Damage analysis of thrust chamber wall structure under the creep-fatigue interaction

-

摘要:

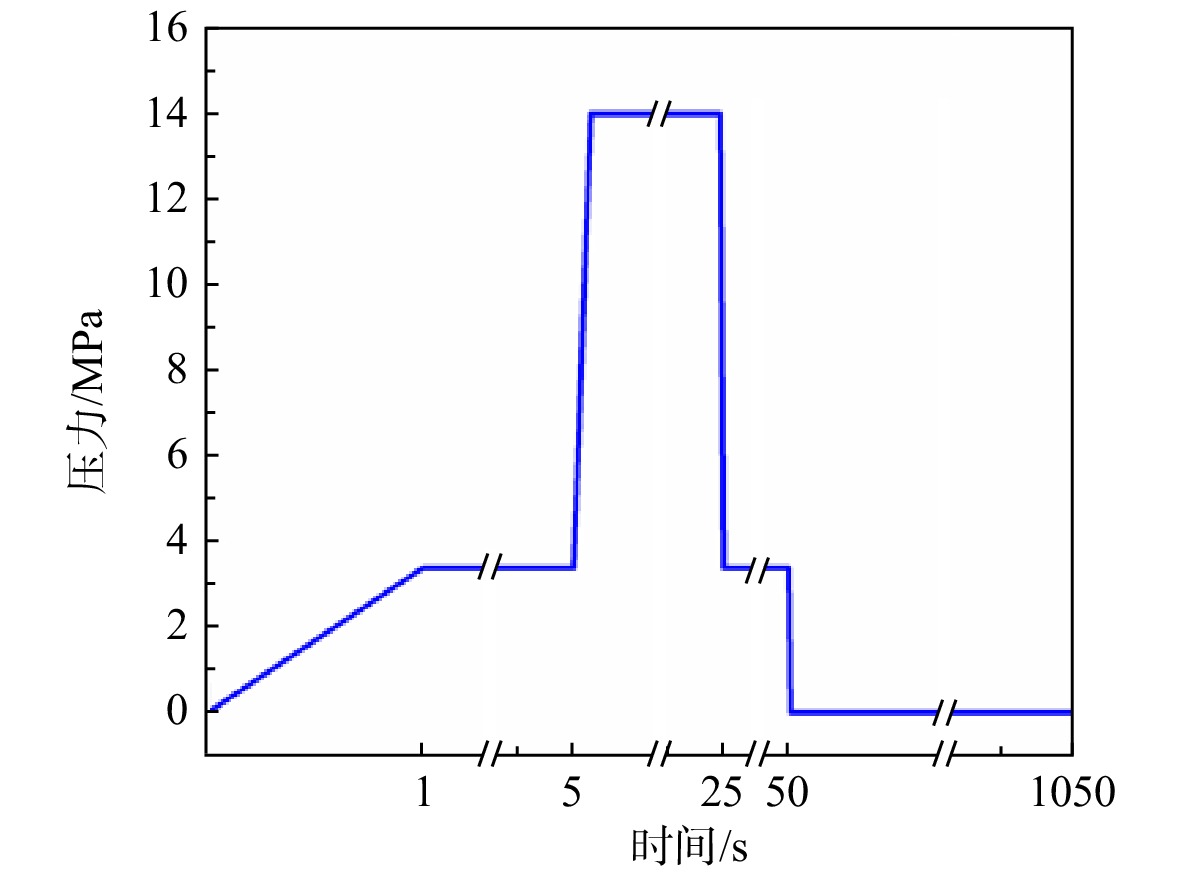

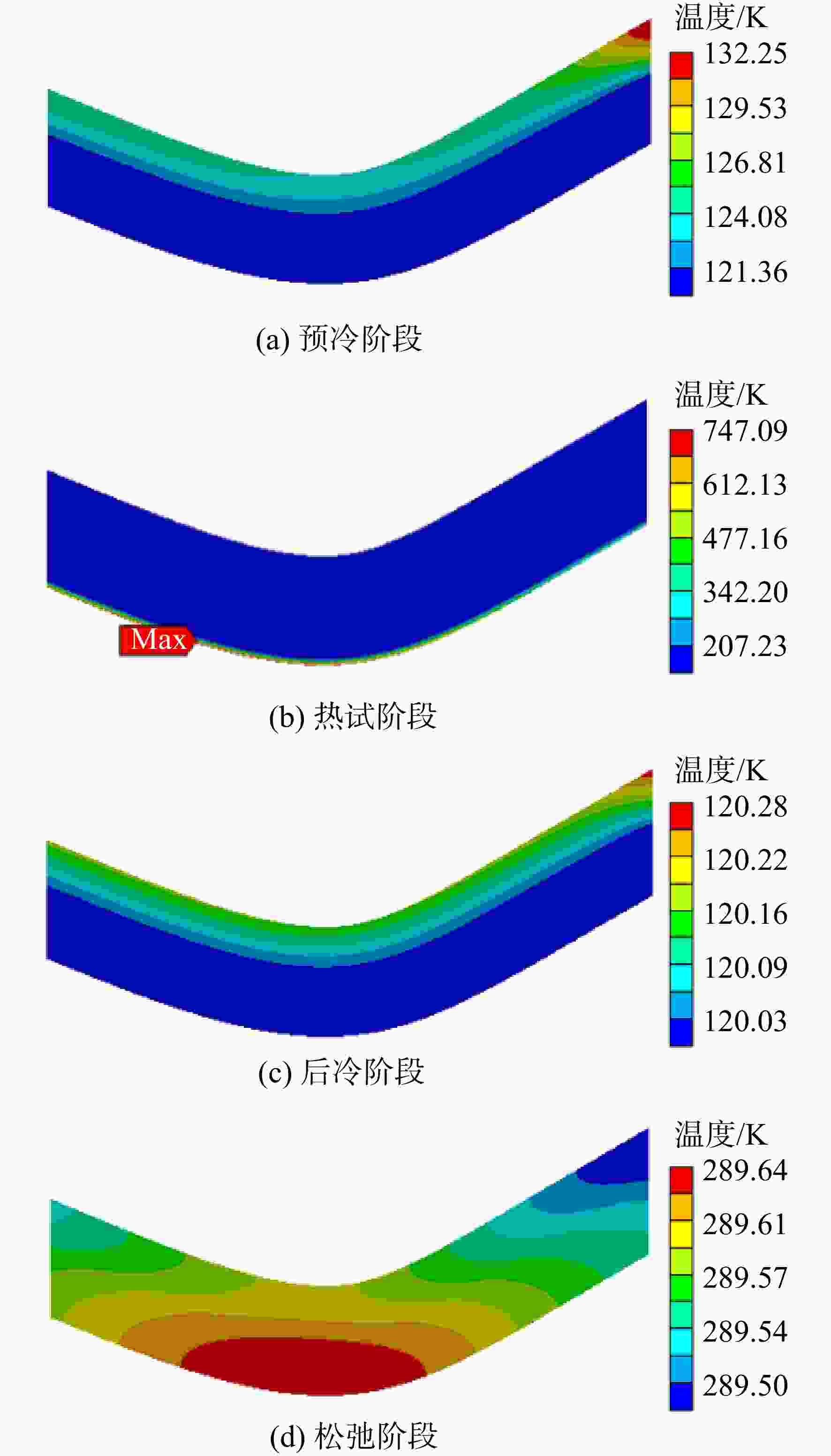

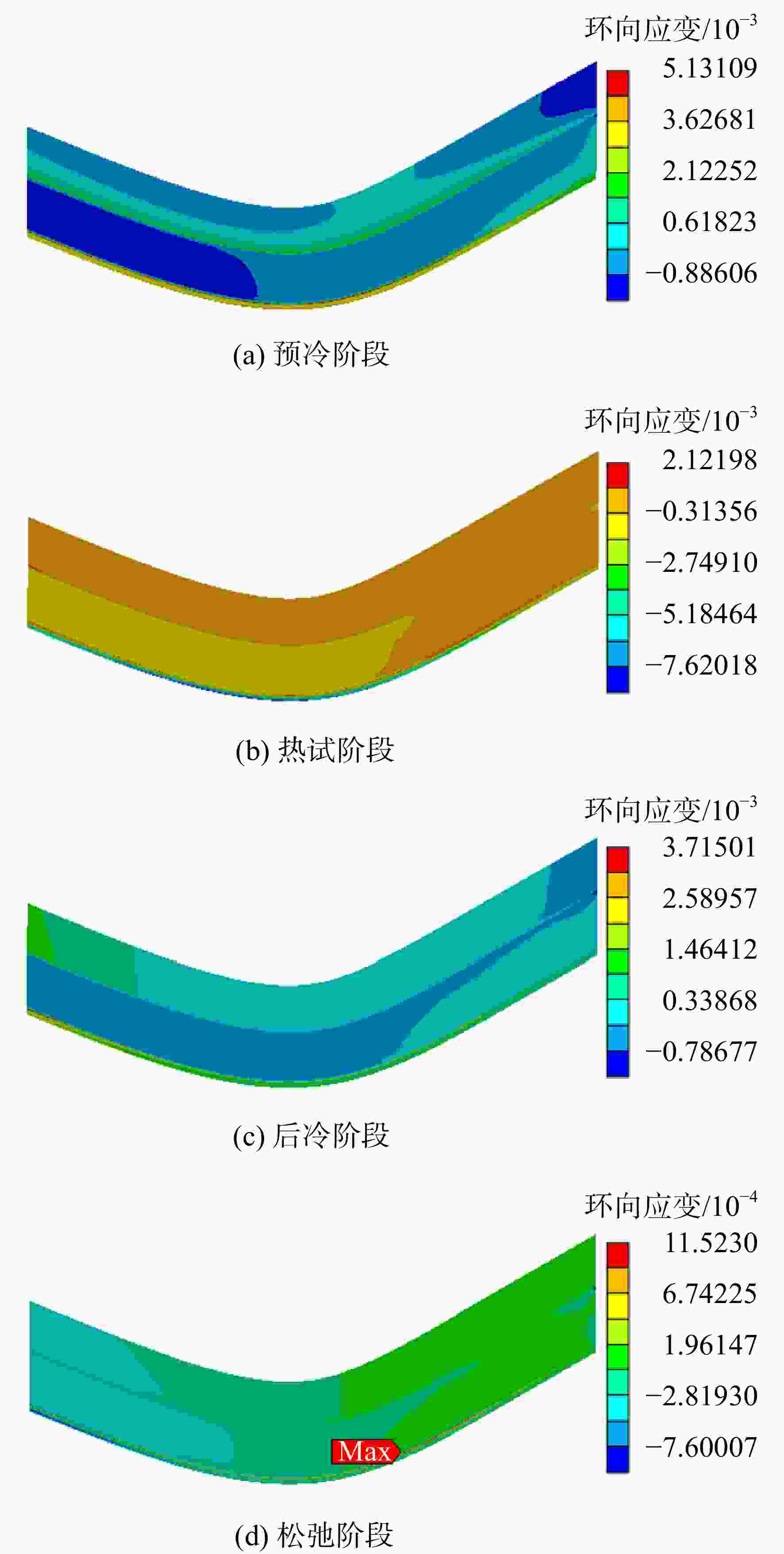

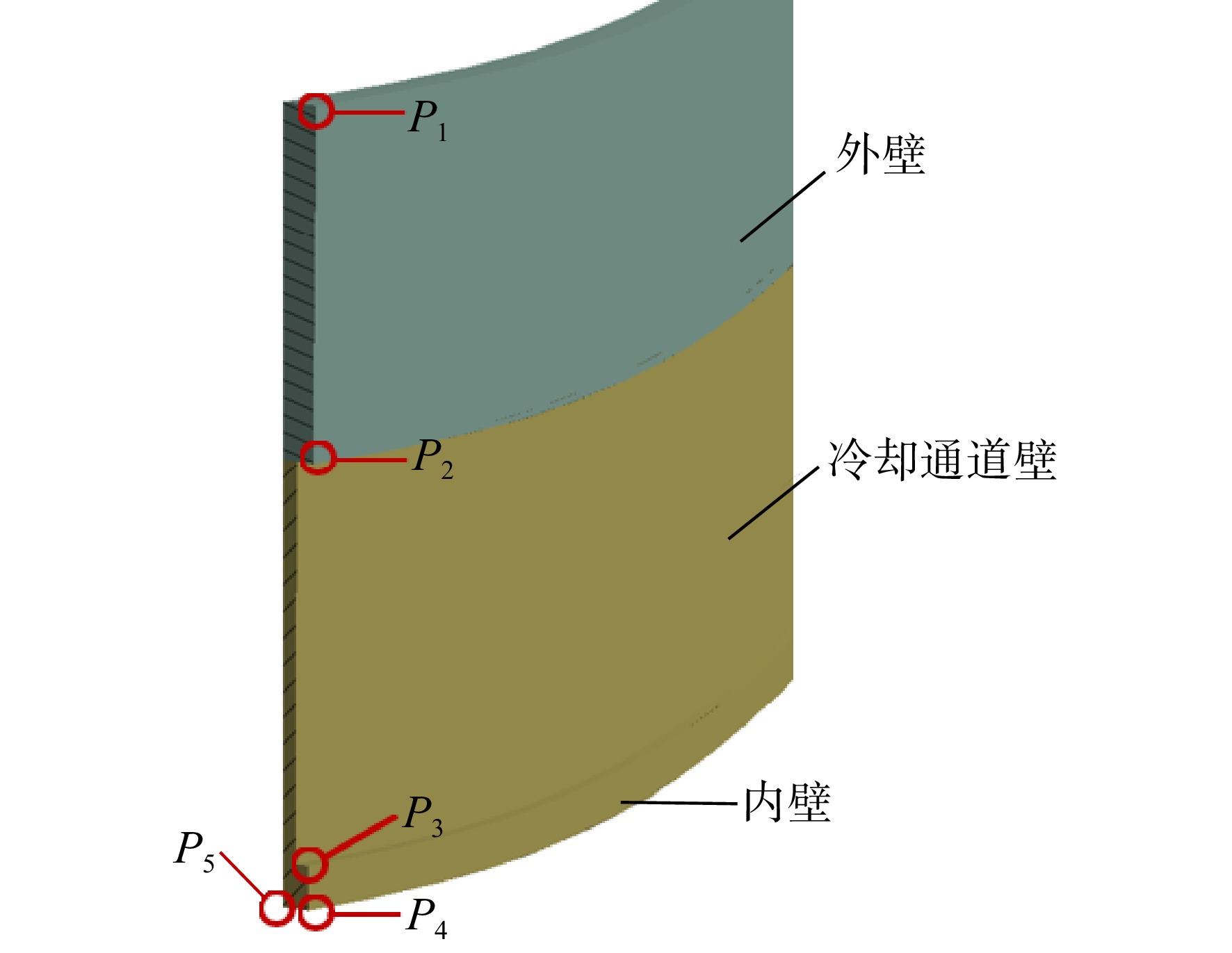

可重复使用液体火箭发动机能大幅降低航天运输成本,其中推力室内壁结构的循环使用寿命是影响可重复使用性能的关键因素。基于Chaboche随动强化模型和Norton蠕变模型建立推力室内壁材料的本构方程;采用瞬态热-力耦合分析方法,获得推力室各工况下的温度场与应力-应变分布;通过Lagneborg累积损伤法建立损伤模型,其中考虑了蠕变-疲劳的耦合作用,以预测内壁结构损伤及循环寿命。研究结果表明:推力室内壁结构损伤形式以低周疲劳损伤和蠕变-疲劳耦合损伤为主,其中低周疲劳损伤占比65.8%,蠕变-疲劳交互作用损伤占比29.8%,因此为了准确预测推力室内壁结构的循环使用寿命,需考虑结构在蠕变-疲劳耦合损伤作用下的影响因素。

Abstract:The reusable liquid rocket engine can greatly reduce the cost of space transportation. One of the key factors for the reusable performances is cyclic life of inner wall structures of thrust chamber. The constitutive equations of wall materials of the thrust chamber were established based on Chaboche kinematic hardening model and Norton creep model. The temperature fields and stress-strain distributions of the thrust chamber under various working conditions were obtained by employing the analysis of transient thermo-mechanical coupling; the damages and cyclic life of the inner wall structure were investigated by Lagneborg cumulative damage model by considering the coupling effects of creep and fatigue. The investigation showed that the key patterns of damage in wall structures of thrust chamber were low-cyclic fatigue and creep-fatigue interaction damage with low-cycle fatigue damage ratio 65.8%, and creep-fatigue interaction damage ratio 29.8%. Therefore, in order to accurately predict the cycle life of thrust inner wall structures, the influencing factors of structures under the action of creep-fatigue interaction damage should be considered.

-

Key words:

- thrust chamber /

- low-cyclic fatigue /

- high temperature creep /

- interactive damage /

- life prediction

-

表 1 不同温度下Chaboche模型参数

Table 1. Chaboche model parameters at different temperatures

温度/K ${C_{ {{\rm{C}},1 } } } $/MPa ${C_{ {{\rm{C}},2 } } } $/MPa ${C_{ {{\rm{C}},3 } } } $/MPa $ {\gamma _1} $ $ {\gamma _2} $ $ {\gamma _3} $ 27.15 5762.8 13657 18812 137 596 2085.8 295.15 21326 4041 15118 1884 118 393.2 533.15 19970 86348 18219 354 12290 1617.3 811.15 20940 2629.7 20941 1091 123 1090.9 表 2 Norton蠕变模型参数

Table 2. Norton creep model parameters

温度/K ${C_{ {{\rm{N}},1 } } }$ ${C_{ {{\rm{N}},2 } } }$ ${C_{ {{\rm{N}},3 } } }$ 293~773 0.97426 1.7639 11529 773~923 2.745×1015 0.8713 11579 923~1073 1.098×1017 0.9043 11593 表 3 交互作用系数计算表

Table 3. Interaction coefficient calculation table

总应变范围/% 蠕变-疲劳失效

循环数蠕变-疲劳失效

保载时间/s疲劳损伤 蠕变损伤 交互作用

系数$H$蠕变-疲劳

交互损伤2.6 102 30600 0.4032 0.1547 1.7712 0.4424 2.6 75 22500 0.2964 0.1137 3.2134 0.5899 0.9 262 78600 0.2241 0.3342 1.6142 0.4418 0.9 317 95100 0.2712 0.4044 0.9801 0.3246 表 4 各考察点损伤计算

Table 4. Damage calculation for each inspection point

考察点 等效应变

范围/%单次循环

疲劳损伤/10−4单次循环

蠕变损伤/10−4交互乘积项 单次循环

交互损伤/10−41-P3 0.742 3.5323 1.3211 1.2206 2.7115 1-P4 1.673 25.510 1.7066 1.7453 11.516 2-P3 0.746 3.6219 1.3668 1.2225 2.7200 2-P4 1.617 24.213 1.7469 1.7077 11.106 3-P3 0.697 3.0084 1.1868 1.1998 2.2671 3-P4 1.330 14.925 1.7241 1.5300 7.7612 表 5 各考察点寿命预测值

Table 5. Life expectancy at each inspection point

考察点 等效应变

范围/%单次循环

总损伤/10−3N 疲劳损伤

占比/%蠕变损伤

占比/%交互损伤

占比/%1-P3 0.742 3.0260 330 46.7 17.4 35.9 1-P4 1.673 15.493 64 65.8 4.4 29.8 2-P3 0.746 3.0835 324 47.0 17.7 35.3 2-P4 1.617 14.826 67 65.3 4.7 30.0 3-P3 0.697 2.5849 386 46.5 18.4 35.1 3-P4 1.330 9.7640 102 61.1 7.1 31.8 -

[1] 丁兆波,孙纪国. 推力室内壁热结构寿命预估及延寿技术研究[J]. 推进技术,2013,34(8): 1088-1094.DING Zhaobo,SUN Jiguo. Studies on life-prediction and life-enhancing technology for regenerative cooling channel[J]. Journal of Propulsion Technology,2013,34(8): 1088-1094. (in Chinese) [2] 丁兆波,王珏. 氢氧推力室内壁用铜合金疲劳及蠕变性能研究[J]. 航天制造技术,2021(5): 30-34,39.DING Zhaobo,WANG Jue. Experimental study on fatigue and creep properties of LOX/LH2 thrust chamber copper alloy liner wall[J]. Aerospace Manufacturing Technology,2021(5): 30-34,39. (in Chinese) [3] 张绿云,曲晶,龙雪丹,等. 2018年国外航天运载器发展分析[J]. 导弹与航天运载技术,2019(1): 36-39,44.ZHANG Lvyun,QU Jing,LONG Xuedan,et al. Review of world launch vehicle in 2018[J]. Missiles and Space Vehicles,2019(1): 36-39,44. (in Chinese) [4] 朱坤,杨铁成,周宁. 从低成本角度探讨航天运载器技术发展路线[J]. 飞航导弹,2021(6): 1-6,13.ZHU Kun,YANG Tiecheng,ZHOU Ning. Discussion on the development route of space launch vehicle technology from the perspective of low cost[J]. Aerodynamic Missile Journal,2021(6): 1-6,13. (in Chinese) [5] RICCIUS J, HAIDN O, ZAMETAEV E. Influence of time dependent effects on the estimated life time of liquid rocket combustion chamber walls[R]. AIAA 2004-3670, 2004. [6] MILLER R. Low-cycle fatigue analysis of a cooled copper combustion chamber[R]. AIAA 74-1079, 1974. [7] COOK R, COFFEY G. Space shuttle orbiter engine main combustion chamber cooling and life[R]. AIAA TP73-1310, 1973. [8] 郭冰彬. 铸造铝合金压蠕变与低周疲劳耦合特性研究与应用[D]. 北京: 北京理工大学, 2016.GUO Bingbin. Study on the coupling characteristics of compression creep and low cycle fatigue of cast aluminum and it’s application[D]. Beijing: Beijing Institute of Technology, 2016. (in Chinese) [9] SUNG I K, ANDERSON W. A subscale-based rocket combustor life prediction methodology[R]. AIAA 2005-3570, 2005. [10] 孙冰,丁兆波,康玉东. 液体火箭发动机推力室内壁寿命预估[J]. 航空动力学报,2014,29(12): 2980-2986.SUN Bing,DING Zhaobo,KANG Yudong. Life prediction of liquid rocket engine thrust chamber liner wall[J]. Journal of Aerospace Power,2014,29(12): 2980-2986. (in Chinese) [11] RICCIUS J, ZAMETAEV E, HAIDN O. Comparison of 2D and 3D structural FE-analyses of LRE combustion chamber walls[R]. AIAA 2006-4368, 2006. [12] LAGNEBORG R,ATTERMO R. The effect of combined low-cycle fatigue and creep on the life of austenitic stainless steels[J]. Metallurgical Transactions,1971,2(7): 1821-1827. doi: 10.1007/BF02913411 [13] 谭晓惠,马建中,刘宇杰,等. 316不锈钢蠕变-疲劳交互作用试验研究[J]. 核动力工程,2013,34(1): 140-145.TAN Xiaohui,MA Jianzhong,LIU Yujie,et al. Experimental study on creep/fatigue interaction correlation[J]. Nuclear Power Engineering,2013,34(1): 140-145. (in Chinese) [14] 彭鸿博,张宏建. 金属材料本构模型的研究进展[J]. 机械工程材料,2012,36(3): 5-10, 75.PENG Hongbo,ZHANG Hongjian. Research development of the constitutive models of metal materials[J]. Materials for Mechanical Engineering,2012,36(3): 5-10, 75. (in Chinese) [15] ELLIS D, MICHAL G M. Mechanical and thermal properties of two Cu-Cr-Nb alloys and NARloy-Z[R]. NASA-CR-198529, 1996 [16] 康玉东,孙冰. 燃气非平衡流再生冷却流动传热数值模拟[J]. 推进技术,2011,32(1): 119-124.KANG Yudong,SUN Bing. Numerical simulation of regeneraive cooling flow and heat transfer with nonequilibrium flow[J]. Journal of Propulsion Technology,2011,32(1): 119-124. (in Chinese) [17] 陈立佳,王中光,田继丰,等. 镍基高温合金的蠕变-疲劳交互作用行为及寿命预测[J]. 航空材料学报,1998,18(3): 1-7,15.CHEN Lijia,WANG Zhongguang,TIAN Jifeng,et al. Creep fatigue interaction behavior of a nickel based superalloy and lifetime prediction[J]. Journal of Aeronautical Materials,1998,18(3): 1-7,15. (in Chinese) [18] 杜大华,王珺,王红建,等. 液体火箭发动机涡轮盘低周疲劳寿命预测[J]. 火箭推进,2020,46(6): 13-21.DU Dahua,WANG Jun,WANG Hongjian,et al. Low cycle fatigue life prediction of a liquid rocket engine turbine disk[J]. Journal of Rocket Propulsion,2020,46(6): 13-21. (in Chinese) [19] WILSHIRE B. New high-precision creep procedures for accurate life extension of plant[J]. International Journal of Pressure Vessels and Piping,1989,39(1/2): 73-82. [20] PIZZARELLI M. An algebraic model for structural and life analysis of regeneratively-cooled thrust chambers[J]. Journal of Propulsion and Power,2020,36(2): 191-201. doi: 10.2514/1.B37669 -

下载:

下载: