Rolling bearing fault diagnosis method based on wavelet packet transform and CEEMDAN

-

摘要:

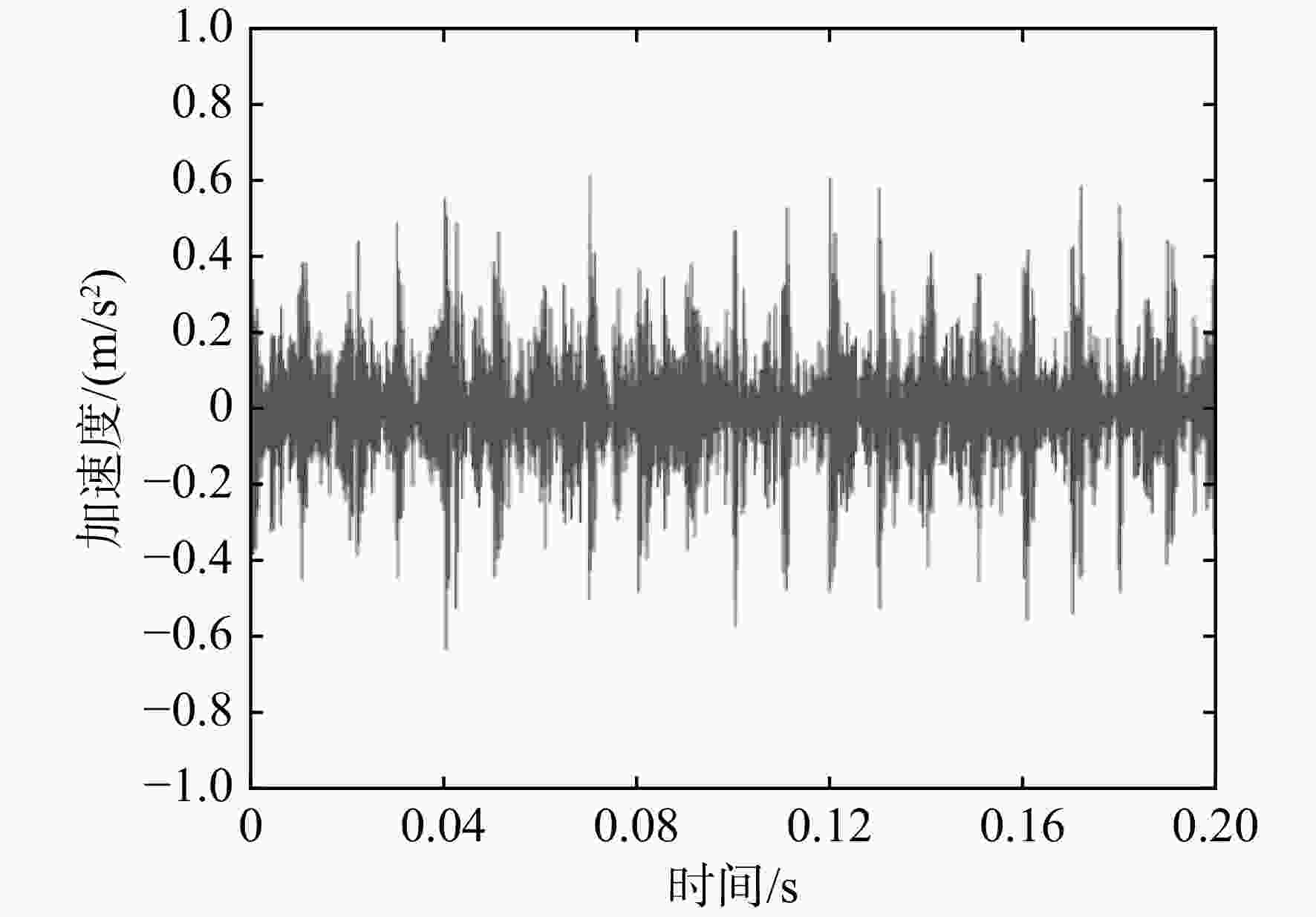

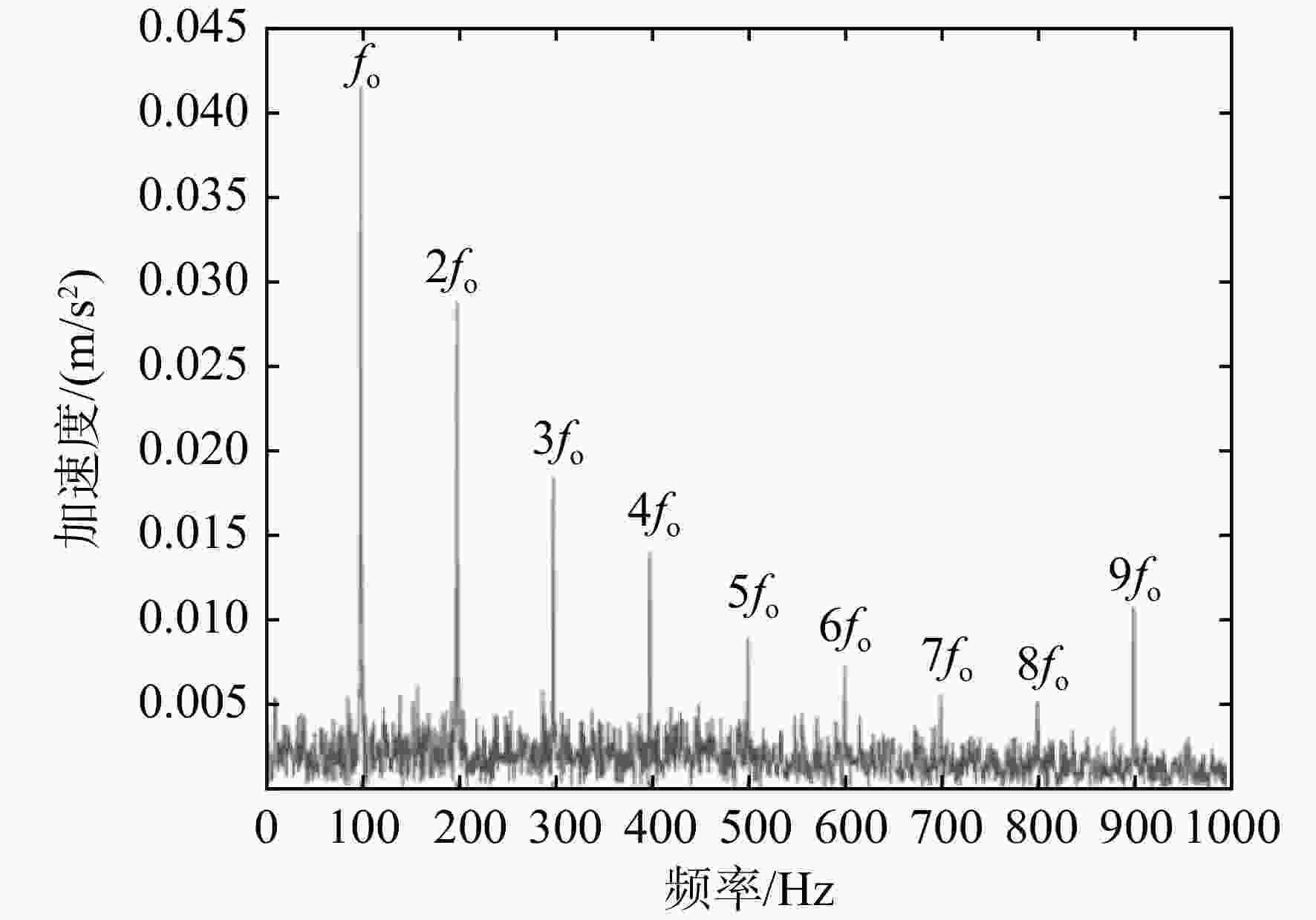

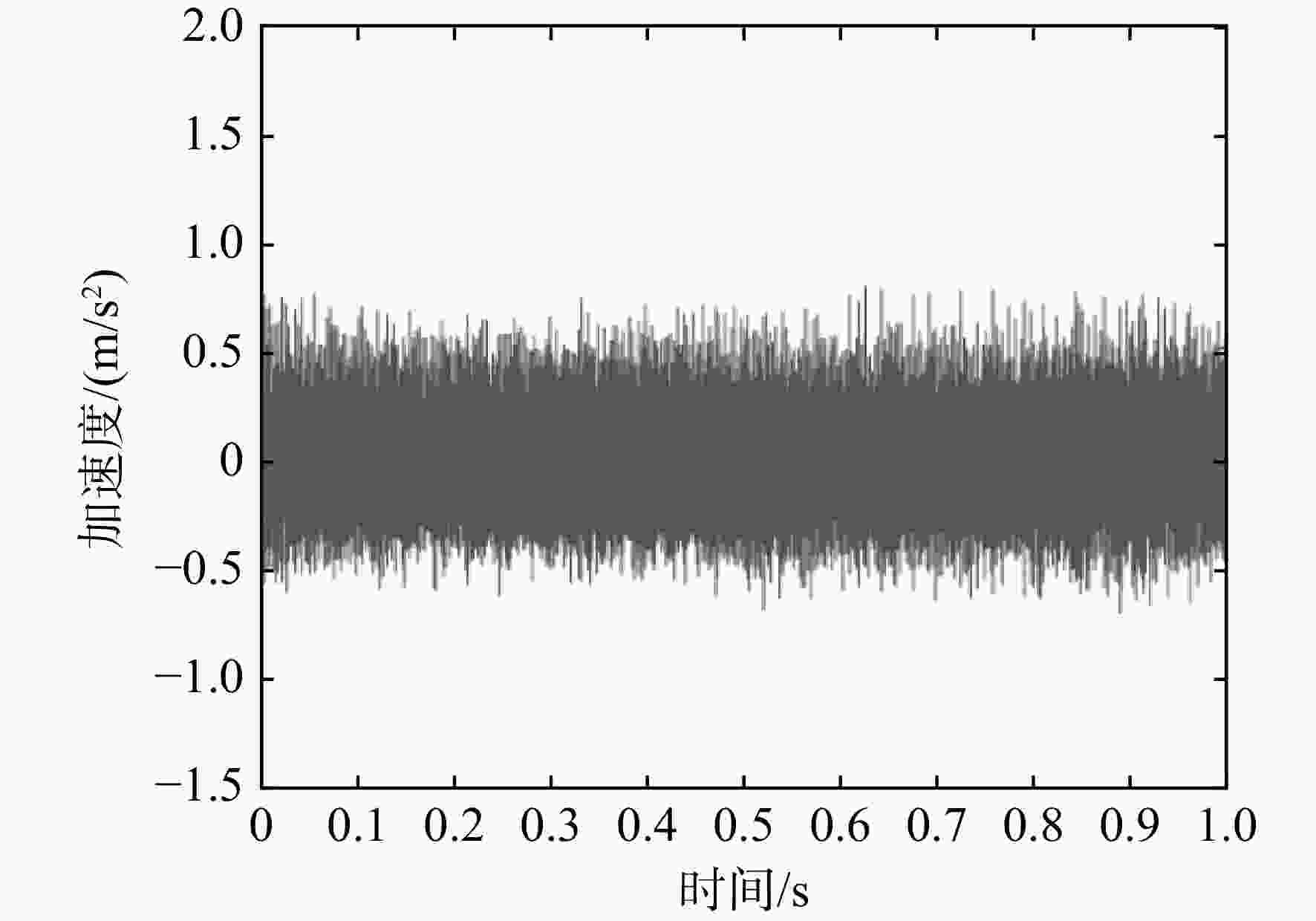

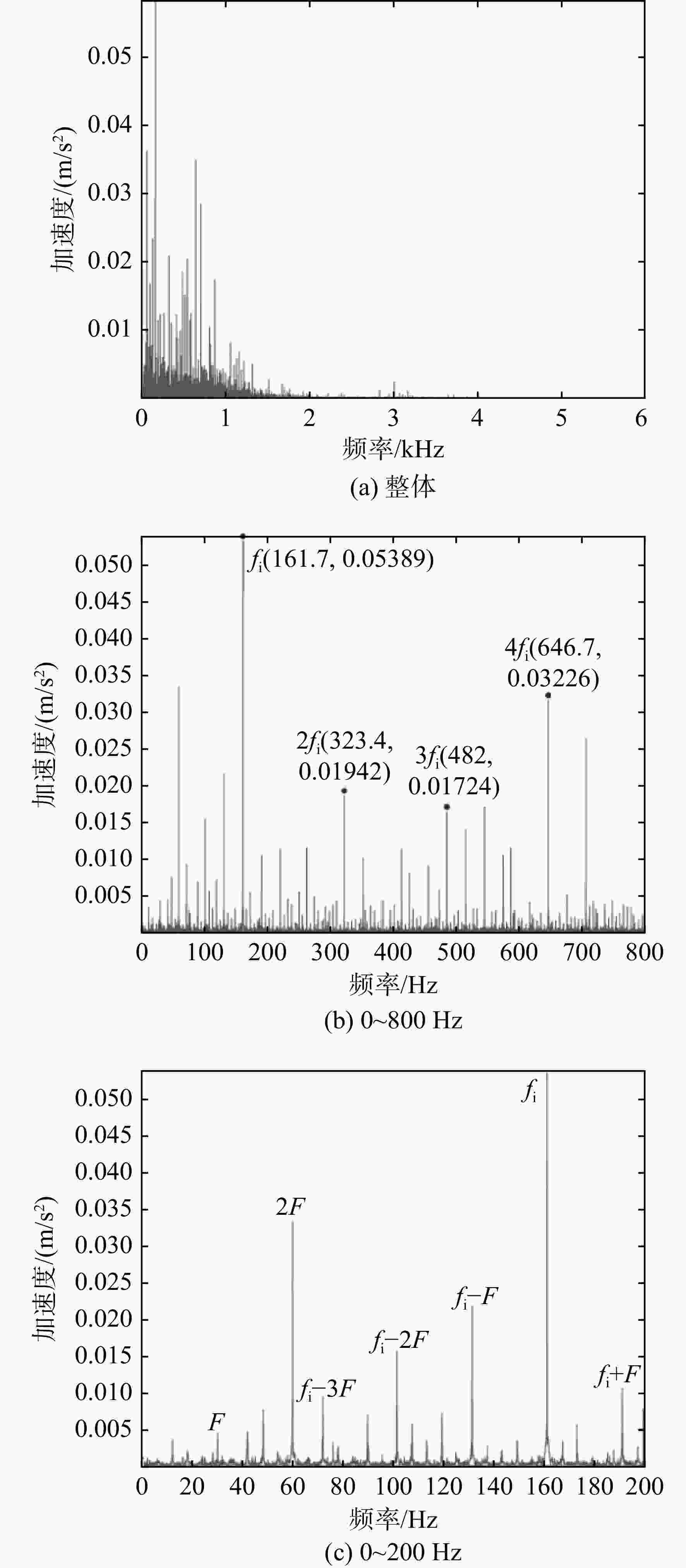

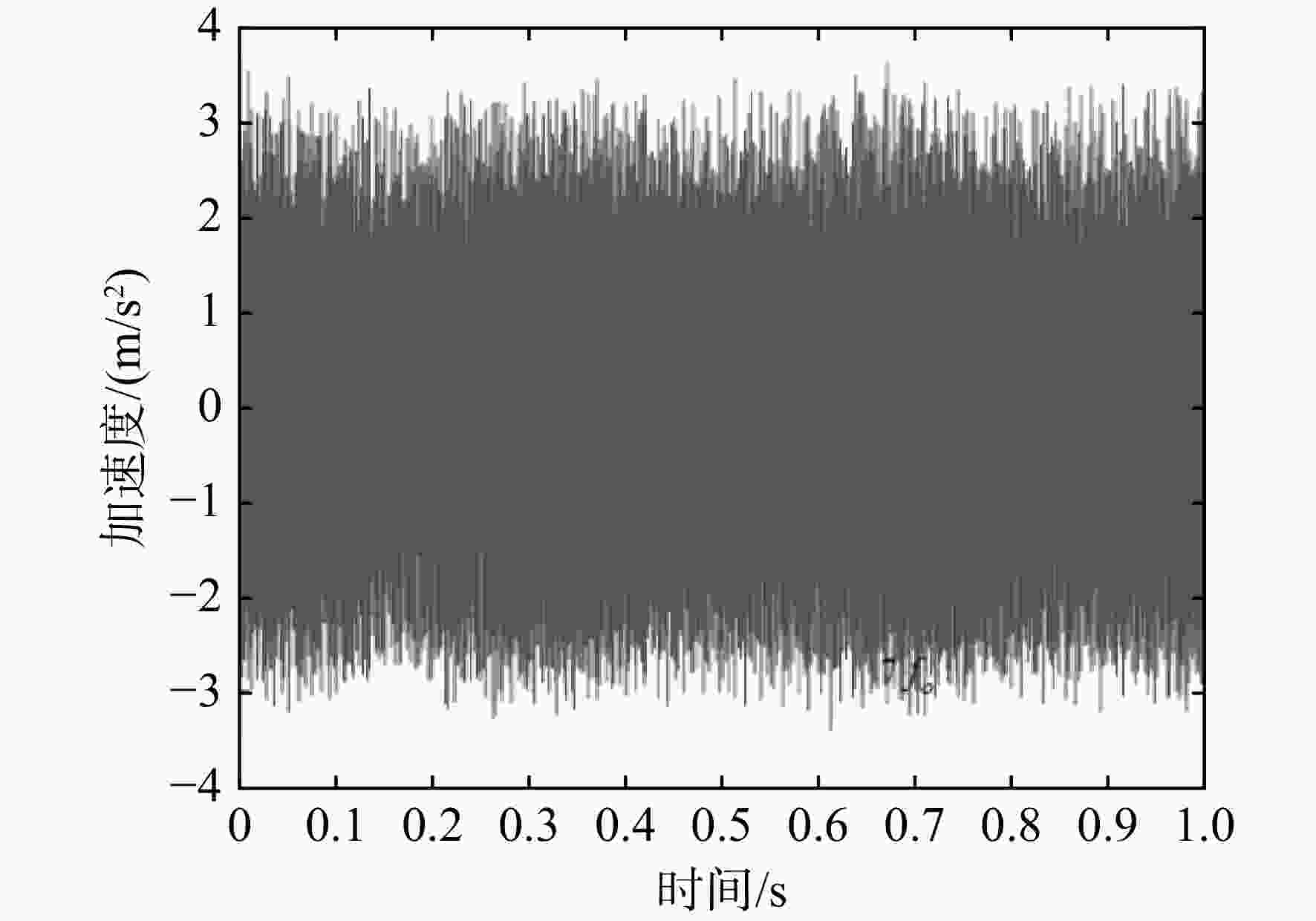

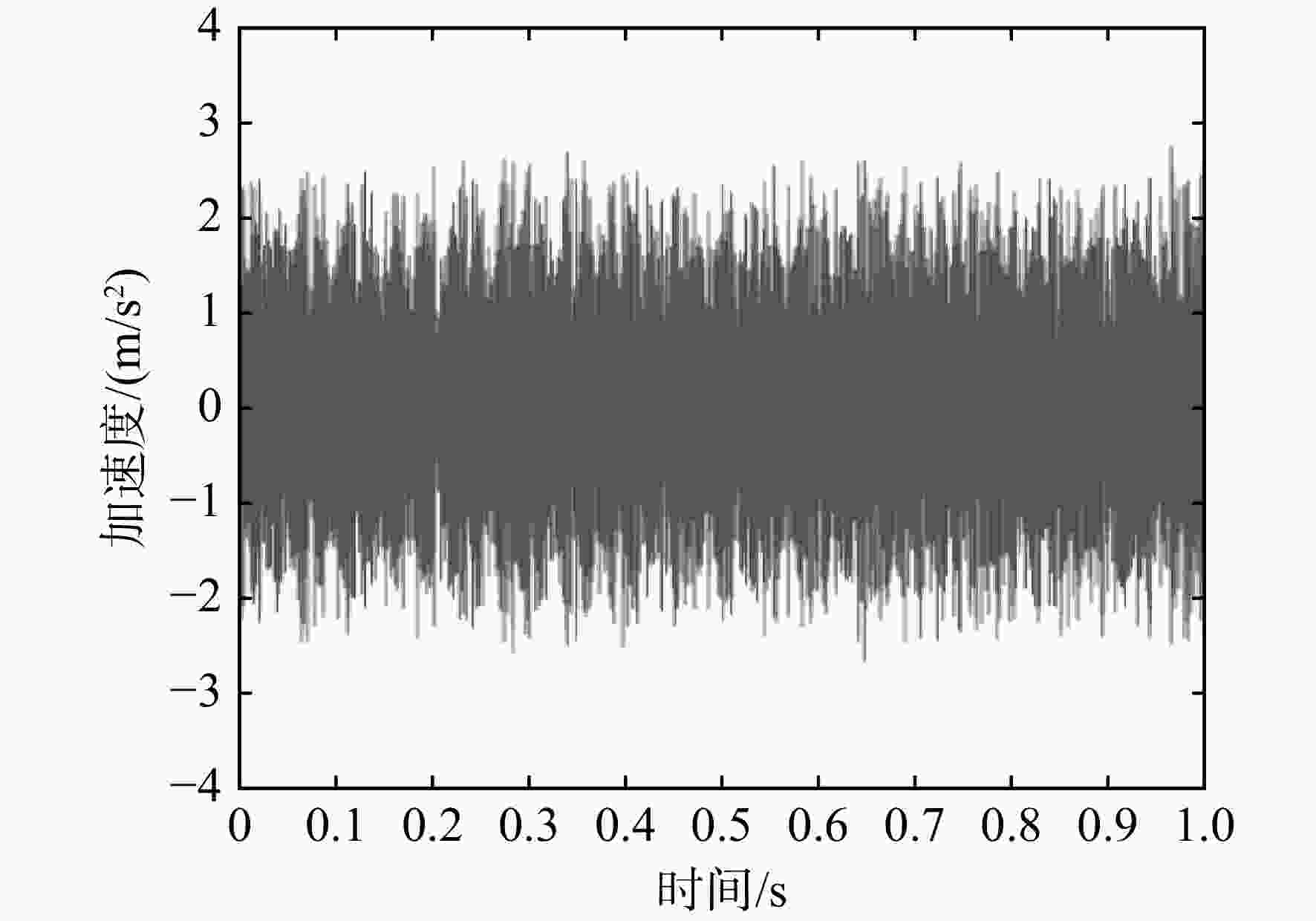

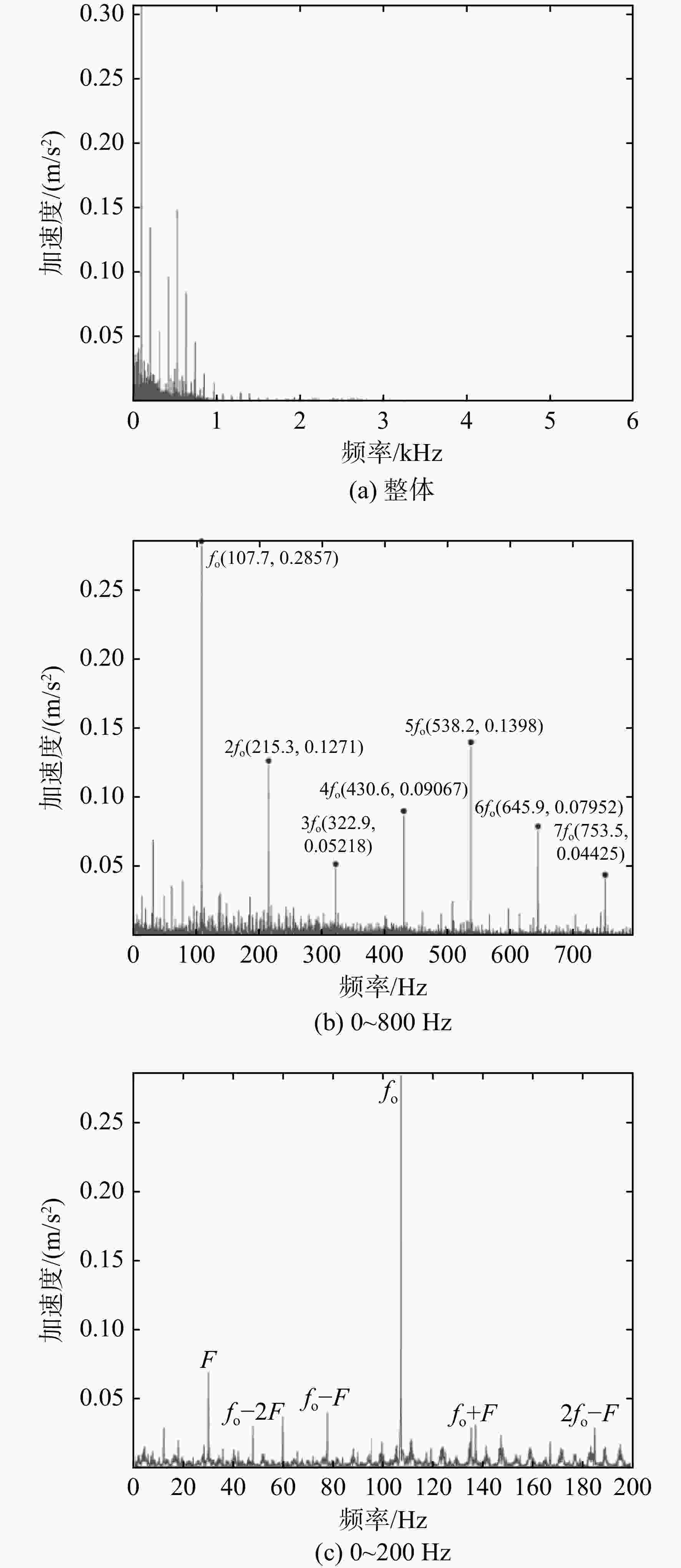

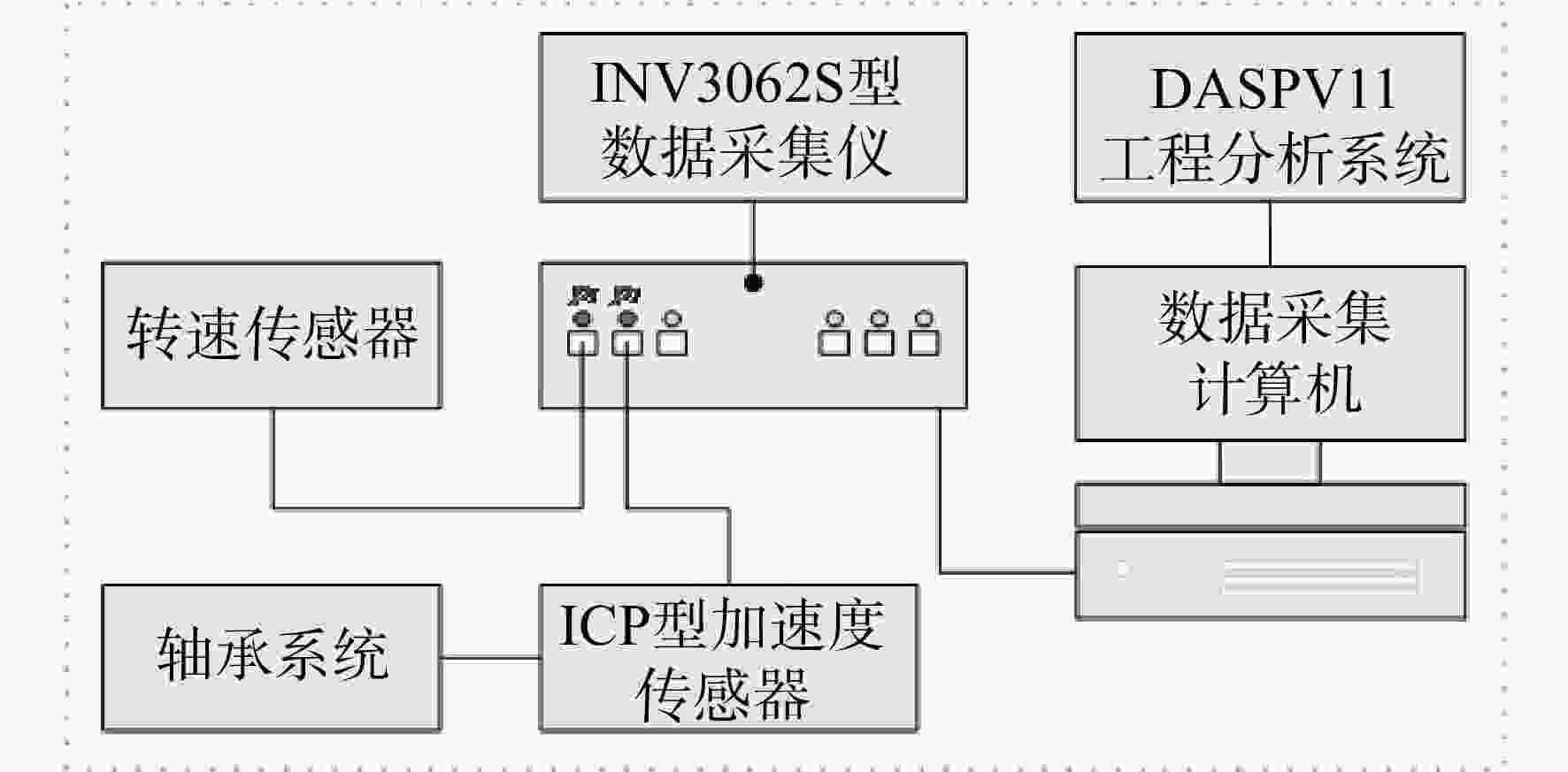

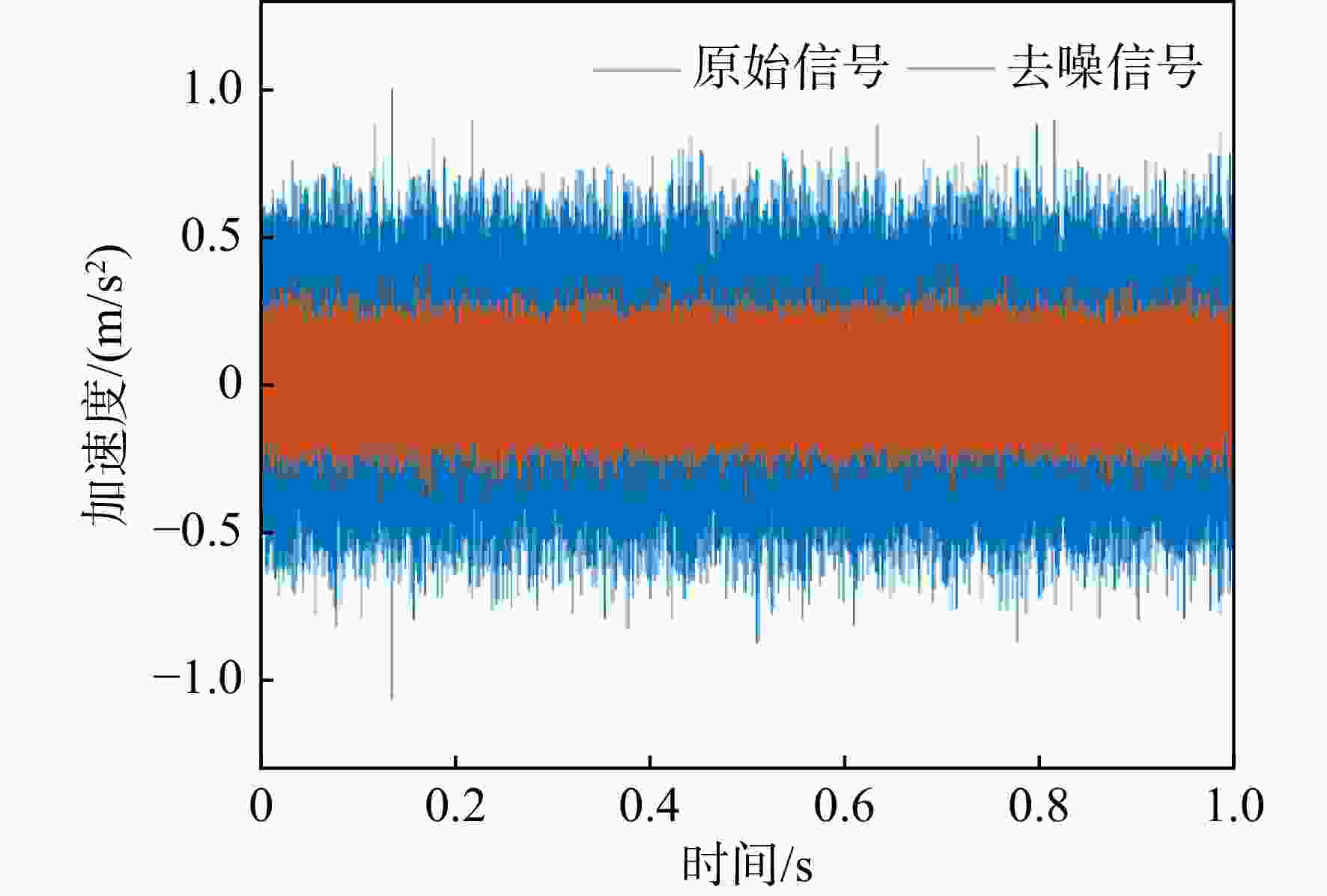

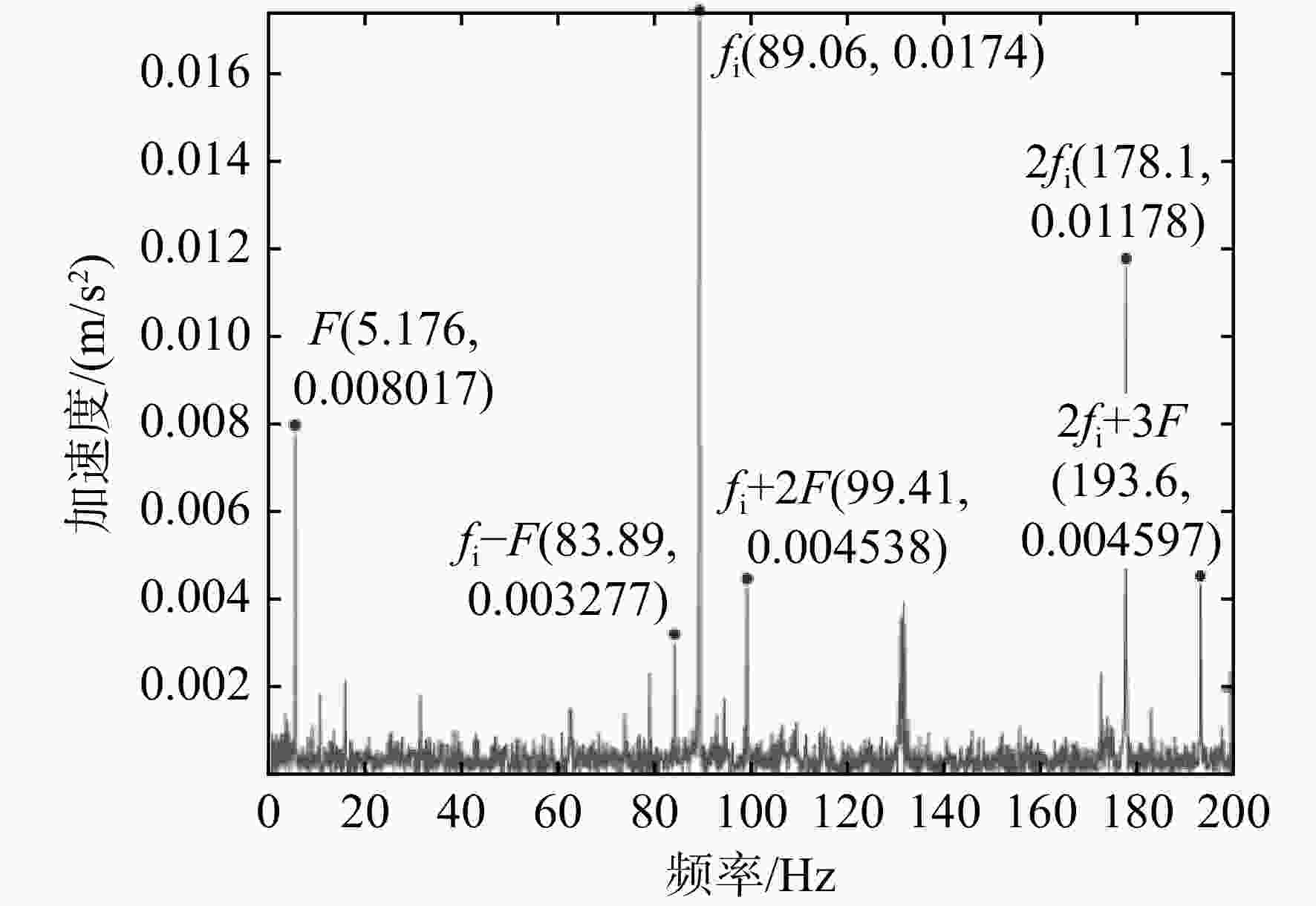

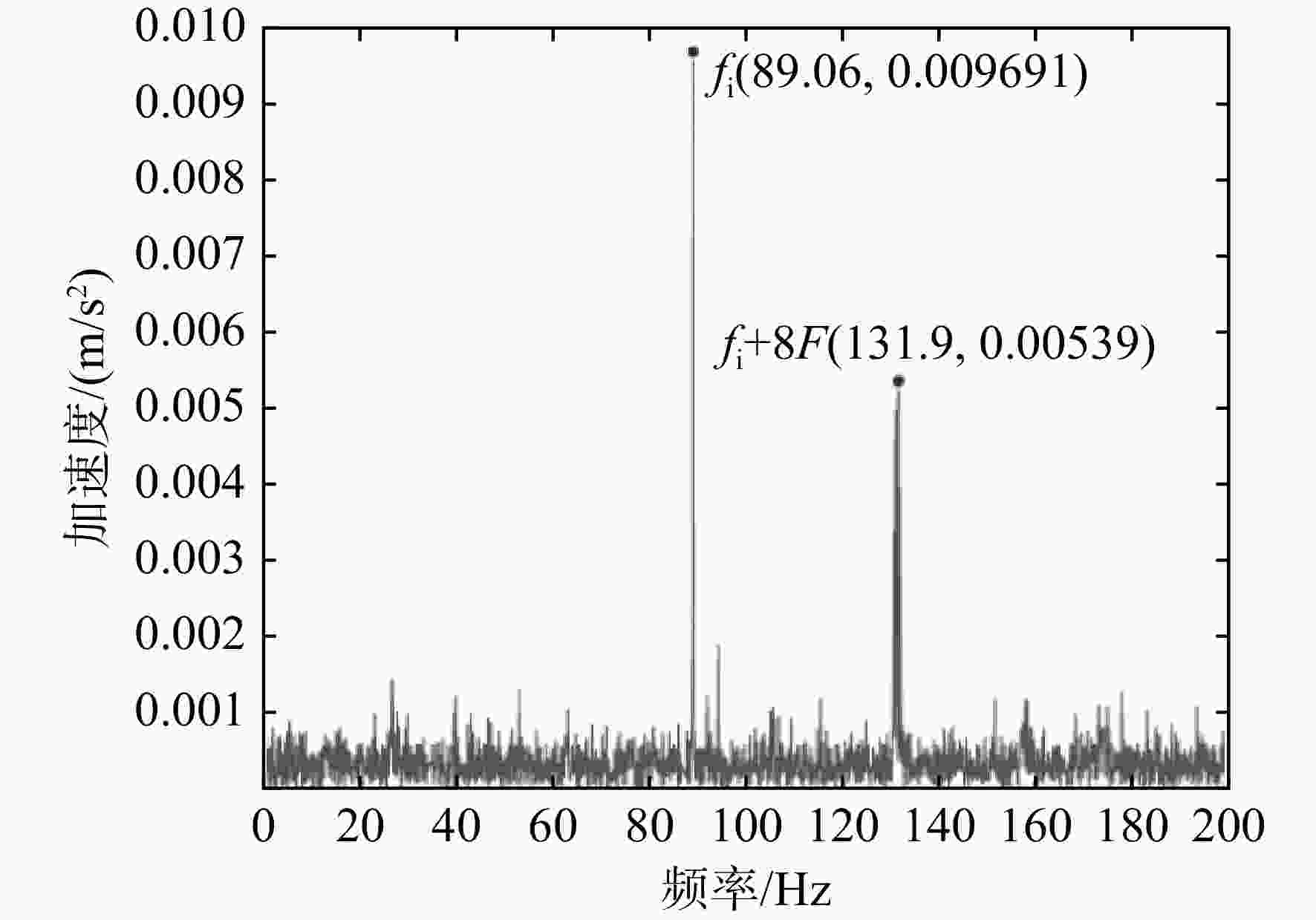

针对滚动轴承诊断受环境噪声影响,特征频率难以提取的问题,提出了一种基于小波包变换与完全自适应噪声集合经验模态分解(CEEMDAN)的滚动轴承故障诊断方法。通过CEEMDAN将传感器收集到的原始振动信号进行分解并依据峭度值-相关系数(K-C)筛选准则划分高噪信号和低噪信号。利用小波包变换分解高噪信号后选取合适分量重构实现环境噪声的滤除并与低噪信号进行整合产生新的振动信号进行包络解调,提取实际故障特征频率实现滚动轴承的故障诊断。经对比试验,所提出的方法清晰地提取出滚动轴承的转频、故障特征频率及其倍频和调制频率,由仿真信号计算可知降噪后的信号信噪比提高了7.61 dB,有效优化了对噪声滤除的效果。

-

关键词:

- 完全自适应噪声集合经验模态分解(CEEMDAN) /

- 峭度值-相关系数筛选准则 /

- 小波包变换 /

- 包络解调 /

- 特征频率 /

- 故障诊断

Abstract:For the problem that rolling bearing diagnosis is affected by the environmental noise so that extraction of characteristic frequency is difficult, a rolling bearing fault diagnosis method based on wavelet packet transform and complete ensemble empirical model decomposition adaptive noise (CEEMDAN) was proposed. The raw vibration signal collected by the sensor was split through CEEMDAN and the high-noise signal and low-noise signal were divided through the kurtosis-correlation coefficient screening criteria (K-C). The wavelet packet transform was used to split the high noise signal and then select appropriate component reconstruction to filter out the environmental noise and integrate with the low noise signal to generate a new vibration signal for envelope demodulation, and the actual fault characteristic frequency was extracted to achieve fault diagnosis of rolling bearings. After comparative experiments, the method proposed clearly extracted the rotational frequency, fault characteristic frequency and its frequency multiplier and modulation frequency of rolling bearings, and the signal-noise ratio after noise reduction was increased by 7.61 dB from the simulation signal calculation, which effectively optimized the effect of noise filtering.

-

表 1 峭度值-相关系数筛选准则信号划分标准

Table 1. Steepness values-correlation coefficient screening criteria signal division criteria

对比结果 信号划分 W ≥ C 高噪信号 W < C 低噪信号 表 2 6205-2RS JEM SKF深沟球轴承参数

Table 2. Parameters of 6205-2RS JEM SKF deep groove ball bearings

参数 数值 轴承滚道节径/mm 39.0390 滚珠直径/mm 7.940 接触角/(°) 0 滚珠数 9 表 3 内、外圈故障试验样本参数

Table 3. Inner and outer ring fault parameters of experiments sample

参数 数值 转速/(r/min) 1797 故障直径/mm 0.1778 故障深度/mm 0.2794 电动机功率/W 0 表 4 简单路径内圈原始信号对比参数

Table 4. Inner ring raw signal comparison parameters of simple path

K0 T C 5.3959 0.2149 1.2149 表 5 简单路径内圈高噪信号分量参数

Table 5. High noise signal component parameters of the inner ring of a simple path

序号 Kc rc W 1 1.5715 0.4162 1.9877 2 0.8055 0.8349 1.6404 3 1.1463 0.3623 1.5085 表 6 简单路径外圈原始信号对比参数

Table 6. Outer ring raw signal comparison parameters of simple path

K0 T C 7.6494 0.2286 1.2286 表 7 简单路径外圈高噪信号分量参数

Table 7. High noise signal component parameters of the outer ring of a simple path

序号 Kc rc W 1 0.7807 0.9739 1.7546 2 1.4033 0.3271 1.7304 3 1.1699 0.0626 1.2325 表 8 试验轴承结构参数

Table 8. Experimental bearing structural parameters

参数 数值 Z 34 Ro/mm 140 Ri/mm 110 d/mm 8 $ \alpha $/(°) 0 表 9 加速度传感器参数

Table 9. Acceleration sensor parameters

测点 序列号 灵敏度/(mV/(m/s2) ) as/g ar/g 1 28389 10.04 ±50 0.000 15 2 28390 10.05 3 28391 9.84 4 28392 10.00 -

[1] 彭畅. 旋转机械轴承振动信号分析方法研究[D]. 重庆: 重庆大学, 2014.PENG Chang. Vibration signal analysis of bearings in the rotating machinery[D]. Chongqing: Chongqing University, 2014. (in Chinese) [2] 杨雅奇,张彩红,林繁云. 滚动轴承故障诊断技术综述[J]. 山东化工,2021,50(21): 83-84, 87.YANG Yaqi,ZHANG Caihong,LIN Fanyun. Summary of rolling bearing fault diagnosis technology[J]. Shandong Chemical Industry,2021,50(21): 83-84, 87. (in Chinese) [3] 车文超,张国强,李文凯. 经验模式分解在旋转机械非平稳振动信号表征中的应用分析[J]. 机械管理开发,2022,37(1): 63-66.CHE Wenchao,ZHANG Guoqiang,LI Wenkai. Application analysis of empirical mode decomposition in the characterization of nonstationary vibration signals of rotating machinery[J]. Mechanical Management and Development,2022,37(1): 63-66. (in Chinese) [4] 樊瑞筱. 滚动轴承故障声发射波形流信号特性试验研究[D]. 黑龙江 大庆: 东北石油大学, 2017.FAN Ruixiao. Experimental study on characteristics of achoustic emission waveform streaming with different kinds of faults for rolling bearing[D]. Daqing Heilongjiang: Northeast Petroleum University, 2017. (in Chinese) [5] 杜岩. 基于时频图像识别的滚动轴承故障诊断方法研究[D]. 北京: 中国矿业大学, 2020.DU Yan. Research on fault diagnosis method for rolling bearings based on time-frequency image recognition[D]. Beijing: China University of Mining & Technology, Beijing, 2020. (in Chinese) [6] 徐柳. EMD算法发展及应用综述[J]. 长江信息通信,2022,35(1): 61-64.XU Liu. Review on the development and application of EMD algorithm[J]. Changjiang Information & Communications,2022,35(1): 61-64. (in Chinese) [7] 朱敏. 数字图像处理技术中小波变换的应用研究[J]. 山东农业工程学院学报,2019,36(8): 22-23.ZHU Min. Application of wavelet transform in digital image processing technology[J]. The Journal of Shandong Agriculture and Engineering University,2019,36(8): 22-23. (in Chinese) [8] 邹娜娜,胡红萍,白艳萍,等. 基于优化的VMD和小波包降噪的联合去噪方法[J]. 数学的实践与认识,2021,51(20): 135-142.ZOU Nana,HU Hongping,BAI Yanping,et al. Joint de-noising method based on the optimized VMD and wavelet packet denosing[J]. Mathematics in Practice and Theory,2021,51(20): 135-142. (in Chinese) [9] 陶珍珍. 基于EEMD与SVM的滚动轴承故障诊断方法研究[D]. 太原: 太原科技大学, 2020.TAO Zhenzhen. Study on fault diagnosis method of rolling bearing based on EEMD and SVM[D]. Taiyuan: Taiyuan University of Science and Technology, 2020. (in Chinese) [10] HUANG N E,SHEN Z,LONG S R,et al. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis[J]. Proceedings Mathematical Physical & Engineering Sciences,1998,454(1971): 903-995. [11] 戴婷,张榆锋,章克信,等. 经验模态分解及其模态混叠消除的研究进展[J]. 电子技术应用,2019,45(3): 7-12. doi: 10.16157/j.issn.0258-7998.182560DAI Ting,ZHANG Yufeng,ZHANG Kexin,et al. The research progress of empirical mode decomposition and mode mixing elimination[J]. Application of Electronic Technique,2019,45(3): 7-12. (in Chinese) doi: 10.16157/j.issn.0258-7998.182560 [12] 李怡,李焕锋,刘自然. 基于CEEMDAN多尺度熵和SSA-SVM的滚动轴承故障诊断研究[J]. 机电工程,2021,38(5): 599-604.LI Yi,LI Huanfeng,LIU Ziran. Fault diagnosis of rolling bearing based on CEEMDAN multi-scale entropy and SSA-SVM[J]. Journal of Mechanical & Electrical Engineering,2021,38(5): 599-604. (in Chinese) [13] WU Zhaohua, HUANG N E. Ensemble empirical mode decomposition: a noise-assisted data analysis method[J]. Advances in Adaptive Data Analysis, 2009,1(1): 1-41. [14] 刘秋风,阎菊婵,乔珍珠,等. 球轴承故障特征频率的诊断[J]. 轴承,1993(6): 21-25, 46.LIU Qiufeng,YAN Juchan,QIAO Zhenzhu,et al. Diagnosis technique on the fault characteristic frequencies of deep groove ball bearing[J]. Bearing,1993(6): 21-25, 46. (in Chinese) [15] 任子晖,成江洋,邢强,等. 基于CEEMDAN与Teager能量算子的谐波检测方法[J]. 电力系统保护与控制,2017,45(9): 56-62.REN Zihui,CHENG Jiangyang,XING Qiang,et al. A harmonic detection method based on CEEMDAN and teager energy operator algorithm[J]. Power System Protection and Control,2017,45(9): 56-62. (in Chinese) [16] 任学平, 庞震, 辛向志, 等. 小波包和峭度在轴承早期故障分析中的应用[J]. 轴承, 2014(3): 45-48.REN Xueping, PANG Zhen, XIN Xiangzhi, et al. Analysis on early fault of bearings by wavelet packet and kurtosis[J]. Bearing, 2014(3): 45-48. (in Chinese) [17] 纪德洋,金锋,冬雷,等. 基于皮尔逊相关系数的光伏电站数据修复[J]. 中国电机工程学报,2022,42(4): 1514-1523.JI Deyang,JIN Feng,DONG Lei,et al. Data repairing of photovoltaic power plant based on Pearson correlation coefficient[J]. Proceedings of the CSEE,2022,42(4): 1514-1523. (in Chinese) [18] 吕作鹏,罗健,杨晓彤,等. 基于小波包和EMD的HHT时频分析方法在航空试验器轴承故障诊断中的应用[J]. 测控技术,2022,41(10): 17-25. doi: 10.19708/j.ckjs.2021.11.284LYU Zuopeng,LUO Jian,YANG Xiaotong,et al. Application of HHT time-frequency analysis technology in aeronautical test-rig bearing fault diagnosis based on wavelet packet and EMD[J]. Measurement & Control Technology,2022,41(10): 17-25. (in Chinese) doi: 10.19708/j.ckjs.2021.11.284 [19] 栾孝驰,沙云东,柳贡民,等. 基于WPD-KVI-Hilbert变换相结合的滚动轴承早期故障特征精准识别[J]. 推进技术,2022,43(2): 362-373.LUAN Xiaochi,SHA Yundong,LIU Gongmin,et al. Accurate identification of early fault characteristics of rolling bearings based on WPD-KVI-Hilbert transform[J]. Journal of Propulsion Technology,2022,43(2): 362-373. (in Chinese) [20] 栾孝驰,那万晓,沙云东,等. 基于特征量阈值判决的轴承故障诊断方法[J]. 推进技术,2022,43(4): 307-317.LUAN Xiaochi,NA Wanxiao,SHA Yundong,et al. Bearing fault diagnosis method based on eigenquantity threshold judgment[J]. Journal of Propulsion Technology,2022,43(4): 307-317. (in Chinese) [21] 栾孝驰,徐石,沙云东,等. 基于GWO-NLM与CEEMDAN的滚动轴承故障诊断方法[J]. 航空动力学报,2023,38(5): 1185-1197. doi: 10.13224/j.cnki.jasp.20210547LUAN Xiaochi,XU Shi,SHA Yundong,et al. Rolling bearing fault diagnosis method based on GWO-NLM and CEEMDAN[J]. Journal of Aerospace Power,2023,38(5): 1185-1197. (in Chinese) doi: 10.13224/j.cnki.jasp.20210547 -

下载:

下载: