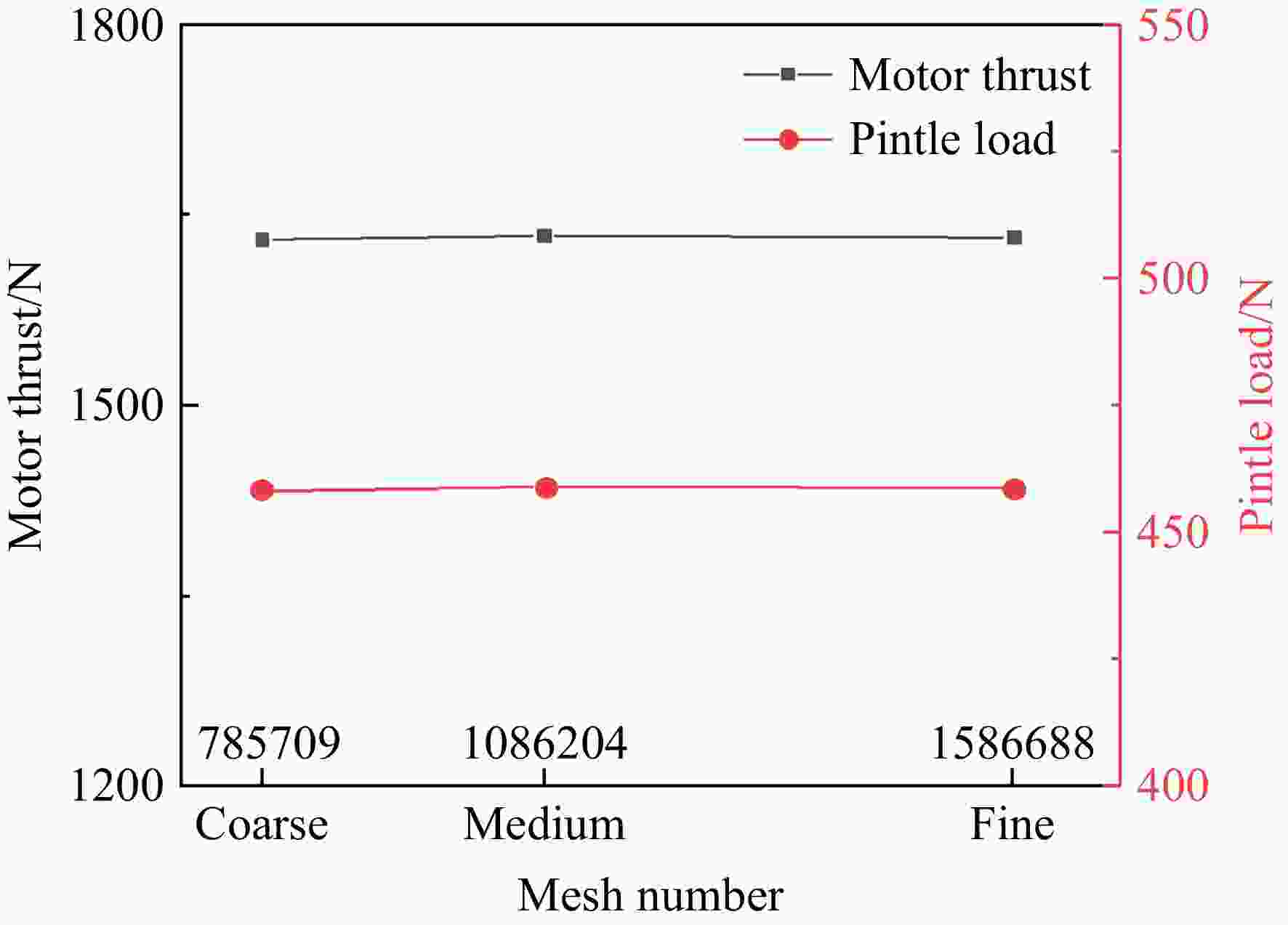

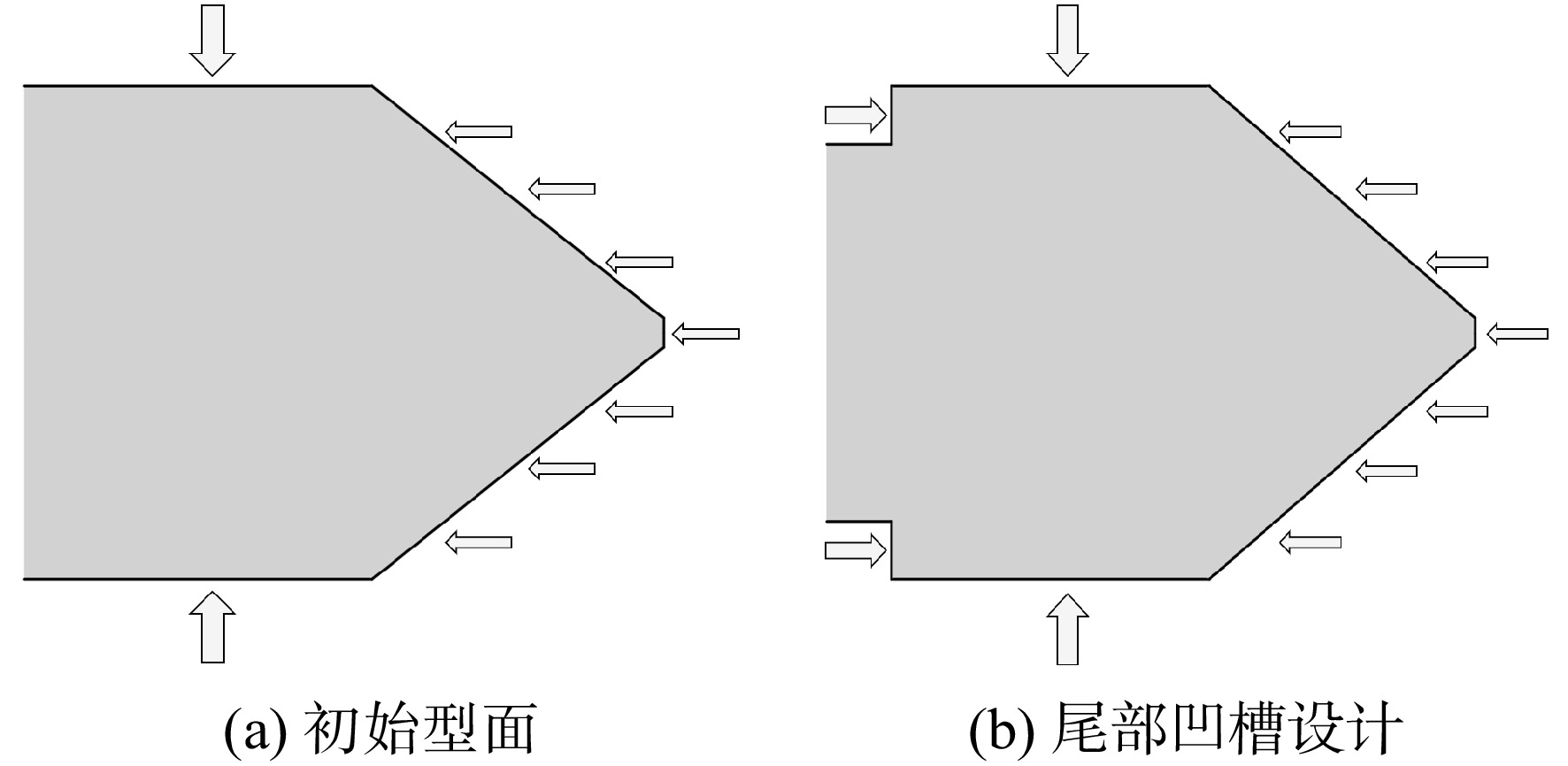

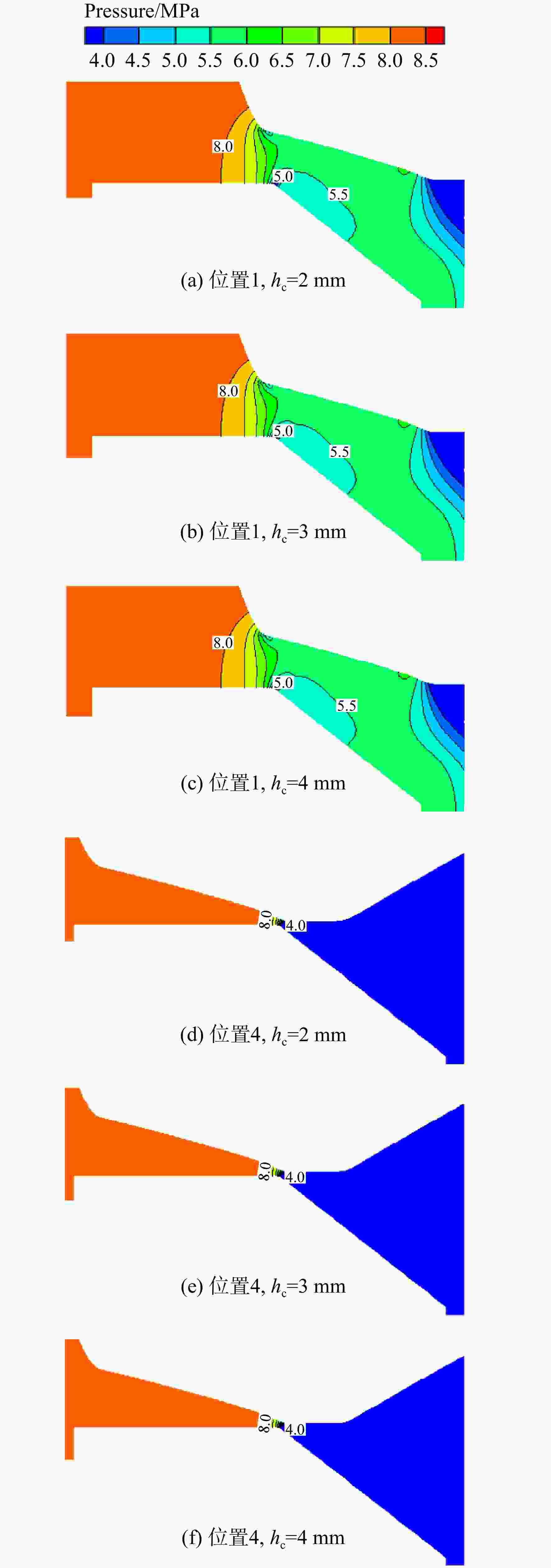

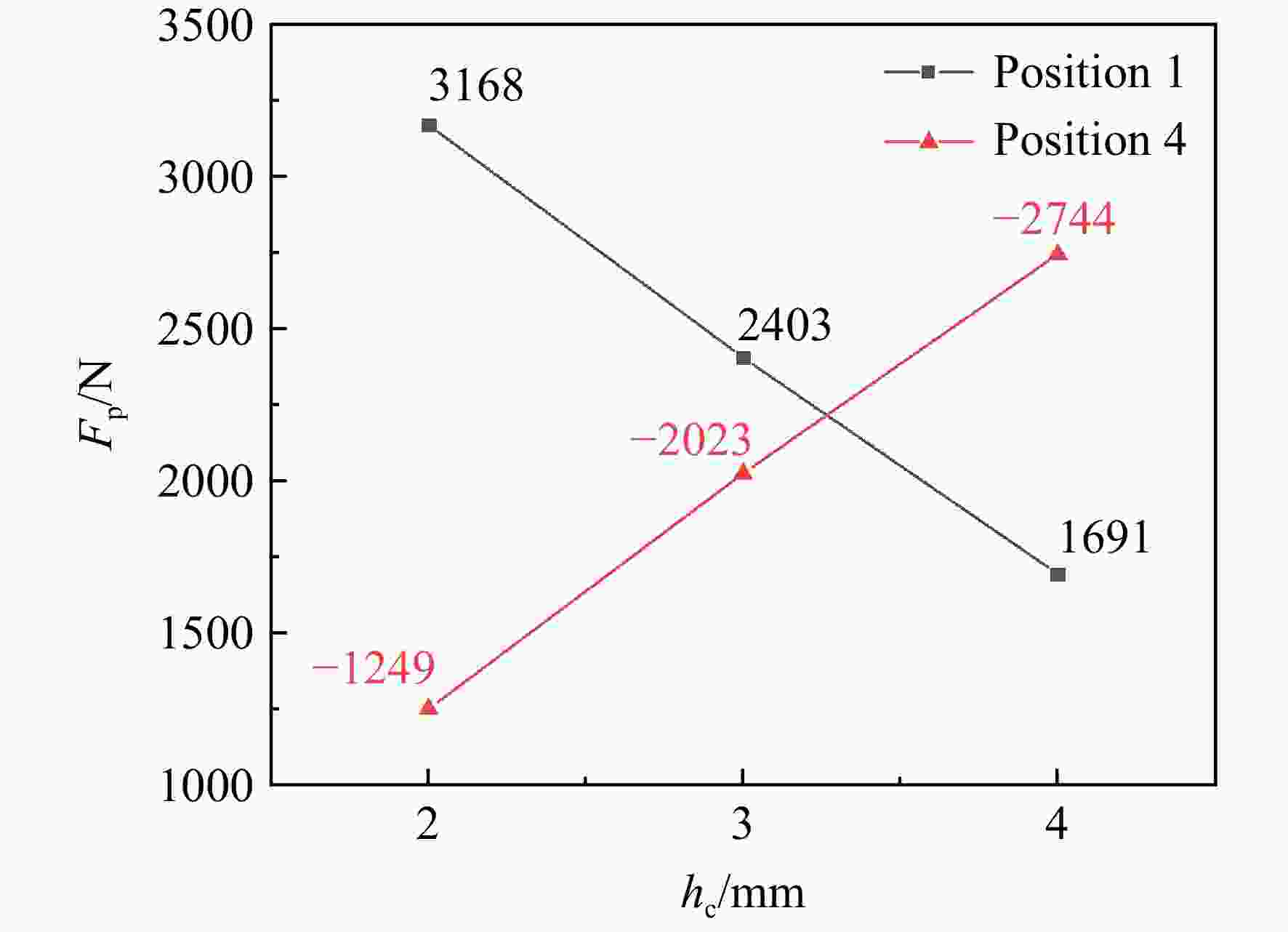

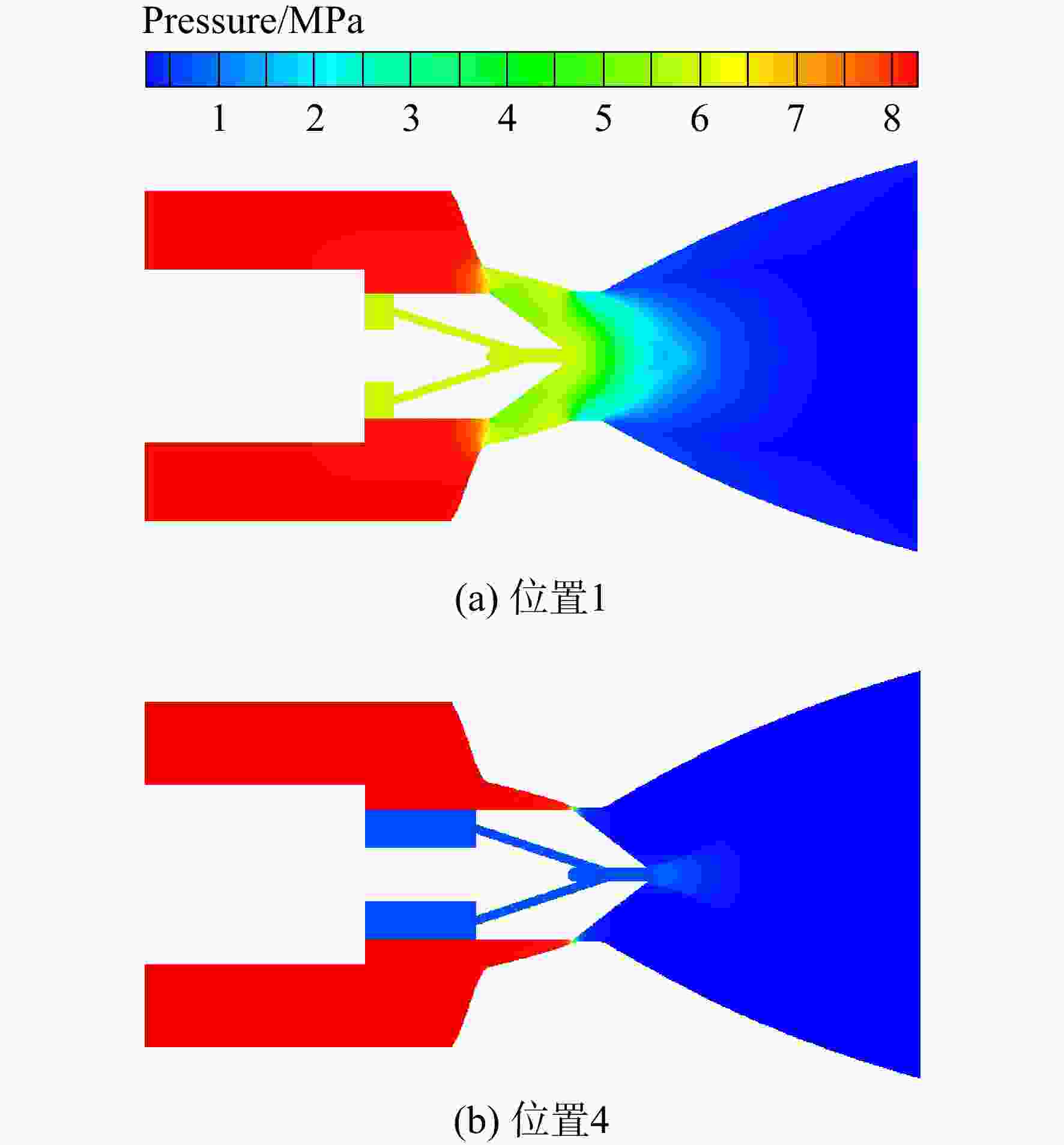

为研究不同因素对针栓式变推力固体火箭发动机内流场流动特性、发动机性能参数及针栓所受载荷的影响,探究其控制性能,采用数值仿真的方法,对不同针栓型面及针栓尾部凹槽设计下的喷管内流场进行计算研究。结果表明:针栓式变推力固体火箭发动机的推力调节范围很大,针栓受力变化也大;针栓型面的改变对针栓载荷无显著影响,最大载荷下降28%;针栓尾部凹槽的设计可以在较大程度上平衡针栓载荷,最大载荷下降56%;针栓阀体导流槽的设计对于针栓所受载荷的降低有显著作用,最大载荷下降91%,大大增强了针栓式变推力固体火箭发动机的控制性能。

Abstract:The influences of different factors on the flow characteristics of the internal flow field, the motor performance parameters and the force on the pintle were studied, and the control performance of the pintle motor was explored. Based on the method of numerical simulation, the flow field in nozzle under different pintle profiles and pintle tail groove designs was calculated and studied. The results showed that the thrust adjustment range of pintle variable thrust solid rocket motor was large, and the force variation of pintle was also large. The change of pintle profile had no significant effect on pintle load, and the maximum load decreased 28%. The design of the tail groove of the pintle can balance the pintle load to a large extent, and the maximum load was reduced by 56%. The design of the guide groove of the valve body of the pintle had a significant effect on reducing the force on the pintle, and the maximum load decreased 91%, which greatly enhanced the control performance of the pintle variable thrust solid rocket motor.

-

Key words:

- pintle /

- solid rocket motor /

- load analysis /

- pintle profile /

- groove balance /

- drainage design

-

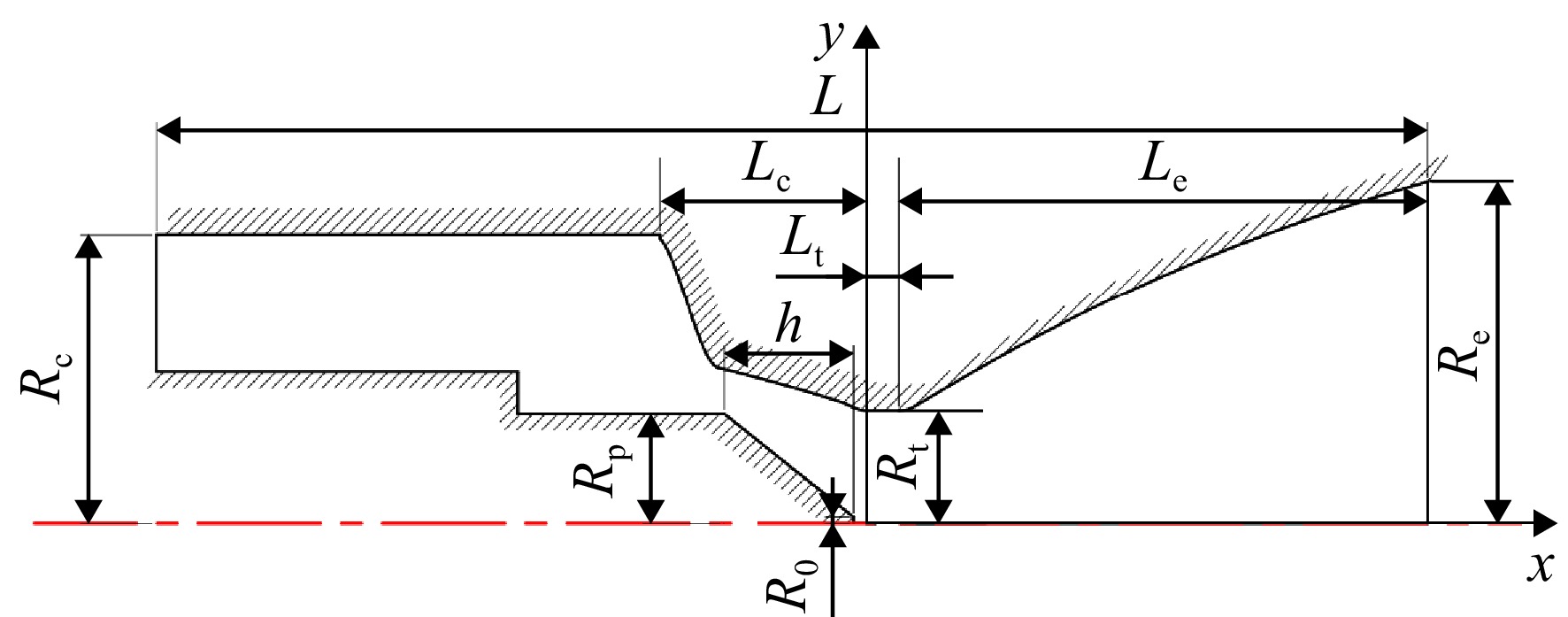

表 1 针栓式变推力固体火箭发动机几何参数

Table 1. Geometric parameters of pintle variable thrust solid rocket motor

mm 参数 数值 燃烧室半径Rc 45 喉部半径Rt 17.5 喷管出口半径Re 53.24 收敛段长度Lc 32 扩张段长度Le 82 喉部平直段长度Lt 5 发动机总长L 197 针栓半径Rp 17 针栓头部高度h 20 针栓头部半径R0 1 表 2 燃气参数

Table 2. Parameters of gas

γ Tc/K cp/(J/(kg·K)) M Rg/(J/(kg·K)) 1.25 1998.5 1 957 21 395.9 表 3 针栓4个位置的数据

Table 3. Data for 4 pintle positions

参数 位置1 位置2 位置3 位置4 s/mm 0 11.80 15.30 20.50 At,eq/mm2 853.96 424.82 297.47 82.74 $\dot m$/(kg/s) 6.24 3.17 2.20 0.64 Ft/N 16314 7833 5967 1633 Is/(N·s/kg) 2614 2471 2712 2552 表 4 不同型面针栓作用的发动机性能计算结果比较

Table 4. Motor performance with different profile pintles

针栓型面 Ft/N Is/(N·s/kg) Fp/N p0,e/p0,c A 1633.62 2678.70 481.58 0.79 B 770.01 2036.40 −13.92 0.83 C 1120.48 2618.10 254.37 0.80 D 1640.46 2702.33 459.86 0.83 E 1643.30 2666.01 457.63 0.75 F 1660.66 2688.26 467.68 0.80 G 1650.94 2698.42 465.06 0.80 H 1580.55 2726.96 447.72 0.79 I 1199.16 2651.02 301.92 0.76 J 1671.68 2673.12 468.97 0.77 表 5 针栓所受载荷总结

Table 5. Pintle load summary

针栓型面 位置1 位置4 ${F_{\text{p}}}$/N ${F_{\text{p} } }/{F_{ {\text{t,max} } } }$ ${F_{\text{p}}}$/N $\left| { {F_{\text{p} } }/{F_{ {\text{t,max} } } }} \right|$ 初始型面 5071 1 481 0.09 ${h_{\text{c}}}$= 2 mm 3168 0.62 −1249 0.25 ${h_{\text{c}}}$= 3 mm 2403 0.47 −2023 0.40 ${h_{\text{c}}}$= 4 mm 1691 0.33 −2744 0.54 导流槽设计型面 476 0.09 −77 0.02 -

[1] 苗禾状. 喉栓式可控固体火箭发动机推力调节研究[D]. 哈尔滨: 哈尔滨工程大学, 2009.MIAO Hezhuang. The study on the performance of pintle controlled thrust solid rocket motor[D]. Harbin: Harbin Engineering University, 2009. (in Chinese) [2] SAYLES D C. Development of test motors for advanced controllable propellants[J]. Journal of Spacecraft and Rockets,1975,12(3): 174-178. doi: 10.2514/3.56962 [3] SEVELLEC J F. Development and testing of carbon/carbon valves and tubing for hot gas flow control[R]. AIAA-1987-1820, 1987. [4] COON J, YASUHARA W. Solid propulsion approaches for terminal steering[R]. AIAA-1993-2641, 1993. [5] OSTRANDER M, BERGMANS J, THOMAS M, et al. Pintle motor challenges for tactical missiles[R]. AIAA-2000-3310, 2000. [6] SMITH-KENT R, LOH H T, CHWALOWSKI P. Analytical contouring of pintle nozzle exit cone using computational fluid dynamics[R]. AIAA-1995-2877, 1995. [7] MARQUETTE T, ROCK S, HABCHI S, et al. Numerical simulation of controllable propulsion for advanced escape systems[R]. AIAA-1995-2877, 1995. [8] LAFOND A. Numerical simulation of the flowfield inside a hot gas valve[R]. AIAA-1999-1087, 1999. [9] PROZAN R, LUKE G. CFD prediction of nozzle flow separation without boundary layer resolution[R]. AIAA-1999-2645, 1999. [10] HARISRINIVASAN U, BASKARAN R V, SANAL KUMAR V R. Design of a pintle nozzle for the augmented thrust propulsion using multiple internal expansion waves[R]. AIAA-2018-4483, 2018. [11] HARISRINIVASAN U, BASKARAN R V, SANAL KUMAR V R. Numerical studies on augmented thrust vectoring system for pintle nozzle using secondary sonic jet[R]. AIAA-2018-4901, 2018. [12] 李娟,李江,王毅林,等. 喉栓式变推力发动机性能研究[J]. 固体火箭技术,2007,30(6): 505-509. doi: 10.3969/j.issn.1006-2793.2007.06.012LI Juan,LI Jiang,WANG Yilin,et al. Study on performance of pintle controlled thrust solid rocket motor[J]. Journal of Solid Rocket Technology,2007,30(6): 505-509. (in Chinese) doi: 10.3969/j.issn.1006-2793.2007.06.012 [13] 王毅林,何国强,李江,等. 非同轴式喉栓变推力固体发动机试验[J]. 固体火箭技术,2008,31(1): 43-46. doi: 10.3969/j.issn.1006-2793.2008.01.010WANG Yilin,HE Guoqiang,LI Jiang,et al. Experiment on non-coaxial variable thrust pintle solid motor[J]. Journal of Solid Rocket Technology,2008,31(1): 43-46. (in Chinese) doi: 10.3969/j.issn.1006-2793.2008.01.010 [14] SONG Anchen,WANG Ningfei,LI Junwei,et al. Transient flow characteristics and performance of a solid rocket motor with a pintle valve[J]. Chinese Journal of Aeronautics,2020,33(12): 3189-3205. doi: 10.1016/j.cja.2020.04.023 [15] 马宝印,李军伟,王兴起,等. 针栓变推力固体火箭发动机动态响应特性研究[J]. 推进技术,2020,41(10): 2161-2172.MA Baoyin,LI Junwei,WANG Xingqi,et al. Simulation on dynamic response characteristics of pintle variable thrust solid rocket motor[J]. Journal of Propulsion Technology,2020,41(10): 2161-2172. (in Chinese) [16] 邓恒,李志浩,张时空,等. 基于零维内弹道模型的变推力发动机喉栓型面设计与工作特性研究[J]. 推进技术,2022,43(11): 39-48.DENG Heng,LI Zhihao,ZHANG Shikong,et al. Pintle profile design method based on zero-dimensional interior ballistic model and performance for variable thrust motor[J]. Journal of Propulsion Technology,2022,43(11): 39-48. (in Chinese) [17] 王鹏宇,王政涛,武泽平,等. 多工况下变推力固体发动机喉栓喷管型面一体化优化设计[J]. 固体火箭技术,2022,45(3): 337-342. doi: 10.7673/j.issn.1006-2793.2022.03.003WANG Pengyu,WANG Zhengtao,WU Zeping,et al. Optimization design for contour of pintle nozzle for variable thrust solid rocket motor under multiple working conditions[J]. Journal of Solid Rocket Technology,2022,45(3): 337-342. (in Chinese) doi: 10.7673/j.issn.1006-2793.2022.03.003 [18] 文谦,杨家伟,武泽平,等. 固体姿轨控发动机喉栓运动时序实验设计方法[J]. 推进技术,2022,43(9): 354-363.WEN Qian,YANG Jiawei,WU Zeping,et al. Time-sequence experiment design for pintle motion scheme of solid divert and attitude control system[J]. Journal of Propulsion Technology,2022,43(9): 354-363. (in Chinese) [19] LEE J H,PARK B H,YOON W. Parametric investigation of the pintle-perturbed conical nozzle flows[J]. Aerospace Science and Technology,2013,26(1): 268-279. doi: 10.1016/j.ast.2012.05.005 [20] COVER C L, DRENDEL A S. Rocket thruster comprising load-balanced pintle valve: US7849695[P]. 2010-12-14. -

下载:

下载: