High-accuracy experimental analysis and correction of blade tip timing measurement error

-

摘要:

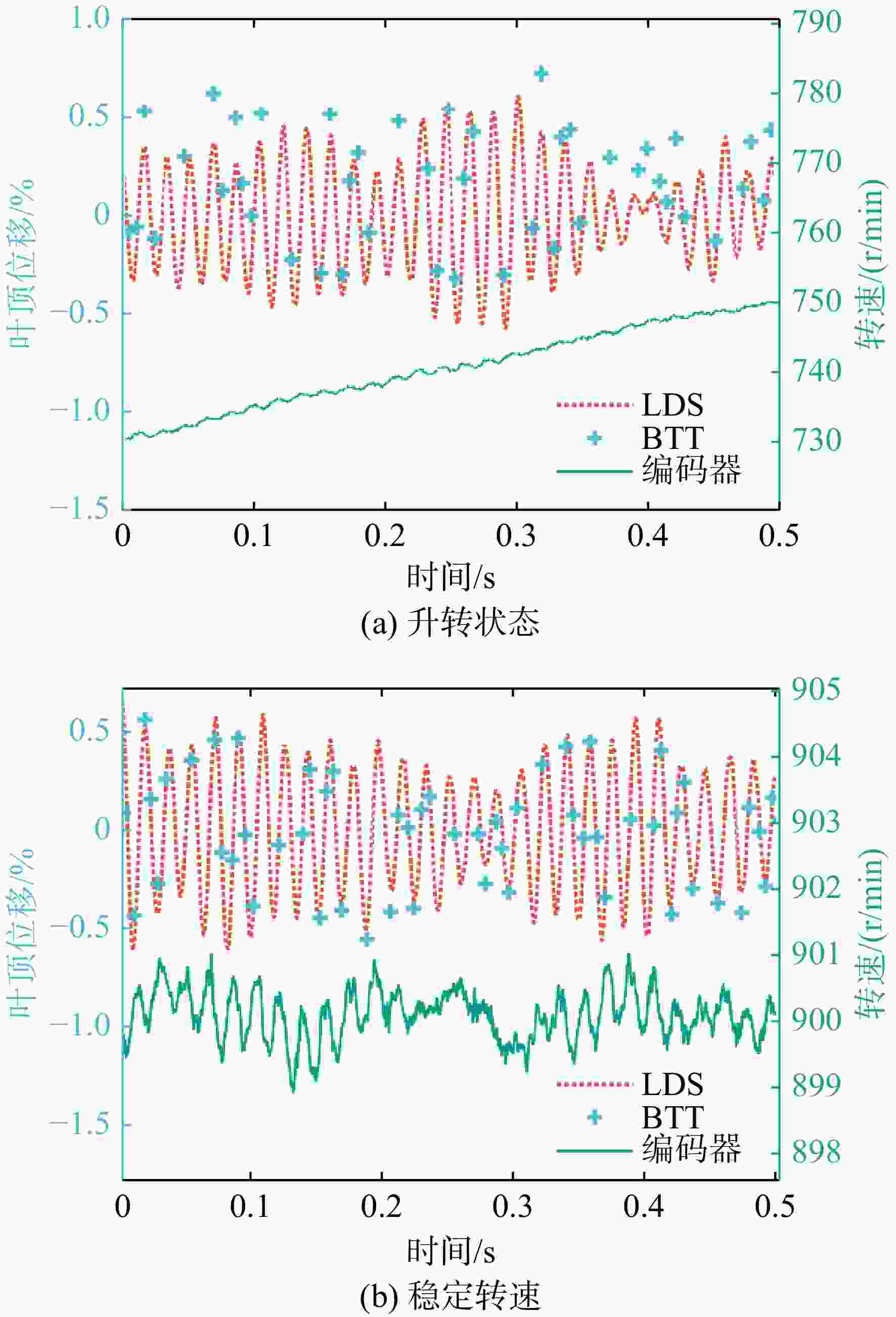

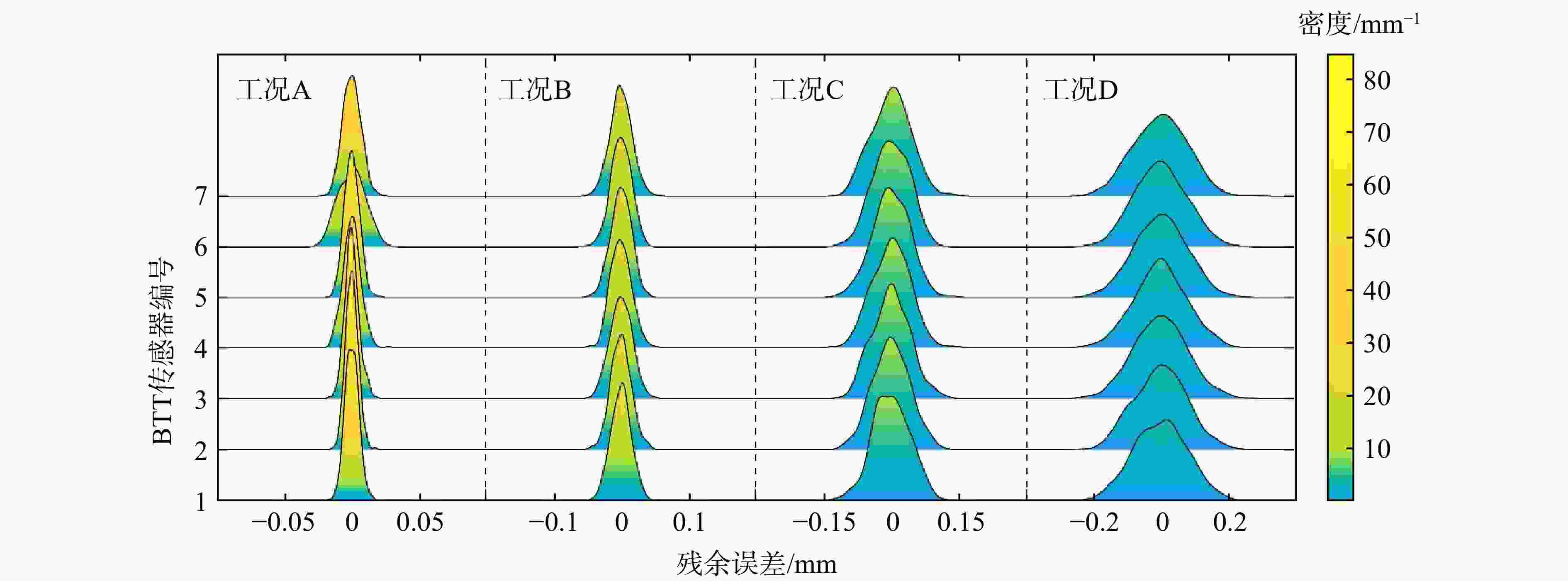

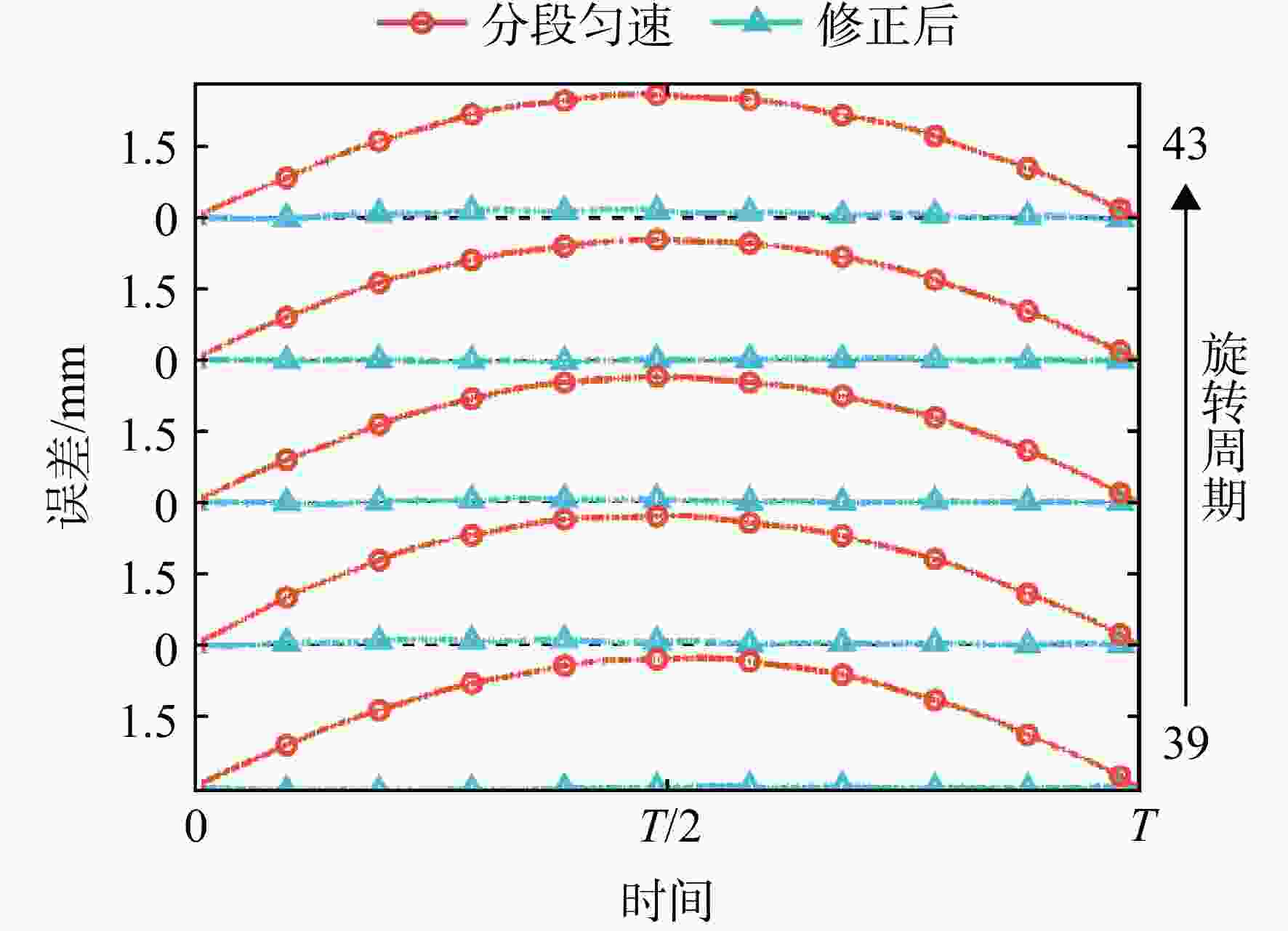

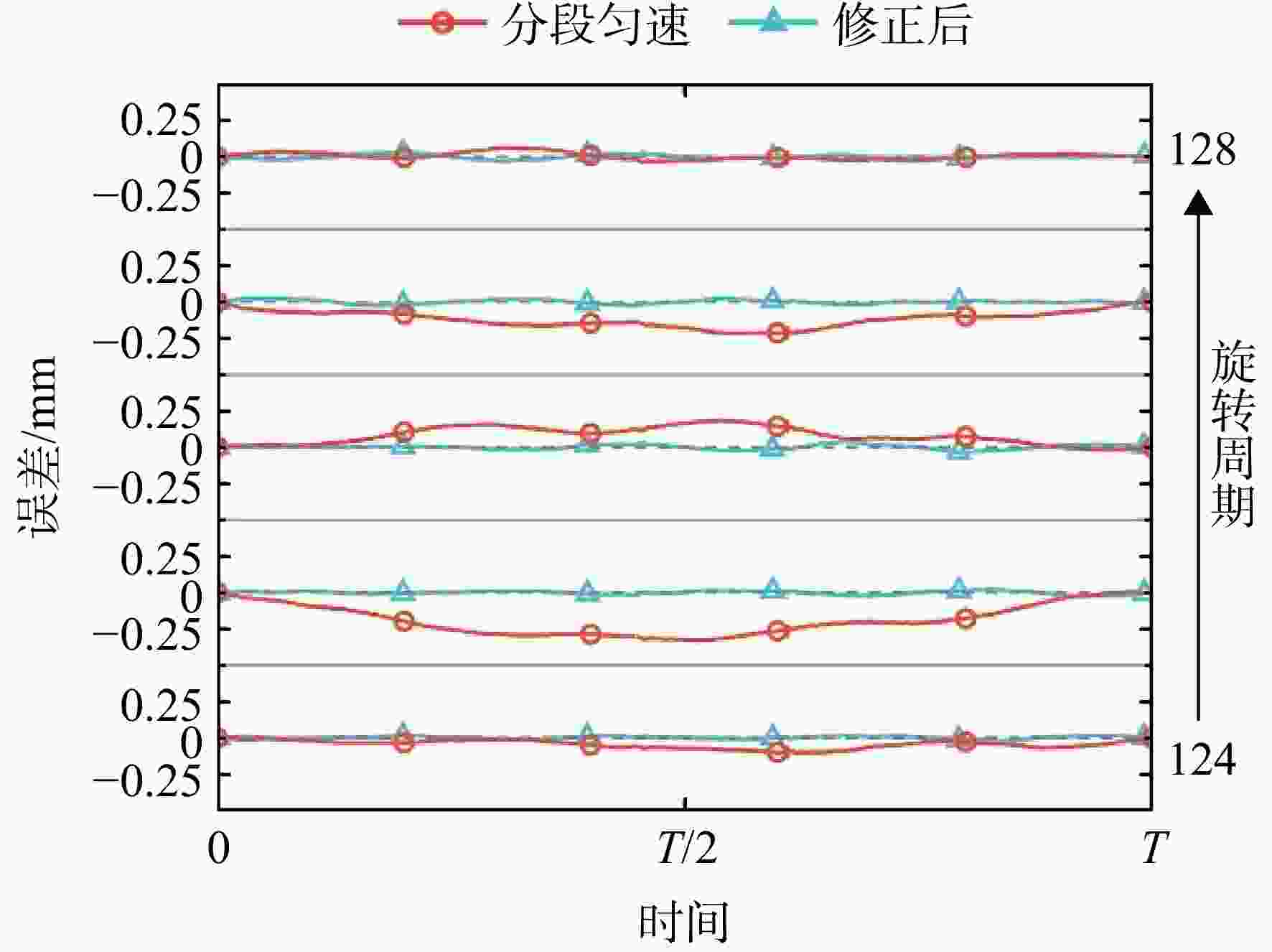

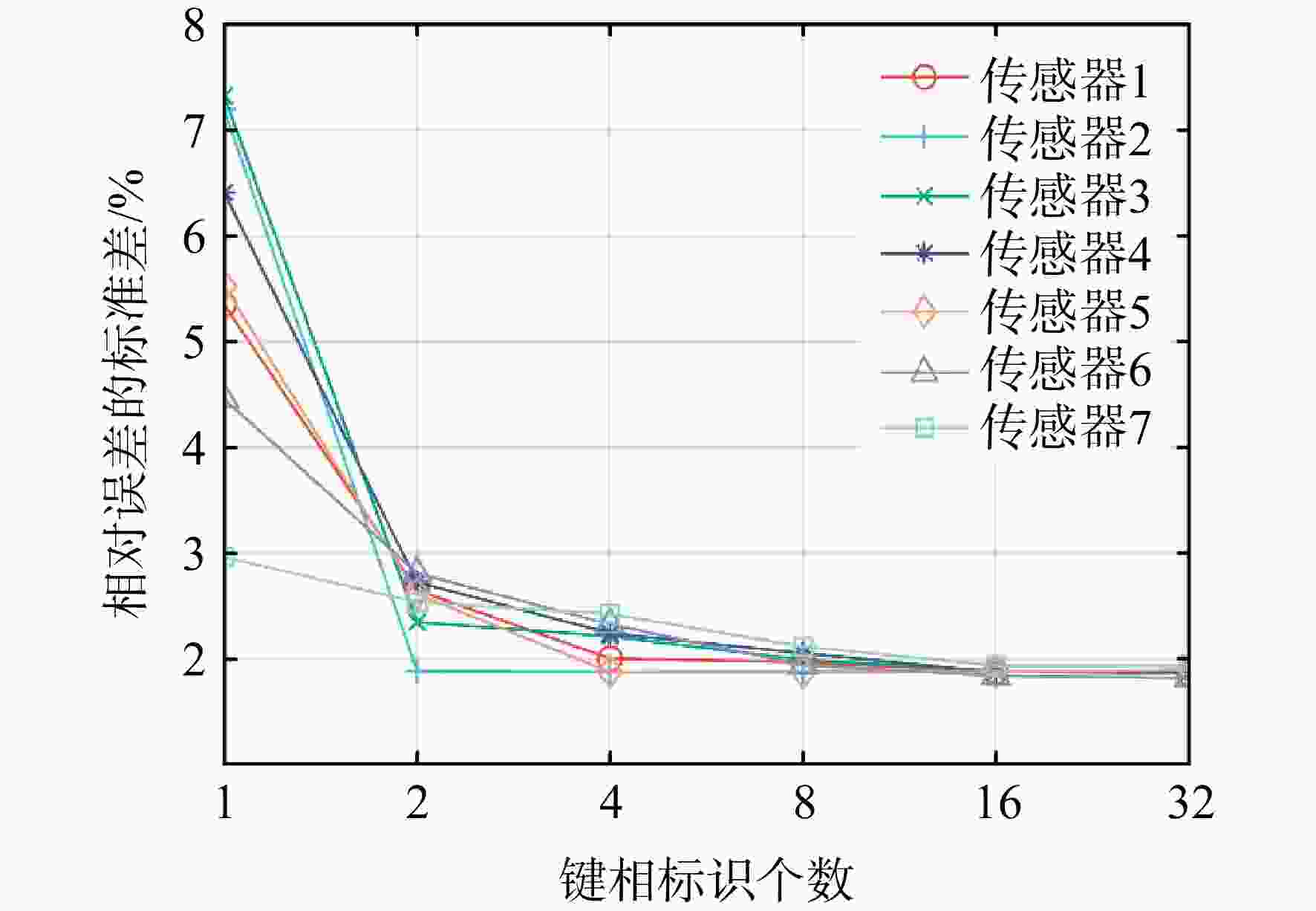

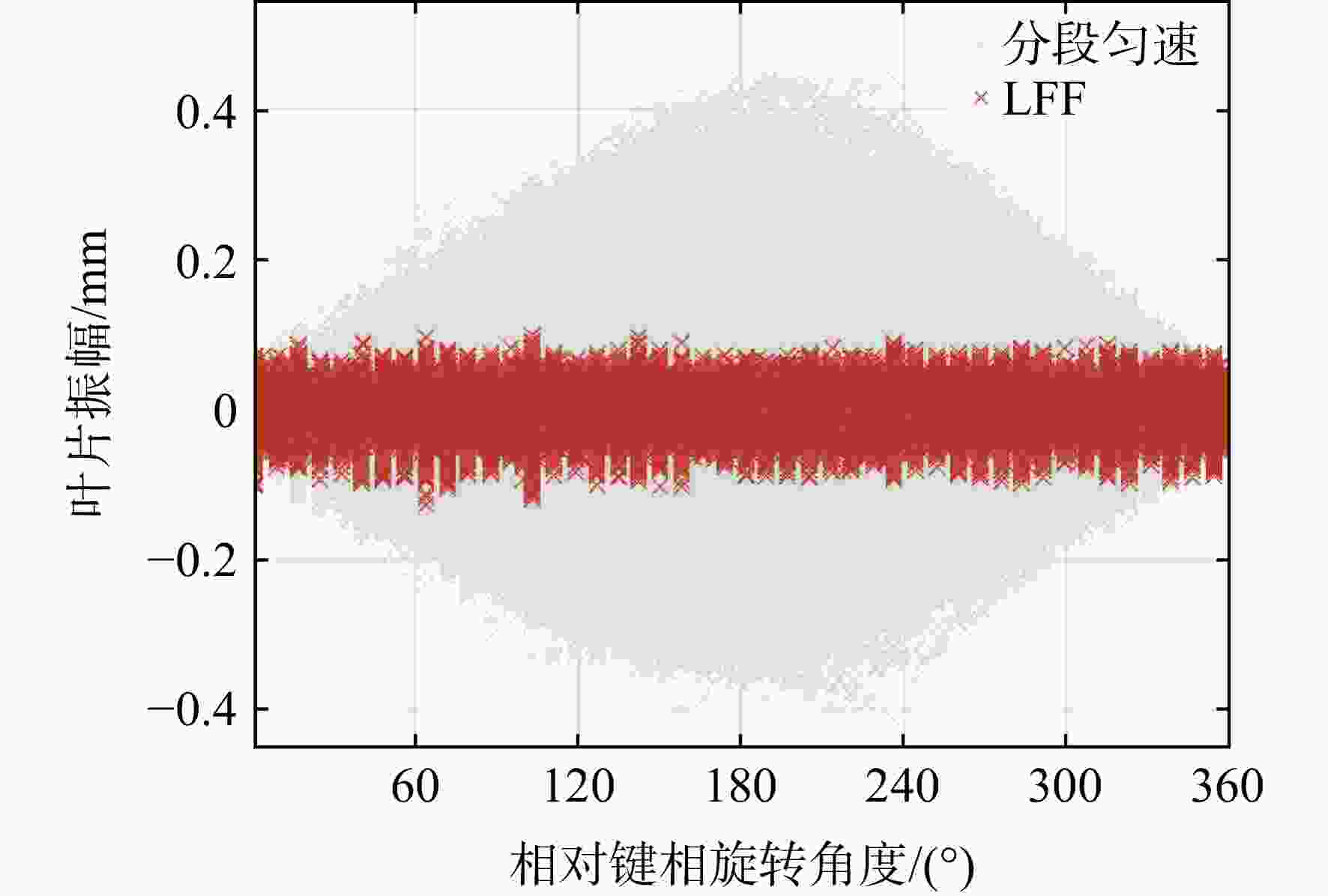

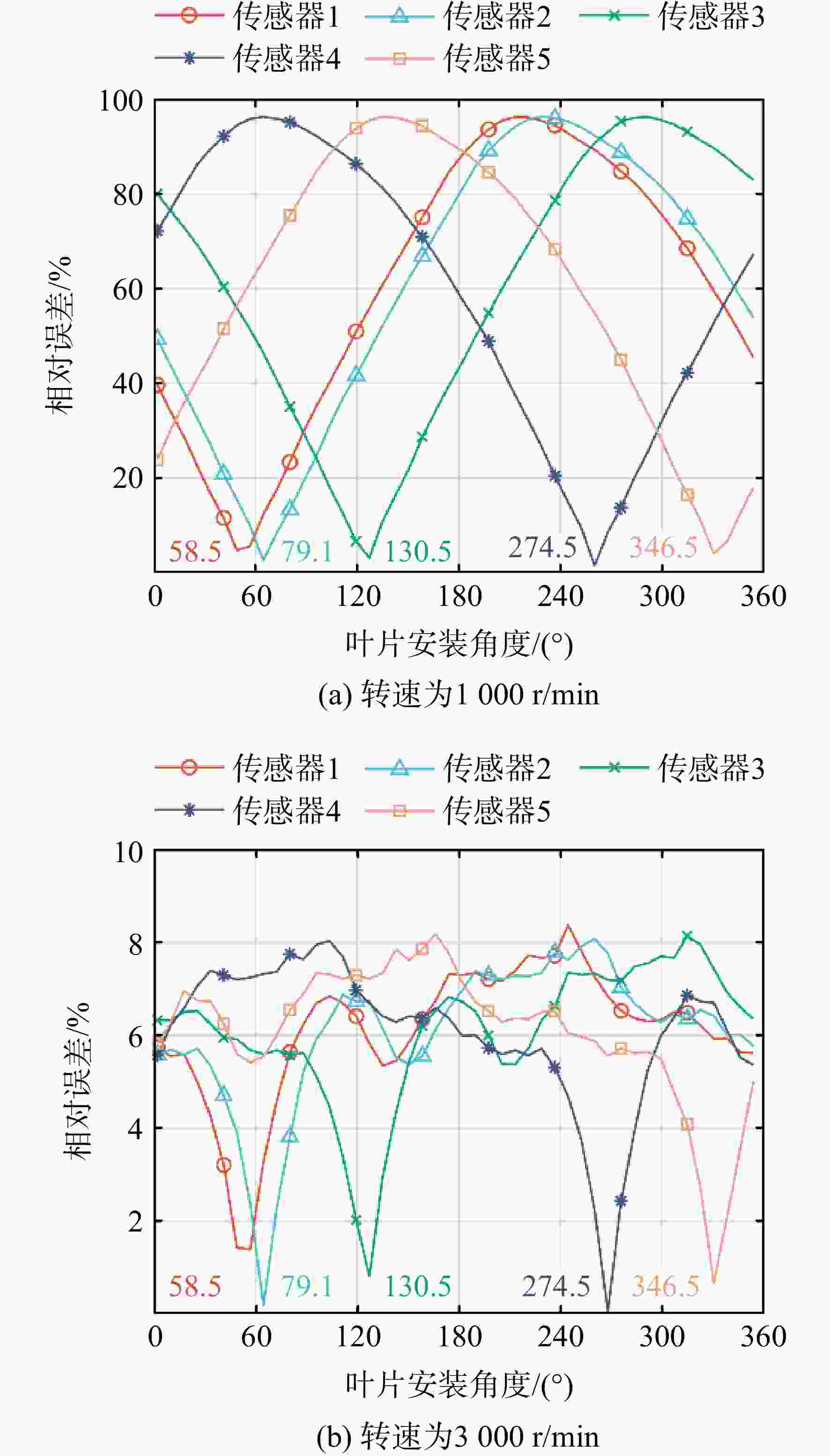

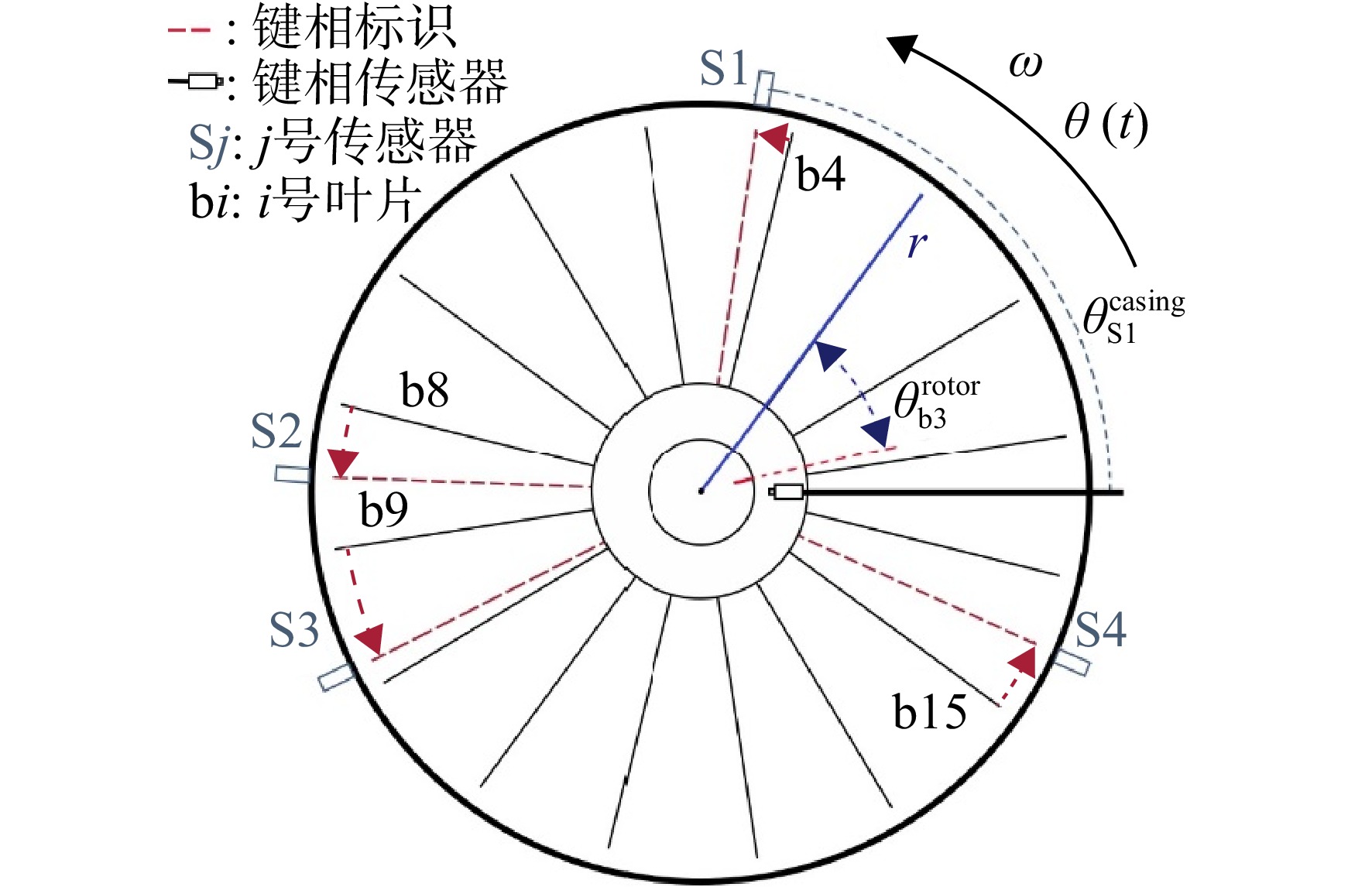

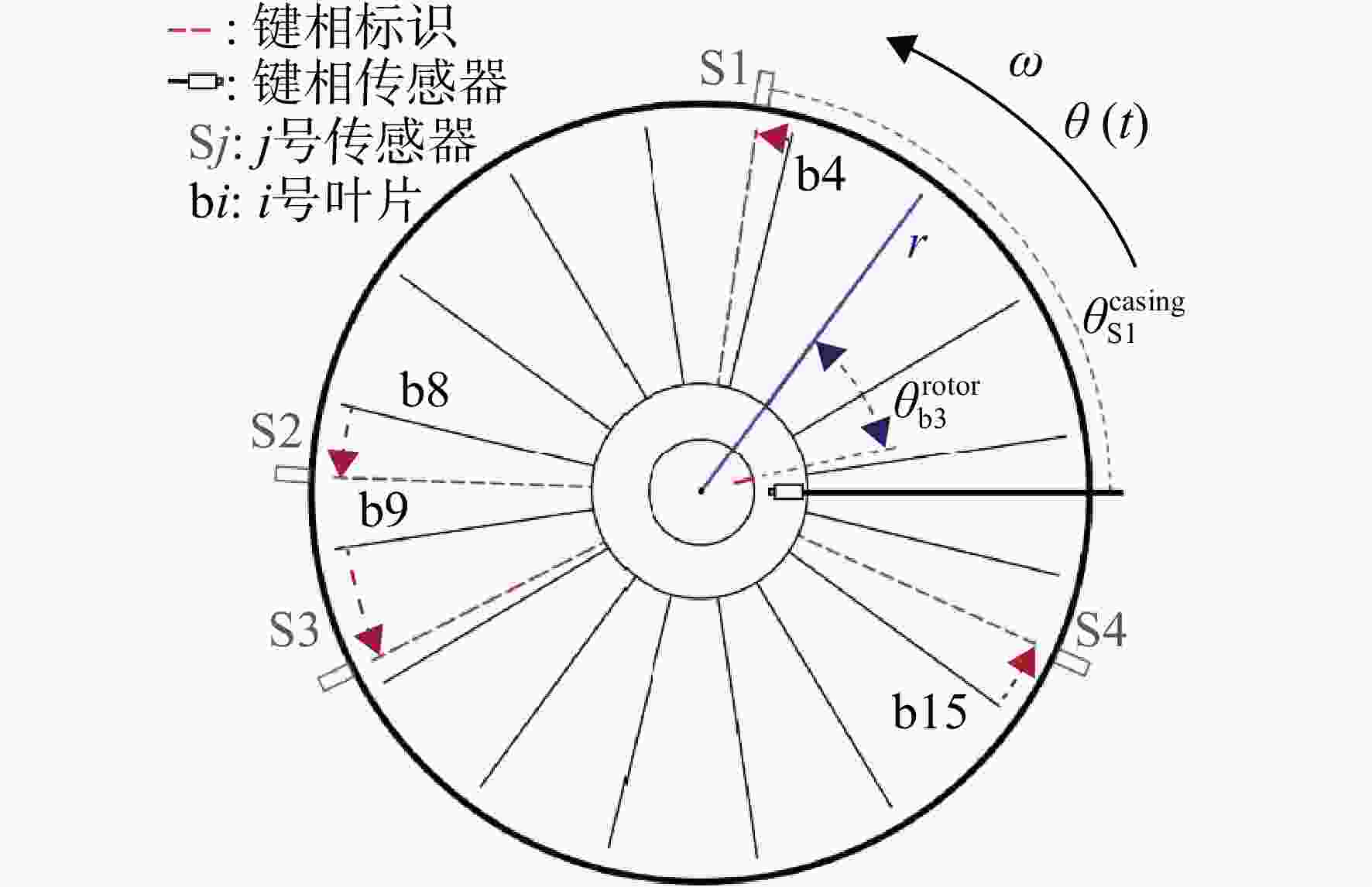

叶顶位移的精确测量是叶尖定时(BTT)技术应用于旋转叶片振动模态重构和实时状态监测的基础。设计了一套基于激光位移传感器的高精度BTT标定装置,在实验中直接获取叶顶位移的时域标定数据,并以此确定了转速波动是叶顶位移测量误差的主要来源之一。在此基础上,提出了局部5阶拟合的转速波动修正方法以提升BTT测量精度,并在标定装置上完成实验验证。结果表明:局部5阶拟合的转速波动修正方法在不同工况下均能有效提高BTT测量准确度。在旋转叶片非线性升转状态下测量误差最高降低90%;在恒定转速条件下误差可以降低38%至63%。将该算法应用在一台单级轴流压气机的实验数据中,修正的误差达0.4 mm,有效降低了BTT技术实时测量叶顶位移量的不确定度。

Abstract:Accurate measurement of blade tip displacement is the basis for the application of blade tip timing (BTT) technology to the vibrational mode reconstruction and real-time condition monitoring of rotating blades. A high-precision BTT calibration device based on a laser displacement sensor was designed. The time-domain calibration data of the blade tip displacement were directly obtained in the experiment, verifying that the speed fluctuation was one of the main sources of the measurement error of the blade tip displacement. On this basis, a local fifth-order fitting rotation speed fluctuation correction method was proposed to improve the BTT measurement accuracy, and the experimental verification was completed on the calibration device. The experimental results showed that the local fifth-order fitting method can effectively improve the BTT measurement accuracy under different working conditions. The measurement error can be reduced by up to 90% under the condition of non-linear increase in rotational speed, and the measurement error can be reduced by 38% to 63% under the condition of constant speed. The algorithm was applied to the experimental data of a single-stage axial flow compressor, and the corrected error was as high as 0.4 mm, which effectively reduced the uncertainty of the real-time measurement of blade tip displacement by BTT technology.

-

Key words:

- blade tip timing /

- blade tip displacement /

- speed fluctuation /

- calibration device /

- error analysis

-

表 1 实验工况

Table 1. Experimental conditions

工况 稳定转速/(r/min) 附加激励频率/Hz A 300 B 600 C 900 D 1200 E 300 53.8 F 600 54.6 G 900 56.1 H 1200 57.5 表 2 总误差与轴位置误差相关的系数

Table 2. Correlation coefficient between total error and shaft position error

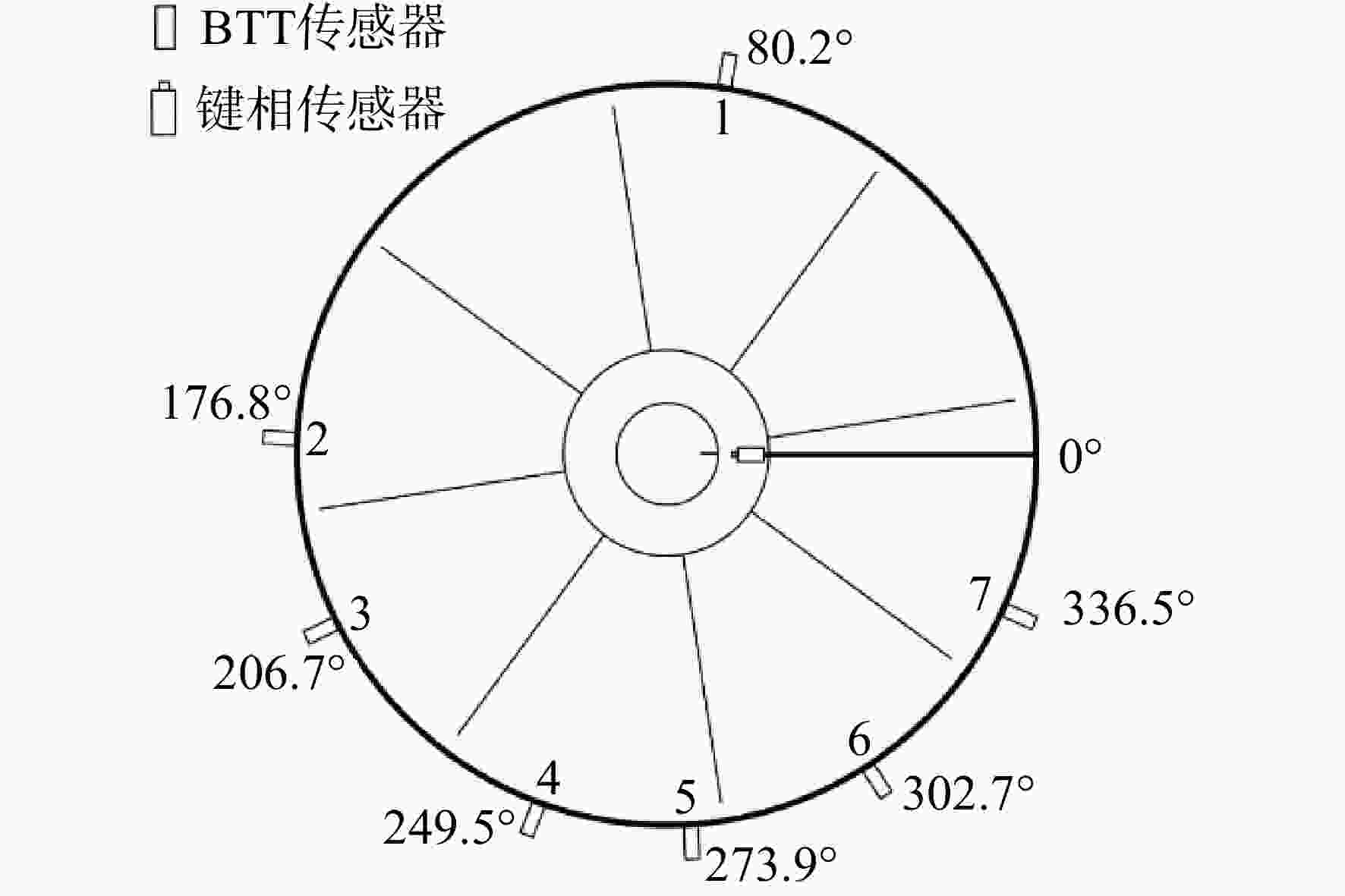

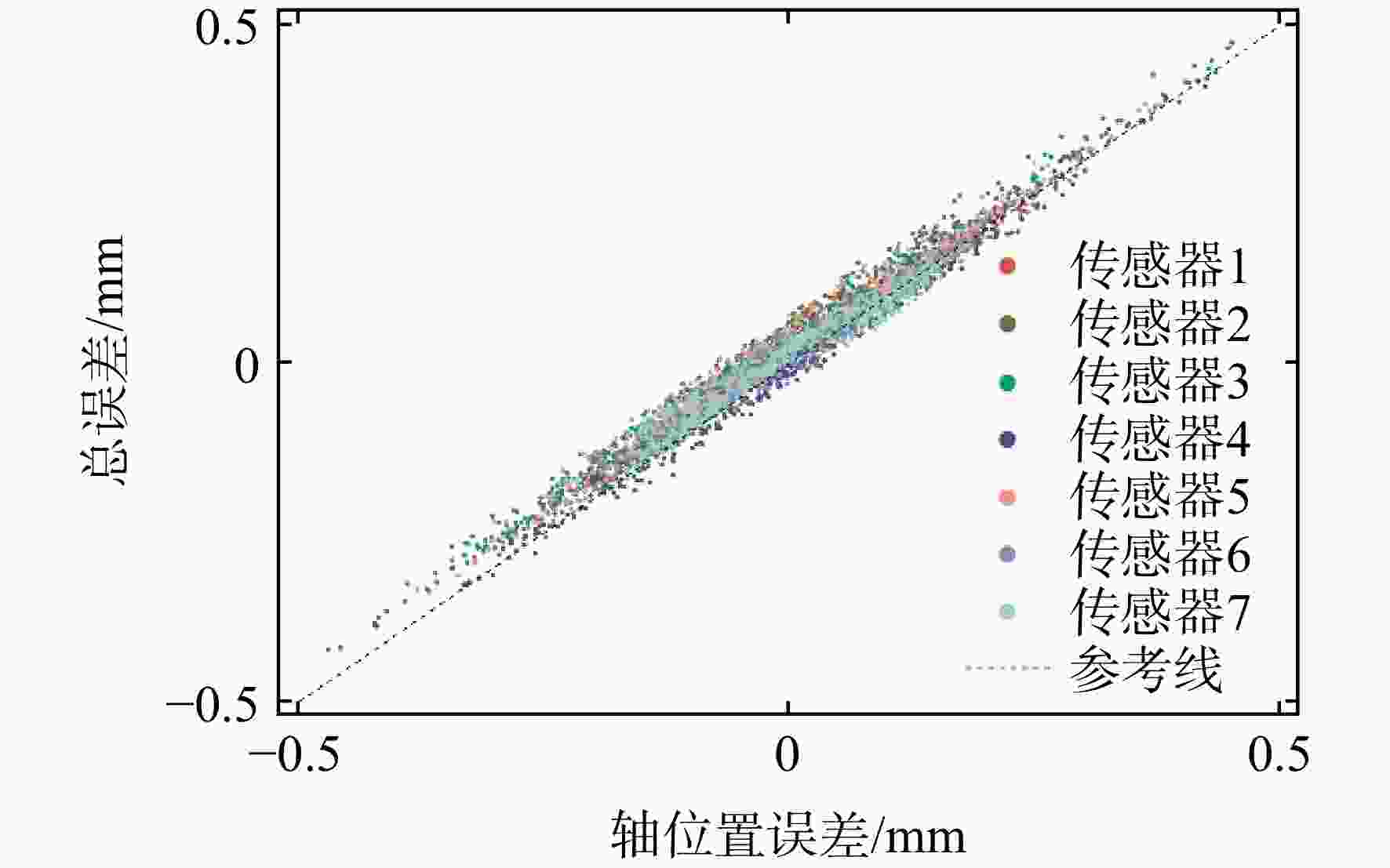

传感器编号 安装角度/(°) 相关系数 1 80.2 0.9910 2 176.8 0.9934 3 206.7 0.9936 4 249.5 0.9896 5 273.9 0.9916 6 302.7 0.9825 7 336.5 0.9829 -

[1] CHEN Zhongsheng,SHENG Hao,XIA Yemei,et al. A comprehensive review on blade tip timing-based health monitoring: status and future[J]. Mechanical Systems and Signal Processing,2020,149(1): 107330.1-107330.21. [2] 高志坤,张成龙,王威,等. 重型燃气轮机压气机第一级转子叶片断裂分析[J]. 航空发动机,2021,47(1): 47-52. doi: 10.13477/j.cnki.aeroengine.2021.01.009GAO Zhikun,ZHANG Chenglong,WANG Wei,et al. Fracture analysis of first stage rotor blade of heavy gas turbine compressor[J]. Aeroengine,2021,47(1): 47-52. (in Chinese) doi: 10.13477/j.cnki.aeroengine.2021.01.009 [3] PRZYSOWA R,RUSSHARD P. Non-contact measurement of blade vibration in an axial compressor[J]. Sensors,2019,20(1): 68. doi: 10.3390/s20010068 [4] 张帅,张强波,张霞妹. 基于方差分析的航空发动机风扇叶片外物撞击识别[J]. 航空学报,2021,42(5): 187-198.ZHANG Shuai,ZHANG Qiangbo,ZHANG Xiamei. Identification of foreign object impact on aero-engine fan blades with variance analysis[J]. Acta Aeronautica et Astronautica Sinica,2021,42(5): 187-198. (in Chinese) [5] 王维民,陈子文,张旭龙,等. 基于叶端定时的转子碰摩故障诊断方法[J]. 航空学报,2022,43(8): 36-45.WANG Weimin,CHEN Ziwen,ZHANG Xulong,et al. Fault diagnosis method of rotor rub impact based on blade tip timing[J]. Acta Aeronautica et Astronautica Sinica,2022,43(8): 36-45. (in Chinese) [6] MOHAMED M,BONELLO P,RUSSHARD P. A novel method for the determination of the change in blade tip timing probe sensing position due to steady movements[J]. Mechanical Systems and Signal Processing,2019,126: 686-710. doi: 10.1016/j.ymssp.2019.02.016 [7] WANG Weimin,HU Dongfang,LI Qihang,et al. An improved non-contact dynamic stress measurement method for turbomachinery rotating blades based on fundamental mistuning model[J]. Mechanical Systems and Signal Processing,2020,144(1): 106851.1-106851.18. [8] CHEN Zhongsheng,HE Jing,ZHAN Chi. Undersampled blade tip-timing vibration reconstruction under rotating speed fluctuation: uniform and nonuniform sensor configurations[J]. Shock and Vibration,2019,2019: 8103216.1-8103216.13. [9] RUSSHARD P. Blade tip timing (BTT) uncertainties[R]. AIP Conference Proceedings, 2016, 1740(1): 020003.1-020003.13. [10] ZABLOTSKIY I Y,KOROSTELEV Y A. Measurement of turbine blades with the ELURA Device[J]. Energomashinostroneniye,1970,2(1): 36-39. [11] HEATH S. A new technique for identifying synchronous resonances using tip-timing[J]. Journal of Engineering for Gas Turbines and Power,2000,122(2): 219-225. doi: 10.1115/1.483198 [12] HEATH S, SLATER T, MANSFIELD L, et al. Turbomachinery blade tip-timing measurement techniques[R]. Brussels, Belgium: Advisory Group for Aerospace Research and Development Conference: 90th Symposium on Advanced Non-Intrusive Instrumentation for Propulsion Engines, 1997. [13] RIGOSI G,BATTIATO G,BERRUTI T M. Synchronous vibration parameters identification by tip timing measurements[J]. Mechanics Research Communications,2017,79: 7-14. doi: 10.1016/j.mechrescom.2016.10.006 [14] ROBINSON W W, WASHBURN R S. A real time non-interference stress measurement system (NSMS) for determining aero engine blade stresses[C]//Proceedings of the 37th International Instrumentation Symposium. San Diego, US: the Instrumentation Society of America, 1991: 91-103. [15] 孙运玺. 基于机匣振动信号的叶片振动分析方法研究[D]. 南京: 南京航空航天大学, 2016.SUN Yunxi. Analysis of the blade vibration based on the casing vibration signal[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016. (in Chinese) [16] CARRINGTON I B,WRIGHT J R,COOPER J E,et al. A comparison of blade tip timing data analysis methods[J]. Proceedings of the Institution of Mechanical Engineers: Part G Journal of Aerospace Engineering,2001,215(5): 301-312. doi: 10.1243/0954410011533293 [17] GARRIDO J G,DIMITRIADIS G. Validating blade vibration amplitudes from blade tip-timing data analysis[J]. IMechE,2004,623(23): 205-213. [18] DONOHO D L. Compressed sensing[J]. IEEE Transactions on Information Theory,2006,52(4): 1289-1306. doi: 10.1109/TIT.2006.871582 [19] CANDES E J,WAKIN M B. An introduction to compressive sampling[J]. IEEE Signal Processing Magazine,2008,25(2): 21-30. doi: 10.1109/MSP.2007.914731 [20] 张智伟,柴鹏飞,孙宗翰,等. 高可靠小条件数压缩感知叶尖定时信号辨识[J]. 航空动力学报,2021,36(3): 509-519. doi: 10.13224/j.cnki.jasp.2021.03.007ZHANG Zhiwei,CHAI Pengfei,SUN Zonghan,et al. High reliability identification method of blade tip timing signals based on compressed sensing under small condition number[J]. Journal of Aerospace Power,2021,36(3): 509-519. (in Chinese) doi: 10.13224/j.cnki.jasp.2021.03.007 [21] RUSSHARD P. Derived once per rev signal generation for Blade Tip Timing systems[C]//IET & ISA 60th International Instrumentation Symposium. London: IET, 2014: 1-5. [22] DIAMOND D H,HEYNS P S,OBERHOLSTER A J. Online shaft encoder geometry compensation for arbitrary shaft speed profiles using Bayesian regression[J]. Mechanical Systems and Signal Processing,2016,81: 402-418. doi: 10.1016/j.ymssp.2016.02.060 [23] ZHOU Changyi, HU Haifeng, GUAN Fengjiao, et al. Modelling and simulation of blade tip timing uncertainty from rotational speed fluctuation[C]//2017 Prognostics and System Health Management Conference. Piscataway, US: IEEE, 2017: 1-5. [24] ZHANG Jiwang,ZHANG Laibin,DING Keqin,et al. Blade tip-timing technology with multiple reference phases for online monitoring of high-speed blades under variable-speed operation[J]. Measurement Science Review,2018,18(6): 243-250. doi: 10.1515/msr-2018-0033 [25] 王维民,任三群,陈立芳,等. 基于键相插值法的叶片振动测量研究[J]. 振动、测试与诊断,2017,37(2): 361-365,409.WANG Weimin,REN Sanqun,CHEN Lifang,et al. The blade vibration measurement research based on the key phase interpolation method[J]. Journal of Vibration, Measurement & Diagnosis,2017,37(2): 361-365,409. (in Chinese) [26] REN Sanqun,XIANG Xiaorong,ZHAO Wei,et al. An error correction blade tip-timing method to improve the measured accuracy of blade vibration displacement during unstable rotation speed[J]. Mechanical Systems and Signal Processing,2022,162(1): 108030.1-108030.23. [27] FAN Zhenfang,LI Hongkun,DONG Jiannan,et al. An improved multiple per revolution-based blade tip timing method and its applications on large-scale compressor blades[J]. Mechanical Systems and Signal Processing,2022,167(1): 108538.1-108538.18. [28] BATTIATO G,FIRRONE C M,BERRUTI T M. Forced response of rotating bladed disks: blade tip-timing measurements[J]. Mechanical Systems and Signal Processing,2017,85: 912-926. doi: 10.1016/j.ymssp.2016.09.019 [29] TAVAKOLPOUR-SALEH A R,SETOODEH A R,GHOLAMZADEH M. A novel multi-component strain-gauge external balance for wind tunnel tests: simulation and experiment[J]. Sensors and Actuators A: Physical,2016,247: 172-186. doi: 10.1016/j.sna.2016.05.035 -

下载:

下载: